Grain Drying Device CFD Simulation, 2-way DPM Model

$200.00 Student Discount

In this project, a Rice drying device using two-way DPM has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Grain Drying Device CFD Simulation Using Two-way DPM Model, Ansys Fluent Training

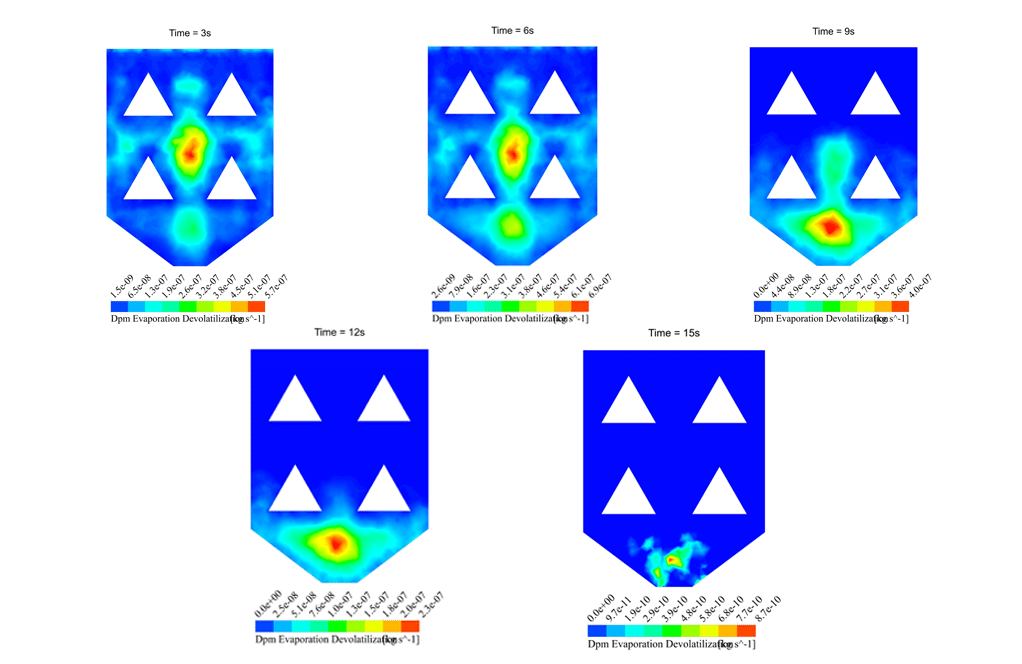

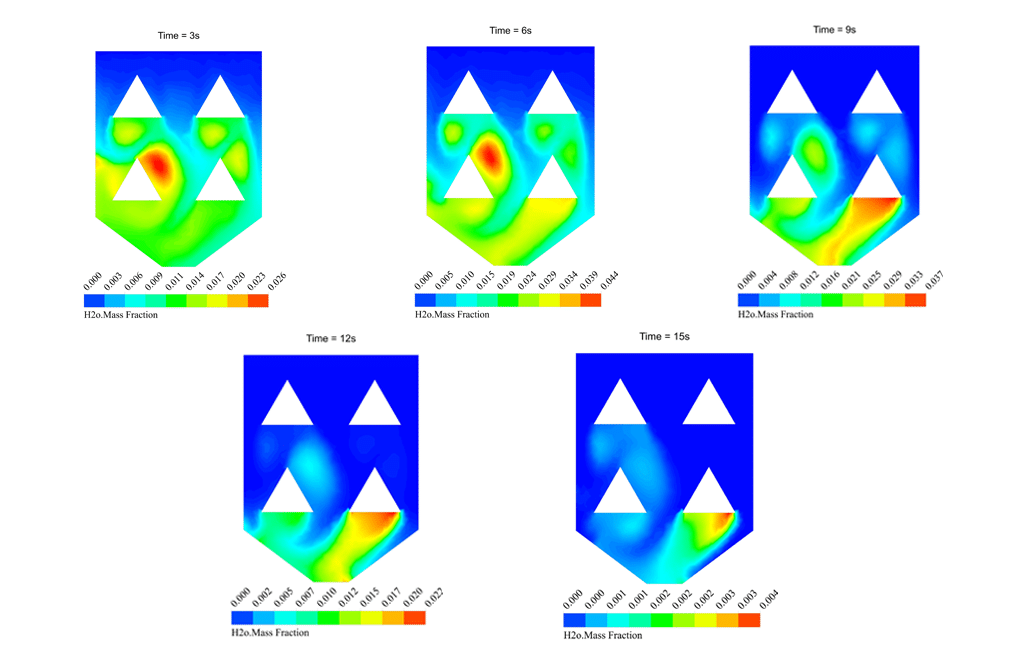

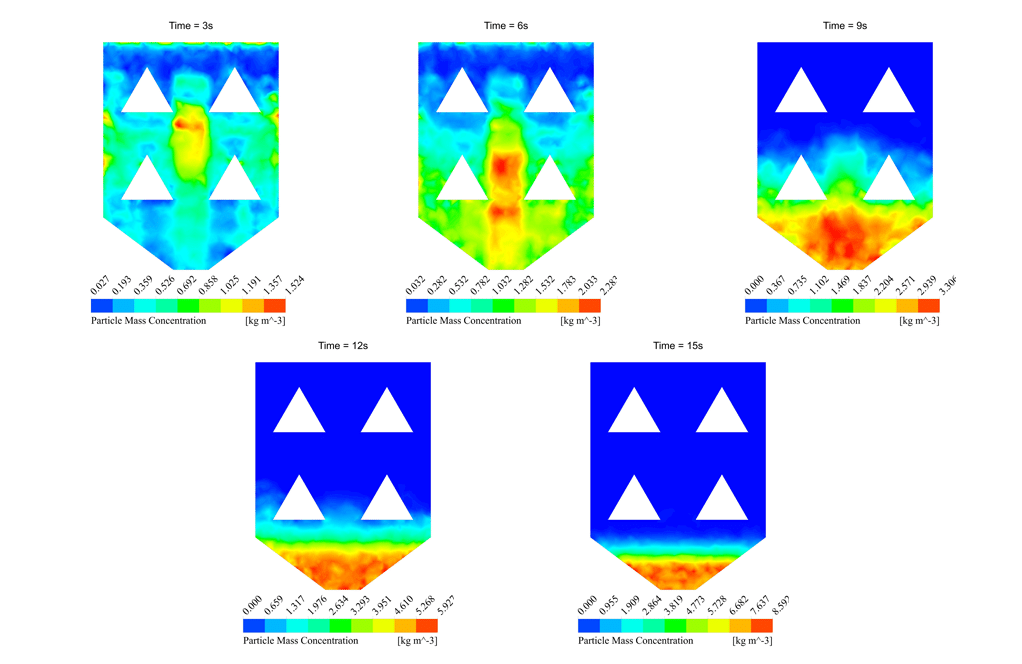

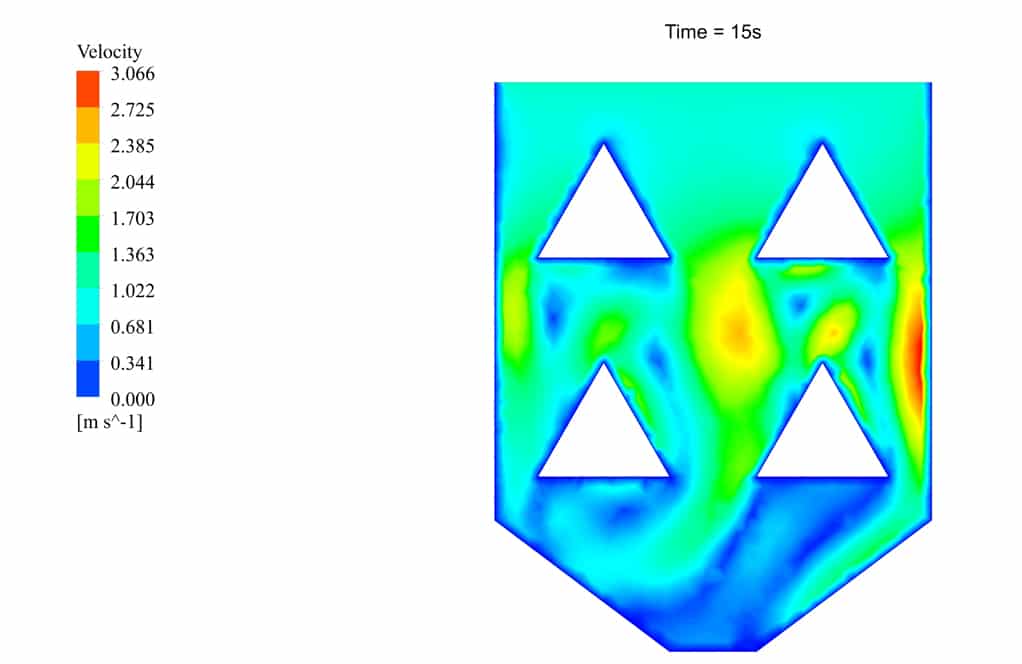

In this project, we studied a Grain Drying Device CFD Simulation using the Two-way Discrete Phase Model(DPM) & Species Model in Ansys Fluent software, and then the results were investigated. Hot air enters the drying device, and then 120000 rice grains with 10% moisture are injected randomly for 6 seconds. The evaporation process continues for 9 seconds after the complete injection. Furthermore, the hot surfaces are in contact with the hot exhaust smoke of the engine, which provides an efficient condition for the drying device.

When rice is harvested, it contains 20-30% moisture which can corrupt the grains in the shortest time. Therefore, drying the grains after harvesting is important before storage and sending them to the rice mill. The rice drying device provides a mechanical method to put rice grains in the exposure of ambient hot air to increase moisture evaporation.

Geometry & Mesh

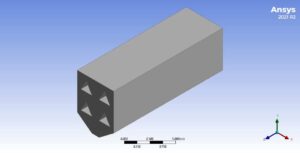

The 3D geometry was generated in Design Modeler software. A 3m*1m channel box contains four triangular passages of 20cm in length.

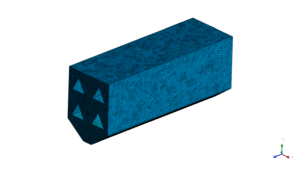

In addition, an unstructured mesh grid was carried out using Ansys meshing software, and overall, 556145 elements were generated.

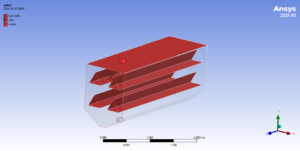

The figure below depicts the boundaries that were defined in this simulation.

Grain Drying Device CFD Simulation

Several assumptions have been considered to simulate Rice Drying Device, including:

- The simulation is Transient(unsteady) to capture the behavior of fluid and particles over time.

- The pressure-based solver type was used due to the incompressibility of the working fluid.

- The Two-way Discrete Phase Model(DPM) was utilized, so the grains of rice particles were injected with our desired condition into the fluid domain.

- Gravitational acceleration effects were considered -9.81m/s^2 in the y-direction.

The following table represents a summary of the solution:

| Models(Viscous) | |||||||

| Energy | On | ||||||

| Viscous | k-epsilon Realizable | Standard Wall Function | |||||

| Species | Species Transport | Mixture-template | |||||

| Discrete Phase Model | |||||||

| Interaction with continuous phase Unsteady particle tracking |

On

On |

||||||

| Injections | |||||||

| Injection Type

Number of streams |

Surface – inlet

10000 |

||||||

| Particle Type | Droplet | ||||||

| Material

Evaporating species Diameter distribution |

Water-liquid

H2o Uniform |

||||||

| Diameter | 0.005m | Stop Time | 6s | ||||

| Temperature | 363.15K | Velocity Magnitude | 0m/s | ||||

| Start Time | 0s | Total Flow Rate | 0.5kg/s | ||||

| Materials | |||||||

| Mixture-template | Definition method | Fluent database | |||||

| Material name | Air | ||||||

| Droplet Particle | Definition method | Fluent database | |||||

| Material name | Water-liquid

Volatile component fraction = 10% |

||||||

| Cell zone condition | |||||||

| Material name | Mixture-template | ||||||

| Boundary condition | |||||||

| Inlet | Type | Velocity inlet | |||||

| Velocity magnitude | 1m/s | ||||||

| Turbulent intensity | 5% | ||||||

| Turbulent viscosity ratio | 10 | ||||||

| Temperature | 363.15K | ||||||

| DPM BC Type | escape | ||||||

| Outlet | Type | Wall | |||||

| DPM BC Type | reflect | ||||||

| Hot walls | Type | Wall | |||||

| Temperature | 773.15K | ||||||

| DPM BC Type | reflect | ||||||

| Solver configuration | |||||||

| Pressure-velocity coupling | Scheme | SIMPLE | |||||

| Spatial Discretization | Gradient | Least squares cell-based | |||||

| Pressure | Second-order | ||||||

| Momentum | Second-order upwind | ||||||

| Turbulent kinetic energy | First-order upwind | ||||||

| Turbulent dissipation rate | First-order upwind | ||||||

| H2o | Second-order upwind | ||||||

| Energy | Second-order upwind | ||||||

| Initialization | Initialization methods | Standard Initialization | |||||

| Run calculation | Time step size | 0.05 | |||||

| Number of time steps | 300 | ||||||

| Max iterations per time step | 40 | ||||||

Results

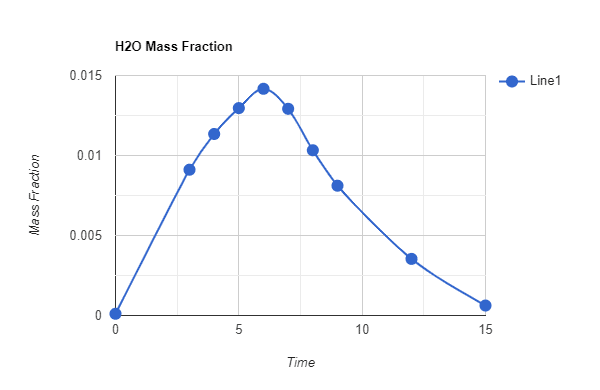

The particle injection into the rice drying device starts with 10000 rice grains. The injection process lasts for 6 seconds. Evaporation is happening by the first second but ignoring that as an assumption for simplification, we can get to the H2o mass fraction graph showing the desired variable over time. The moisture(H2o) reaches its highest value at the end of injection, nearly 0.015 and then, it takes approximately 9 seconds to fall to 0 due to evaporation.

Related products

-

HAWT (Horizontal Axis Wind Turbine) ANSYS Fluent CFD Simulation Training

Rated 4.00 out of 5$140.00 Student Discount

Reviews

There are no reviews yet.