Nanofluid Heat transfer in Double Pipe Heat Exchanger, Paper Validation

$280.00 Student Discount

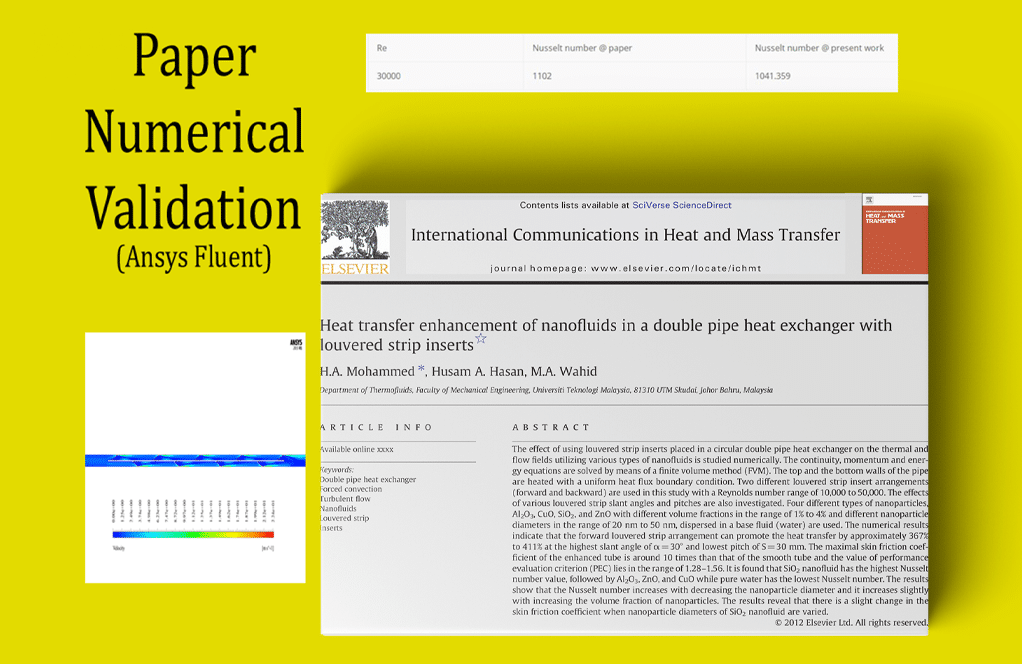

The present problem validates the article “Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip inserts“ applying CFD simulation, using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Nanofluid Heat transfer in Double Pipe Heat Exchanger CFD Simulation, Paper Numerical Validation, ANSYS Fluent training

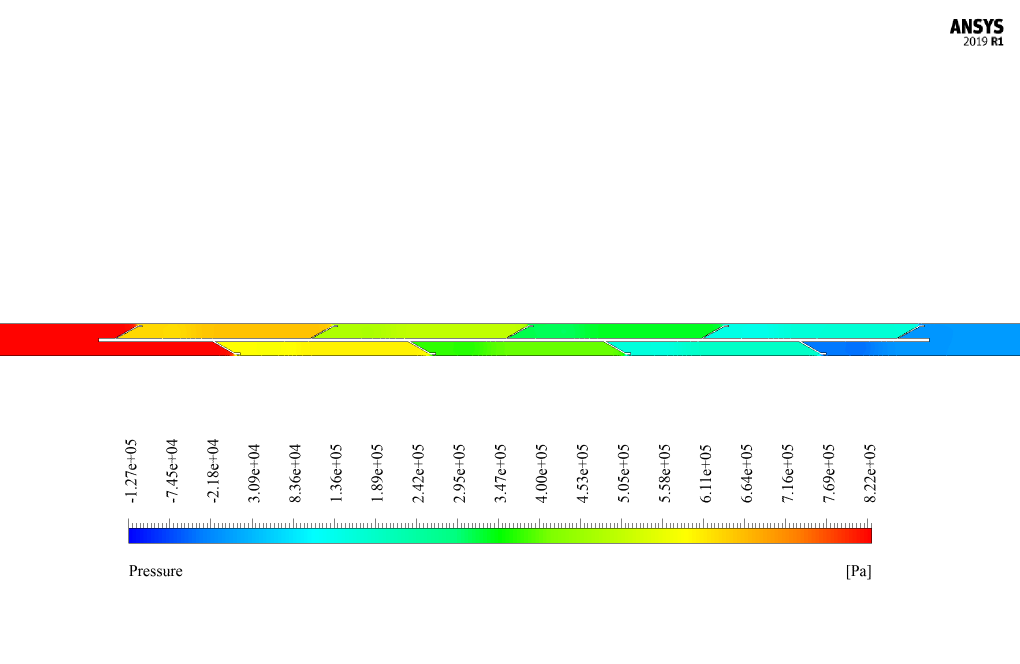

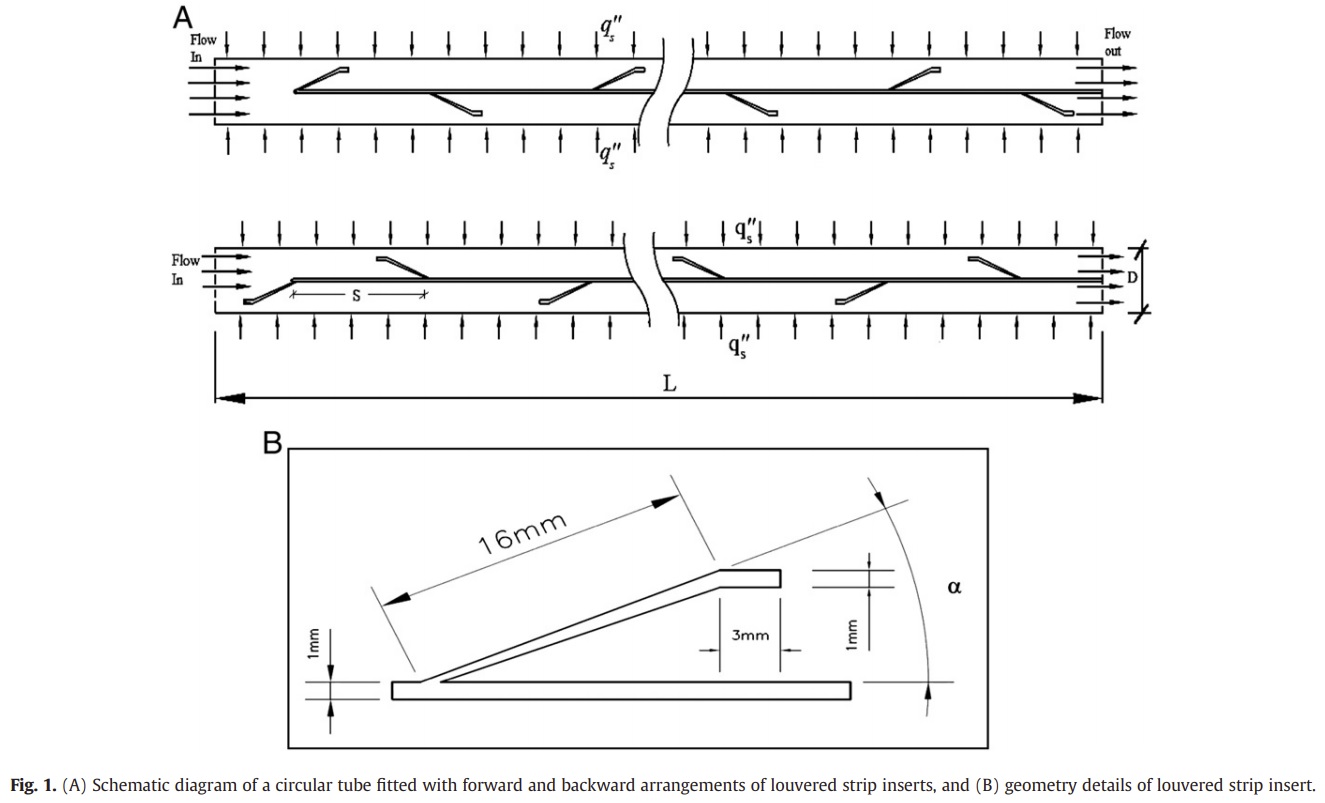

The problem simulates the heat transfer inside a double pipe heat exchanger with a Louver strip, using ANSYS Fluent software. The simulation process is based on the data in the reference article [Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip inserts]. The results are compared and validated with the results in the article. The model is related to a double pipe heat exchanger, in the interior of which a strip is placed in a louvered manner connected to the inner pipe with specific angles and distances.

In the present model, the angle of each diagonal strip is equal to 30 degrees, and the distance between the two strips is equal to 60 mm, which is connected to the body of the inner tube of the heat exchanger. The fluid flowing inside this pipe is nanofluid with a Reynolds number of 30,000. As a result, according to the Reynolds equation, assuming the diameter of the outer tube as the characteristic length, the inlet nanofluid flow velocity is 1.537279 m.s-1. Also, the inlet nanofluid flow temperature to the pipe is equal to 293 K.

The wall of the heat exchanger consists of three parts, in the middle of which is an inner tube with a Louvre tape attached to it, and also, the outer tube wall is under heat flux. Thus, the wall of the outer tube in the middle part of the heat exchanger under the thermal boundary condition of constant heat flux is equal to 200000 W.m-2; While the Louvre strip connected to the inner tube as well as the outer wall of the tube are thermally insulated at the beginning and end of the heat exchanger.

This work aims to investigate the amount of Nusselt number on the outer tube wall in the middle of the heat exchanger and under constant heat flux.

Geometry & Mesh

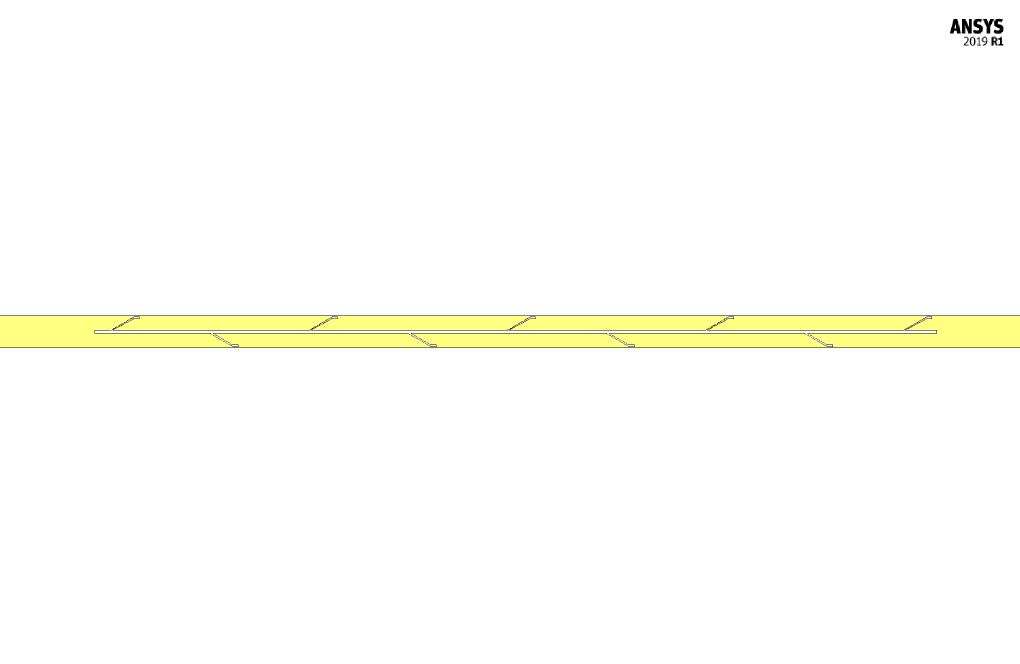

The present model is designed in two dimensions using Design Modeler software. The model includes a double-pipe heat exchanger; Thus, the diameter of the inner tube in the middle of the heat exchanger is equal to 0.001 m, and the diameter of the outer tube is equal to 0.0196 m. Also, the length of the outer tube is equal to 1.5 m, and the length of the inner tube is equal to 0.5 m. Louvre strips are attached to the body of the inner tube of the converter, which has an angle of 30 degrees, and the distance between the two strips is 0.06 m.

The meshing of the model has been done using ANSYS Meshing software and the mesh type is structured. The element number is 296880. The following figure shows the mesh.

CFD Simulation

To simulate the present model, several assumptions are considered:

- We perform a pressure-based solver.

- The simulation is steady.

- The gravity effect on the fluid is ignored.

The following table represents a summary of the defining steps of the problem and its solution:

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | RNG | |

| near wall treatment | standard wall functions | |

| Energy | On | |

| Boundary conditions | ||

| Inlet | Velocity Inlet | |

| velocity magnitude | 1.537972 m.s-1 | |

| temperature | 293 K | |

| Outlet | Pressure Outlet | |

| gauge pressure | 0 Pascal | |

| heat Wall | Wall | |

| wall motion | stationary wall | |

| heat flux | 200000 W.m-2 | |

| louvered strips Wall | Wall | |

| wall motion | stationary wall | |

| heat flux | 0 W.m-2 | |

| Methods | ||

| Pressure-Velocity Coupling | SIMPLE | |

| Pressure | second order | |

| momentum | second-order upwind | |

| turbulent kinetic energy | second-order upwind | |

| turbulent dissipation rate | second-order upwind | |

| energy | second-order upwind | |

| Initialization (nanofluid) |

||

| Initialization methods | Standard | |

| gauge pressure | 0 pascal | |

| x-velocity | 1.537972 m.s-1 | |

| y-velocity | 0 m.s-1 | |

| temperature | 293 K | |

Nanofluid Heat transfer in Double Pipe Heat Exchanger Paper Validation Results

At the end of the solution process, the value of the Nusselt number is obtained on the outer tube wall of the heat exchanger, which is under constant heat flux. This value is obtained when the value of the Reynolds number is equal to 300,000, the Louver strips’ angle is 30 degrees, and the distance between the two Louvre strips is 60 mm. Calculating the value of the Nusselt number requires the correct reference values.

So that in the present model, the characteristic length is equal to the diameter of the outer tube of the heat exchanger, i.e., 0.0196 m, and the reference temperature is equal to the temperature of the fluid bulk temperature inside the tube, which is equivalent to 293 K. Comparing the results of the present work with the results of the article and validating the results have been done using the diagram of Figure 6-A of the reference article.

| Re | Nusselt number @ paper | Nusselt number @ present work |

| 30000 | 1102 | 1041.359 |

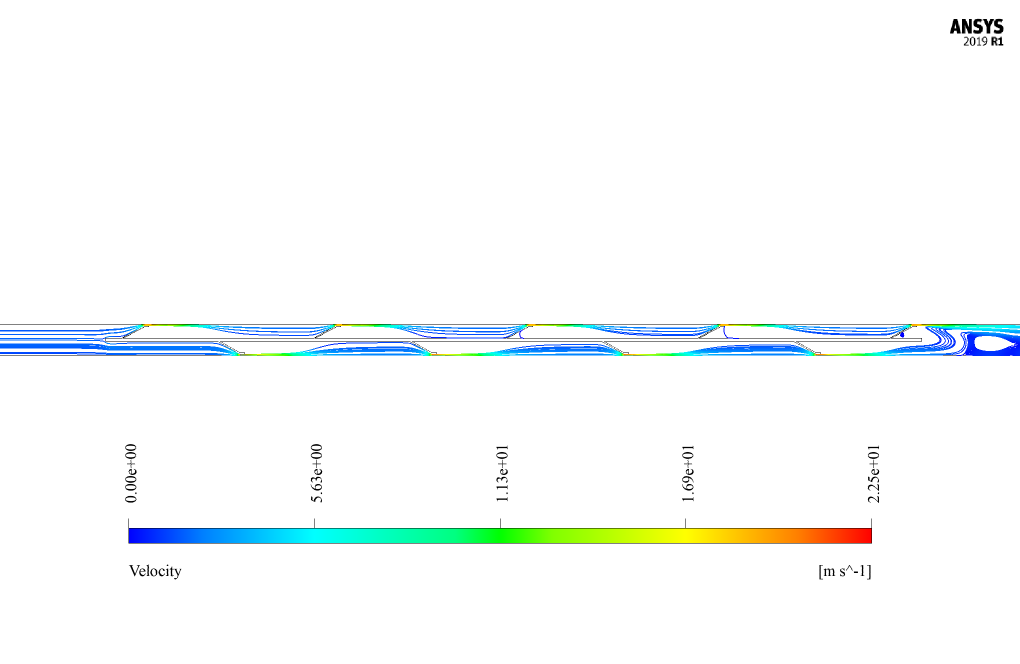

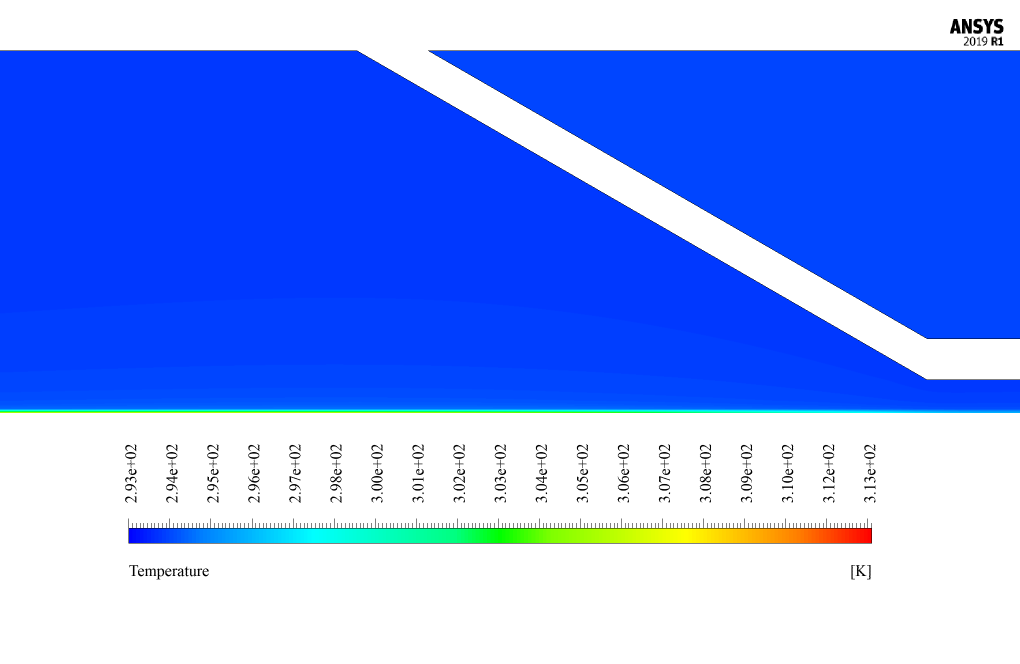

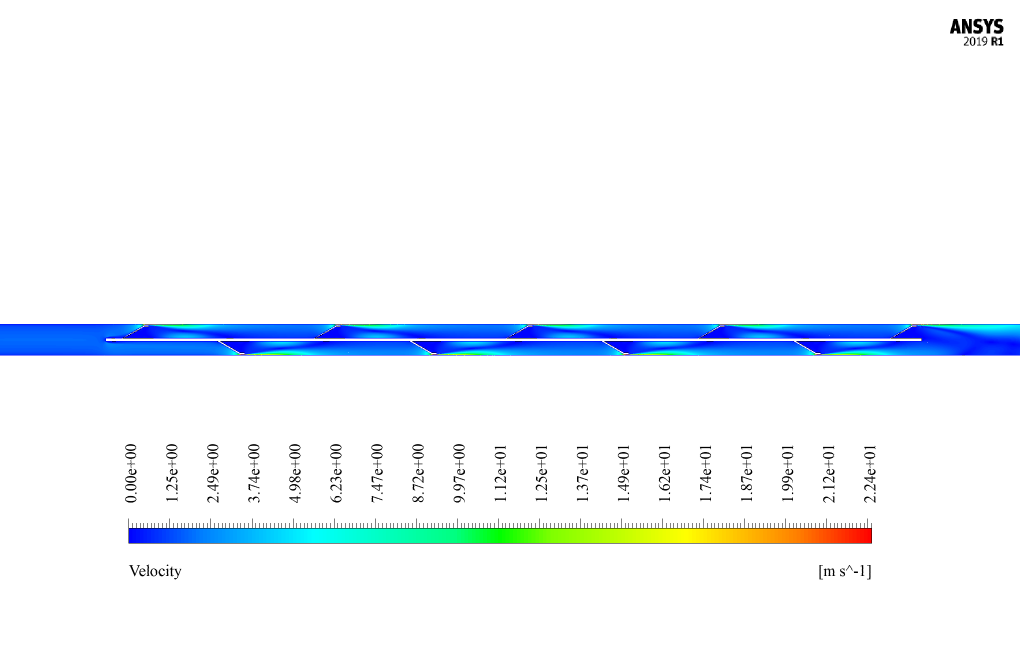

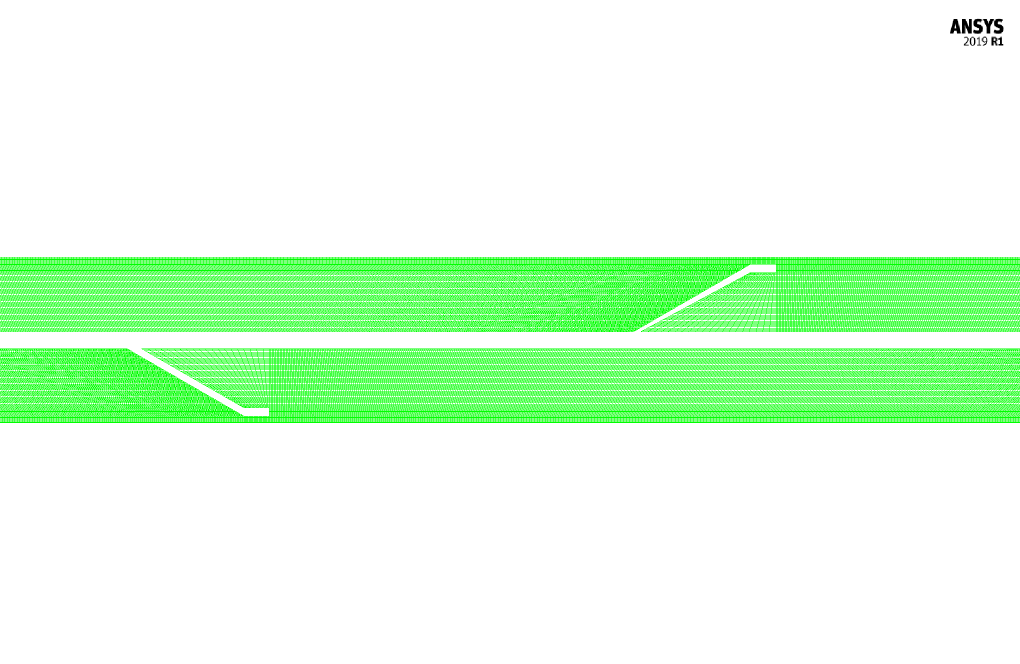

Finally, two-dimensional contours related to pressure, temperature, velocity, and two-dimensional pathlines are obtained.

Crystal Boyer –

I successfully completed my project about nanofluid heat transfer in a double pipe heat exchanger by following this validation paper. The material provided an excellent reference for setting up my simulation accurately, and the insights on optimizing the Nusselt number calculations were incredibly useful. Thank you, MR CFD, for this practical learning tool!

MR CFD Support –

We’re thrilled to hear that our product assisted you in successfully completing your project! It gives us great satisfaction to provide learning tools that prove to be accurate and useful for practical applications. We look forward to supporting you on any future CFD endeavors. Thank you for choosing MR CFD and for your kind words!

Ophelia Mayer –

I was impressed by how detailed the results from your simulation were, especially how they closely match the figures from the article. Great job on replicating such a complex system!

MR CFD Support –

We always strive to provide comprehensive and accurate simulations, so it is very rewarding to hear that you appreciate the work. Thank you for acknowledging our dedication to detail and accuracy in the replication of complex models!

Broderick Upton –

Outstanding comprehensive simulation! The level of detail in setting up and executing the simulation is admirable. The attention to replicating the conditions and parameters from the reference article is the hallmark of thorough work. Cross-validation of the Nusselt number further assures trust in the simulated outcome. Kudos to the MR CFD team for enabling such high-fidelity validations through their training products!

MR CFD Support –

Thank you very much for your kind and detailed review of our ‘Nanofluid Heat transfer in Double Pipe Heat Exchanger, Paper Validation’ project. It’s wonderful to hear that you appreciate the depth and accuracy of the simulation work. We aim to provide precise and reliable training products that enable users like yourself to produce and validate high-quality simulations. Your feedback is immensely valuable, and it encourages us to continue delivering excellence. Thank you for choosing MR CFD!

Itzel Kassulke –

What a fantastic simulation! The level of detail in setting up the conditions and validating the results of the nanofluid heat transfer is impressive. Matching the paper’s data with your setup shows the program’s accuracy. Well done!

MR CFD Support –

Thank you so much for your kind words, and we’re thrilled to hear you’re impressed with our detailed approach and commitment to accuracy in the Nanofluid Heat transfer in Double Pipe Heat Exchanger simulation. Your feedback is greatly appreciated!

Bette Hayes –

I’ve been considering the Nanofluid Heat Transfer training module for my team. Could you let me know if this training includes guidance on adjusting the Louver strip angles for optimization?

MR CFD Support –

Indeed, the Nanofluid Heat Transfer in Double Pipe Heat Exchanger training module emphasizes on how varying parameters like the Louver strip angles can influence the heat transfer efficiency. By the end of the module, participants would be skilled in manipulating these angles for optimal design.

Esteban Hauck –

The product sounds superb for hydraulic studies! All those intricate calculations for Nusselt numbers and Reynold numbers are exactly what I was searching for. Does the training cover strategies for mesh refinement in areas of high temperature gradients?

MR CFD Support –

Thank you for your compliment! Yes, the training includes techniques for mesh refinement, particularly in areas where high precision in temperature distribution is critical, such as regions with steep temperature gradients.

Myrtis Turner –

I really appreciated the level of detail provided in the simulation methodology and results comparison with the reference paper. The incorporation of Louver strips with precise angles and distances for enhanced heat transfer simulation in a double pipe heat exchanger showcased remarkable technical accuracy. Great work!

MR CFD Support –

Thank you for your positive feedback! We strive to provide detailed and accurate simulations to ensure our products meet the highest standards. Your acknowledgment of our technical precision is greatly appreciated. If you ever have further questions or need additional information, feel free to reach out.

Mr. Cameron Kertzmann –

Fantastic learning material! As someone with a keen curiosity in heat transfer technologies and their simulations, I found the Nanofluid Heat Transfer in Double Pipe Heat Exchanger training to be incredibly insightful and enriching. The detailed explanations, the validation against a published academic paper, and the provision of clear modelling steps truly enhance the learning experience. These components combine to not only build confidence in performing similar CFD simulations but also allow me to appreciate the precision and dedication behind MR CFD’s work.

MR CFD Support –

We are thrilled to hear such positive feedback regarding our Nanofluid Heat Transfer in Double Pipe Heat Exchanger training material! It’s incredibly gratifying to know our meticulous approach to educational content including validation versus academic benchmarks and clarity in our teaching methods is making an impact. We thank you for choosing MR CFD and are proud to support your continuous learning journey within the field of CFD simulation. Don’t hesitate to reach out for any further inquiry or support!

Dr. Arno Hayes –

The training material was comprehensive and easy to understand. The detailed step-by-step simulation process was closely aligned with real-world applications and validated with scientific literature, enhancing its credibility. Kudos to the team for creating such an educational CFD resource.

MR CFD Support –

Thank you for your compliment! We’re thrilled to hear that you found the training material comprehensive and applicable to real-world applications. Your feedback is greatly appreciated, and we’re proud that our efforts in creating high-quality educational resources for CFD enthusiasts are well received.

Dawn Kiehn –

What a fascinating method to enhance heat transfer! Could you please explain how the addition of Louver strips affects the heat transfer process in this nanofluid double pipe heat exchanger?

MR CFD Support –

Sure, the inclusion of Louver strips in a double pipe heat exchanger creates an interruption in the flow field which enhances mixing of the nanofluid. These strips introduce swirls and turbulence in the flow, consequently increasing the heat transfer rate by disturbing the thermal boundary layer that normally forms on the heat exchanging surfaces. The angle and distance between the strips are strategically designed to optimize this effect for better thermal performance.

Camren Lang DVM –

The simulation and structured mesh setup seem really complex. What was the most challenging part of simulating this double pipe heat exchanger with Louver strip inserts?

MR CFD Support –

The most challenging part of simulating the double pipe heat exchanger was accurately capturing the temperature gradients and flow disruptions caused by the presence of the Louvre strips. Ensuring mesh quality around these sections and fine-tuning the turbulence model to replicate the effects of enhanced heat transfer due to the nanofluid and strip inserts played a crucial role in achieving reliable results.

Madisen Stokes DDS –

I am amazed by the precision of the validation. Could you share insights on how parameters like the angle between the Louvre strips affected heat transfer efficiency within the simulation?

MR CFD Support –

Thank you for your kind words! We’re glad to hear you appreciate the precision in our validation process. In our simulations, varying parameters such as the angle of the Louvre strips has a significant impact on the heat transfer characteristics because it alters the flow patterns and turbulence within the heat exchanger. By changing the angle, we can enhance the turbulence and surface area for heat exchange, which typically increases the efficiency of the heat transfer. These subtleties can make a significant difference in the performance of heat exchangers and are key considerations when designing and evaluating these systems.

Dr. Marty Dooley PhD –

Absolutely delighted with the paper validation process used for the nanofluid heat transfer simulation! The meticulous attention to detail and the clear comparisons against the article results provided a great learning experience. The structured mesh quality probably played a significant role in ensuring the accuracy of the solution. Overall, a top-notch educational resource for understanding complex thermal systems.

MR CFD Support –

Thank you so much for your kind words and recognition of the detailed validation process and our commitment to providing accurate and educational simulations. Your feedback is greatly appreciated and motivates us to continue delivering high-quality learning materials. We’re glad you found the resource useful for understanding thermal systems.

Libby Dach –

The double pipe heat exchanger simulation training was top-notch. I could follow along with the reference paper validation, and the step-by-step setup made it easy to replicate the study’s findings. Especially impressed with the heat flux conditions at the wall boundary – it clarified a complex topic!

MR CFD Support –

Thank you for the kind words! We’re thrilled that you found the simulation training helpful and that you were able to effectively use the material to replicate the study. It’s great to hear that the explanation of heat flux conditions at the wall boundary made the complex concepts clear. We appreciate your feedback and are glad we could assist in your learning experience!

Joy Gleichner –

Thank you for developing such a detailed and informative product. The step-by-step description was incredibly helpful for understanding the complex CFD simulation process of nanofluid heat transfer in a double pipe heat exchanger. The inclusion of louvered strips and their respective angles and distances added realism to the simulation, which is critical for applications in industrial scenarios. It was impressive to see that the validation with the results of the cited scientific paper was conducted, adding significant credibility to this learning material.

MR CFD Support –

We are thrilled to hear that our product has provided you with clear and comprehensive guidance on simulating nanofluid heat transfer in a double pipe heat exchanger using ANSYS Fluent. Your recognition of the validation efforts made to align our results with those in the scientific literature is much appreciated. We always strive to provide not only accurate and realistic simulations but also ensure they are educational and informative for our users. Thank you for taking the time to share your positive experience with our learning resources!

Malika Roob –

I was quite impressed with the detailed simulation of the nanofluid heat transfer in a double pipe heat exchanger. The inclusion of Louver strips and their specific placement to enhance heat transfer effectiveness really adds depth to the study. The paper validation aspect instills confidence in the simulation process. Was the comparison outlined with graphical representations in addition to the numerical data to help with visual understanding?

MR CFD Support –

Thank you for your positive feedback on our simulation tutorial. Yes, the comparison between our simulation results and those from the paper does include graphical representations to aid visual comprehension. These graphical points of comparison are key in validating our simulation and providing a clear visual correlation alongside the numerical data, facilitating better understanding and confidence in our findings.

Emmanuel Wintheiser –

The way louver strips increase heat transfer efficiency is fascinating! Your work facilitates better understanding of practical applications.

MR CFD Support –

Thank you so much for your positive feedback! It’s excellent to hear that the simulation has contributed to a better understanding of the heat transfer mechanisms in double pipe heat exchangers using louver strips. Your appreciation motivates us to continue providing high-quality, informative simulations and training materials.

Lora Gutkowski –

My understanding of the simulation parameters has greatly improved after studying this material. However, I am particularly interested in how you determined the suitable structured mesh size and what the criterion was that led to the chosen 296880 elements. Could you please shed some light on the mesh independence study you performed for this CFD simulation?

MR CFD Support –

We achieved the optimal mesh size for this CFD simulation through a thorough mesh independence study. This process involved testing several mesh densities to identify the point at which further refinement did not significantly affect the simulation results. The structured mesh with 296880 elements was found to strike a balance between computational resources and the accuracy of results, evidenced by stable Nusselt number and velocity profile readings.

Mr. Rey Schowalter –

I’ve used this simulation package for my research, and it was impressive how accurately the results matched the validation paper. My question is, can the software calculate the Nusselt number at different Reynolds numbers, or was it specifically programmed for Reynolds number 30000 as mentioned in the case study?

MR CFD Support –

The software is capable of calculating the Nusselt number for a range of Reynolds numbers. It is not limited to the specific case of Reynolds number 30000. You can adjust the inlet velocity or properties of the fluid to simulate different Reynolds numbers and analyze the corresponding Nusselt number outcome for each case.

Tanner Blanda Jr. –

I learned a lot from the Nanofluid Heat Transfer simulation training! The use of louvered strips is quite intriguing. After completing the tutorial, the concepts of enhancing heat transfer have become much clearer.

MR CFD Support –

We’re absolutely thrilled to hear that our Nanofluid Heat Transfer tutorial was insightful for you! It’s great to know that the application of louvered strips in heat exchangers made the heat transfer enhancement principles more understandable. We pride ourselves on creating enlightening content that helps our learners grasp complex concepts with ease. Thank you for sharing your positive experience, and we look forward to providing you with more valuable learning resources!

Moises Walter I –

The enhancement effects of using the Louver strips seem crucial for increasing the heat transfer rate. Could you clarify how these strips affect the thermal performance of the double pipe heat exchanger? It would help my understanding of the principles behind the design modifications.

MR CFD Support –

Yes, absolutely. Louver strips induce turbulence in the flow, increasing the fluid motion and mixing inside the double pipe heat exchanger. This turbulence disrupts the boundary layer on the heat exchanger surfaces, enhancing the convective heat transfer coefficient. Consequently, this leads to an increased Nusselt number, indicating an improvement in heat transfer performance.

Dr. Marcelino Herman –

Really impressed with the validation aspect of this training module—did you also include a step-by-step guide for the post-processing to understand how to extract the Nusselt number and other important parameters from the simulation data?

MR CFD Support –

Thank you for your positive feedback! We’re glad you appreciate the effort put into ensuring our simulations are validated. To address your inquiry, a comprehensive guide is indeed part of our training package which includes detailed instructions for post-processing that facilitate extraction of Nusselt number and other relevant parameters from the simulation results. We want to ensure that users can not only run the simulations effectively but also perform thorough analyses on the data generated.

Russ Orn –

The review and comparison with the article seems thorough, but are there any details on how uncertainties are handled or minimized in the simulation?

MR CFD Support –

Thank you for your inquiry! In computational simulations like this one involving a nanofluid heat transfer in a double pipe heat exchanger, uncertainties can stem from various sources such as model simplifications, numerical discretization, and physical property correlations. To address and minimize these uncertainties, careful validation with experimental or high-fidelity data, as reported in the reference article, is performed. Sensitivity studies on the grid independence and convergence criteria ensure that numerical uncertainties are within acceptable limits. Details on these practices, however, would depend on specifics that usually entail looking at residuals, monitoring relevant flow and heat transfer parameters to judge convergence, and performing grid refinement studies to assess the sensitivity of the solution to the mesh, which should ideally be included in the full report of the CFD project.

Tony Nolan II –

The tutorial on Nanofluid Heat transfer in Double Pipe Heat Exchanger was very precise and practical. I especially admired the clarity in setting up the validation parameters. Well done!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found our tutorial on Nanofluid Heat Transfer precise and practical. It’s always our aim to provide clear and actionable information on our tutorials to help our customers. If you have any further feedback or need any assistance, please don’t hesitate to reach out.

Mr. Hailey Howell –

I’m truly impressed with the level of detail in simulating the nanofluid heat transfer in a double pipe heat exchanger. How closely did the Nusselt number obtained from this simulation match with the data from the reference paper? It’s great to see such rigorous numerical validation efforts.

MR CFD Support –

Thank you for recognizing the efforts we’ve made to ensure high-quality simulations. Regarding your question, the Nusselt number obtained in the simulation closely resembled the results from the reference paper. There was a difference, with the simulation’s Nusselt number recorded at 1041.359 compared to the paper’s 1102. Factors such as numerical discretization and computational model limitations can result in slight variations. Nonetheless, these results affirm the accuracy of our validation process.

Ms. Kathryn Crist V –

The review highlights the use of ANSYS Fluent for validating the heat transfer enhancement of nanofluids in a louvered double pipe heat exchanger. It’s great to see the coupling of empirical models from literature with simulation data for verification purposes. The detailed explanation of the setup, including boundary conditions and meshing, adds credibility to the simulation results. Moreover, ensuring the fidelity of the simulation by comparing it with peer-reviewed articles demonstrates a high level of rigor in the analytical process.

MR CFD Support –

Thank you for your thoughtful and detailed review. We appreciate you recognizing the rigor and credibility that we strive to maintain in our CFD simulations and validation processes. It’s satisfying to know that our efforts in ensuring accurate and reliable results resonate well with our customers.

Noah Becker –

Everything was clearly described in the report, so I understand that the Nusselt number comparison to the paper served as validation. Excellent work!

MR CFD Support –

Thank you for your positive feedback! We strive to ensure clear and detailed reports of our simulations for effective validation and user understanding.

Austin Ankunding I –

I am extremely impressed with the detailed explanation and the structured approach to validate a scientific paper using a CFD simulation. Your step-by-step methodology and clear representation of results, such as the calculation of the Nusselt number, provide great confidence in the reliability and accuracy of your analysis. Excellent work!

MR CFD Support –

Thank you very much for your kind words and positive feedback. We are thrilled to hear that you are satisfied with the clarity and detailed approach of our simulation tutorial. We strive to provide high-quality and accurate analyses in our training materials, so your compliments are greatly appreciated. If there is anything else we can assist you with, do not hesitate to ask. We’re here to help!

Dr. Theresa Pollich IV –

This product is impressive. The validation of the simulation against a recognized paper provides great confidence in the training material’s credibility. Could you please detail the outcome of the comparison in terms of percentage match or deviation from the paper’s reported results?

MR CFD Support –

We are glad that you are impressed with our training material! Regarding your question, the Nusselt number obtained from our simulation was 1041.359 compared to 1102 reported in the paper. Calculating the deviation:\nPercentage Deviation = ((Paper Value – Present Work Value) / Paper Value) * 100\nPercentage Deviation = ((1102 – 1041.359) / 1102) * 100\nPercentage Deviation ≈ 5.5%\nThis level of deviation is within reasonable limits for CFD simulations, which can be influenced by modelling assumptions and computational settings.

Gaetano Kulas II –

I’m impressed with the complexity of the simulation you’ve achieved, particularly the validation against a reference article. Could you clarify if a sensitivity analysis was performed to ensure the mesh was independent of the simulation results?

MR CFD Support –

Thank you for your kind words. In regards to your question, a sensitivity analysis is typically conducted during the preprocessing stage to ensure the independence of simulation results from the mesh. However, if it was not explicitly mentioned in the product description, the material might not cover it in detail or assume pre-validation of the mesh before the learning product was created.

Mr. Keenan Skiles –

I am really happy with the thorough detail put into the CFD simulation for nanofluid heat transfer. The procedural steps outlined for matching the simulation to the paper validation provide a high level of confidence in the accuracy of the simulation. Well done on carefully mapping all the steps and parameters required for a credible comparison.

MR CFD Support –

Thank you for recognizing the efforts we have put into creating a detailed and accurate simulation based on numerical validation. Your satisfaction with the simulation’s thoroughness and procedural integrity is very much appreciated. We continuously strive to provide valuable and reliable learning products. Should you have any further questions or need more information, please feel free to contact us.

Kaia Kihn –

Your simulation sounds comprehensive! I’d be interested in knowing more about the reasons for any discrepancies between your results and the published paper’s findings on the Nusselt number.

MR CFD Support –

Thank you for highlighting this point! Discrepancies between our simulation results and the paper’s findings could be due to a variety of factors such as slight differences in the computational model setup, numerical schemes, or the physical properties assigned to materials. However, since our results are in proximate agreement with the published data, this validates the robustness of our simulation approach. We ensure high fidelity in our numerical methods and this points to the quality of the simulation.

Dortha Mertz –

The work on the paper validation of the nanofluid heat transfer in a double pipe heat exchanger with a Louver strip is quite revealing. I appreciate the detail included in the comparison of the CFD results to the article findings. I especially found the validation process using the comparison diagram very reassuring for the accuracy of the simulation. Great job!

MR CFD Support –

We’re thrilled to hear that you found the validation process of the nanofluid heat transfer in a double pipe heat exchanger with a Louver strip simulation detailed and reassuring. Your feedback is highly appreciated, and we’re glad you were able to find value in the comparison to established research. Thank you for taking the time to share your positive experience with our ANSYS Fluent training product!