Oil Jet Impact on the Water Tank (Three Phases), Ansys Fluent Simulation Training

$120.00 Student Discount

In this project, Oil Jet Impact on the Water Tank has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Oil Jet Impact Project Description

In this project, numerical simulation of Oil Jet Impact on the Water Tank has been done using Ansys Fluent software. the system consists of three different fluids, including air as the primary fluid and one secondary fluid is liquid water, and the last is oil. The Eulerian multiphase model has been used. The oil is entering the domain with the speed of 8m/s with gravity considered as -9.81 m/s-2 on the y-axis.

Geometry & Mesh

The 2-D domain of this simulation has been designed in Design Modeler software. Domain has to inlet as jet flow entrance and sides as an outlet. Also, the pipe side is wall boundary.

The meshing of this present model has been generated by Ansys Meshing software. The mesh grid is unstructured, and the total cell number is 3661601.

Oil Jet Impact CFD Simulation

To simulate the present model, several assumptions are considered, which are:

- The solver is pressure-based and transient.

- Simulation has only examined fluid behavior; in other words, heat transfer simulation has not been performed.

- The effect of gravity on the flow is considered to be 9.81 m.s-2 and along with the y-axis in the present model.

The following is a summary of the steps for defining the problem and its solution.

| Models | ||

| K-omega | Viscous model | |

| SST | k-omega model | |

| shear flow corrections | k-omega options | |

| air | primary phase | |

| water | secondary phase | |

| Oil | Secondary phase | |

| explicit | formulation | |

| Boundary conditions | ||

| Velocity-inlet | inlet | |

| 0 | initial gauge pressure | mixture |

| 8 m/s | velocity magnitude | oil |

| 1 | volume fraction | |

| Pressure outlet | outlet | |

| 1 | backflow volume fraction | air |

| 0 | backflow volume fraction | mixture |

| wall | wall | |

| stationary wall | wall motion | |

| Solution Methods | ||

| Phase coupled | pressure-velocity coupling | |

| PRESTO! | pressure | |

| first-order upwind | momentum | |

| first-order upwind | specific dissipation rate | |

| first-order upwind | volume fraction | |

| Initialization | ||

| standard | initialization method | |

| 8 m/s | oil velocity (0,y,0) | |

| 1 | the secondary phase volume fraction | |

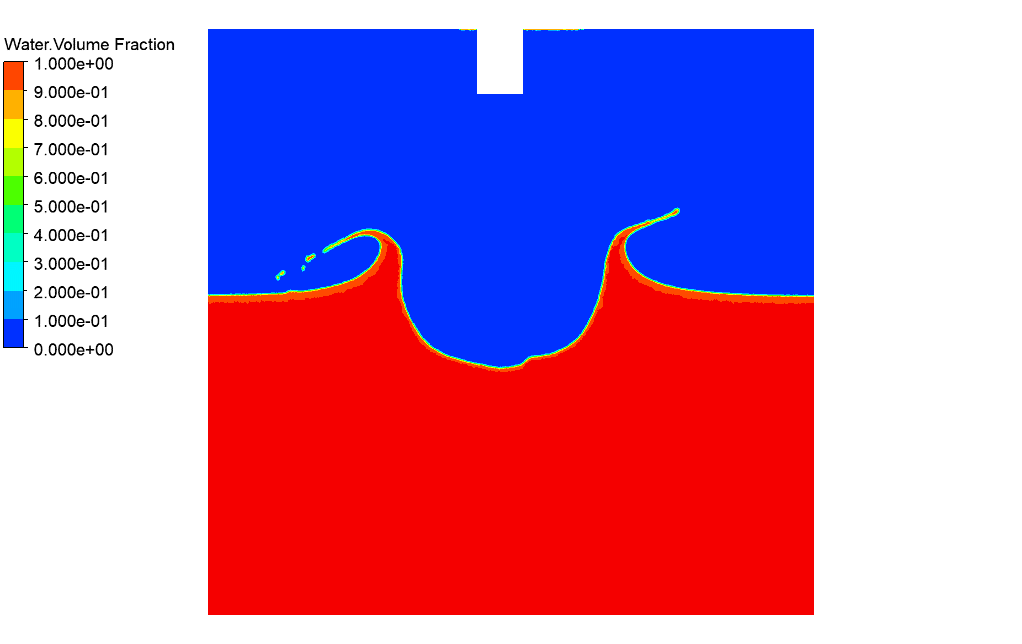

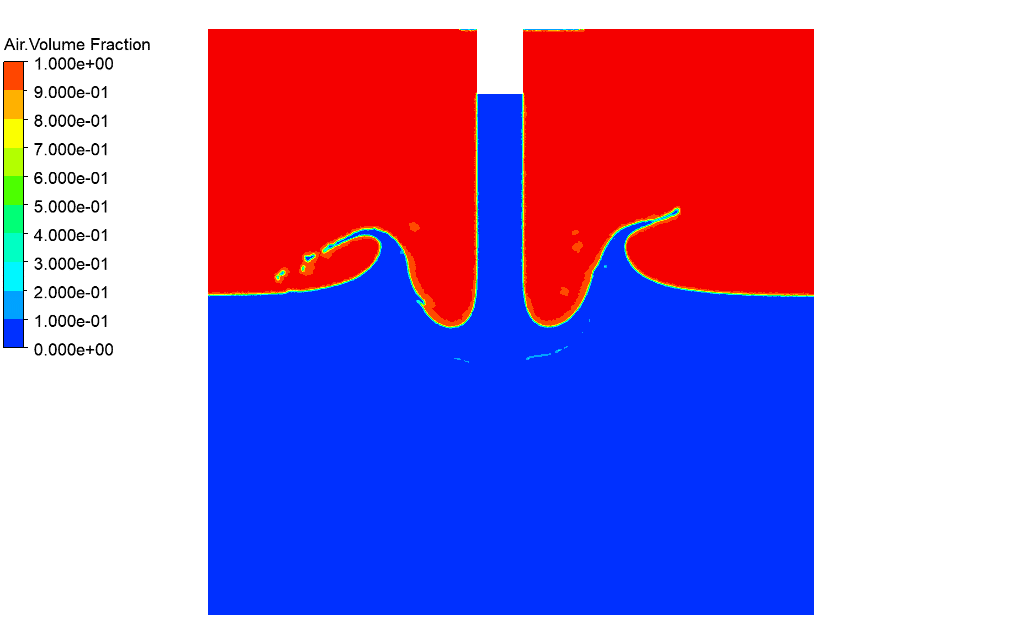

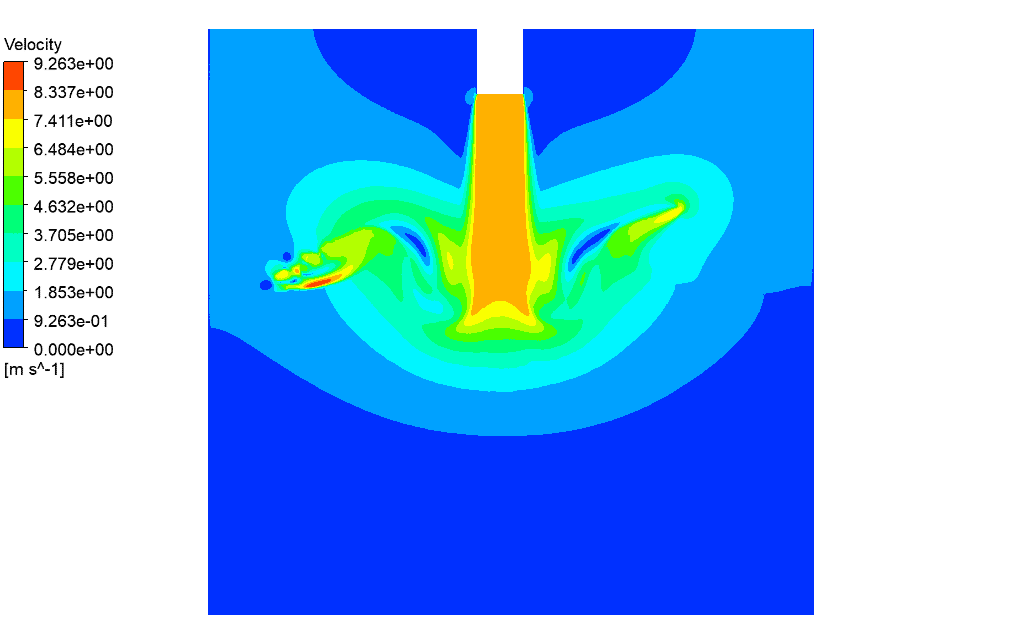

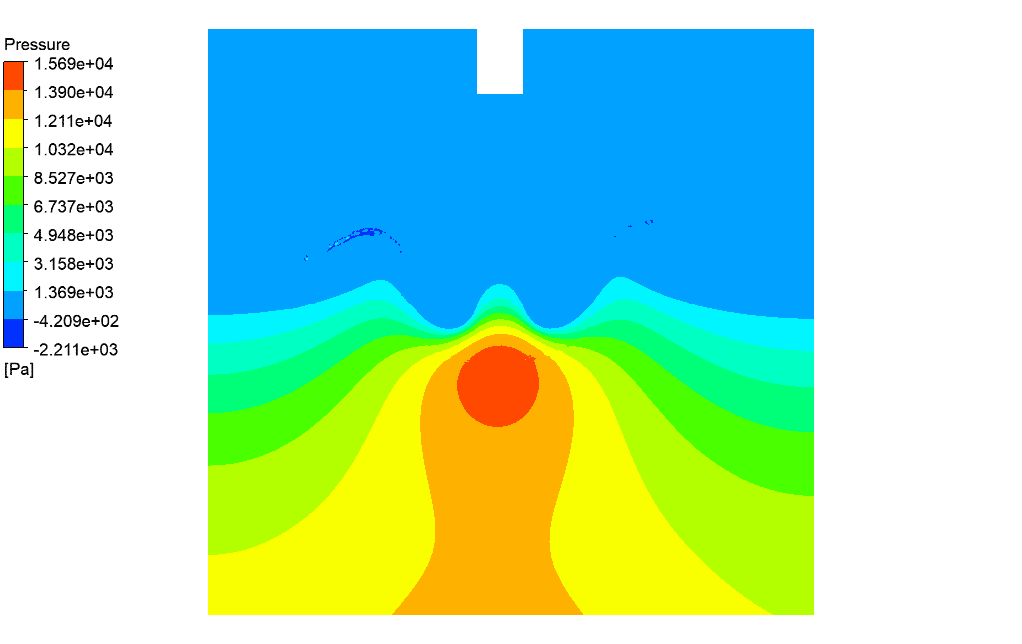

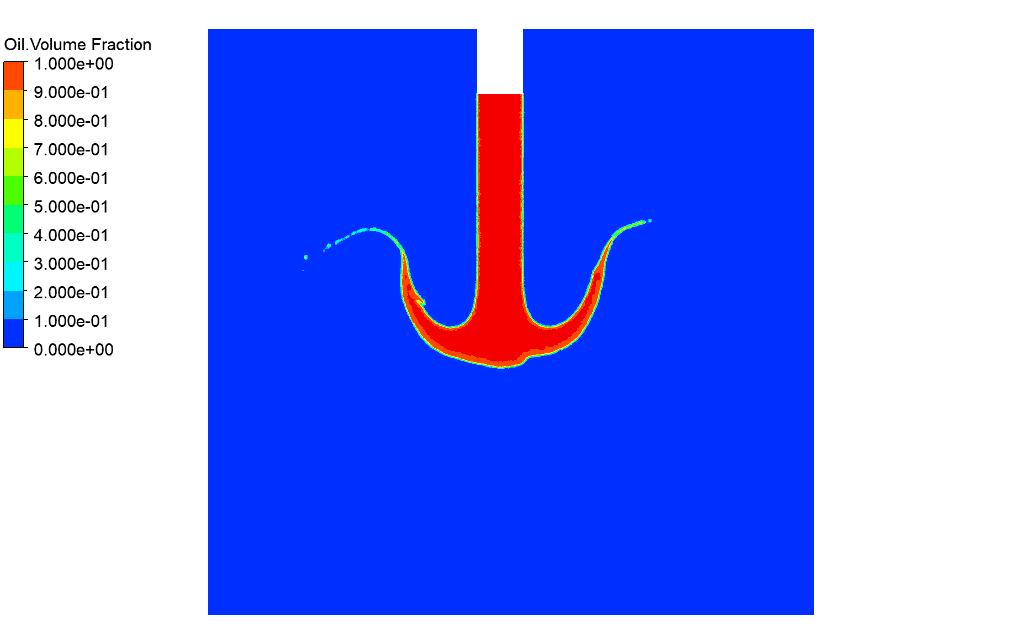

Oil Jet Impact Results

At the end of the solution process, two-dimensional animation and counters of velocity, air, and water volume fraction are obtained. The goal is to simulate a three-phase system as so in the beginning domain contains to liquid water and air, by the time oil jet enters domain and continues to reach water surface, as impact because of the heterogeneousness of water and oil they don’t mix. So oil pushes water around, and spall’s this and makes a vortex. This simulation is an excellent example of three heterogeneous fluid in one domain and they behavior.

Anissa Russel –

I’m truly impressed with the detail and realism the Oil Jet Impact on the Water Tank simulation offers, showcasing complex three-phase interactions seamlessly.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the Oil Jet Impact simulation met your expectations and provided a comprehensive understanding of fluid behaviors. Your satisfaction with the complexity and detail of our CFD simulation is highly appreciated!

Mrs. Tressa Herzog –

I was impressed with the detailed results of the Oil Jet Impact simulation. Towards the end, how do the water and air volume fractions change? Do they mix, or does each fluid maintain its individual characteristics throughout the simulation?

MR CFD Support –

Thank you for your kind words on our Oil Jet Impact simulation. The water and air maintain their individual characteristics due to the multiphase flow model used in the simulation. They do not mix. The oil jet initially distorts the interface between the air and water due to its velocity and momentum, creating a vortex around the impact zone. The results show the air volume fraction mainly remaining above the water, with the water being pushed aside and forming vortices due to the impact of oil. This keeps the fluids mostly separate and demonstrates their separate behaviors in accordance with heterogenous multiphase flow dynamics.

Mr. Henri Waelchi –

I am very interested in the specific results of the oil impact on water in the simulation. Does the tutorial comprehensive enough to clearly show how the oil creates vortices and displaces the water in the tank?

MR CFD Support –

Yes, the tutorial specifically focuses on demonstrating the interaction between the oil and water phases. You will see clear presentations of velocity counters, volume fraction changes, and the formation of vortices as a result of the oil jet impact on the water surface in the simulation. This should give a solid understanding of the fluid dynamics involved in the three-phase system behavior.

Dr. Lela Fritsch –

The diversity of phase interactions in this simulation is fascinating! How is the behavior difference between the oil and water phases accounted for within the solver?

MR CFD Support –

Within the solver, the behavior difference between the oil and water phases is accounted for by using an Eulerian multiphase model. This model allows for the simulation of multiple, interacting fluid phases, each with its own properties, including density and viscosity. The Eulerian framework mathematically represents each fluid phase as a continuum, and interactions between them such as relative velocity and interfacial tension are considered to predict the correct physical behavior, such as oil and water not mixing and the formation of vortices due to their heterogeneous nature.

Mireya Schaefer –

Your Oil Jet Impact on the Water Tank training was detailed and well-structured. I managed to follow along the steps and set up my simulation perfectly. The quality and level of detail in the tutorials made the complex concepts much clearer. Great job on the tutorials!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our training materials were helpful to you and made the process clearer. If you have further questions or need more assistance in the future, feel free to reach out. Enjoy your simulations!

Enola Grady DVM –

This learning product clearly demonstrates a complex three-phase fluid interaction. Could you provide insights on the practical applications of this kind of simulation?

MR CFD Support –

Absolutely! This type of simulation is highly practical for industrial processes where oil, water, and air interactions are important. An example might be in oil spill scenarios, understanding how the oil behaves when it comes into contact with water is crucial for designing effective containment and remediation strategies. Similarly, in the food industry, such simulations can assist in optimizing processes that involve the mixing of different fluids to ensure quality and consistency of products.