Horizontal Axis Wind Turbine (HAWT) CFD Simulation by MRF Method, ANSYS Fluent Tutorial

$140.00 Student Discount

- The problem numerically simulates the Horizontal Axis Wind Turbine (HAWT) using ANSYS Fluent software.

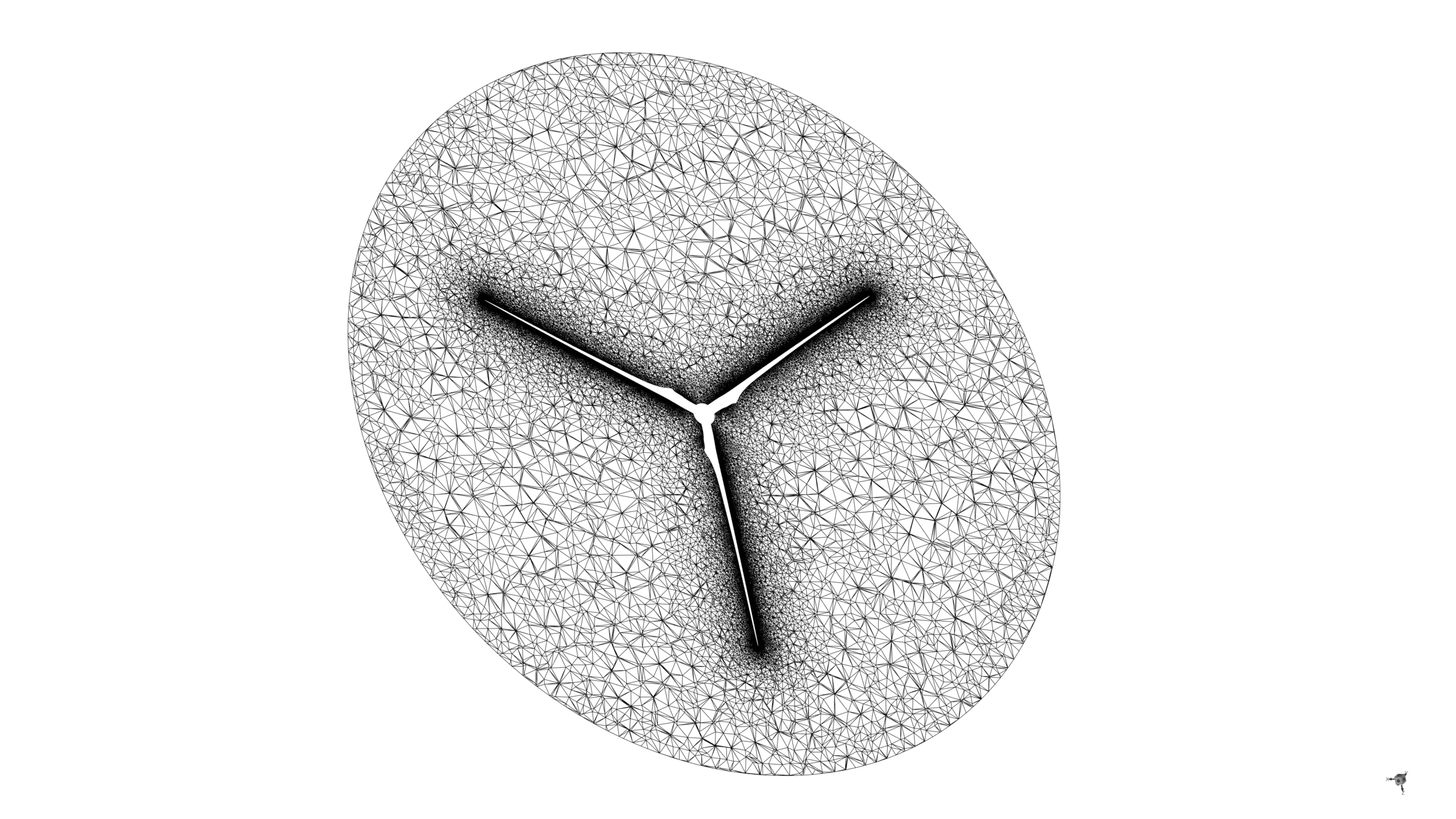

- We design the 3-D model by the Design Modeler and create the mesh using ANSYS Meshing software.

- The element number equals 2,696,011.

- The MRF option (Frame Motion) is enabled to define the rotational motion of the wind turbine.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates the air around a Horizontal Axis Wind Turbine (HAWT) by ANSYS Fluent software. In the present case, it is assumed that the wind turbine is rotating with a rotational velocity of 72 rad/sec while the air is blowing at the speed of 15 m/s.

This simulation shows how the air treats around the blades of the wind turbine by presenting different solution parameters.

The geometry of the present model is three-dimensional and has been designed using Design Modeler software. We do the meshing of the present model by ANSYS Meshing software. The mesh type is unstructured, and the element number is 2,696,011.

Methodology: Horizontal Axis Wind Turbine (HAWT)

The Multiple Reference Frames (MRF) method is enabled to model the rotational movement of the wind turbine. The solution is independent of Time (Steady State), and SST K-Omega is chosen for the turbulence model.

Conclusion

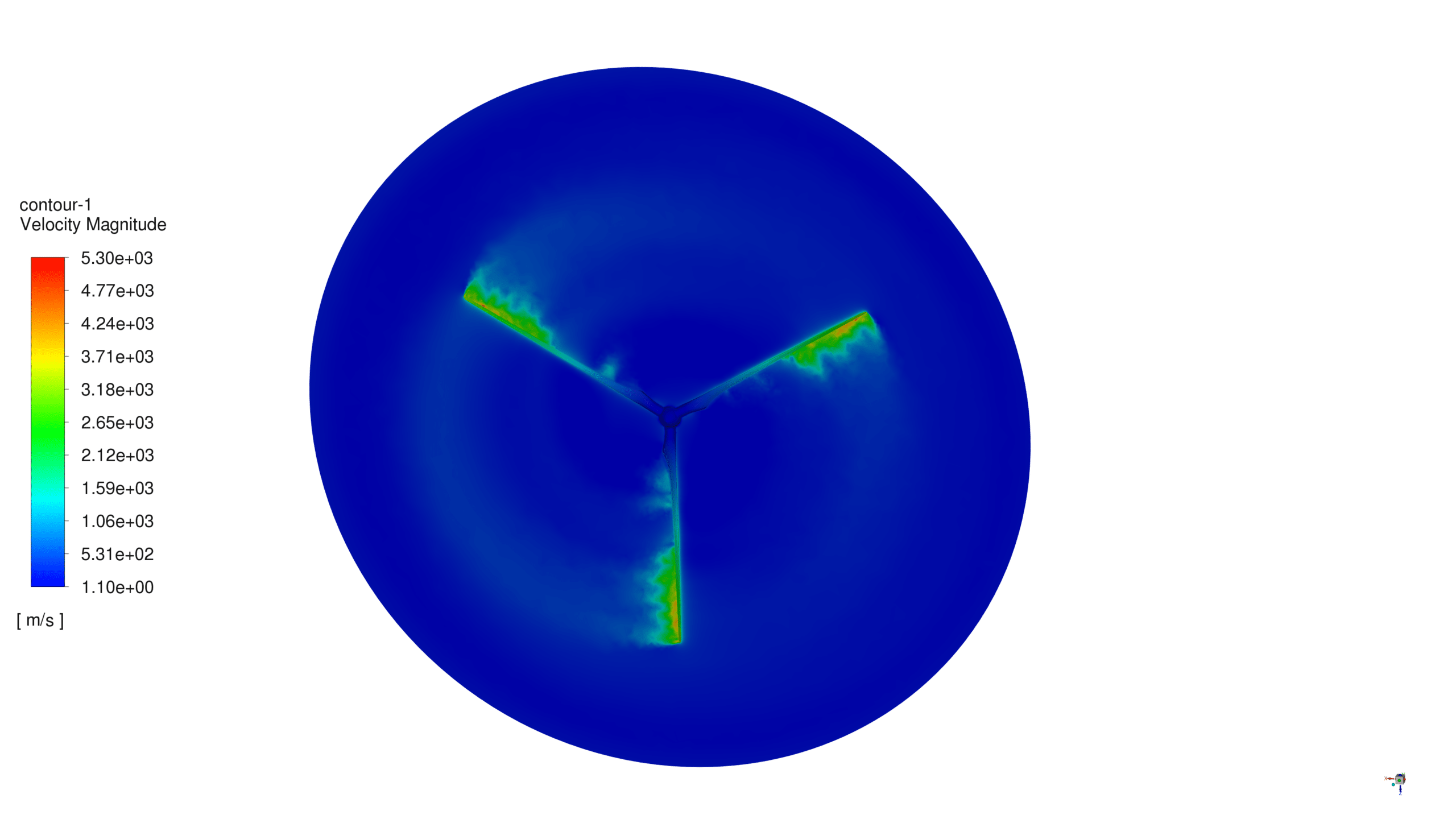

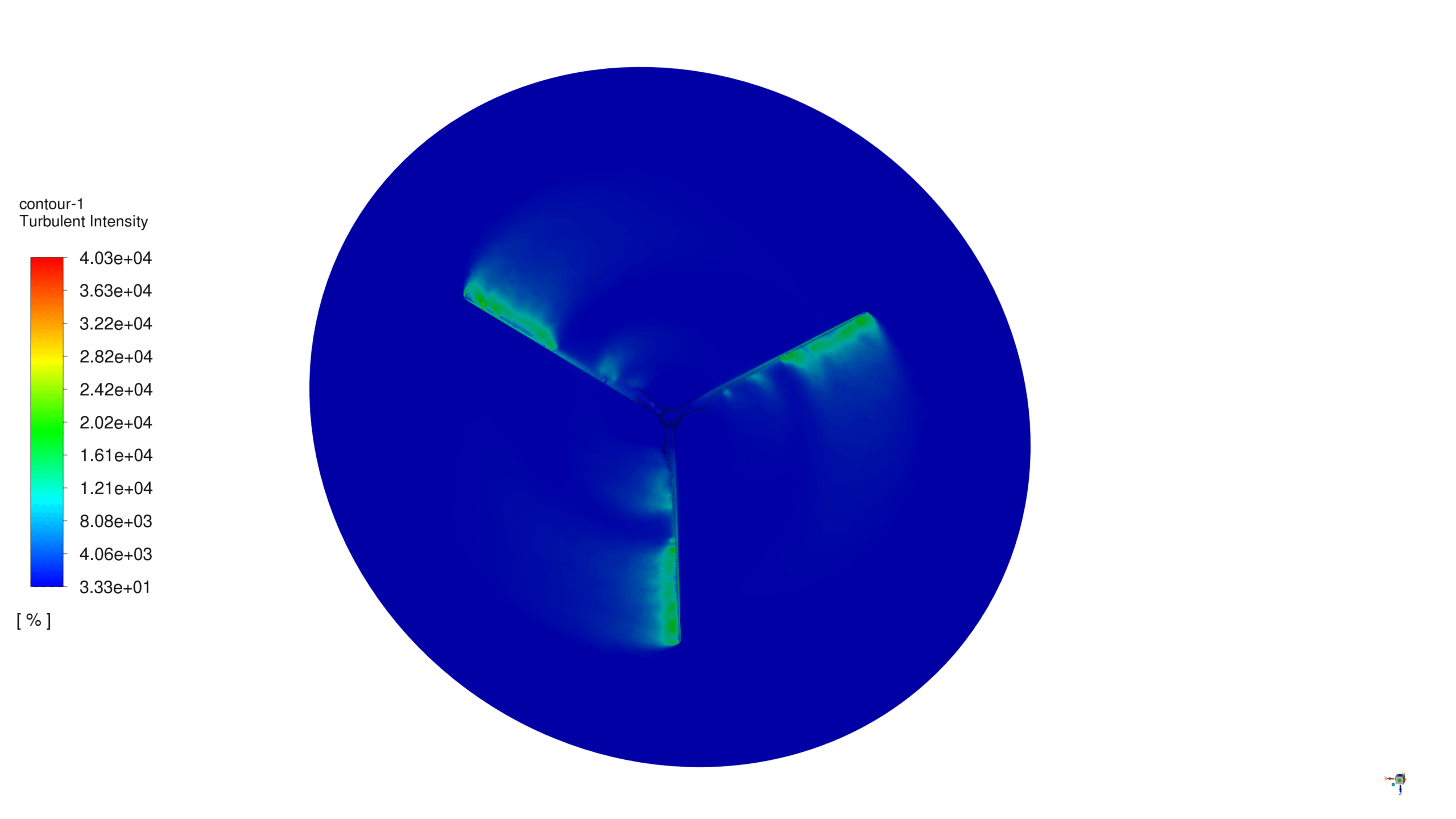

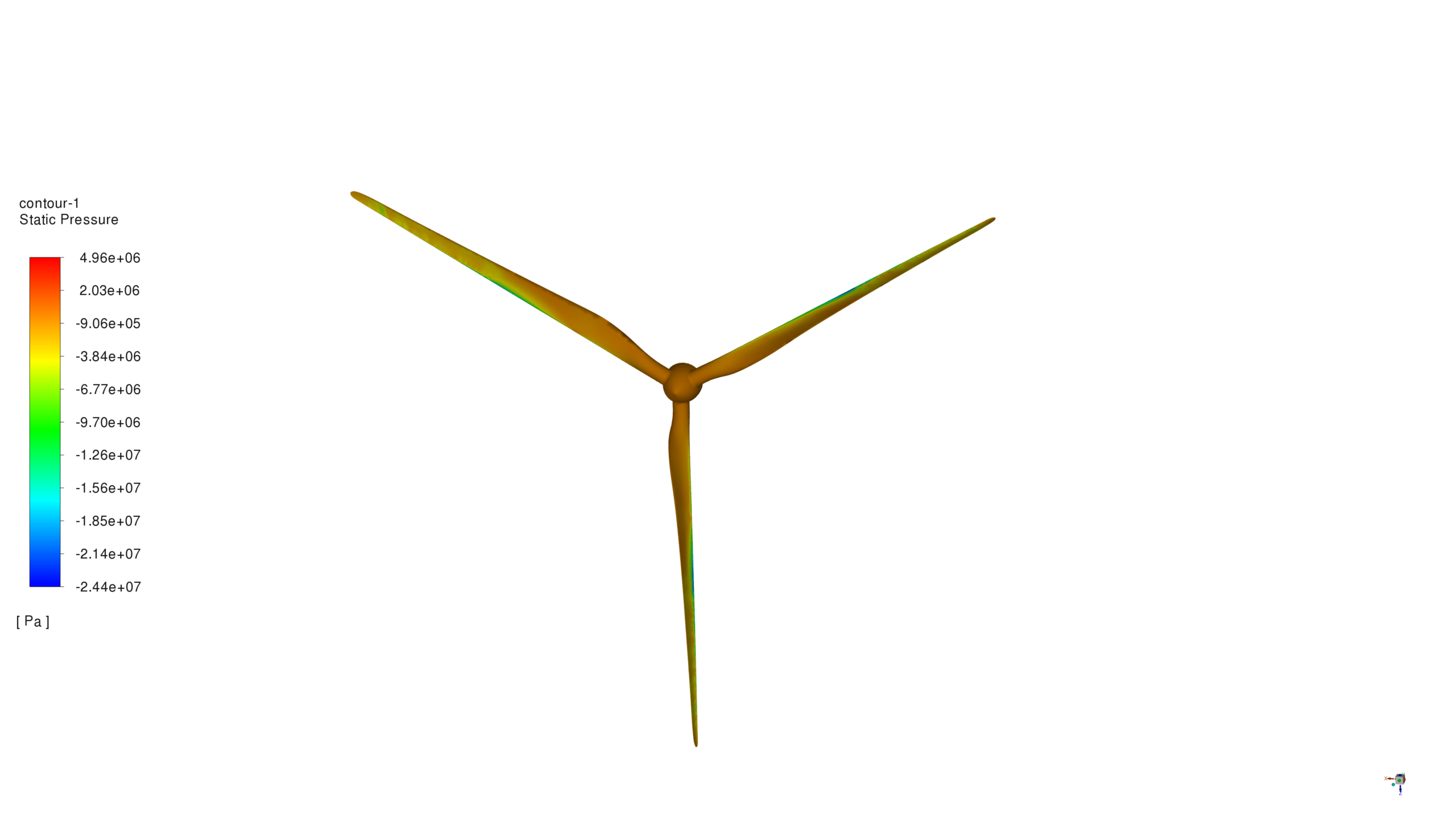

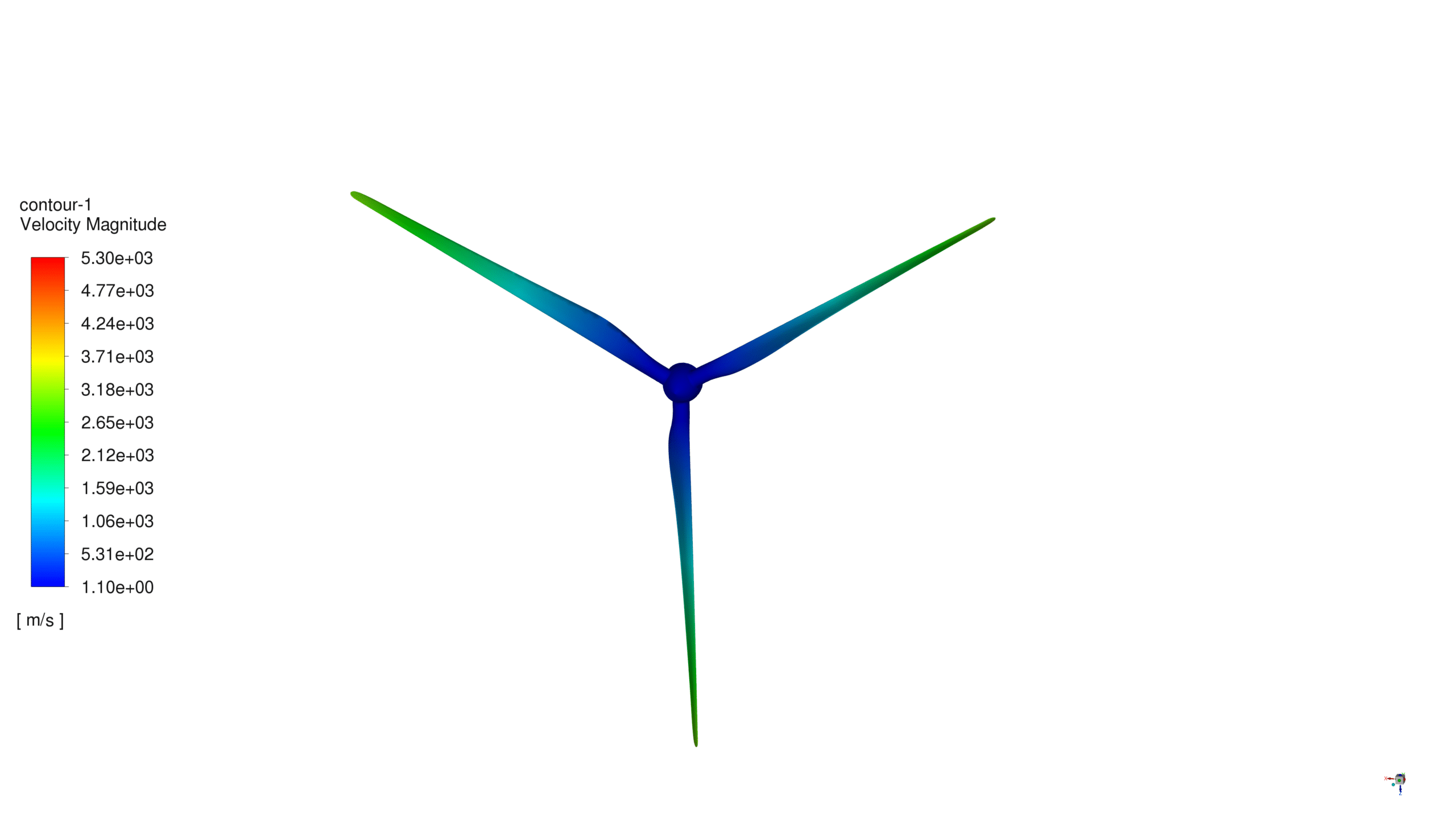

Since the main purpose of the issue is to investigate air movement around a Horizontal Axis Wind Turbine, its related contours can be shown in the figures. Two-dimensional contours related to pressure, velocity, as well as turbulent intensity were obtained.

In the case of pressure, it is visible that the amount of air pressure increases with distance from the hub. Also, It is true for the turbulent intensity parameter.

The speed of the turbine blades rises by moving away from the hub, as do the vorticities formed behind them.

Augusta Funk –

I was highly impressed by the details presented in the Horizontal Axis Wind Turbine (HAWT) CFD Simulation. The visuals in the resulting contours were elaborate and served as a great aid in understanding the dynamics. Kudos to the MR CFD Company for crafting such an insightful tutorial.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our tutorial on the Horizontal Axis Wind Turbine (HAWT) CFD Simulation has provided you with helpful insights and a clear understanding of the dynamics involved. Your satisfaction is our top priority, and we appreciate you taking the time to acknowledge the details and visuals in our product.

Prof. Constantin Considine I –

I’m so impressed with the intuitive setup of this HAWT simulation! The use of the MRF method for modeling the blade rotation is clever, and the results in the contours provide such clear visual feedback on the pressure distribution and turbulence caused by the blades. Really well-executed tutorial!

MR CFD Support –

Thank you very much for your positive feedback! We’re thrilled to hear you found the HAWT simulation tutorial understandable and informative. We pride ourselves on creating clear and intuitive learning resources, and it’s rewarding to know it’s appreciated by our customers. If you have any further questions or need more resources, feel free to reach out!

Rosamond Thompson –

I was impressed with the smooth results from MRF and how it captured the air pressure variations and turbulent intensity around the turbine. It made understanding wind turbine aerodynamics much clearer!

MR CFD Support –

We are thrilled to hear that the MRF method in the HAWT simulation provided clarity on aerodynamics. It’s our goal to offer comprehensive learning tools that contribute to a deeper understanding of such complex phenomena. Thank you for your feedback!

Rusty Kihn –

I was really impressed with the clarity of the contours showcasing the pressure and turbulent intensity around the blades. The differentiation between regions based on the distance from the hub was insightful. Additionally, seeing the effects of vorticity caused by the blade motion was fascinating! This simulation offered a great visual understanding of aerodynamics in HAWT systems.

MR CFD Support –

Thank you so much for your positive feedback! We’re glad you found the simulation insightful and that the visual representations of the aerodynamic parameters were clear and helpful. We always strive to provide comprehensive simulations to aid understanding of complex phenomena. If you have any more questions or need further assistance, feel free to reach out!

Mr. Cody Jacobson –

The tutorial was incredibly detailed. Learned a lot about the MRF method and how it’s used to simulate turbine rotation. The visuals were especially helpful in understanding the flow patterns around the blades.

MR CFD Support –

Thank you for your positive feedback! We are really thrilled that you found the HAWT CFD Simulation tutorial detailed and educational. We always strive to provide clear visuals to aid in the comprehension of complex flow patterns and principles. If you have further inquiries or need assistance with other simulations, feel free to reach out.

Miss Kayla Torp –

I’ve just completed a simulation test with this HAWT tutorial, and I’m thrilled with your clear, step-by-step process. It helped me understand how the blades interact with the air and various forces involved. Big thanks to the MR CFD team for this brilliant content.

MR CFD Support –

You’re very welcome! We are genuinely delighted to hear that our Horizontal Axis Wind Turbine tutorial has been beneficial to you and that the content was easy to follow. Thank you for your kind words and for choosing our learning products. Should you have any more inquiries or need further assistance in the future, please don’t hesitate to reach out!

Greg Eichmann –

I found the explanation of using the MRF method for simulating rotation very interesting. Could you elaborate on how the different rotational speed of the wind turbine affect the simulation outcomes, especially the pressure distribution and vorticity around the blades?

MR CFD Support –

Certainly! In the simulation using the MRF method, varying the rotational speed of the wind turbine blades affects several aspects. Faster rotational speeds typically result in increased centrifugal forces, leading to a higher pressure gradient from the hub towards the tip of the blades. This can impact the force distribution and thus affect the effective lift and drag forces acting on the blades. Accelerated speeds can also enhance vorticity, manifesting in more pronounced wake rotation and turbulence intensity in the air behind the turbine. These effects are critical for assessing turbine performance and optimizing design.

Mr. Kris Ratke –

The CFD simulation of the HAWT by MRF method is impressive. Seeing the airflow treatment and resultant pressure, velocity, and turbulence contours around the turbine blades provides great insight into the turbine’s performance characteristics.

MR CFD Support –

Thank you for your positive review. We’re delighted to hear that our simulation and the provided data gave you valuable insights into the wind turbine aerodynamics. If you have any further questions or want to dig into other aspects of CFD analysis, please let us know.

Gennaro VonRueden IV –

I was amazed by the clarity of the results in the HAWT CFD simulation tutorial! The contours of pressure, velocity, and turbulent intensity were particularly revealing and helped me understand the aerodynamic behavior around the turbine blades. Fantastic work.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our Horizontal Axis Wind Turbine CFD simulation tutorial was helpful to you. Understanding air movement around the blades is crucial, and we’re glad that the pressure and velocity contours were clear and informative. Your understanding and appreciation truly make our efforts worthwhile!

Theodora Feil Sr. –

The MRF method was a fantastic choice for simulating the HAWT—an insightful analytical selection for steady-state conditions. The clear explanations in the results about pressure distribution and turbulent intensity make understanding the turbine’s functioning intuitive even to someone not proficient in fluid dynamics. Appreciation for a well-structured tutorial.

MR CFD Support –

Thank you so much for your positive feedback on our HAWT CFD simulation tutorial using the MRF method. We’re glad to hear that the tutorial was informative and easy to understand. If you have any more questions or need further assistance with simulation and analysis, please feel free to reach out.

Pearlie Little –

I’m really impressed with the detailed result analysis for the Horizontal Axis Wind Turbine described. Your simulation parameters and methodology provide a thorough understanding of the wind turbine efficiency under various conditions.

MR CFD Support –

We greatly appreciate your positive feedback on our Horizontal Axis Wind Turbine CFD Simulation tutorial. It’s wonderful to hear when our efforts in providing detailed and insightful analysis meet the needs and expectations of our customers.

Connie Swift –

I’m fascinated by the MRF modeling technique! Could you explain why MRF is appropriate for this type of simulation rather than, for instance, using a sliding mesh method?

MR CFD Support –

MRF (Multiple Reference Frame) is particularly suitable for this type of simulation because it allows for the efficient calculation of the average effect of the rotating wind turbine blades on the airflow. Unlike the more computationally expensive sliding mesh method, MRF simplifies the problem by dividing the domain into a stationary part and a rotating part, thus avoiding the necessity to constantly remesh as would be the case in a sliding mesh method. MRF is preferred when the concern is in the steady-state behavior of the turbulent flow around the blades, whereas sliding mesh would be used for transient phenomena.

Ms. Margie Cartwright –

I found the HAWT CFD Simulation fascinating and extremely educational! The visuals of the pressure distribution and vorticity in the wake of the turbine blades were particularly insightful.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the visual representations in the HAWT CFD Simulation informative and that they added to your understanding. If there’s more we can help with or additional information you seek, please do let us know!

Ms. Letha Quigley DVM –

I really liked how the MRF method was implemented to capture the rotational effects of the HAWT. The detailed vortex formation behind the turbine blades was particularly interesting. Great work on the meshing too!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you are satisfied with the HAWT CFD simulation tutorial and found the depiction of vortex formation insightful. Your appreciation for the mesh quality is also greatly valued. We strive to provide detailed and accurate simulations, so it’s rewarding to receive positive feedback from our customers!

Alyce Abernathy I –

The MRF method you applied for the wind turbine simulation sounds intriguing. I am curious, could the simulation have been done using a transient solver to capture dynamic effects, and how would that compare to the steady-state solution obtained with the MRF method?

MR CFD Support –

Absolutely, the simulation could also be conducted using a transient solver to capture the time-dependent effects and the dynamics of the wind turbine blades’ motion. Both steady-state and transient analyses have their applications. A transient solver would provide insight into how the flow changes over time, potentially leading to a better understanding of transient phenomena such as gusting of the wind. However, this would increase computational resources and time significantly. The MRF method used in this simulation provides an approximation to the mean rotational flow field in a time-averaged sense, which is appropriate for many engineering purposes where the steady-state solution is the primary interest, particularly in the initial design phase.

Al Stamm –

I’m thrilled with how detailed the simulation captures the air movements around the wind turbine blades. The visuals for pressure and turbulence are particularly impressive.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our HAWT simulation could provide such intricate and valuable insights for you.

Kamren Schinner PhD –

This tutorial really laid out everything I needed to understand HAWT simulations. The videos and examples made it easy to follow along. The final contour results helped me solidify the concepts. Awesome work!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our tutorial was helpful and that the examples and contour results enhanced your understanding. Your feedback is greatly appreciated, and we look forward to providing you with more high-quality learning materials in the future.

Fritz Crooks –

I’ve thoroughly enjoyed learning from the HAWT CFD Simulation with the MRF method tutorial! The material was well-organized and clear, allowing me to grasp the complexities of wind turbine simulations. Thanks for an excellent resource!

MR CFD Support –

Thank you for your positive feedback on our Horizontal Axis Wind Turbine (HAWT) CFD Simulation tutorial! We’re delighted to hear that the content was clear and helpful. Your understanding and appreciation of our product mean a lot to us.