Radiator Heated by a Solar Panel CFD Simulation, ANSYS Fluent Training

$60.00 Student Discount

- The problem numerically simulates Radiator Heated by a Solar Panel using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 2031556.

- The Energy Equation is activated to consider heat transfer inside the room.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

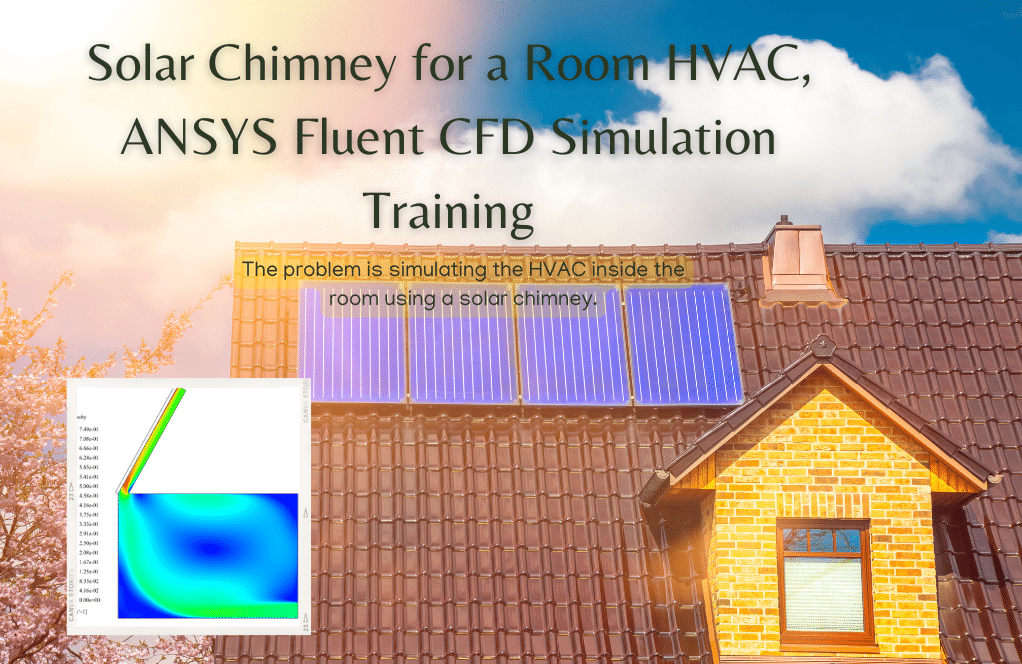

Radiators are one of the most common heating devices in homes and office spaces and significantly impact the energy consumption rate. In this project, the fluid is simulated inside the Radiator Pipes, and heated by a Solar Panel by ANSYS Fluent software.

We perform this CFD project and investigate it by CFD analysis.

The simulations are done for 0.01 and 0.05 Kg / s fluid mass inlet and two types of pipe, adiabatic and convective.

Solar Panel Methodology

The energy model is activated, and the standard k-epsilon model is used for analyzing the fluid flow. Geometry is designed in the ANSYS Design Modeler software.

Then the model meshes in ANSYS meshing. The meshes used for this geometry are unstructured, and the total number of mesh cells is 2031556.

Solar Panel Conclusion

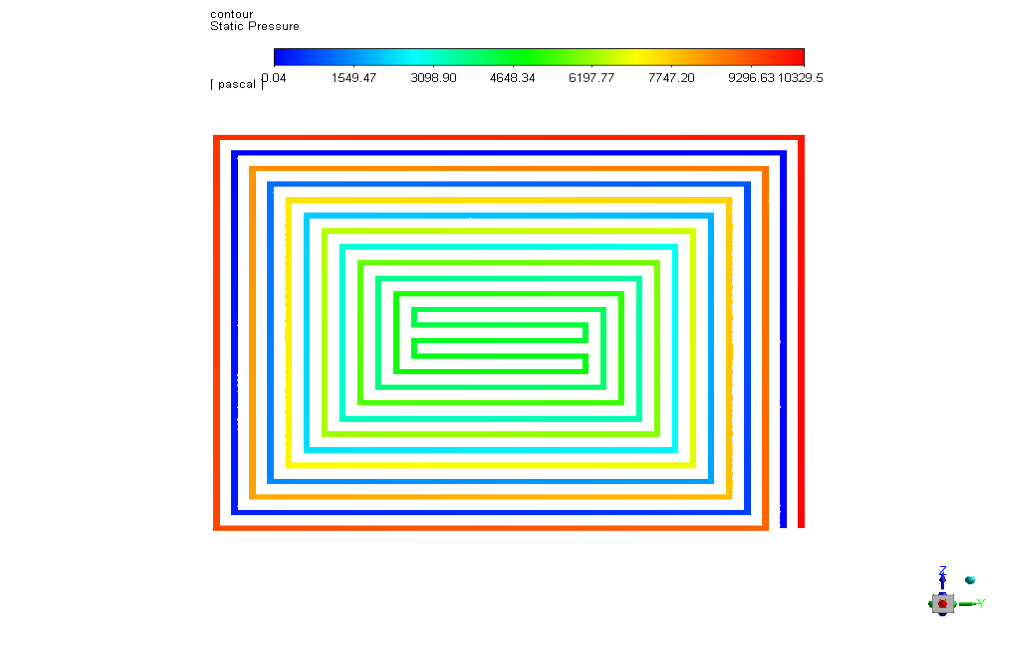

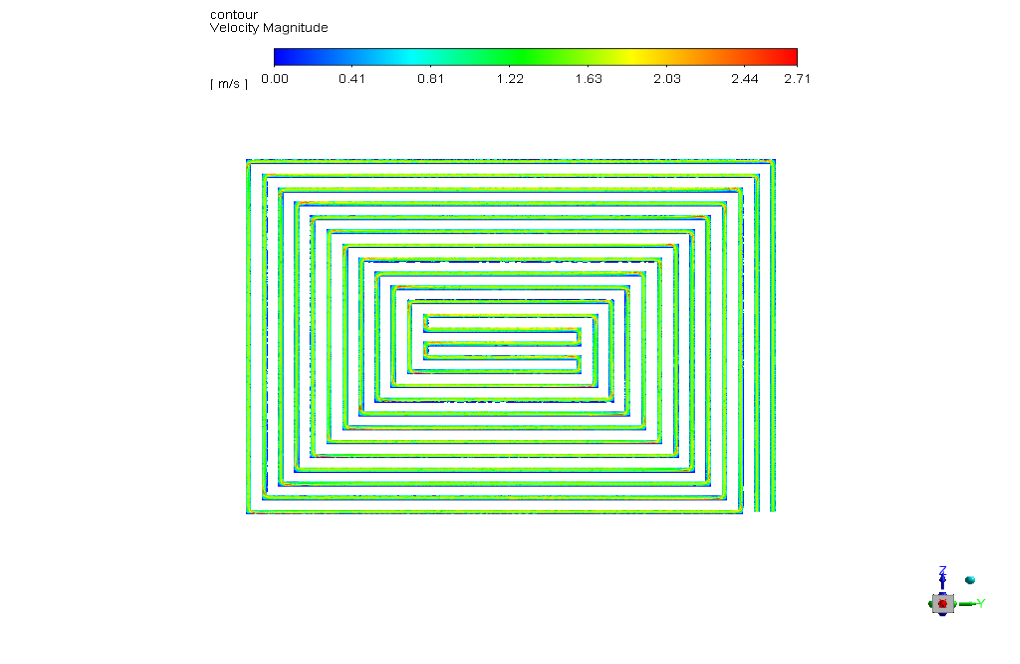

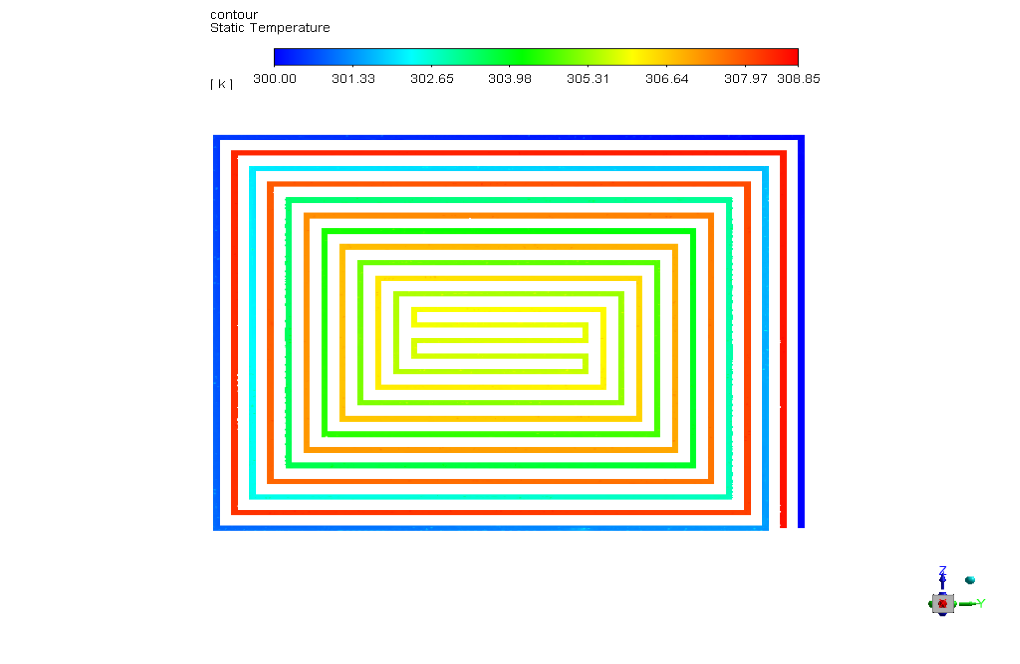

Pressure drop and velocity distribution can be seen with the related contours. Also, the temperature contours show that the water enters the radiator pipe at 300K and exits at 308.85k. The heat transfer rate can be obtained easily, with the temperature magnitudes at the inlet and outlet.

Skyla Emmerich –

please upload mesh file link

MR CFD Support –

hi, you can go to the following link:

http://www.mr-cfd.com/shop/reverse-cross-flow-plate-heat-exchanger-cfd-simulation

Philip Wolff –

I prepared this product by introducing one of my colleagues, and I will introduce it to my other friends.

Miss Ottilie Howe III –

very nice, I am thankful your efforts…

Corine Cummings Jr. –

How does the simulation model the heat transfer from the solar panel to the radiator?

MR CFD Support –

The simulation uses a coupled heat transfer model that accurately captures the heat transfer from the solar panel to the radiator.

Germaine Smith –

Can i know more about the efficiency of the solar panel?

MR CFD Support –

Yes, the simulation provides a highly accurate prediction of the solar panel’s efficiency based on the environmental conditions and the design of the panel.

Tony Pagac –

The MR-CFD’s mastery on the software and its topics was perfect.

Mrs. Dina Eichmann –

How does the simulation get a handle on the way fluid is flowing through the radiator?

MR CFD Support –

The simulation uses a really smart fluid dynamics model to nail down the exact way fluid is moving through the radiator.

Gabriel Jacobson –

After working through the Radiator Heated by a Solar Panel CFD Simulation training, I’ve gained a clear understanding of the principles and practical implementation of thermal systems in fluent. The training was concise yet comprehensive, making it a fantastic learning tool!

MR CFD Support –

Thank you for your positive review! We are thrilled to hear that our Radiator Heated by a Solar Panel CFD Simulation training provided you with a strong understanding of thermal systems in CFD. Your feedback is very important to us, and we are glad that you found the training both comprehensive and interesting. Keep up the great work, and we look forward to assisting you in furthering your understanding and skills in the future!

Evangeline Weimann –

This learning module has enhanced my understanding of integrating renewable energy with heating systems. The analysis is comprehensive, yet I am curious about one aspect. Have environmental conditions such as ambient temperature or solar irradiance variations been taken into account in the simulations?

MR CFD Support –

In this Regard, it must be stated that, typically, conditions such as ambient temperature and solar irradiance are essential factors in solar panel efficiency and, consequently, the radiator’s performance. However, these are parameters often configured in a CFD simulation according to the desired scenario and goals of the project. They can be adjusted to reflect different environmental conditions and analyze their impact on the system’s functionality.

Ms. Brisa Wisoky –

Incredible depth of detail in these simulations! The balance of real-world applicability with rigorous computational methods like the standard k-epsilon model for fluid dynamics really shows the dedication to quality. Admin, keep up the great work!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear you appreciate the level of detail in our simulations. Our team is dedicated to providing high-quality and accurate CFD learning materials, and it’s great to know our efforts resonate with our users. If you have any more questions or need further assistance, feel free to reach out!

Eldon Hyatt III –

I’m delighted with the clear results showing how efficiently the radiator heats the water using solar energy. The precision in temperature measurement from inlet to outlet is impressive!

MR CFD Support –

Thank you for your kind words! We’re pleased that our simulation met your expectations and gave you a clear understanding of the heating process. We aim to provide precise and valuable insights with our simulations.

Rebeka Little –

I’m very satisfied with the clarity and detail provided in the simulation results. Seeing the temperature change from inlet to outlet helps understand the efficiency of the solar heating process on the radiator.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the simulation results were clear and informative. It’s great to know that you gained valuable insights into the solar heating process. If you have any further questions or need assistance with your future CFD projects, feel free to reach out to us.

Tianna McCullough –

I love how in-depth the CFD training for the radiator heated by a solar panel goes. The level of detail in setting up the energy model and using different mass inlet rates was particularly impressive. The training really provided me with a practical understanding of how different variables affect the system’s performance.

MR CFD Support –

We are grateful for your positive feedback! It’s wonderful to hear that the training gave you a comprehensive understanding of the CFD processes involved in simulating a radiator heated by a solar panel. Thank you for acknowledging the depth and practicality of the practice — we aim to provide valuable learning experiences for our users. If you have any more questions or need further assistance, feel free to reach out.

Matt Boyle –

I’m very impressed with my first experience of ANSYS Fluent, as the instructions were clear, allowing me to follow each step without confusion. The visualization of the temperature distribution was particularly striking, and it showcased the effectiveness of combining solar panels with a heating system. I appreciate the innovation and relevancy of this simulation to sustainable design applications.

MR CFD Support –

Thank you for taking the time to provide your feedback! We are delighted to hear that you found our ANSYS Fluent training product clear and effective. It’s wonderful that the visualization aspects were especially beneficial for you, and we’re grateful that you appreciate the sustainable approach of this simulation. If you ever have any questions or need further assistance, don’t hesitate to reach out to us.

Prof. Waylon Schaden Sr. –

Great

Rowan Cummings –

How to model the effect of different operating conditions on the mixing process?

MR CFD Support –

the simulation can be adjusted to model different operating conditions, such as the speed of the mixer and the temperature of the fluid.

Rebecca Lueilwitz –

I found the inclusion of both adiabatic and convective pipes for comparison really enlightening. It helped visualize the differences effective insulation makes in energy conservation.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to know you found the comparison enlightening. Understanding the impact of insulation on energy efficiency is essential, and we’re glad that our simulation could provide you with clear visualizations of these effects. If you have any further questions or need additional insight on energy conservation methods, feel free to reach out to us.

Freda Roberts –

Did you use solar radiation in this project?

MR CFD Support –

We first simplify and calculate the solar radiation in this project and apply its amount.

Mrs. Josie Ullrich IV –

I’ve enjoyed learning through the radiator heated by a solar panel CFD simulation. Interesting to see how alternative energy sources can be integrated into home heating. The modeling and results were clearly explained!

MR CFD Support –

We appreciate your feedback on the Radiator Heated by a Solar Panel CFD Simulation tutorial using ANSYS Fluent. It’s fantastic to hear that you found the integration of alternative energy sources into home heating informative and the explanations clear. Thank you for choosing our training product!

Verner O’Keefe –

I’m impressed with the simulation’s capability to model different flow rates within the radiator. The insight into energy efficiency and performance at different mass flow rates is valuable for optimizing heating systems.

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that the simulation’s results were helpful and offered valuable insights into optimizing heating systems using solar energy. We continuously aim to provide detailed analyses to assist in making efficient and informed decisions.

Dr. Luigi Konopelski MD –

I’m very impressed with how realistic the simulation sounds! Can this training project present the effect of varying the pipe materials and diameters on the heat transfer efficiency?

MR CFD Support –

Thank you for your positive feedback! We are glad to hear that you find the simulation realistic. Yes, indeed, our training project can accommodate variations in pipe materials and diameters, which will affect the heat transfer efficiency due to changes in thermal conductivity and surface area. If you require detailed insights on this aspect, such variables can be specified and simulated to understand their impact on system performance.

Nels Gislason –

The solar panel simulation for the radiator was quite insightful. The visualization of temperature distribution helped me understand the heat transfer process deeper. Wonderful job on the detailed setup and clear results!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our simulation and visualizations have deepened your understanding of the heat transfer process. If you need further information or have any more questions, feel free to ask. We’re always here to help!

Dr. Mateo Harber –

I am super impressed with the level of detail in the radiator heated by a solar panel CFD simulation. It’s exciting to see sustainable energy applications in everyday appliances. The results are promising for energy-efficient heating solutions!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you appreciate the detail and sustainable energy application presented in the radiator simulation. It’s always rewarding when our customers recognize the value of our work. If you have any further interest or questions on sustainable energy solutions or CFD, feel free to reach out to us.

Gino Moore –

I’m delighted with the detail in the simulation project. The visualizations really helped me understand the flow of heated water in the solar panel radiator system. Fantastic work!

MR CFD Support –

Thank you so much for your kind words! We are thrilled that the project details and visualizations met your expectations and were instrumental in enhancing your understanding of the solar panel radiator system. Your satisfaction is our biggest motivation!

Jace Yundt –

Is the project capable of identifying efficiency changes at different solar intensities?

MR CFD Support –

The project primarily focuses on the established conditions including a water temperature increase from 300K to 308.85K. Adjusting solar intensities could affect the heat transfer rate. Therefore, different solar intensities would likely show variations in efficiency. For this particular simulation, additional scenarios might need to be conducted to observe efficiency changes related to varying solar intensities.

Adelbert Gottlieb –

The project presents a novel use of technology at home and the effort to make it more energy-efficient is commendable.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the practical application of this project resonates with your vision of energy efficiency and modern home technology.

Miss Reta Wyman –

I had a great experience using the solar panel radiator simulation provided by MR CFD. The results were very insightful in understanding the fluid temperature variations within the radiator pipes. The comparison between different fluid mass flows and pipe types was very useful for my research on sustainable heating solutions.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation for the radiator heated by a solar panel was helpful for your research. It is wonderful to know that the insights you gained on temperature variation and heat transfer were valuable. If you have any more questions or need further assistance with your sustainable heating solutions research, please don’t hesitate to reach out to us. We’re committed to supporting your work with high-quality CFD simulations.

Ansel Bayer I –

I’m extremely pleased with the solar-powered radiator simulation product! It was very thorough in addressing energy consumption concerns and understanding fluid dynamics.

MR CFD Support –

We are glad to hear that you are satisfied with the Radiator Heated by a Solar Panel CFD Simulation training. It’s always great to receive positive feedback about the comprehensiveness of our energy-related CFD analysis tools. Thank you for your appreciation!