RQ-170 Drone CFD Simulation, ANSYS Fluent Tutorial

$60.00 Student Discount

- The problem numerically simulates an RQ-170 UAV using ANSYS Fluent software.

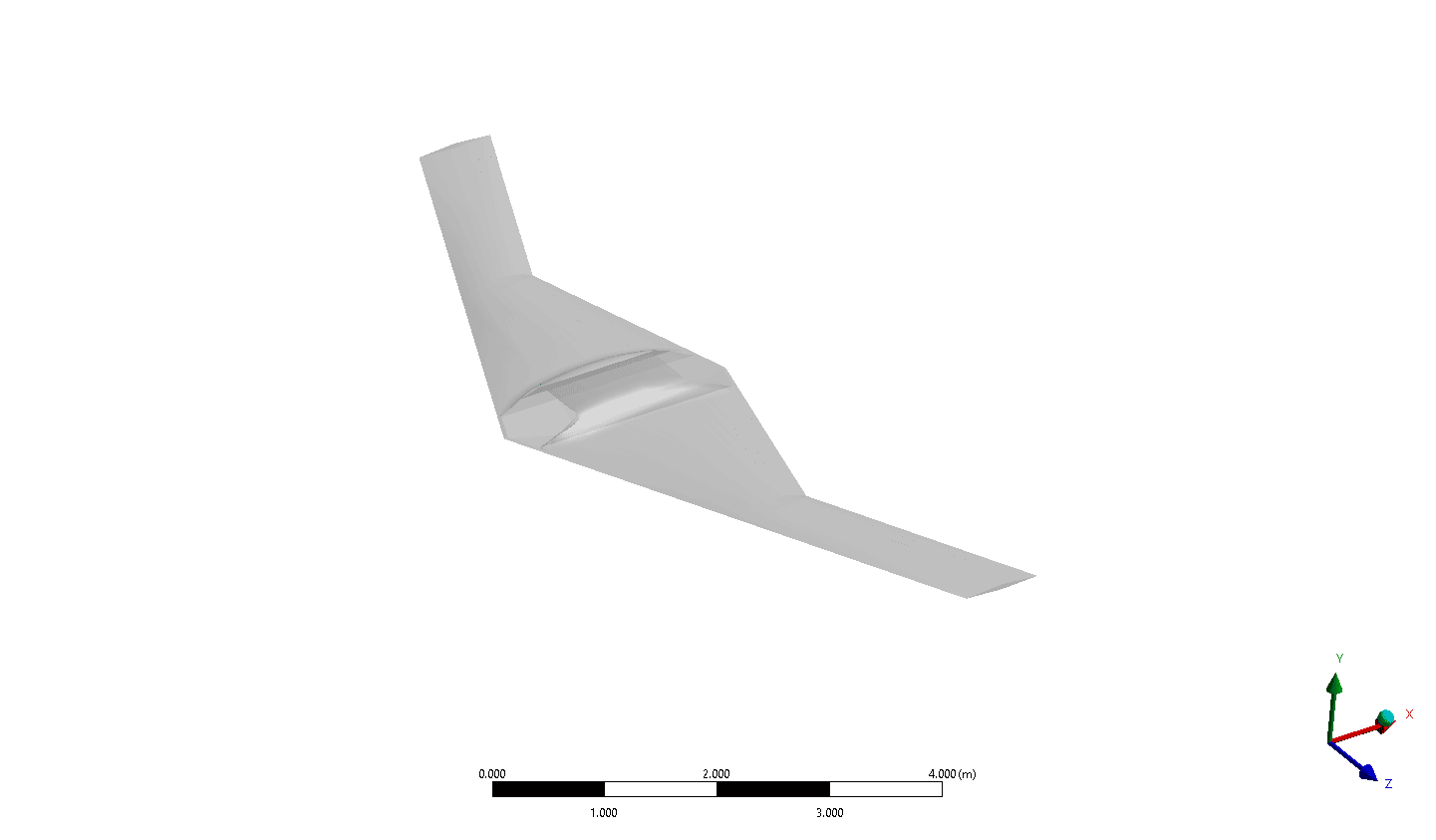

- We design the 3-D model with the Design Modeler software.

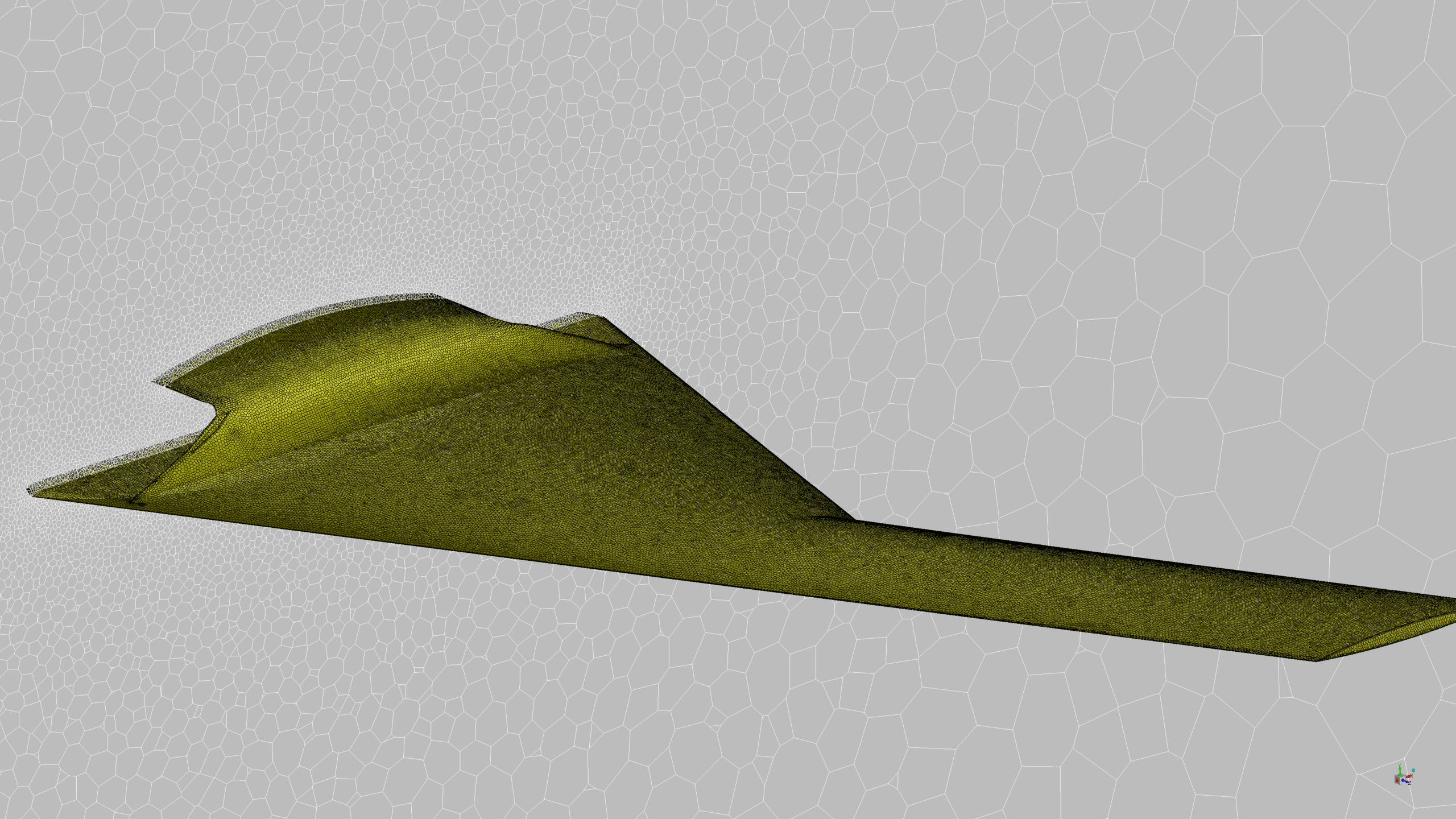

- We mesh the model with ANSYS Meshing software. The element number equals 2,415,175 and their type is polyhedra.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

RQ-170 UAV Aerodynamic CFD Simulation, ANSYS Fluent Tutorial

Introduction

The RQ-170 is a high-altitude, long-endurance unmanned aerial vehicle (UAV). The UAV can take real-time images and send them to the ground control station through a line-of-sight communication data link.

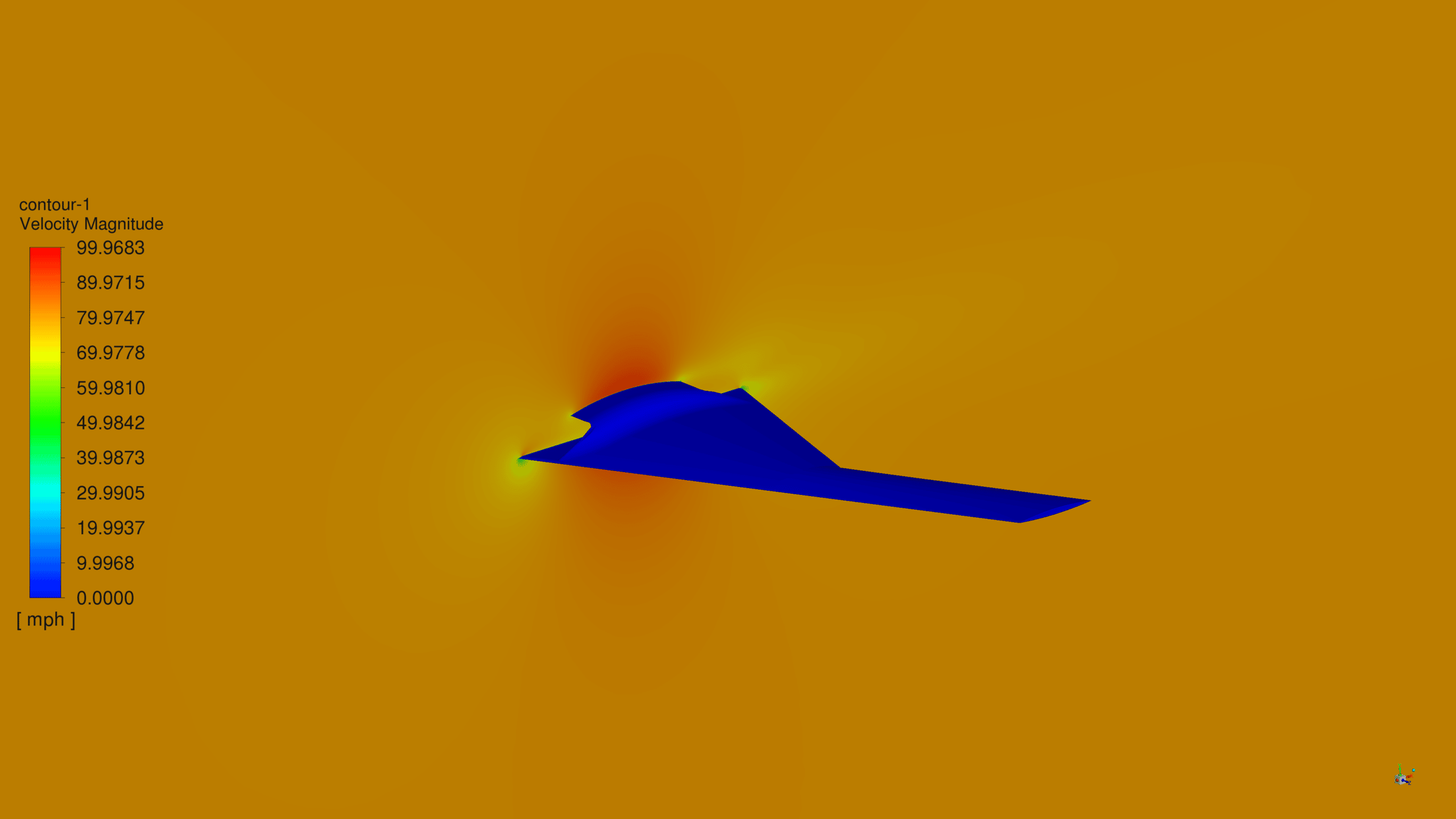

In this simulation, an RQ-170 UAV is modeled using ANSYS Fluent software. The device is moving at a speed of 80 mph.

The geometry of the present model is three-dimensional and has been designed using Design Modeler software. We do the meshing of the present model with ANSYS Meshing software. The mesh type is Polyhedra, and the element number is 2,415,175.

Methodology: RQ-170 UAV CFD Simulation

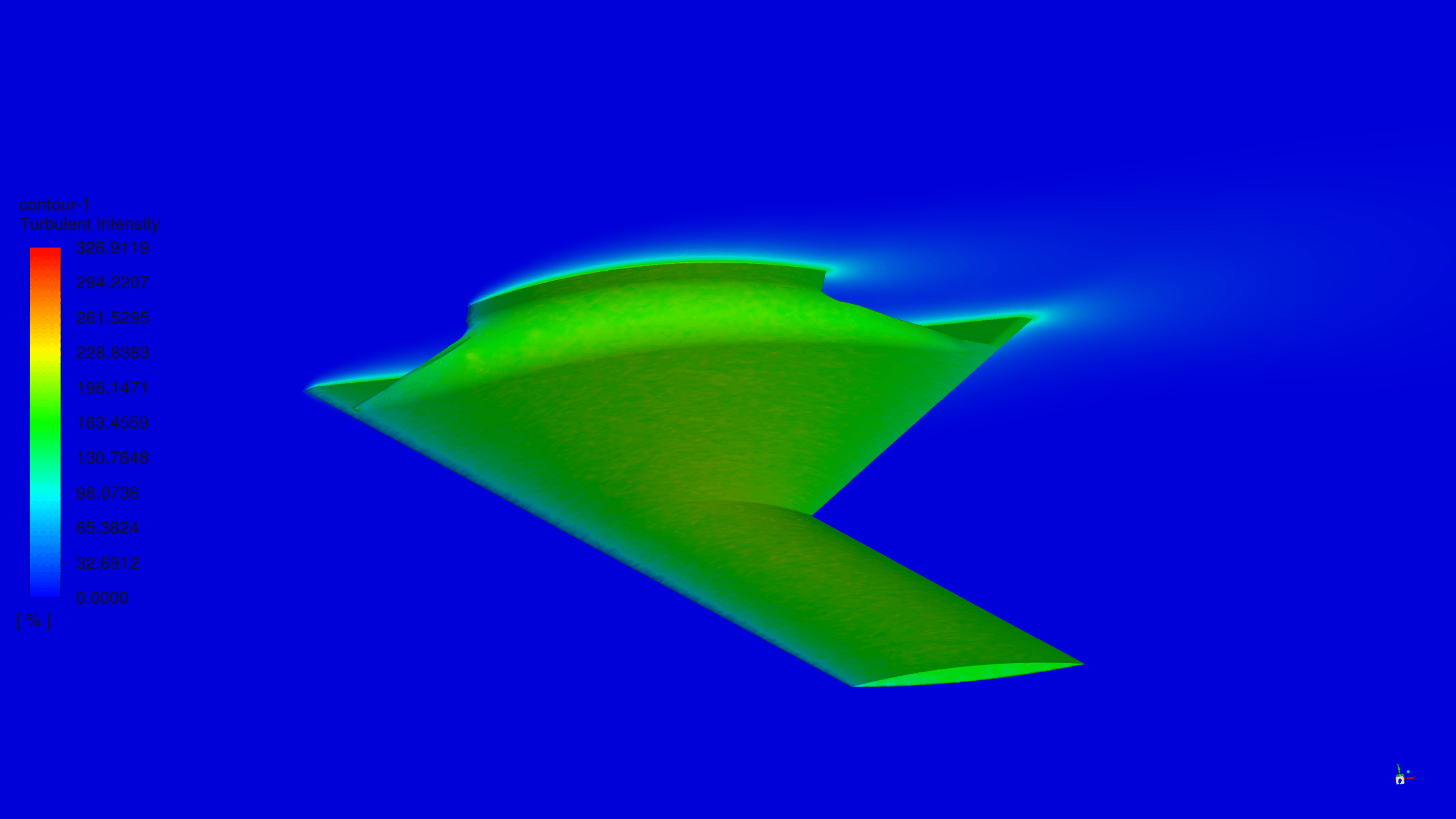

Due to the high speed of airflow during flight and the possibility of very high separation in such flows, the Realizable k-epsilon model using standard wall functions is exploited to analyze the airflow turbulence.

Conclusion

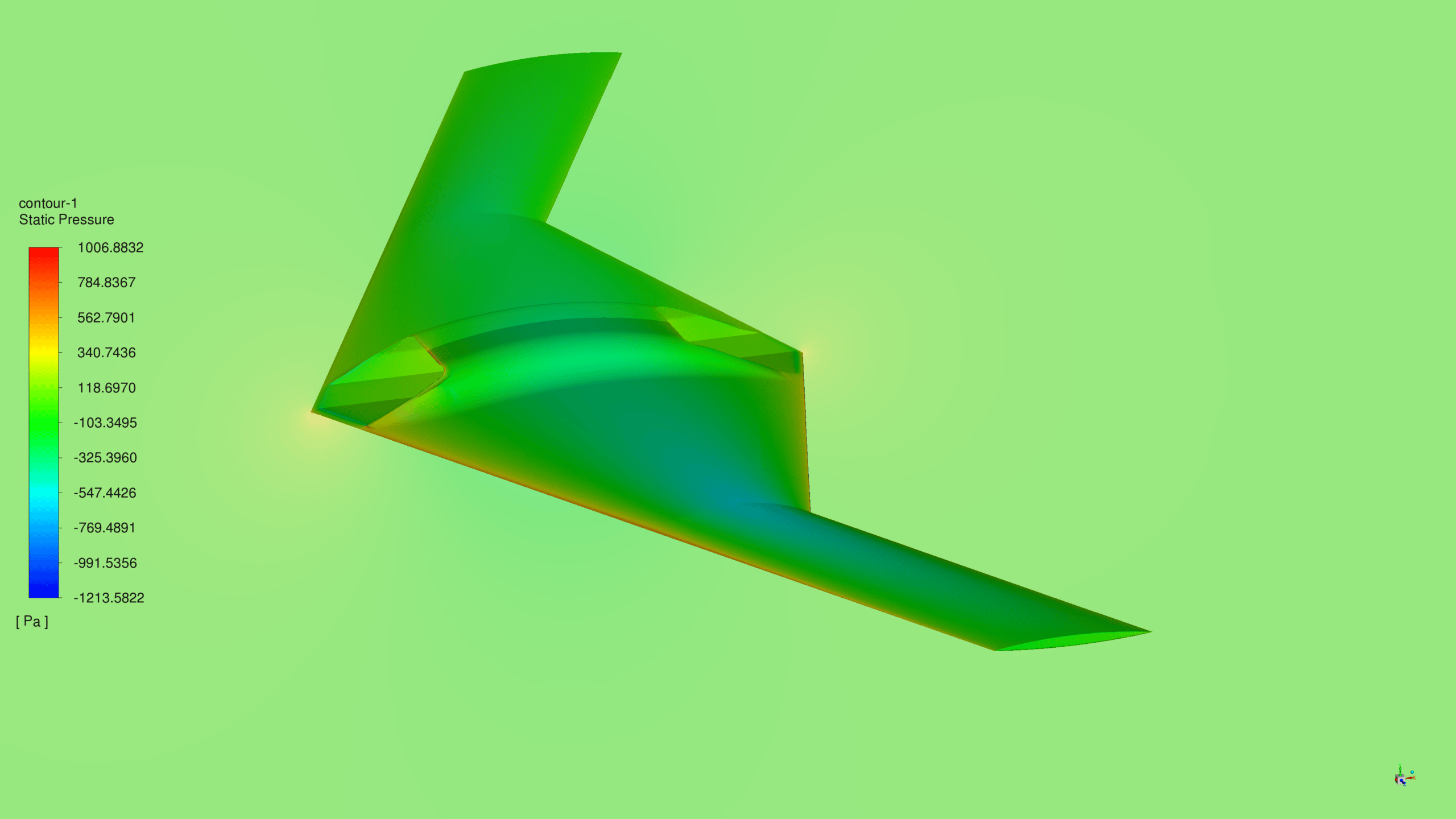

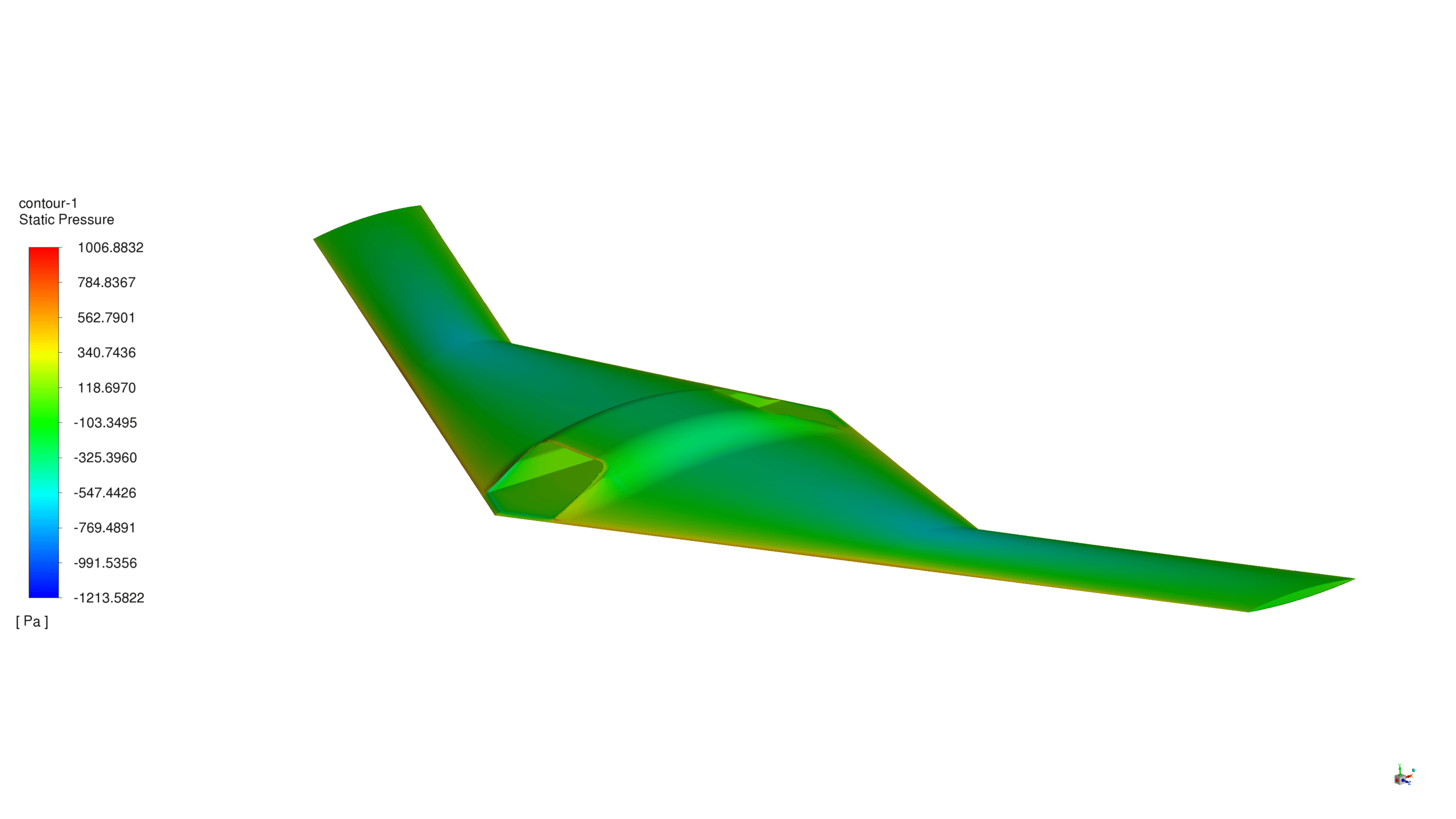

After the simulation process was finished, contours and vectors for parameters such as velocity, pressure and turbulent intensity were obtained. The velocity contours show that the Kutta condition on the trailing edge is visible.

Compared to other UAVs, this model endures less amount of drag force. One of the reasons for this is the absence of a propeller on the device. Instead, a jet engine that produces the thrust needed for flight is placed inside its compartment.

In the static pressure parameter case, as it was predictable, the UAV’s front surfaces endure the highest pressure, which tells us about the necessity of the manufacturing focus on this component.

Prof. Ali Bahringer DDS –

The provided ANSYS Fluent tutorial for simulating the aerodynamics of the RQ-170 drone was incredibly detailed and clear. I could follow each step without confusion, and the visual aids were very helpful. Seeing the velocity and pressure contours gave me a strong understanding of the UAV’s performance characteristics. I was particularly impressed by the effectiveness of the Realizable k-epsilon model in capturing the separation of high-speed airflow. Great job on a comprehensive tutorial!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found our ANSYS Fluent tutorial for the RQ-170 drone simulation to be clear, detailed, and helpful. We strive to create educational content that is both informative and easy to follow, and we’re glad to see we hit the mark for you. Your satisfaction with the tutorial’s instructional quality means a lot to us. If you have any more feedback or require further assistance, please don’t hesitate to reach out.

Prof. Javon Stark –

This tutorial was fantastic! It guided me through every step, and I was able to simulate the RQ-170 UAV with ease. The clarity on applying the Realizable k-epsilon turbulence model was especially helpful. Great work.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that the tutorial on the RQ-170 Drone CFD Simulation in ANSYS Fluent was helpful for you. It’s our aim to provide comprehensive guidance for our simulations. Your success is our success!

Dr. Marilyne Bayer –

The Polyhedra mesh was a great choice for this complex geometry! Results on drag and flow turbulence around the drone were clearly presented, helped immensely in understanding aerodynamic properties. Great tutorial.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our tutorial was helpful and that you appreciated the complex meshing approach and detailed results on the RQ-170 Drone simulation. If you have any more feedback or need further assistance, feel free to reach out!

Ephraim Bruen –

Absolutely fascinating tutorial! I was able to fully comprehend the aerodynamics of the RQ-170 UAV through the simulation in ANSYS Fluent; the explanation of the methodology was clear and the resultant data was extraordinarily insightful.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that the tutorial met your expectations and provided you with clear and valuable insights into UAV aerodynamics. Your feedback is appreciated, and it motivates us to continue delivering quality tutorials. If you have any more questions or need further assistance, feel free to reach out.

Virgie Klocko –

The RQ-170 tutorial was clear and informative. I could successfully simulate the UAV’s aerodynamics and understand the significance of design details like the jet engine compartment and lack of a propeller. This was a truly helpful resource!

MR CFD Support –

Thank you for your review! We’re thrilled to hear that our RQ-170 drone CFD simulation tutorial was able to assist you in your simulation efforts and help enhance your understanding of UAV aerodynamics. If you need further assistance or have any more feedback, feel free to reach out. Happy simulating!

Abe Gusikowski –

I was blown away by the high level of detail in the RQ-170 UAV CFD Simulation tutorial. ANSYS Fluent’s capability to represent such complex aerodynamic calculations and provide such clear results is impressive. This tutorial has been particularly helpful for my studies on drone design, and the high-quality visuals made the learning process much more engaging.

MR CFD Support –

Thank you for your positive review of the RQ-170 UAV CFD Simulation tutorial! We’re glad to hear that our tutorial could assist you in your drone design studies and that you found the visuals engaging. Your feedback is greatly appreciated, and it motivates us to keep providing detailed and high-quality learning materials. If you ever have more inquiries or need further assistance, don’t hesitate to reach out.

Bridie Pfeffer –

I was able to visualize airflow over the UAV thanks to your detailed CFD simulation. Impressive work showing how pressure distributes across the drone’s body.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear that the RQ-170 drone CFD simulation was helpful to you and that the depiction of airflow and pressure distribution enhanced your understanding of the UAV’s aerodynamic characteristics.

Helmer Terry –

I was fascinated by the high level of replication accuracy in the airflow simulation at 80 mph for the RQ-170 model. The UAV’s post-simulation parameters, especially regarding pressure distributions, show meticulously detailed aerodynamics of the platform. Thanks for a compelling tutorial!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our tutorial met your expectations and provided you with detailed insights into the aerodynamics of the RQ-170 drone. Our goal is to deliver thorough and accurate simulations that are beneficial and educational. We appreciate your acknowledgment of the efforts we put into creating this intricate simulation.

Mr. Miguel Labadie III –

This tutorial for the RQ-170 simulation was amazing, everything was very clear and my results matched the expected outcome. Especially the part explaining the Realizable k-epsilon model really helped me understand flow separation on UAVs.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that the tutorial met your expectations and that you found the explanation of the Realizable k-epsilon model useful. It’s always great to hear our tutorials are helping our customers understand complex concepts. If there’s anything more we can help you with in the future, please let us know!

Lue Thiel –

The tutorial on the RQ-170 drone CFD simulation was outstanding. It guided me through the complex process with ease and shed light on the intricate nature of UAV aerodynamics. Realizing the importance of the design’s input on drag reduction, the practical insights twisted my perception on drone engineering. Couldn’t have asked for more from this learning resource!

MR CFD Support –

Thank you for your kind words! We’re really glad to hear that our RQ-170 drone CFD simulation tutorial was helpful to you. Understanding UAV aerodynamics is vital, and we are happy our tutorial made that complex subject clear. We always aim to provide valuable insights that can influence the engineering process. Your satisfaction is incredibly encouraging to our team!

Lisandro Paucek –

I just completed the RQ-170 Drone CFD Simulation tutorial and I’m impressed with the level of realism in the simulation. It really provides an insight into the aerodynamic performance of high-altitude, long-endurance UAVs.

MR CFD Support –

Thank you for taking the time to provide feedback. We’re glad to hear that you are impressed with the realism and the details provided in the RQ-170 Drone CFD Simulation tutorial. Your insight is important to us and helps us continue to improve and offer high-quality educational material.

Trycia Kulas –

I was intrigued by the use of the Realizable k-epsilon model in this RQ-170 drone simulation. Can you explain why this particular turbulence model was chosen over others?

MR CFD Support –

The Realizable k-epsilon model is preferred in this kind of high-speed aerodynamic simulation due to its robustness and its ability to capture the effects of the high shear and strain rates prevalent around aerospace vehicles like drones. Moreover, it provides more accurate predictions for separating and reattaching flows, which is essential for understanding the aerodynamic performance of the RQ-170 UAV.

Emely Paucek –

I’m fascinated by the RQ-170 UAV simulation! Can you tell me what type of validation was used to ensure the simulation results are accurate and reflect the UAV’s behavior in an actual flight?

MR CFD Support –

To ensure the accuracy of the RQ-170 UAV simulation results, the validation process involves comparing the CFD results with available flight data or wind tunnel testing outcomes for the UAV. If such data is not available, comparisons are made with simulations and tests of similar UAV models or using established aerodynamic principles for high speed, high altitude UAV flights.

Dr. Julian McCullough –

I found the video tutorial on the RQ-170 Drone simulation extremely helpful, particularly the comprehensiveness and level of detail. Your explanation made the complex modeling and meshing process seem much more approachable. Thanks for including the discussion on the impacts of different design choices, like the absence of propellers and internal jet engine placement on the aerodynamic performance!

MR CFD Support –

Thank you for your kind review! We are really glad to hear that you found our RQ-170 Drone CFD simulation tutorial helpful and easy to understand. It’s great to know that the explanation of the impacts of design choices on the aerodynamics was valuable to you. If you ever have more questions or need further assistance in your simulations, feel free to reach out. Happy simulating!

Prof. Dylan Little Sr. –

The tutorial for the RQ-170 Drone CFD Simulation was fantastic! It provided clear insights on setting up the problem and helped me understand the use of the Realizable k-epsilon turbulence model. I particularly appreciate the information on the effects of not having a propeller on the drag forces.

MR CFD Support –

We are delighted to receive such positive feedback on our RQ-170 Drone CFD Simulation tutorial! It’s great to know that the details provided in our tutorial were informative and helpful. Thank you for acknowledging the efforts we made in demonstrating the impact of design choices like omitting the propeller on aerodynamic drag. Your appreciation motivates us to keep providing high-quality learning materials!

Nona Kiehn –

I recently completed the RQ-170 Drone CFD Simulation tutorial using ANSYS Fluent and was truly impressed by the clarity and depth of instruction provided. The Polyhedra mesh’s intricacy complemented the fluid analysis, providing me keen insights into the aerodynamics of the UAV. The explanations around the utilization of the Realizable k-epsilon model along with the standard wall functions were crucial in understanding turbulence analysis. Viewing the low drag conditions and the velocity contours, especially the Kutta condition on the trailing edge, was fascinating. Moreover, understanding the pressure distribution across the UAV’s architecture underscored the importance of structural integrity at high speeds. An excellent tutorial overall, one that has significantly contributed to my burgeoning knowledge of aerodynamic simulation in aerospace contexts!

MR CFD Support –

Thank you so much for your positive feedback on our RQ-170 Drone CFD Simulation tutorial! We are thrilled to hear that you found the tutorial to be clear, insightful, and beneficial for understanding aerospace aerodynamics through ANSYS Fluent. Your enthusiasm for learning is the kind of motivation that encourages us to keep delivering comprehensive and high-quality educational content. We look forward to supporting your growth in CFD knowledge further!

Myrtis Towne –

I was wondering if the use of standard wall functions with the Realizable k-epsilon turbulence model is typical for simulations involving high-speed airborne devices like the RQ-170 drone; does it accurately capture the complex flow phenomena associated with UAV aerodynamics?

MR CFD Support –

Yes, the Realizable k-epsilon turbulence model with standard wall functions is commonly used in CFD analyses of high-speed airflow over airborne devices. It can capture significant boundary layer phenomena effectively, although some complex flow situations may require more advanced turbulence models or wall treatments for increased accuracy. The choice of model depends on the specific goals of the simulation, computational resources available, and the level of precision needed. For the RQ-170 drone simulation, the Realizable k-epsilon was deemed suitable for obtaining a general insight into aerodynamic behavior.

Mario Heller –

The level of detail in this simulation is commendable. From the accuracy in modeling the UAV’s geometry to the insightful conclusion that emphasizes the importance of structural integrity on the front surfaces, it’s clear that a decent amount of work went into this project. Great job capturing the aerodynamics nuances of the RQ-170.

MR CFD Support –

We appreciate your recognition of the effort and detail put into this simulation! Our team strives to provide accurate and insightful models. Thank you for taking the time to acknowledge the work involved. We’re pleased that you found the information useful and insightful!