Microchannel Heat Sink for Heat Transfer Enhancement

$80.00 Student Discount

- The problem numerically simulates the heat transfer of water flow inside a microchannel heat sink using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 1500000.

- The Energy Equation is activated to consider heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Microchannel Heat Sink, Heat Transfer Enhancement, ANSYS Fluent Training

The present problem simulates the heat transfer of water flow inside a microchannel heat sink using ANSYS Fluent software.

One of the serious problems in designing electronic equipment due to its small structure is eliminating the generated heat. This simulation investigates the thermal performance of a cylindrical microchannel heat sink for electronic equipment cooling.

This thermal sink consists of 86 microchannels with a rectangular cross-section with a hydraulic diameter of 560 micrometers around the cylindrical geometry. Water flows at a rate of 0.59 m/s, and a temperature of 297 K enters the microchannel duct.

The present model is designed in three dimensions using Design Modeler software. The model is related to a cylindrical heat sink with a microchannel. The internal radius of the model is equal to 5 mm, and its thickness is equal to 10 mm.

Due to the symmetrical structure of the geometry, only one segment of it is designed, and the periodic boundary condition is used.

We carry out the model’s meshing using ANSYS Meshing software. The mesh type is structured. The element number is 1500000.

Microchannel Methodology

The model’s central core is considered a heat source; thus, the model’s inner wall is assumed to have a constant flux boundary condition equal to 243507 W/m2.

Microchannel Heat Sink for Heat Transfer Enhancement Conclusion

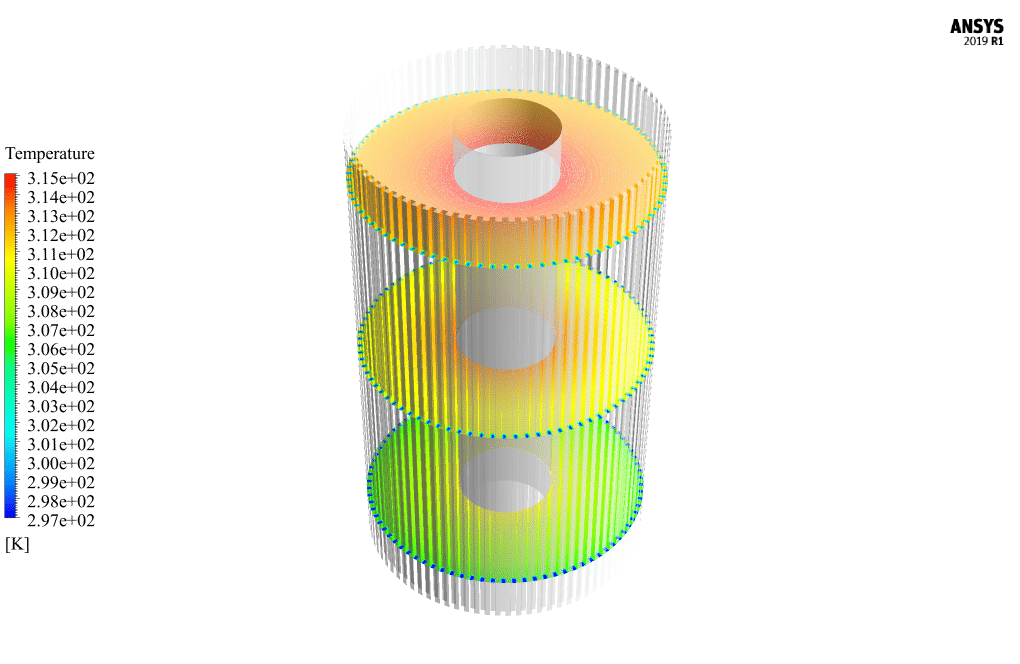

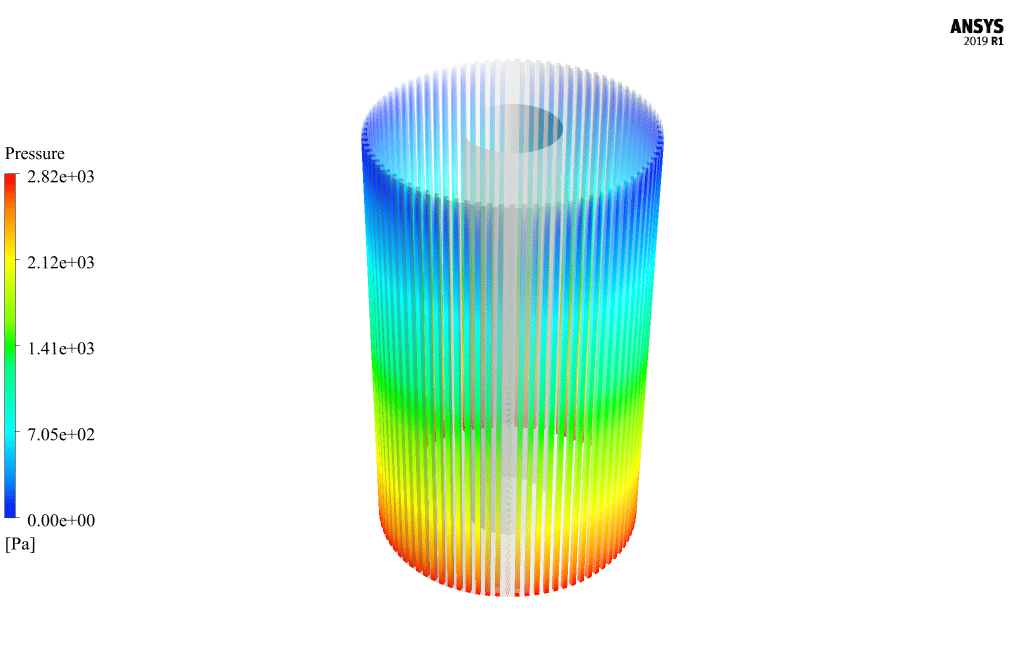

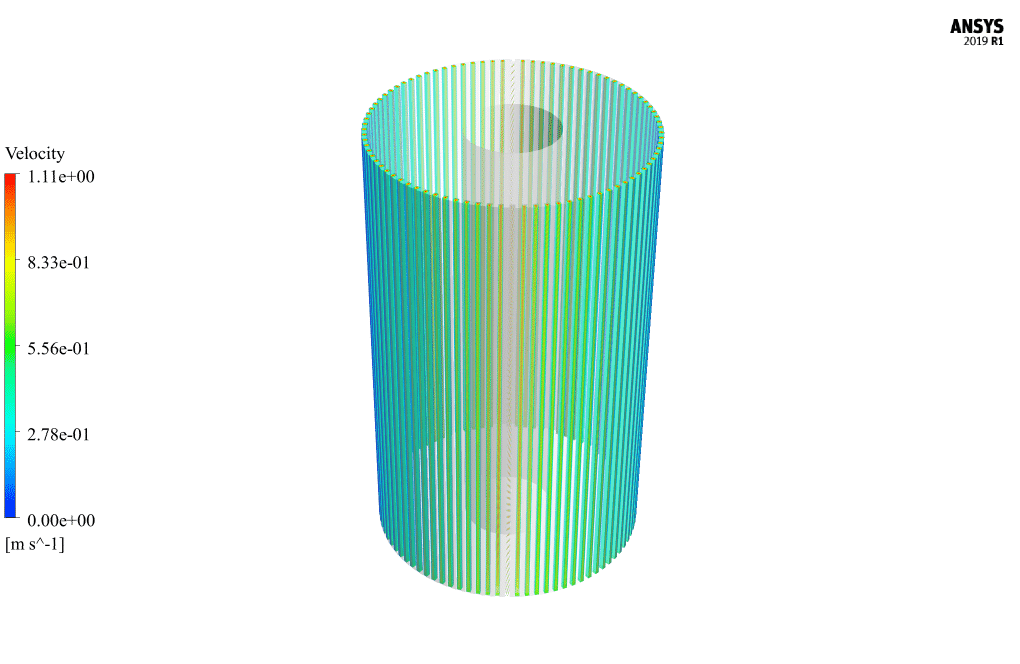

At the end of the solution process, three-dimensional contours related to pressure, temperature, and velocity are obtained. These three-dimensional contours are related to the interior of the microchannel. Also, the two-dimensional temperature contour is obtained in three sections of the model.

It includes the flow of fluid inside the microchannel and the solid part of the model. It should be noted that this simulation is performed only for one segment of the model and with the periodic boundary condition.

Therefore, at the end of the work, the segment is rotated around a central axis so that the contours can be formed in three dimensions. Temperature counters show well that the solid part of the model has decreased in temperature, resulting in the cooling process.

Shyanne Schinner –

What a fantastic resource! The attention to detail in the use of a symmetric structure and periodic boundary conditions likely makes this complex heat transfer analysis more efficient and more accessible to study. In-depth thermal analysis within those tiny microchannels is no simple task, and mastering it is crucial for cutting-edge electronics. It’s delightful to see that the simulation also includes the visualization of temperature distribution, reflecting the heat sink’s performance. Well done!

MR CFD Support –

Thank you very much for your kind review! We’re thrilled to hear that you found the symmetric structure and the utilization of periodic boundary conditions in the Microchannel Heat Sink simulation helpful. Our goal is to provide detailed, realistic simulations to improve heat transfer designs and we are glad you recognize the efficiency and accessibility of our approach. It’s rewarding to see your appreciation of the complexities involved in such analyses. Again, thank you for taking the time to complement our product.

Dr. Walton Lindgren II –

I recently completed the Microchannel Heat Sink ANSYS Fluent Training, and I was really impressed at how well the simulation represented the heat dissipation in such a detailed system. The process used beauty in both design and function!

MR CFD Support –

We’re thrilled to hear that you found the Microchannel Heat Sink training helpful and that it met your expectations in terms of representation and functionality. Thank you so much for taking the time to provide such positive feedback!

Prof. Harvey Connelly PhD –

The analysis and visualization results have been amazing! Particularly impressed with the multi-dimensional results obtained which will significantly help in understanding the heat transfer characteristics more deeply.

MR CFD Support –

Thank you for your positive feedback! We’re delighted that our simulation was able to provide you with detailed insights into the heat transfer process within the microchannel heat sink. It’s great to hear that the multi-dimensional results were especially useful for you. If you have any more questions or need further assistance, feel free to reach out to us. We’re committed to helping our customers make the most of our products.

Lavonne Herzog –

I’m amazed by how well you managed to simulate the heat sink with detailed geometrical consideration of microchannels. The provided structured mesh and boundary conditions undoubtedly contributed to the precise results. I’m especially curious about how you maintained a balance between computational efficiency and accuracy in your simulation.

MR CFD Support –

Thank you for your kind words. We ensure an optimal balance by carefully selecting the mesh density to be fine enough to capture the relevant physics accurately but not too dense to avoid excessive computational costs. The periodic boundary condition also allows us to simulate just one segment and accurately predict the behavior for the entire structure, enhancing computational efficiency without compromising on the accuracy of the results.

Dr. Ford Emmerich IV –

I was really impressed with the Microchannel Heat Sink simulation you are offering! The intricate details of heat transfer enhancement and the structured mesh type show thorough research and attention to detail. This kind of resource is invaluable for someone learning the ropes of electronic equipment cooling. The fact that it addresses the serious challenge faced in electronics design within such small structures makes it incredibly relevant to current engineering issues.

MR CFD Support –

Thank you for your kind words! We are delighted to hear that our Microchannel Heat Sink simulation has been beneficial for your understanding of heat transfer in electronic equipment cooling. Our goal is to provide highly detailed and relevant simulations to aid in the learning process of thermal management. If you have any further questions or need more information, feel free to reach out to us. Your feedback motivates us to keep creating quality educational content!

Shirley Mann –

I’m really fascinated by the concept of the microchannel heat sink method for enhancing heat transfer. How does the periodic boundary condition in this model exactly work to represent the full cylindrical geometry effectively?

MR CFD Support –

The periodic boundary condition in ANSYS Fluent allows the simulation of a small, repeatable section of the full geometry to imply the behavior of the entire system. Since the microchannel heat sink has a symmetrical and repeatable pattern, you only need to simulate one segment. The periodic boundary condition mathematically enforces the continuity of flow properties (temperature, velocity, pressure, etc.) from one face of the segment to the opposite face. This creates an ‘infinite’ pattern of segments, mimicking a full cylindrical heat sink without the computational expense of modeling the entire geometry. The heat source within the central core applies consistently across all simulated periodic sections, providing accurate temperature distribution and flow characteristics for the whole system.

Marcia Veum –

I’m impressed with the thermal performance analysis provided by the Microchannel Heat Sink product for cooling electronic equipment. The detailed three-dimensional and sectional temperature analysis shows that the product effectively decreases temperature in the solid parts of the model, clearly indicating the heat sink’s ability to enhance heat transfer. Well-executed CFD study!

MR CFD Support –

Thank you for your thoughtful review! We appreciate your acknowledgement of the detailed analysis this product provides. It’s gratifying to hear that the simulation met your expectations and effectively demonstrated the cooling efficiency of the cylindrical microchannel heat sink. We are committed to providing high-quality simulations, and feedback like yours helps us maintain our standards. If you have any further questions or need clarification, please don’t hesitate to contact us.

Domenick Herzog –

I’m impressed with the granularity of the microchannel design in this heat sink simulation. The structured mesh and the detailed heat source conditions must have provided very accurate thermal performance predictions. Well done on implementing such a precise CFD model with such a massive number of elements for a very complex geometry!

MR CFD Support –

Thank you for your kind words. It’s gratifying to learn that our customers appreciate the level of detail and effort we put into our simulations. Our goal is always to provide the most accurate and realistic predictions, and we’re thrilled that you’ve recognized the precision of our work. If you have any more feedback or questions, please don’t hesitate to reach out.

Chance Nienow DVM –

I’m amazed! The simulation method sounds very intricate. Was the simulation stable throughout the process, especially with 1.5 million elements?

MR CFD Support –

Thank you for the compliment! Yes, the simulation remained stable throughout the process since measures such as structured mesh type, proper boundary conditions, and appropriate numerical settings ensured efficient problem-solving stability despite the high number of elements.

Margie Schuppe –

I’m thoroughly impressed with the level of detail in the Microchannel Heat Sink simulation. The accurate replication of thermal management challenges in electronic components is crucial and it seems like MR CFD Company’s product delivers on that. Bravo for facilitating advanced learning in heat transfer enhancement with such clarity!

MR CFD Support –

We’re pleased to hear that you appreciate the Microchannel Heat Sink simulation’s depth and accuracy. Ensuring a clear understanding of thermal management in electronic components is one of our primary goals, so your positive feedback means a great deal to us. Thank you for your kind words!

Lourdes Cassin –

I appreciated the intricate design of the microchannel heat sink in this ANSYS Fluent simulation. I was able to get a good visual understanding of how the heat transfer occurs within the system, and the cooling process was clear in the results, particularly seeing how the high temperatures were managed effectively. The structured mesh you employed seems to have captured the critical aspects perfectly. Thank you for providing such a detailed and practical learning tool!

MR CFD Support –

Thank you for your kind words. We’re thrilled to hear that our microchannel heat sink simulation was effective in demonstrating the cooling process and that the visuals helped in your understanding of heat transfer aspects. Your feedback is greatly appreciated, and it propels us to continue developing detailed and valuable learning resources for our customers.

Prof. Tatum Haag III –

The description of this simulation is clear and detailed; it truly showcases the effectiveness of a microchannel heat sink in dissipating heat. Excellent work!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the details provided in our training material met your expectations and were able to clearly convey the science behind microchannel heat sinks for heat transfer enhancement. Your satisfaction is our top priority!