Icing of a 3-D Airfoil Surface CFD Simulation, ANSYS Fluent Tutorial

$140.00 Student Discount

- The problem numerically simulates the Icing of a 3-D Airfoil Surface using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 978532.

- We perform this simulation as unsteady (Transient).

- We use the Eulerian Wall Film (EWF) model to estimate the formation of a thin film of liquid on the wall surfaces.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

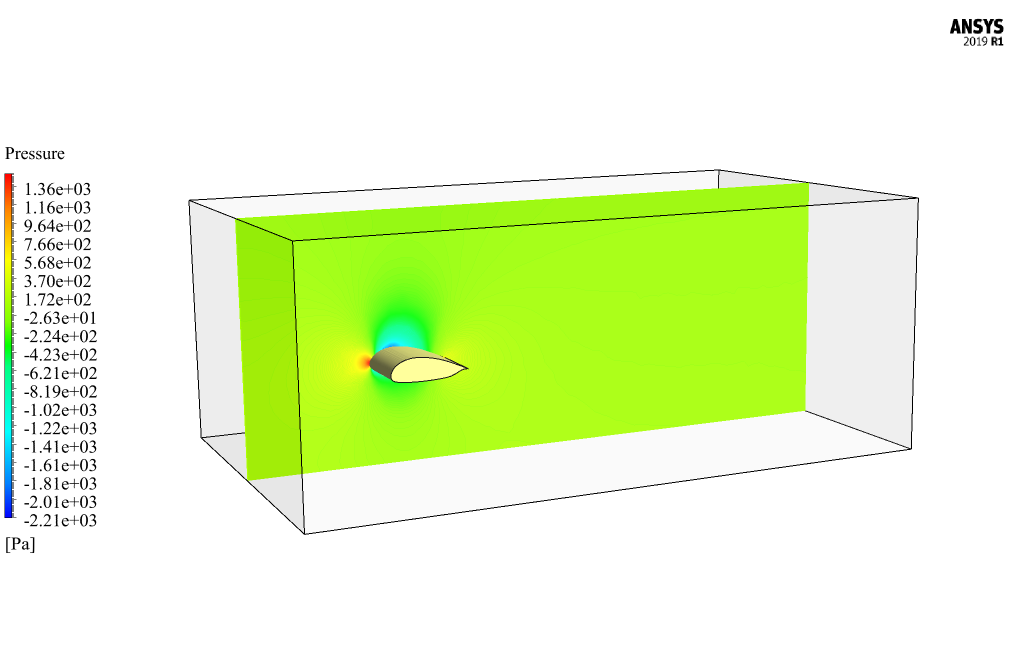

The present problem simulates the airflow around the airfoil and creates a water film on the surface of the airfoil body using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

In fact, when moisturized air and water droplets hit the surface of the airfoil, a water film may form on the airfoil surface.

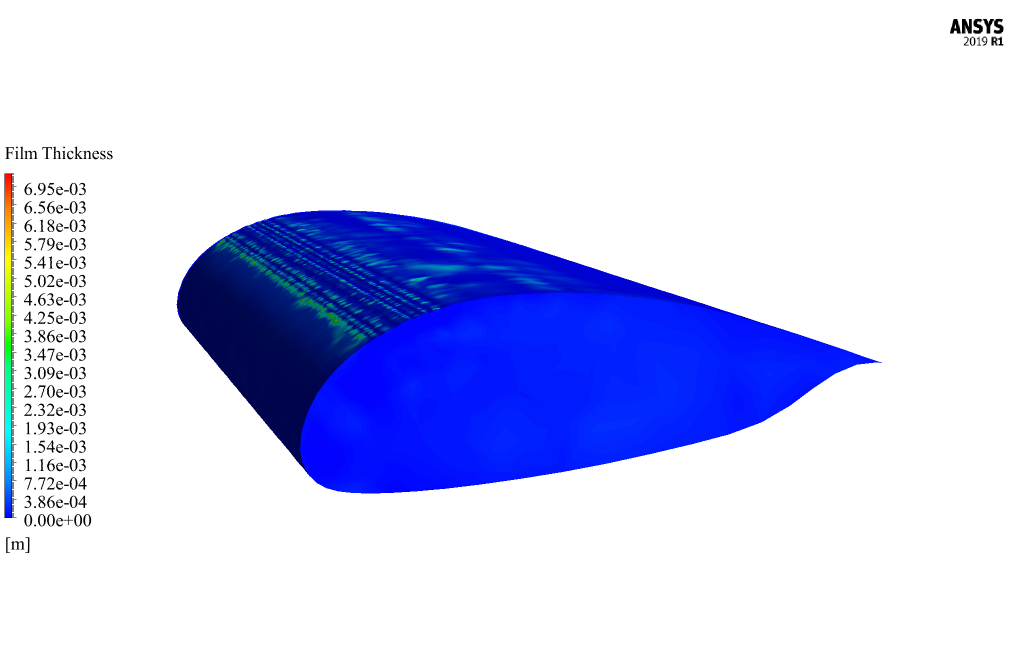

The purpose of this work is to investigate the thickness of the produced and flowing fluid layer on the airfoil body; This is because the presence of this layer of film on the fuselage of the aircraft can cause water droplets to freeze on the surface of the airfoil at very low temperatures.

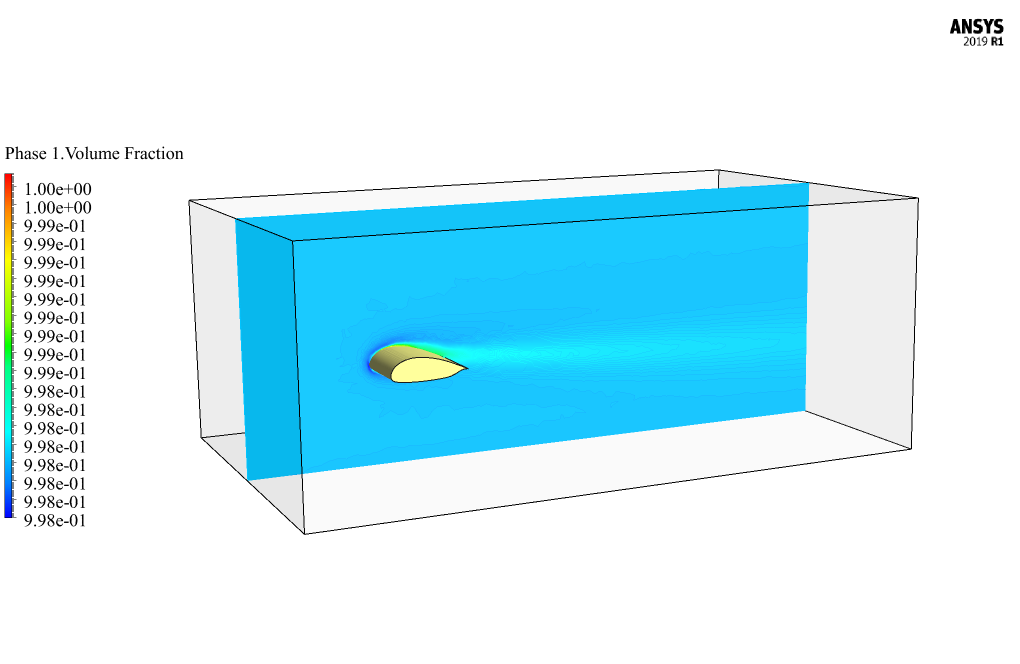

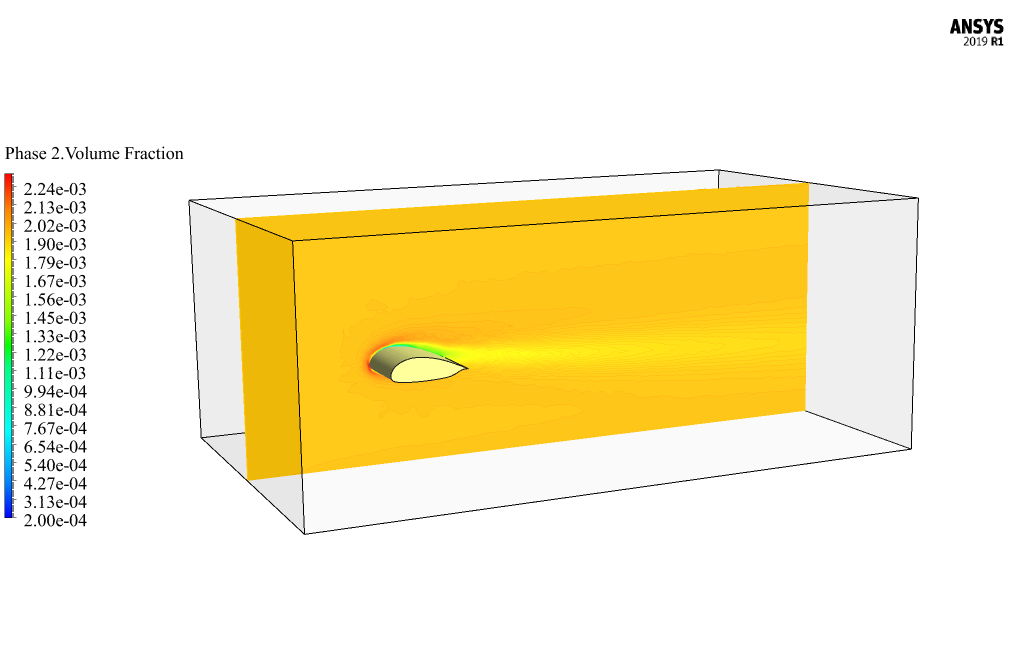

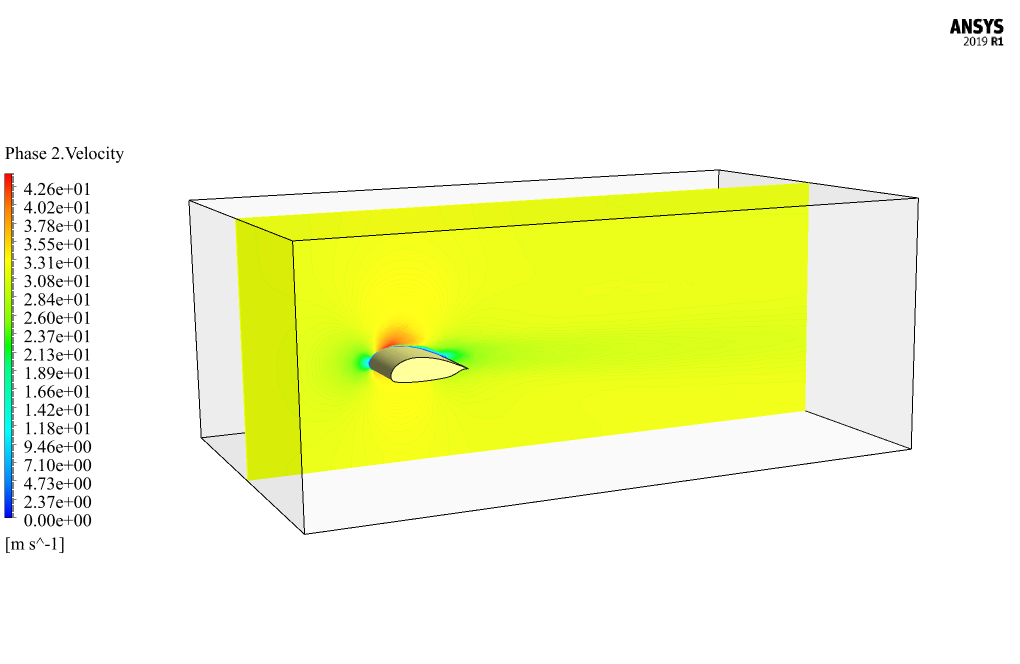

In the present simulation, the primary phase of the Eulerian model is air and its secondary phase is liquid water droplets, which are also defined as the constituents of the Eulerian liquid film.

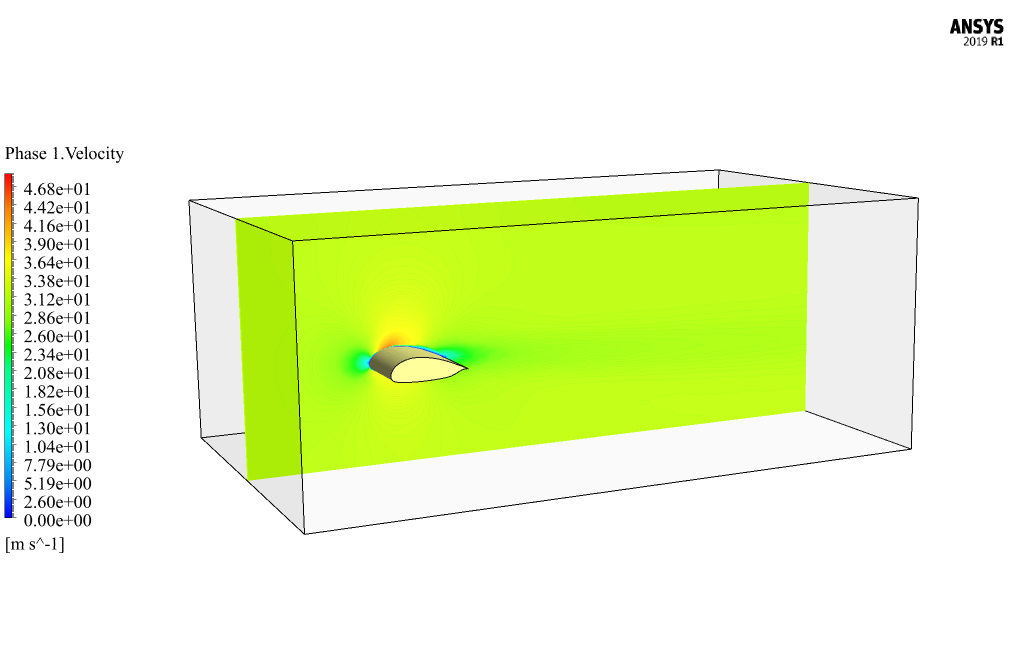

The mixture of airflow and water droplets moves towards the airfoil body at a speed of 30 /.s and a temperature of 250 K; So that the volume fraction of water droplets is equal to 0.002.

The boundary condition of the airfoil wall is defined in such a way that in the initial state, the liquid film has a specific height and zero velocity. The simulation process was performed in 1s with a time step size equal to 0.0001s.

The present model is designed in three dimensions using Design Modeler software. The meshing of the model has been done using ANSYS Meshing software and the mesh type is unstructured. The element number is 978532.

Icing Methodology

The Eulerian wall film (EWF) model was used to simulate and estimate the amount of liquid film produced. This model is used to estimate the formation or flow of a thin film of liquid on the wall surfaces. This model can only be used for 3D geometric models and to use it, the Eulerian multi-phase model must be activated.

Unlike other models in the software (such as the VOF model and radiation model, etc.), the Eulerian wall film model has the ability to correct the initial boundary conditions on the walls and, therefore, has a good interaction with the liquid films.

Icing Conclusion

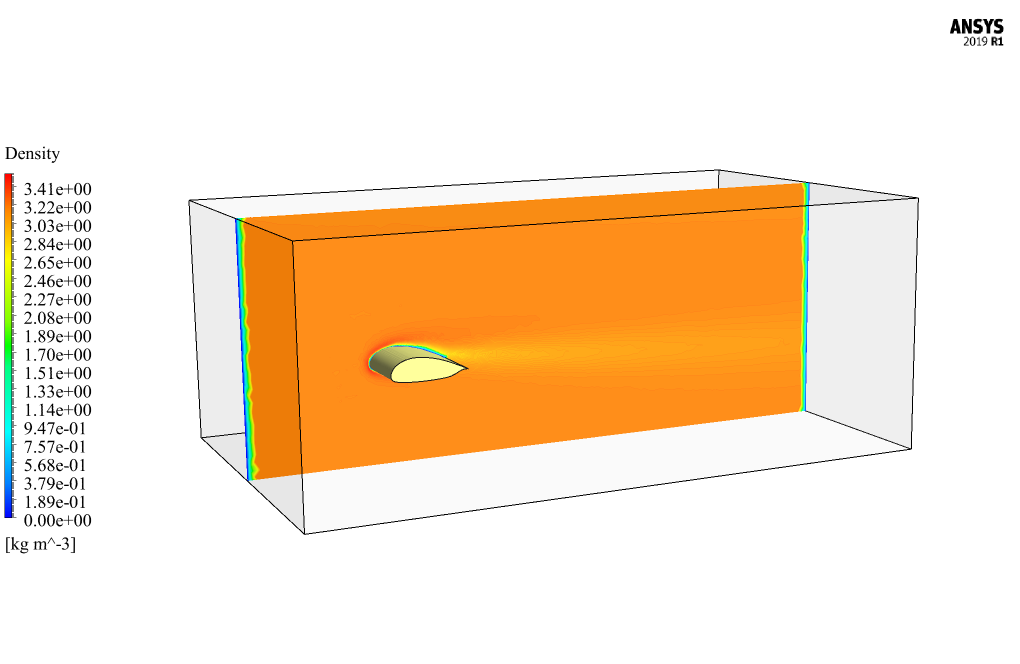

At the end of the solution process, two-dimensional contours related to density, pressure, water velocity, air velocity, water volume fraction and air volume fraction are obtained. The contour of the thickness of the film created on the body of the airfoil is also obtained.

All contours correspond to the last second of the simulation process. The contours clearly show that the purpose of this project, ie icing, is well done and the ice layer is formed.

Reinhold Walsh –

After completing the Icing CFD simulation tutorial, I was impressed by how effectively the Eulerian wall film model estimated the formation of the liquid film on the airfoil. The detail in the calculations for the airfly icing conditions gave me a solid understanding of the process. Great work!

MR CFD Support –

Thank you for your positive feedback on the Icing CFD simulation tutorial! We’re thrilled to hear that the tutorial provided you with a comprehensive understanding of the liquid film formation and icing conditions on the airfoil surface. We appreciate you taking the time to let us know how well the Eulerian wall film model worked for you. If you need any further assistance or have more questions about our tutorials, please feel free to reach out.

Eli Hammes –

Great tutorial for simulating airfoil icing in ANSYS Fluent! It’s fascinating to see how the combination of air and water droplet flow was managed and the icing effect was captured. The details on the setup and boundary conditions are very enlightening.

MR CFD Support –

Thank you so much for your kind words! We’re glad to hear you found the tutorial valuable and that it provided useful insights into simulating airfoil icing. If you have any questions about the tutorial or need further help with your simulations, please let us know.

Prof. Elmira Wintheiser MD –

I love how detailed the explanation of the icing process on the airfoil is! The use of the Eulerian model for simulating the air and water droplet mixture is impressive. Well done on showcasing the impact of ice formation on aerodynamics effectively.

MR CFD Support –

Thank you for your kind feedback! We’re thrilled to hear that you appreciated the detailed explanation and the use of the Eulerian model in our simulation. If you’re interested in more insights or have any other questions, we’re here to help. Don’t hesitate to reach out or try our other simulation products!

Dr. Oral Ziemann –

Is this product suitable for students who are new to CFD or do they need prior experience?

MR CFD Support –

This product is designed with comprehensive tutorials and methodologies which aid in understanding the concepts behind icing on airfoil surfaces. While some foundational knowledge in CFD might be beneficial, the step-by-step approach makes it accessible for dedicated beginners as well.

Dr. Arnoldo Conn –

The explanation was thorough, and the CFD analysis on airfoil icing was fascinating. The details on methodology, especially the use of the Eulerian wall film model and its interaction with boundary conditions, enhanced my understanding. Great job!

MR CFD Support –

We sincerely appreciate your positive feedback on our airfoil icing CFD simulation tutorial. It’s wonderful to hear that the methodology and the use of specialized models clarified the concept of icing for you. Thank you for choosing our learning materials!

Demarcus Weimann –

This tutorial must be fascinating! Does the simulation also account for the change in airfoil performance caused by the icing, such as changes in lift and drag?

MR CFD Support –

In this specific CFD project, the main focus is on the formation of the ice layer on the airfoil and understanding the film thickness characteristics. Performance changes like lift and drag alteration due to icing are not directly included in the simulation’s outputs.

Vesta Bruen –

Are there any limitations or assumptions in this CFD project that I should be particularly aware of when interpreting the results?

MR CFD Support –

In the icing simulation project, one important assumption is the initial boundary condition for the liquid film, which begins with a designated height and zero velocity on the airfoil wall. Also, the simulation uses the Eulerian wall film model which is idealized and may not capture the complete physical complexity of icing such as non-uniform droplet size. Interpretation of results should keep these model simplifications and assumptions in mind.

Gunner Schmidt –

I was impressed with the level of detail in your Icing of a 3-D Airfoil Surface CFD Simulation tutorial. The incorporation of the EWF model to predict liquid film formation on the airfoil sounds intricate. Could you explain if this method also accounts for the phase change from liquid to solid for the freezing process, or is it strictly for film thickness estimation?

MR CFD Support –

In the Icing of a 3-D Airfoil Surface CFD Simulation, the Eulerian Wall Film (EWF) model is primarily used to simulate the formation and behavior of a liquid film on the airfoil surface. The simulation focuses on the liquid phase and factors like thickness and momentum of the liquid film. While the EWF model in ANSYS Fluent may not directly simulate the phase change from liquid to ice, it sets the stage to understand initial liquid film formation, which is crucial for icing predictions. For the phase change, additional modeling techniques or assumptions may have to be used to simulate the actual freezing of the water film into ice.

Mrs. Tiara Lockman I –

The simulation is intriguing! Was real data about airfoil ice formation used to validate this simulation?

MR CFD Support –

While specific information about real data validation is not provided in the description, such simulations typically require validation against experimental or historically accurate data to ensure accuracy and relevance of the CFD predictions to real-world behavior.

Constance Yost –

It’s fascinating to see how this simulation can mimic the formation of ice on an airfoil surface. Does the model take into account the phase change from water to ice, or is it just focused on the water film formation?

MR CFD Support –

In this simulation, the Eulerian wall film (EWF) model is primarily focused on monitoring the water film formation on the airfoil’s surface. Specific phase change from water to ice is generally modeled using additional physical models which account for heat transfer and change of state, which might not be explicitly described in this particular simulation setup. To rigorously simulate the icing phenomenon, one would need to consider the thermodynamic properties and the cooling rate that causes water droplets to freeze upon the airfoil surface.

Melody Mills II –

This is a detailed simulation that captures critical elements in icing studies. The use of the Eulerian wall film model to simulate the liquid film is impressive. Great job on identifying the formation of the ice layer, it’s a crucial factor for airfoil performance and safety.

MR CFD Support –

We sincerely appreciate your positive feedback on our airfoil icing CFD simulation tutorial. It’s always inspiring to hear from satisfied customers. Your recognition of our attention to detail and modeling efforts means a lot. Thank you for choosing our product and taking the time to share your experience with others!

Diego Hartmann –

I was extremely impressed with the detail and realism the Icing of a 3-D Airfoil Surface CFD Simulation managed to capture. The methodology explained was quite insightful for understanding how the Eulerian wall film model works. Excellent tutorial!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the simulation detailed and the tutorial helpful. It’s our goal to provide realistic and comprehensive guidance for complex CFD processes, and we’re glad we could achieve that for you. Your satisfaction with the learning experience is our top priority.

Imelda Oberbrunner –

The tutorial was technical and comprehensive! You showed everything step by step, making it easy to understand the icing process on an airfoil surface. This could be really useful for anti-ice system design. Great job!

MR CFD Support –

Thank you for your positive feedback! We strive to provide detailed and informative tutorials that are both useful and easily understood. Your input assures us that our approach is working, and we appreciate knowing that our tutorial will be beneficial in designing anti-ice systems. If you have any further questions or needs, feel free to reach out. Thanks again for choosing our learning products.

Breanna Hermann –

Is there any environment temperature changes in the simulation process to induce icing effect or is it just caused by the initial conditions?

MR CFD Support –

In this simulation, the temperature is set to a consistent value of 250 K throughout the simulation process. The icing effect is mainly induced by the interaction of the moisturized air and water droplets at this constant low temperature with the airfoil surface, leading to the formation of a water film that may eventually freeze into an ice layer.

Yolanda Pfannerstill –

Could you provide insights on how the water droplets freezing process is depicted in the simulation when the airfoil surface temperature is lower than freezing?

MR CFD Support –

For depicting the water droplets’ freezing process within the simulation framework mentioned in the description, a phase change modelling approach has to be used. In ANSYS Fluent, this might typically involve coupling between the thermal and flow fields, where the temperature of the water film impacting the airfoil is tracked and when it reaches below the freezing point, the properties and behavior of the droplets change to match that of ice. While the specific methodology isn’t detailed in this description, ANSYS Fluent has the capabilities to execute such advanced multiphase simulations involving solidification and melting based on predefined material properties and phase change temperatures. If solidification was modeled in this exercise, appropriate user-defined functions (UDFs) or available models would’ve been utilized to simulate the transition from water to ice upon contact with the cold surface of the airfoil.

Prof. Sarai Willms Sr. –

The tutorial was fantastic and made learning the implementation of the Eulerian Wall Film model very intuitive. The step-by-step guidance, along with visual results, really cemented my understanding of the icing process on airfoil surfaces.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our tutorial on icing of a 3-D airfoil surface using ANSYS Fluent was helpful and intuitive. If you have any more questions or need further assistance in your CFD learning journey, feel free to reach out.

Isaias Lynch –

I thoroughly enjoyed the detail and depth of this tutorial. The application of the Eulerian wall film model was particularly insightful for understanding ice formation on the airfoil.

MR CFD Support –

Thank you for your positive feedback! We are glad to hear that you found the tutorial on icing of a 3-D airfoil surface using ANSYS Fluent insightful and useful for understanding the complex phenomena of ice formation in airflow conditions. Your satisfaction with the content depth is greatly appreciated!

Henry Littel –

The tutorial was great for understanding the icing process on an airfoil. Learning how the water film evolves was fascinating. It gave me a real sense of what pilots or engineers have to manage in cold environments. Great visuals and explanation!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the tutorial provided a clear understanding of the icing process on an airfoil and that the visuals and explanations helped convey the concept effectively. If you have any more questions or need further assistance, feel free to reach out.

Aron Rutherford –

The tutorial was impressive! I was wondering, how does the software determine the freezing point on the airfoil, and could you simulate various temperatures to observe different icing patterns?

MR CFD Support –

In the simulation, the software detects the freezing point based on the predefined temperature conditions and the physical properties of the materials involved. Yes, you can simulate at various temperatures to observe different icing patterns. By specifying different air and wall temperatures, you can analyze how varying thermal conditions affect the formation and characteristics of the ice layer on the airfoil.

Taya Hahn –

Is it possible to visualize the actual ice formation on the airfoil in the simulation?

MR CFD Support –

Yes, within the ANSYS Fluent software, you can create contour plots that show the thickness of the liquid film on the airfoil. These can be used as an indication of where and to what extent ice might form, especially when you correlate this data with other thermal factors that cause the water to freeze.

Prof. Ulices McCullough IV –

The tutorial was incredibly informative on how to simulate an icing scenario on an airfoil. The intricate details of how moisture interacts with the surface were eye-opening, helping me understand how vital CFD analysis is for aviation safety. Having for us examples and a step-by-step approach to follow made this complex process feel manageable. Well done on creating such a comprehensive guide!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the ‘Icing of a 3-D Airfoil Surface CFD Simulation’ tutorial was helpful to you. Ensuring aviation safety through CFD analysis is indeed vital, and we’re glad that the tutorial could clarify this complex phenomenon for you. We aim to provide valuable and practical learning experiences to our users. Your positive feedback motivates us to keep creating high-quality, informative material!

Tressie Graham DVM –

I’m fascinated by how this model accounts for the phase change from liquid to ice. Could you explain how this transition is simulated in ANSYS Fluent?

MR CFD Support –

Certainly! The phase change from liquid to ice is simulated using appropriate phase change models within ANSYS Fluent. The software provides capabilities, such as defining latent heat and setting temperature conditions that trigger the phase change. The mesh is fine-tuned to capture the liquid’s behavior as it comes into contact with the cold airfoil and begins to freeze, allowing for accurate simulation of the icing process on the airfoil surface.

Prof. Mathilde Ebert –

I was surprised to see the level of detail in the simulation results. Could you tell me more about how accurately the software predicts the actual icing conditions that might occur in real flight situations?

MR CFD Support –

Absolutely, the ANSYS Fluent simulation for the aircraft icing conditions uses advanced multiphase flow and heat transfer models to predict quite accurately how ice would form on a 3D airfoil surface. Factors like air and water droplet temperature, airfoil surface characteristics, and airflow velocity are meticulously taken into account. Although the simulation provides a close approximation, it should be noted that actual flight situations might have additional variables. The real aim is to get qualitative understandings and for engineering insights that ensure design robustness and safety against in-flight icing.

Dr. Noah Torp Sr. –

I had a great time learning from the ‘Icing of a 3-D Airfoil Surface CFD Simulation’ tutorial. The step-by-step guidance made complex concepts easy to understand, and I could really grasp how the Eulerian wall film model works in the context of icing on airfoil surfaces. The visual aids and the detailed explanation on the setup of boundary conditions and the post-simulation analysis were incredibly helpful.

MR CFD Support –

We’re thrilled to hear you enjoyed the tutorial and found it enlightening! Understanding the complexities of icing on airfoil surfaces is crucial, and using the Eulerian wall film model correctly is key in such simulations. We’re glad that the tutorial’s content was presented in an accessible manner and that it contributed positively to your learning experience. If you have any further thoughts or need more assistance, don’t hesitate to reach out. Thank you for choosing our tutorial, and we appreciate your positive feedback!