Nanofluid optimum concentration for Heat Transfer enhancement, Paper Validation

$360.00 Student Discount

- The problem numerically simulates the Nanofluid optimum concentration and Heat Transfer enhancement using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 40000.

- This project is validated with a reference article.

- The Energy Equation is activated to consider heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

The nanofluid optimum concentration for Heat Transfer enhancement, Paper Numerical Validation, CFD Simulation by ANSYS Fluent

Nanofluids, solid-liquid composites, have higher thermal conductivity and convection heat transfer performance than base fluid without nanoparticles. Therefore, using nanotechnology, the heat transfer process can be optimized.

Nanoparticle concentration is an important parameter in increasing heat transfer under free convection, as many studies show that heat transfer is proportional to the nanoparticle concentration.

It is also important to understand the mechanism of increasing heat transfer at the optimum concentration of nanoparticles. In addition, many researchers still focus on developing mathematical formulas for the various properties of nanofluids and using those models in natural convection analysis.

The present study aimed to identify the optimal concentration of nanoparticles when using TiO2 nanoparticles with water to discover the possible mechanism of increased heat transfer.

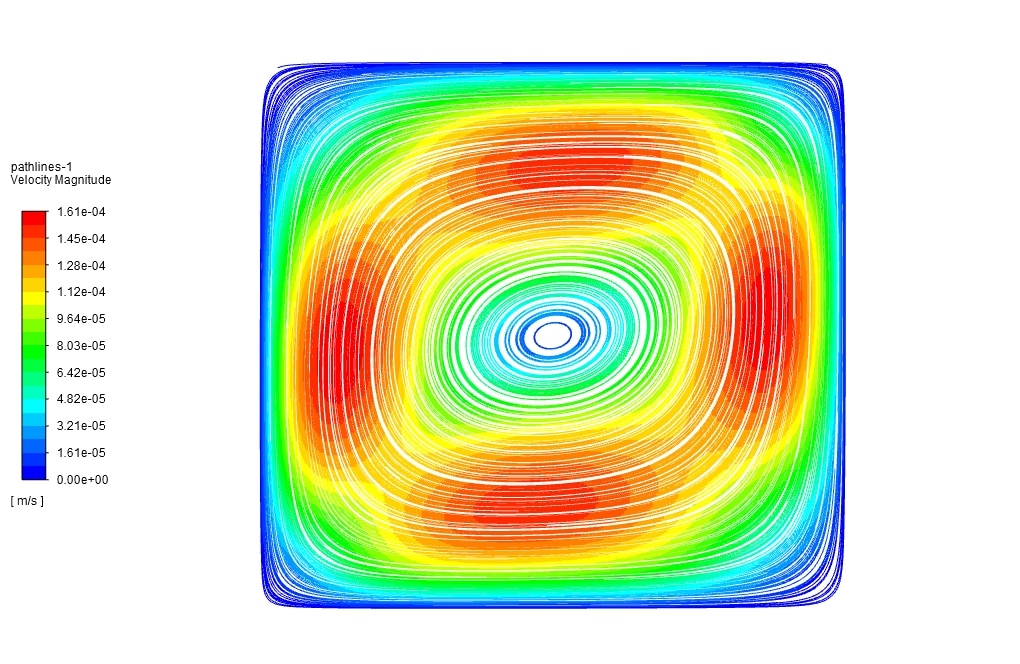

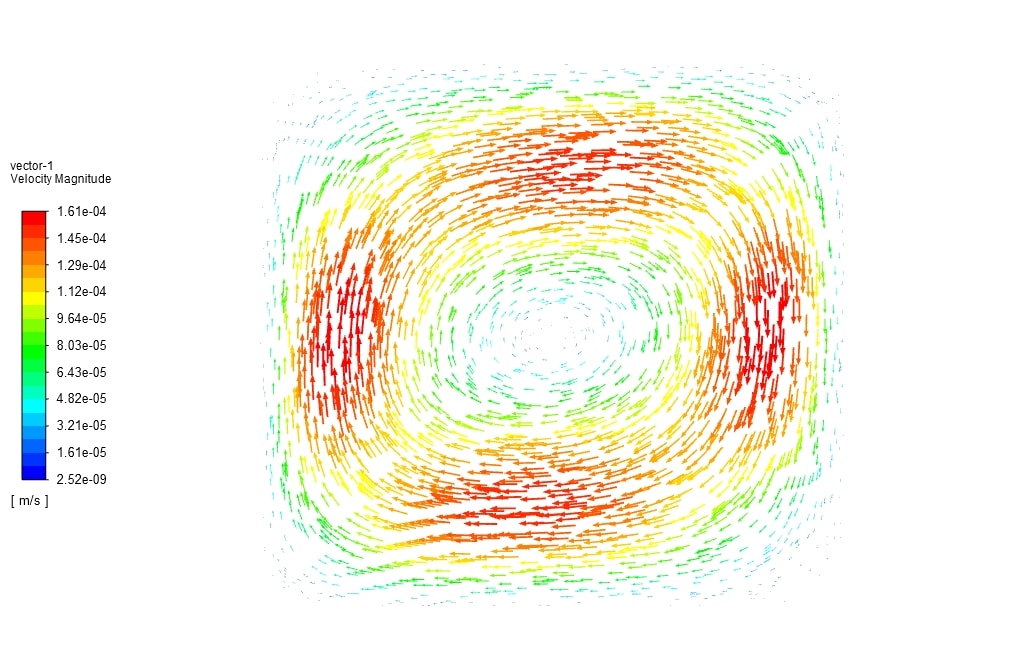

This project simulates the process of combining water and nanofluid in a laboratory chamber by ANSYS Fluent software.

This work is based on the paper “Optimal Concentration of Nanofluids to Increase Heat Transfer under Natural Convection Cavity Flow with TiO2 – Water,” The quasi-simulation results are compared with the results of the paper.

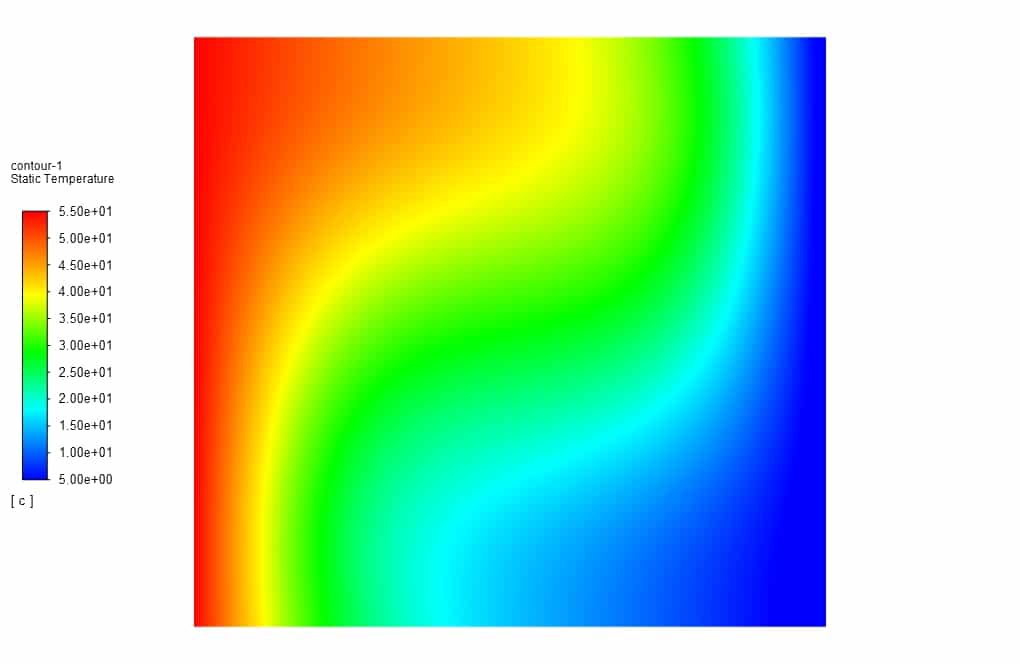

In experimental research, a mixture of titanium dioxide and water is used as a nanofluid. The nanofluid is composed of nanoparticles with an average size of 50 nanometers. We change the temperature of the heat and cool walls and the nanofluid’s volume fraction to investigate their effects on heat transfer.

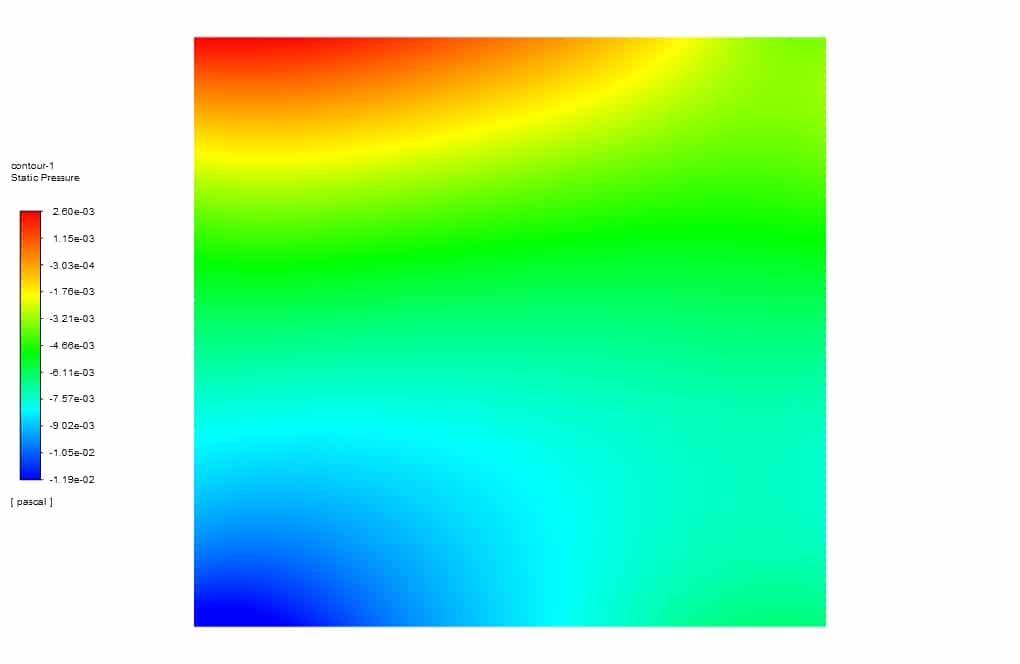

The volume fraction of nanofluids varies from 0.05 vol% to 0.8 vol%, and Ra in this study varies from 4.9 * 108 to 1.47 * 109. First, the geometry of the test chamber was designed in Design Modeler software and prepared for meshing.

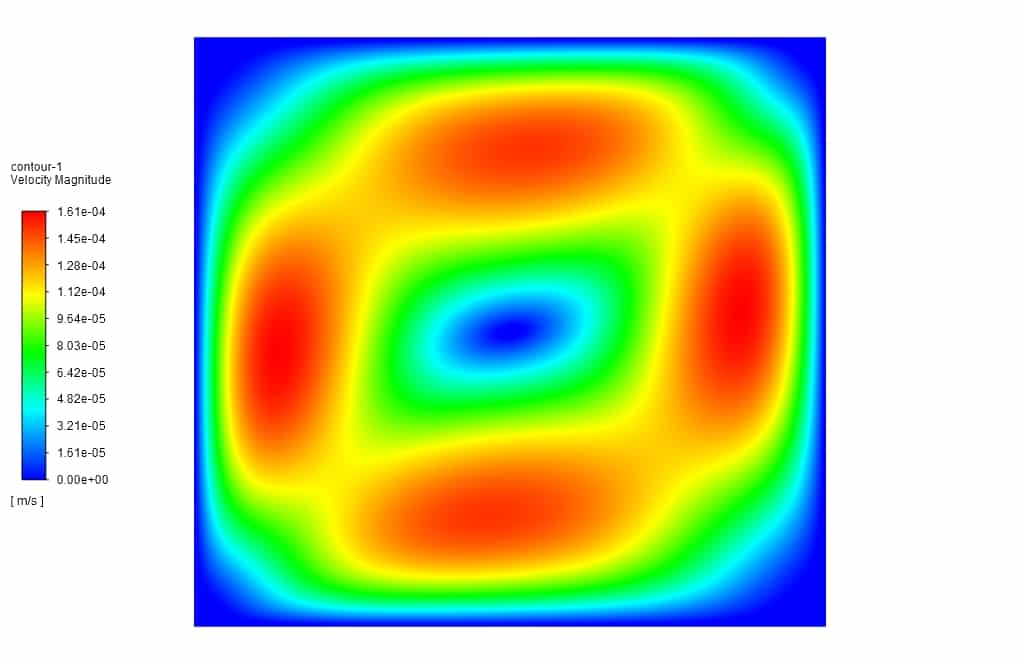

The geometry file was implemented in ANSYS Meshing software to create mesh and boundary conditions name selection. The dimensions of this problem are 120 * 96 * 103 mm as a cube. The mesh type is hexahedral. The element number is 40000.

Nanofluid Methodology

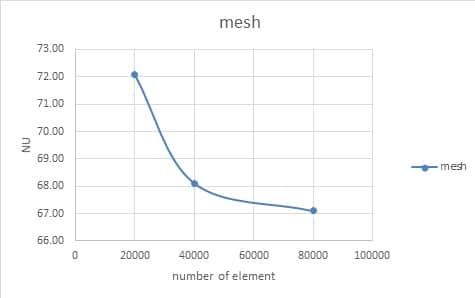

As the number of elements in the mesh increases, the Nusselt number changes, but with increasing more than a certain value, these changes become very small.

As shown in the diagram and table above, the difference between the results of the two grids of 40,000 and 80,000 elements is less than 2%. Therefore, the mesh independence is done at elements number equal to 40000.

Nanofluid Conclusion

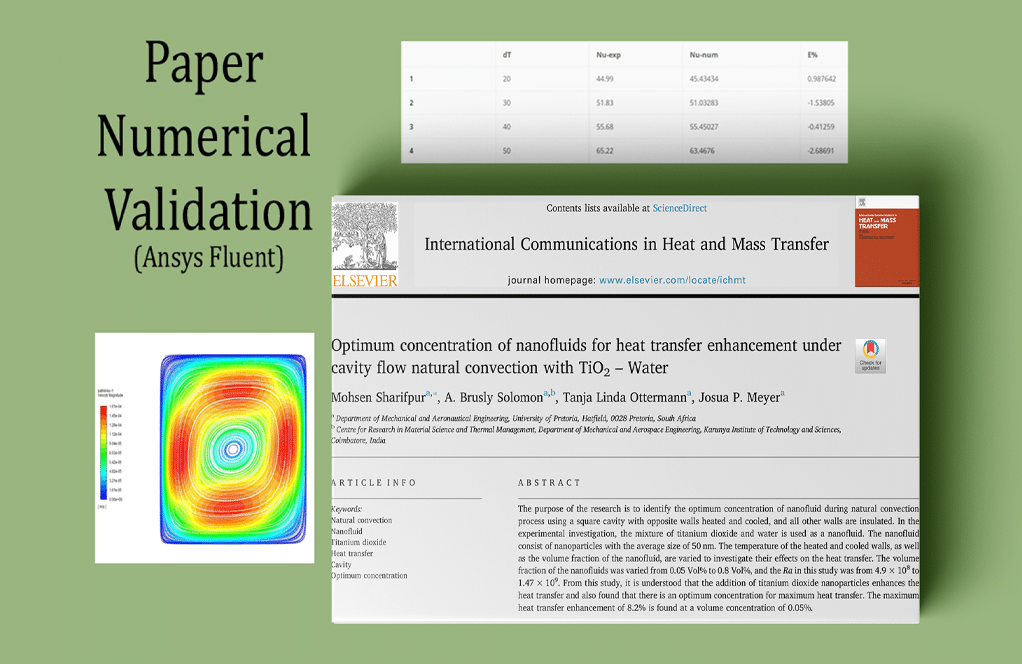

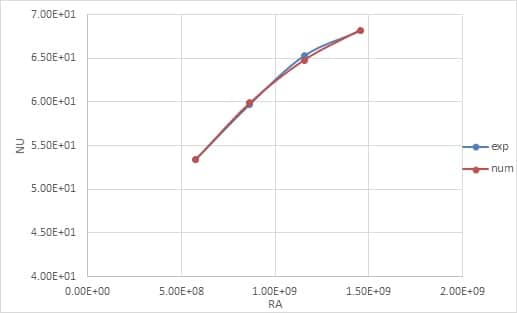

This study aimed to identify the optimum nanofluid concentration during the free convection process using a square chamber with hot and cold opposite walls, and all other walls were insulated. The Nusselt numbers reported in the paper with their corresponding numbers in the current CFD simulation are validated as follows.

| Experiment result (based on paper) | Numerical result (based on simulation) | ||

| RA | NU | RA | NU |

| 5.76E+08 | 5.34E+01 | 5.76E+08 | 53.43 |

| 8.65E+08 | 5.97E+01 | 8.65E+08 | 59.88 |

| 1.16E+09 | 6.53E+01 | 1.16E+09 | 6.48E+01 |

| 1.46E+09 | 6.81E+01 | 1.46E+09 | 6.82E+01 |

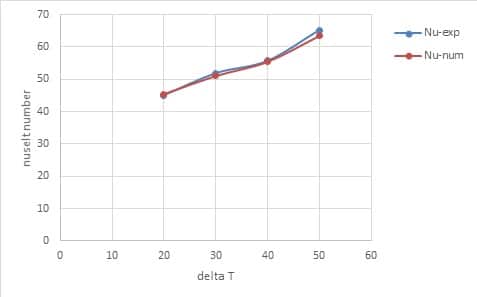

This comparison shows that the present numerical results are comparable to the theoretical and experimental results. At different temperature differences between the walls, the Nusselt number is reported. Numerical CFD Simulation and experimental values in different temperature differences are as follows.

| dT | Nu-exp | Nu-num | E% | |

| 1 | 20 | 44.99 | 45.43434 | 0.987642 |

| 2 | 30 | 51.83 | 51.03283 | -1.53805 |

| 3 | 40 | 55.68 | 55.45027 | -0.41259 |

| 4 | 50 | 65.22 | 63.4676 | -2.68691 |

The figure above shows the change in the Nusselt number in terms of the Rayleigh number for a concentration of 0.8% nanofluid. The Nusselt number increases with increasing Riley number and concentration of nanofluid.

This study focuses on free convection in a water-based titanium dioxide nanofluid. The effects of a temperature change, as well as volume concentration, were investigated. When investigating the effect of volume concentration on heat transfer, it was found that there is an optimal volume concentration.

From this study, it can be seen that the addition of titanium dioxide nanoparticles increases heat transfer. The maximum increase in heat transfer is 8.2% at a volume concentration of 0.05% and a temperature difference of 50 °C.

This study also shows the correlation between the simulation and experimental and theoretical results. Therefore, this research supports the idea that any nanofluid with a higher thermal conductivity than its base fluid may increase heat transfer under the same conditions.

Mr. Lisandro Skiles –

I found the information about how nanoparticle concentration affects heat transfer fascinating. Can you expand on why there’s an optimal concentration and what happens beyond that point?

MR CFD Support –

Nanofluids display an optimal concentration level due to a balance between increased thermal conductivity and the associated increase in viscosity that occurs with higher nanoparticle loads. Beyond the optimal concentration, the viscosity increases significantly which can impede flow and convection currents, potentially reducing the efficiency of heat transfer.

Elenor Wunsch –

The work on identifying the optimal nanoparticle concentration for heat transfer enhancement is fascinating. Nonetheless, could you specify the simulation conditions that are held constant besides the volume fraction and temperature, ensuring a fair evaluation of these parameters’ effects?

MR CFD Support –

In this simulation, several conditions are kept constant to ensure accurate assessment of the nanoparticle concentration and temperature effects on heat transfer. These include the properties of the base fluid (water), the properties of the titanium dioxide nanoparticles, the coolant chamber’s geometry, boundary conditions around the simulation domain such as wall temperatures, and finally, the physical model settings within ANSYS Fluent. Consistency across these conditions keeps the simulation results reliable and directly comparable.

Baron Labadie –

Can you explain the significance of the nanoparticle concentration on heat transfer? How does it impact the efficiency in this simulation?

MR CFD Support –

The nanoparticle concentration is crucial because it affects thermal conductivity and the overall heat transfer efficiency. As the concentration increases, heat transfer tends to improve due to the enhanced thermal properties of the nanofluid. In this simulation, there is an optimal concentration where the heat transfer enhancement is maximized.

Keaton Morissette Jr. –

I found the details on the nanofluid concentration’s effects fascinating. Could you explain how you ensured the accuracy of the CFD results in comparison with the experimental data?

MR CFD Support –

In the simulation process, we maintained a rigorous approach to ensure accuracy. Mesh independence was verified, numerical methods were validated against theoretical predictions, and simulation results were carefully compared to experimental data from the reference paper. Differences were minimized, indicating a high degree of reliability in our numerical approach.

Rick Upton I –

The results are impressive! Does this research suggest which applications could benefit most from this concentration optimization of nanofluids in heat transfer processes?

MR CFD Support –

Thank you for your kind words! This study mainly highlights the effectiveness of optimizing nanoparticle concentration for enhanced heat transfer, particularly under free convection conditions. While it specifically investigates TiO2 nanoparticles with water, the implications suggest that similar nanofluid applications could benefit systems where cooling or improved thermal management is crucial, such as electronic devices cooling, automotive radiators, heating, ventilation, and air conditioning (HVAC) applications, and other thermal energy systems.

Gordon Hauck –

The simulation results are very detailed and closely match with the paper’s experimental and numerical results. It’s clear that MR CFD’s simulation offered comprehensive insights into nanofluid heat transfer optimization.

MR CFD Support –

Thank you for recognizing the precision and depth of our simulation results. We at MR CFD strive to provide accurate and detailed analyses, and we’re delighted to see that our efforts resonate well with you.

Orie Runte –

How closely does the Nusselt number obtained from the simulation match the experimental results, and what could cause them to differ?

MR CFD Support –

From the provided data, the Nusselt number obtained from the simulation closely aligns with the experimental results, showing a maximum deviation of around 2.68691%. This excellent agreement between numerical simulation and experimental data indicates a validated simulation process. Variabilities in experimental setup, minor differences in environmental conditions, or precision and accuracy of instrumentation, as well as the exactitude in the representation of physical phenomena in simulation, could cause discrepancies.

Muriel Bailey –

This CFD simulation was powerfully corroborative of the existing research on nanofluids and their impact on heat transfer optimization. It’s rare to see such a detailed and precise study that offers both numerical and experimental validation. Well done!

MR CFD Support –

Thank you for your kind words and recognition of the detailed work involved in the ‘Nanofluid optimum concentration for Heat Transfer enhancement’ simulation study. We’re glad that the precision and validation efforts made a positive impression on you!

Mario Hauck –

I very much appreciate the effort in validating the model against experimental data. Can you share insights on how the nanoparticle dispersion within the base fluid was ensured in the simulation?

MR CFD Support –

We are thrilled you enjoyed our meticulous validation approach. The dispersion of nanoparticles in the base fluid is modeled using effective medium theories which provide thermophysical properties based on nanoparticle concentration. In ANSYS Fluent, this is incorporated into the simulation through custom-defined functions that account for the presence of nanoparticles, ensuring a uniform dispersion is integrated into the computation of fluid properties and interaction with thermal fields.

Keenan Bergnaum –

Fantastic paper validation work on the nanofluid heat transfer enhancement! The meticulous methodology and favorable comparison with experimental data give great confidence in computational fluid dynamics’ robustness.

MR CFD Support –

Thank you for your kind words! We are delighted to hear you found the paper validation of nanofluid concentration for heat transfer enhancement so thorough and satisfactory. We strive to provide accurate and reliable simulations that support theoretical and experimental findings.

Prof. Lelia Corwin II –

What is the optimal volume concentration of TiO2 nanoparticles found in this study for enhancing heat transfer?

MR CFD Support –

The optimal volume concentration of TiO2 nanoparticles for enhancing heat transfer in this study is discovered to be 0.05%.

Dr. Sidney O’Kon II –

I was amazed by the level of detail in the validation of the CFD simulations against experimental results in the study. How accurately did the simulation results correlate with the experimental data overall in terms of percentage error?

MR CFD Support –

Thank you for your positive feedback on the study! The simulation results correlated very accurately with the experimental data. The percentage error ranged from as low as 0.987642% to -2.68691%, indicating a strong agreement between the simulations and the experimental results.

Dr. Halie Kuhlman –

I appreciate the detailed explanation of the effects on heat transfer with varying nanofluid concentrations. Could you elaborate on how the experimental paper’s values for Nusselt numbers were validated against the CFD simulations here?

MR CFD Support –

Sure, in the process of validating the numerical CFD results against the experimental data provided in the paper, specific Nusselt numbers were compared directly between the two. This was done by ensuring that the Rayleigh numbers (Ra) created in the simulation accurately represented the ones in the experiment. Then, the resultant Nusselt number (Nu) from both resources were contrasted. As indicated in the provided data, minor differences showing the numerical results are comparable within a reasonable error margin demonstrate successful validation.

Travon Spencer –

Is the study able to present how the nanoparticle size affects heat transfer or only reviews the volume concentration effects?

MR CFD Support –

The primary focus of the study is on identifying the optimum nanoparticle concentration for enhancing heat transfer. It does not explicitly indicate an analysis of how different nanoparticle sizes affect heat transfer; it assumes a consistent nanoparticle size of 50 nanometers for the TiO2 nanoparticles used.

Kari Russel –

What are the steps followed in this study to identify the optimal concentration of nanoparticles for maximizing heat transfer?

MR CFD Support –

The steps followed to identify the optimal concentration of nanoparticles include (1) varying the nanofluid’s volume fraction within a laboratory chamber simulation, (2) analyzing the effects of different temperature gradients and nanoparticle concentrations on heat transfer by altering the temperatures of the hot and cold walls, and (3) comparing the Nusselt number obtained from these simulations against experimental and theoretical data for verification. This comprehensive approach helps in determining the concentration at which the heat transfer is maximized.

Prof. Abel Feeney IV –

Outstanding work on the CFD simulation for Nanofluid optimum concentration! The comparison to the research paper’s results really shows the accuracy and potential of nanofluids for thermal applications.

MR CFD Support –

Thank you very much for your positive review! We are pleased to hear that the accuracy of our CFD simulation has met your expectations, and that the data presented was informative and aligned with current research in the field of nanofluids and heat transfer enhancement. We look forward to providing more quality simulations and validations in the future.

Mr. Armani Marks –

Thank you for providing a thoughtful review of MR CFD’s lessons! The comparison data and percentage difference in reporting the Nusselt number were insightful. It’s intriguing how the nanofluid concentration affects heat transfer.

MR CFD Support –

Thank you for your positive feedback on our nanofluid simulation product! We’re pleased to hear that you found the data comparison and insights about nanofluid concentration effects on heat transfer to be helpful. If you have any more questions or need further assistance, feel free to reach out to us.

Lon Green –

I was wondering if this simulation study includes considerations for nanoparticle agglomeration effects on the heat transfer enhancement?

MR CFD Support –

The simulation study primarily focuses on understanding the heat transfer enhancement due to the presence of nanoparticles rather than specific particle dynamics like agglomeration. Agglomeration effects might be considered in a more advanced and detailed study, but the summary does not mention them directly. It focuses on finding the optimum concentration of nanoparticles for the best heat transfer performance based on temperature change and volume concentration.