Sedimentation and Erosion in a Shell and Tube, Ansys Fluent CFD Simulation Training

$140.00 Student Discount

- The problem numerically simulates Sedimentation and Erosion in a Shell and Tube Heat Exchanger using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 640618.

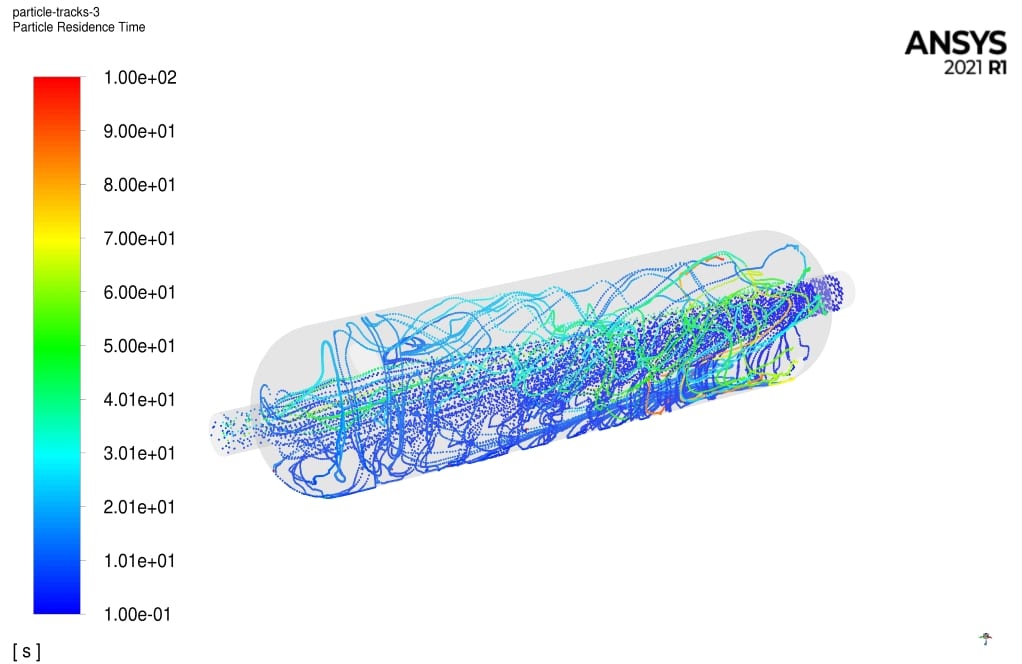

- We perform this simulation as unsteady (Transient).

- We use Discrete Phase Model (DPM) to define Sand Injection inside the heat exchanger.

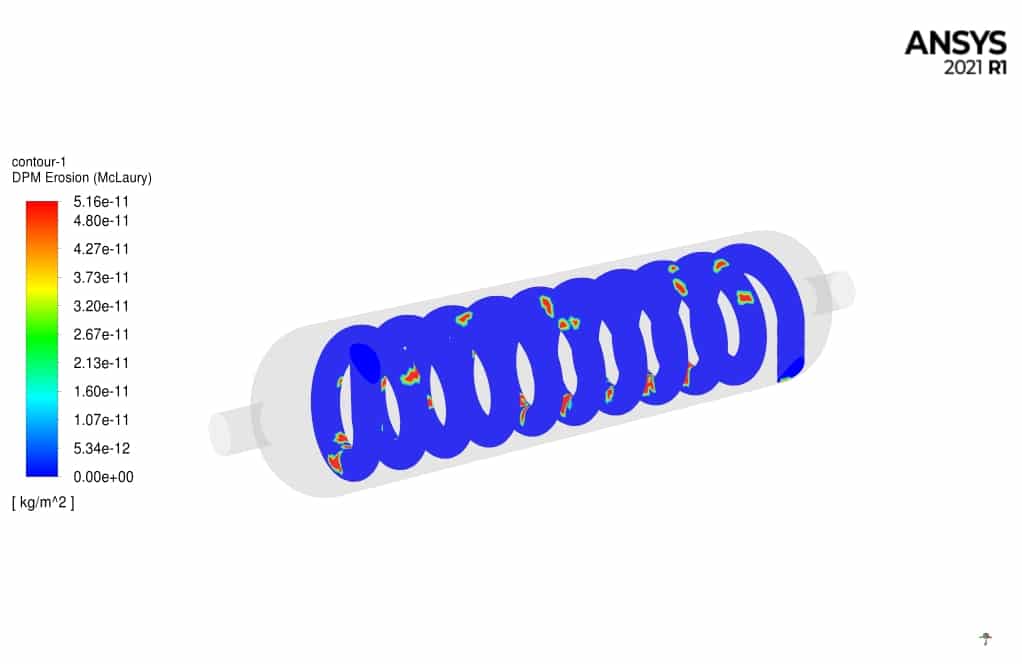

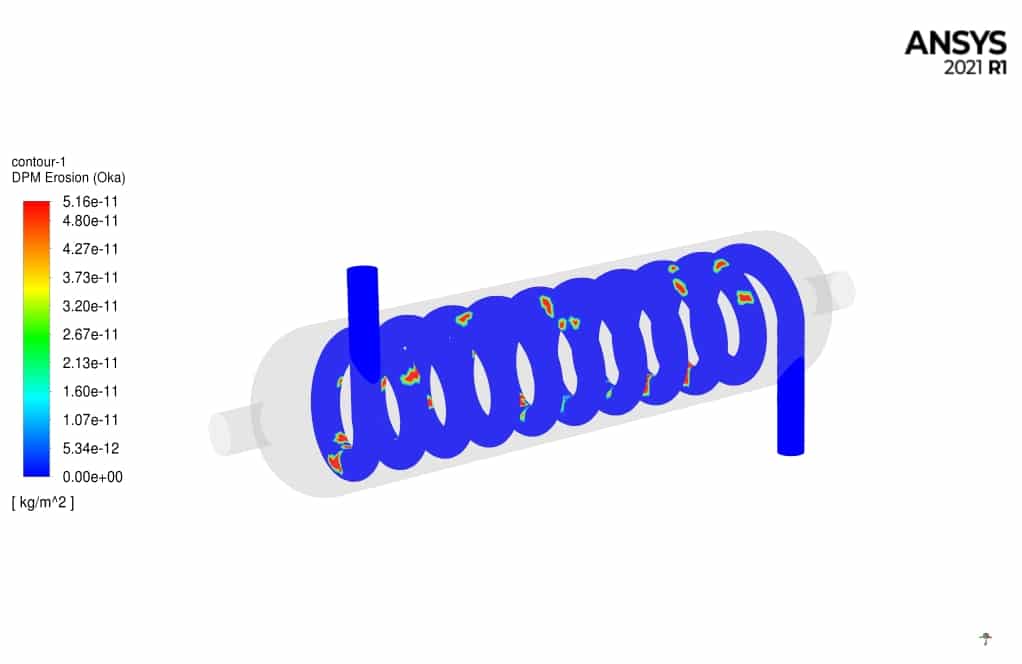

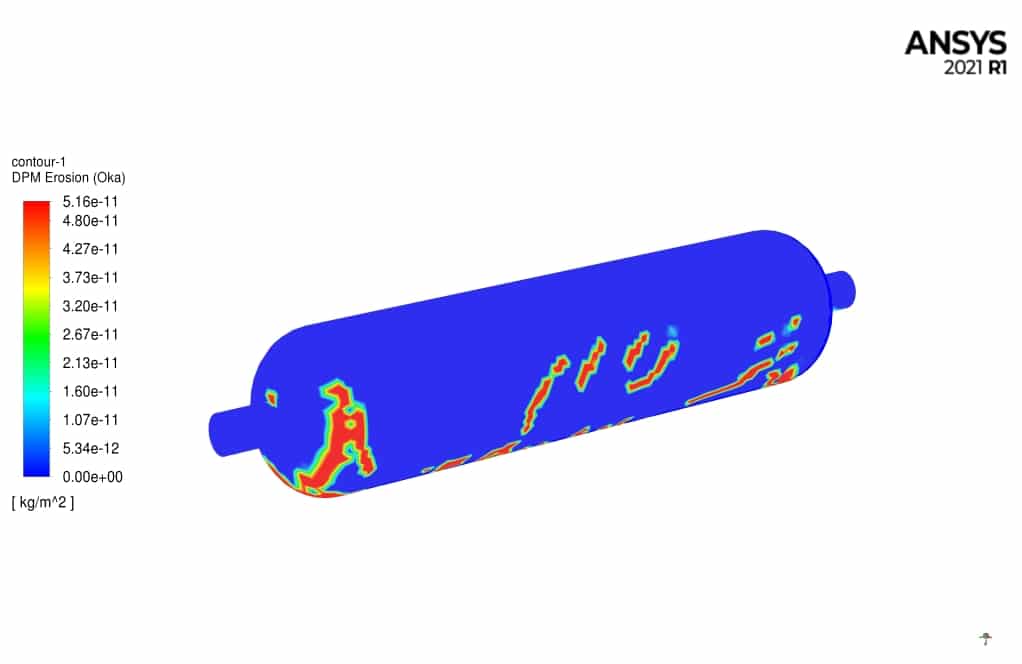

- We aim to predict the Erosion Effect by different methods: Finnie, Oka, and Mclaury.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates sedimentation and erosion in a shell and tube using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

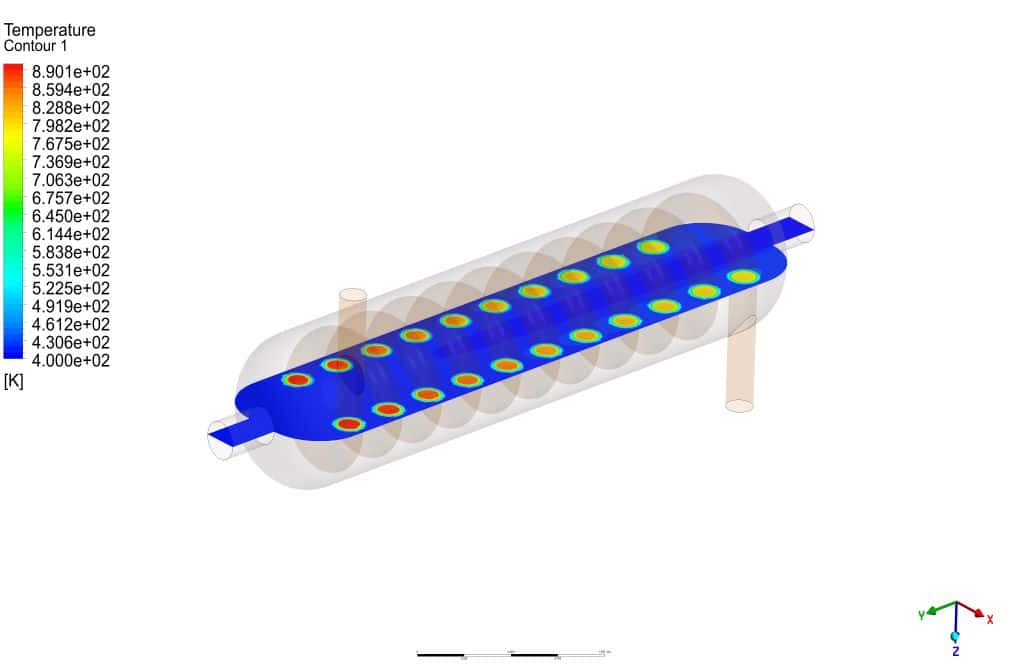

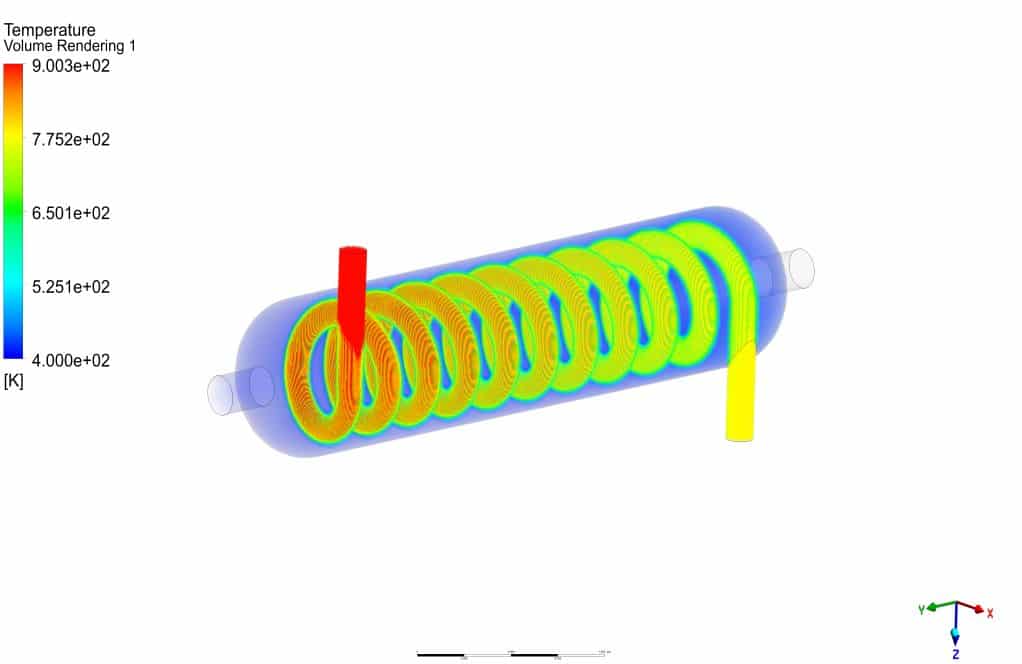

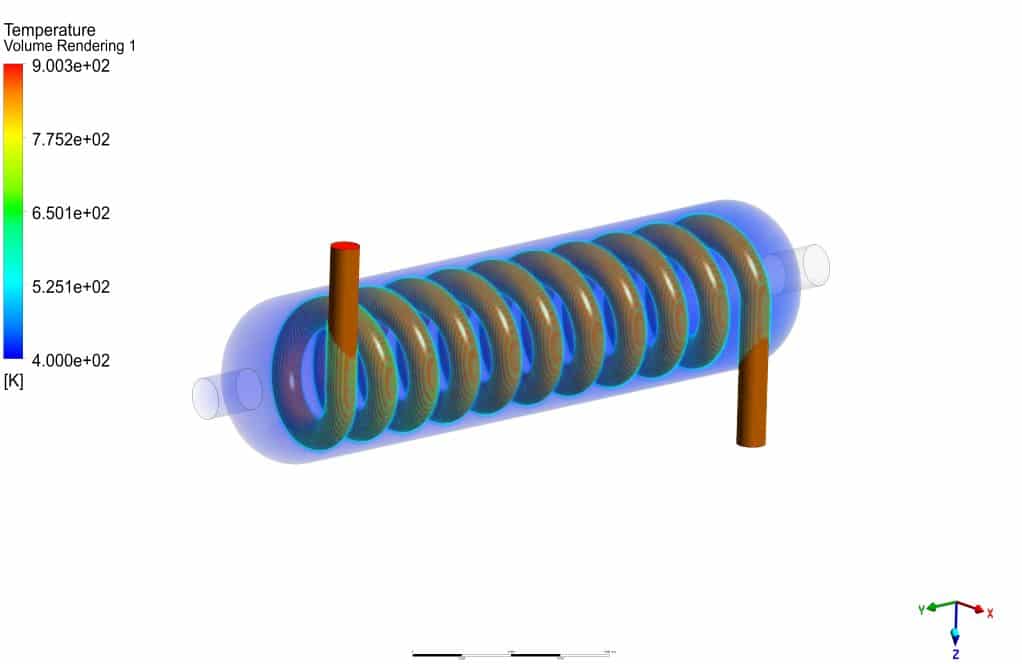

The present model is designed in three dimensions using the Design Modeler software. The geometry consists of two-section, 1-shell 2-Tube. The inlet diameters of the shell and tube are 20 cm, and the outlet diameter for both shell and tube is 20 cm.

The meshing of the model was done using ANSYS Meshing software. The element number is 640618.

Also, due to the nature of the problem, the transient solver is enabled.

Sedimentation and Erosion Methodology

In this study, using the DPM (Discrete phase material) method, sedimentation and erosion in a shell and tube were investigated by Ansys Fluent software.

The two-way DPM model, along with the erosion/accretion model, is enabled to accurately investigate the particles’ behavior and the erosion phenomenon in the pipe.

Also, rosin-rammler diameter distribution was used to simulate realistic particle distribution inside the domain.

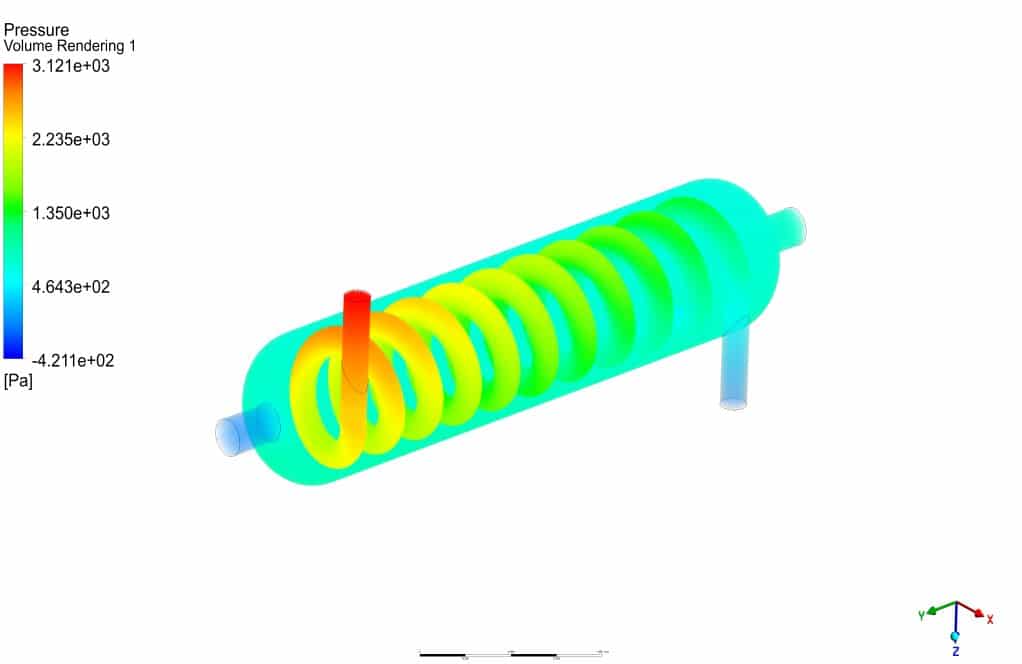

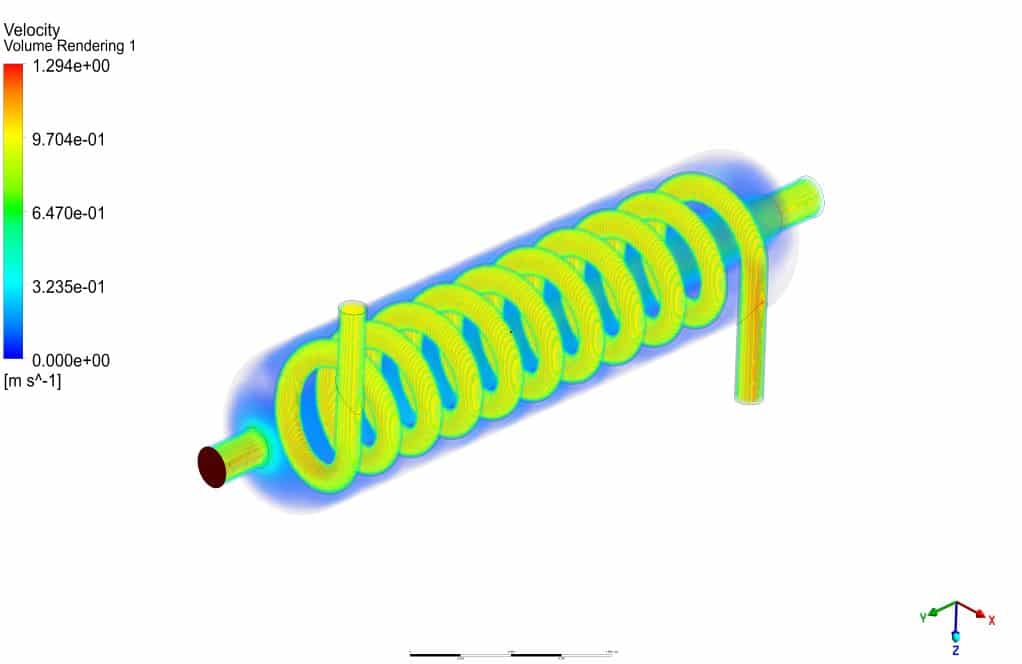

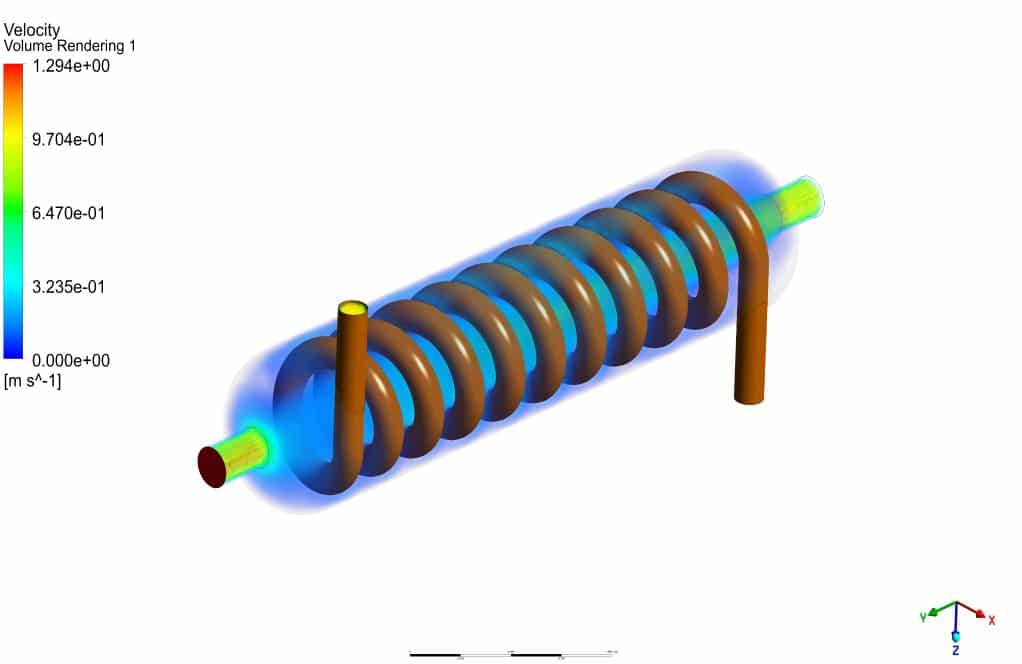

The system consists of two fluids, oil, and water (Water flows in the shell and oil in the tube). Using Ansys Fluent software, the impurity distribution was observed. The software’s different erosion models help correctly predict the erosion effect in other cases according to different working conditions.

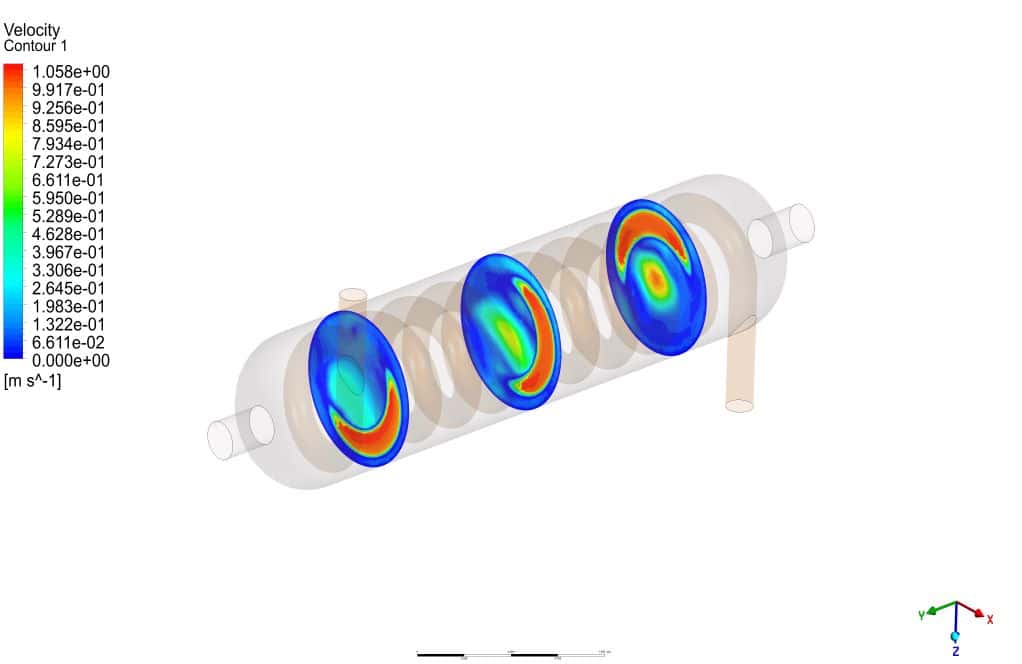

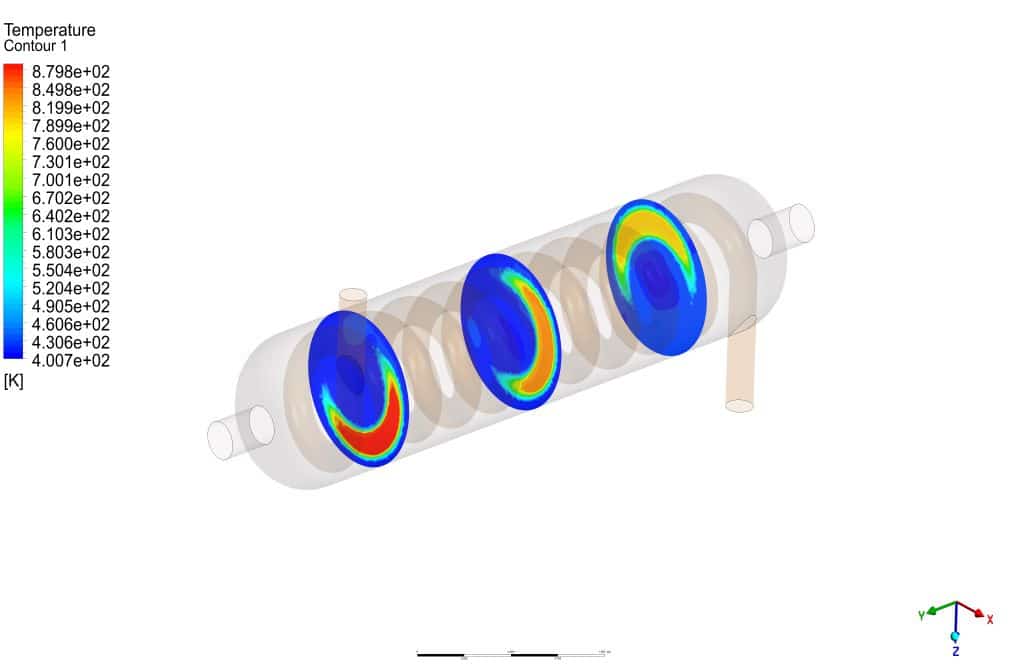

The velocity inlet of oil and water enters the domain with the speed of 1 m/s with gravity considered as -9.81 m/s-2 on the z-axis. Moreover, the RNG k-epsilon model and energy equation are used to solve the turbulent fluid equations and calculate temperature distribution inside the domain.

Sedimentation and Erosion Conclusion

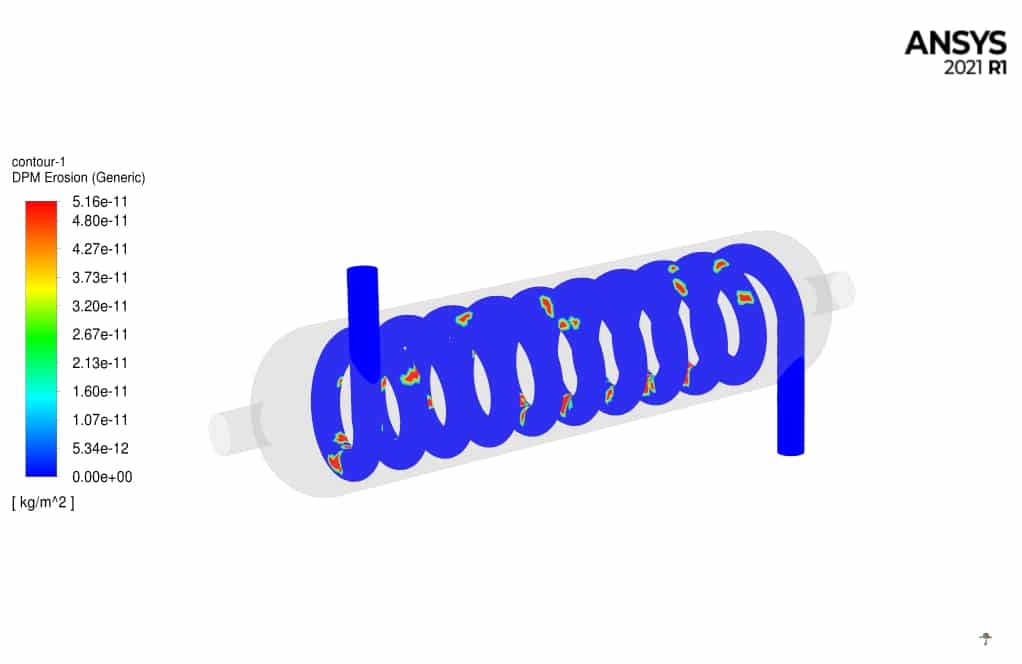

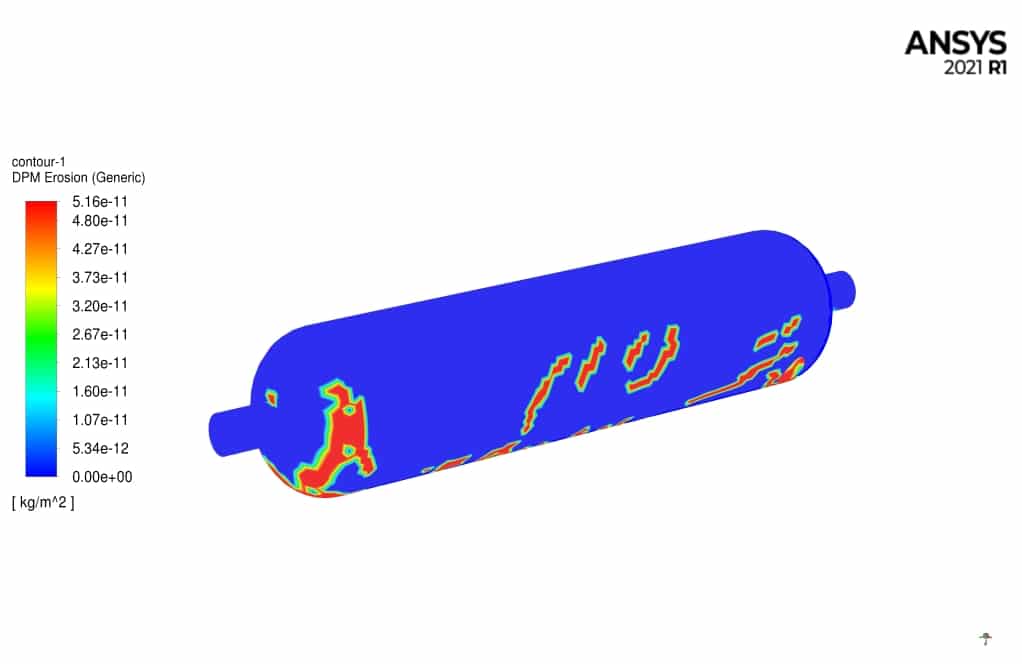

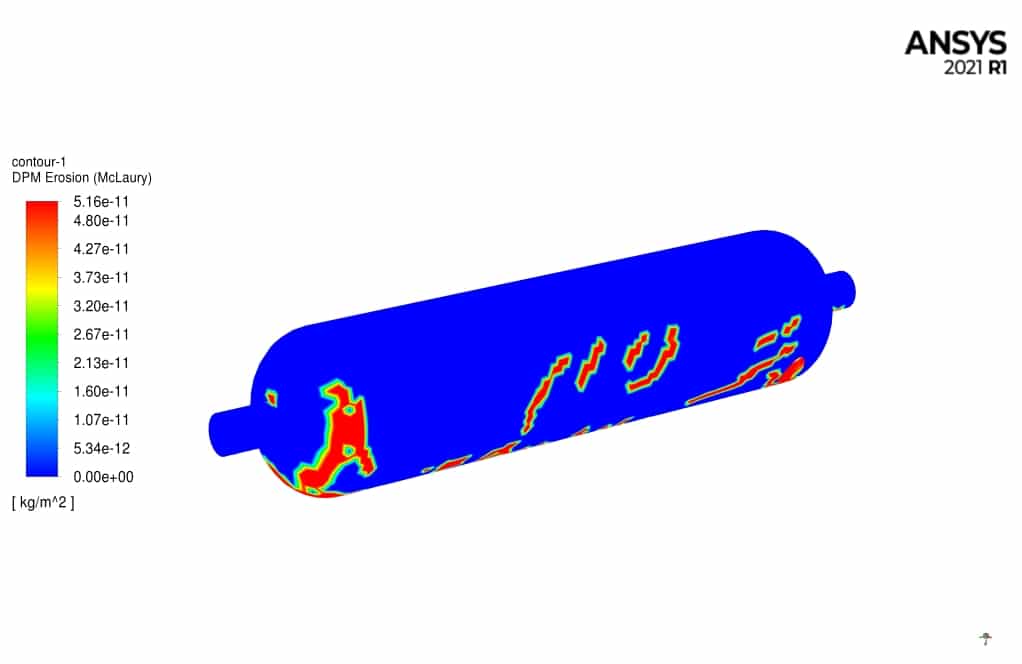

At the end of the solution process, outlet temperature, velocity, pressure, and erosion for the sedimentation and erosion simulation in a shell and tube are obtained. We see the amount of sand deposition in the shell. Erosion models are first examined.

In model Finnie, like Oka and Mclaury models, uses an empirical correlation to predict erosion. It is used primarily for malleable materials in which the Collision angle and velocity are effective.

The model Oka considers the effect of wall hardness and may be more suitable for investigating the erosion of transmission pipes. Model Mclaury is used to study suspended solids in water and was ideal for the present case.

| zone | The temperature of the inlet(k) | The temperature of the outlet(k) |

| Tube | 900 | 776 |

| shell | 400 | 414.28 |

| zone | oka [kg/m^2] | Mclaury [kg/m^2] |

| Tube | 2.452726e-10 | 3.028e-08 |

| shell | 4.9492331e-09 | 6.43e-07 |

Kareem Hyatt –

The provided study of sedimentation and erosion includes DPM method details, but could you please elaborate on how the simulation calculates and presents erosion rates on different surfaces within the shell and tube setup?

MR CFD Support –

In the simulation, the erosion rates are calculated based on the interaction of the particulate flow with the tube and shell surfaces. The software employs the use of specified erosion models, namely the Finnie, Oka, and Mclaury models, which take into account empirical correlations, impact angles, particle velocities, material hardness, and other factors to estimate the erosion rates. These are presented in terms of kilograms per square meter on respective surfaces within the domain, providing a quantitative measure of erosion that occurs within the shell and tube over the simulation period.

Oleta Batz –

I found the results for sedimentation and erosion models very interesting. Have the simulation results been validated against any real-world data or experimental results?

MR CFD Support –

There is no mention of validation against real-world data within the description provided. MR CFD simulations focus on using robust methods and adequate mesh-size to achieve accurate predictions, but for this particular simulation, no comparison with experimental data has been specified.

Mr. Rocio Langworth II –

I learned so much from the Sedimentation and Erosion CFD training course and found the techniques for calculating erosion particularly insightful. Could you please explain why different erosion models like Finnie, Oka, and Mclaury are chosen for analysis, and how do I decide which one to apply in different scenarios?

MR CFD Support –

Each erosion model, such as Finnie, Oka, and Mclaury, has been developed based on different empirical correlations and takes into account specific factors such as material hardness, particle impact angle, and velocity. The selection of an erosion model is contingent upon the material properties involved and the nature of the flow. For instance, the Finnie model is generally suitable for ductile materials where the impingement angle and velocity are imperative variables, while the Oka model is apt for assessing erosion when hardness of the wall is a significant factor. The McLaury model is particularly useful for evaluating the transportation of solids in fluids such as water. To decide which erosion model to apply, one must understand the characteristics of the system being analyzed, such as the type of materials involved (ductile or brittle), the operational environment (transportation of solids), and the required accuracy of prediction for a specific application.

Mr. Dallin Ruecker V –

I found the use of different erosion models in your simulation really insightful. It helped me understand how various factors like collision angle, velocity, material hardness, and particle-laden fluids affect erosion rates. The specific data on temperature changes and erosion rates provided a clear picture of performance under different operating conditions. Kudos on the successful application of the DPM method and erosion models for such a complex analysis!

MR CFD Support –

Thank you for your thoughtful review! We’re thrilled to hear that our simulation was able to provide you with a clear understanding of sedimentation and erosion dynamics in shell and tube systems. Your feedback is appreciated, and it emphasizes the value of integrating diverse erosion models to capture realistic operational influences. If you need further assistance or have more questions about our simulations or other products, feel free to reach out.

Prof. Daren Conn PhD –

I truly appreciated the depth of analysis in the sedimentation and erosion simulation study—the visualizations of erosion patterns and the temperature distribution inside the domain were especially informative and helpful for my project.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our sedimentation and erosion simulation was informative and aided in your project. At MR CFD, we strive to provide comprehensive and detailed analyses to support our customers’ success. If you need further assistance or have more projects in the future, do not hesitate to reach out.

Willard Harber –

I thoroughly enjoyed the comprehensive nature of the sedimentation and erosion simulation training. The incorporation of different erosion models ensured a broader understanding of particle behavior in different materials, essential for accurate predictions in my field work.

MR CFD Support –

Thank you for your positive feedback on the sedimentation and erosion simulation training. We’re delighted to hear that the in-depth analysis and variety of erosion models provided in the course have enhanced your comprehensive understanding and will be beneficial in your professional applications.

Mr. Casimir Jacobson V –

Just superb! The detail in your simulation for sedimentation and erosion clearly demonstrates the power and versatility of using ANSYS Fluent for CFD studies. The dual-phase modeling with the Water and Oil while considering temperature distributions and using different erosion models gives a very thorough understanding of the system! Awesome job by the MR CFD team!

MR CFD Support –

Thank you very much for your kind words! We’re thrilled to hear that you found the simulation valuable and insightful. MR CFD is always excited to help our customers gain a comprehensive understanding of fluid dynamics and we look forward to providing more quality simulations to assist your future studies!

Irma Frami –

I am thoroughly impressed by the thoroughness of the sedimentation and erosion simulations in shell and tube systems. It is fascinating to see how modern tools like ANSYS Fluent can predict complex phenomena like erosion using various erosion models and the DPM method. This knowledge can be crucial for the design and operation of industrial piping and equipment to prevent premature failure due to erosion.

MR CFD Support –

Thank you for your positive review! We are pleased to hear that you recognize the comprehensive and detailed approach of our CFD simulation training for sedimentation and erosion in shell and tube systems. It’s our goal to provide useful and accurate analysis using ANSYS Fluent software to assist in better understanding and managing erosion challenges in industrial applications. Your acknowledgment motivates us to continue delivering high-quality CFD education and analysis.

June Upton –

I’m impressed with the level of detail in this simulation. Has the simulation accounted for different particle sizes affecting erosion rates, or is it based on a uniform particle size assumption?

MR CFD Support –

Thank you for your positive feedback! The simulation indeed considers varying particle sizes affecting erosion rates. It utilizes the Rosin-Rammler diameter distribution to simulate the realistic particle size distribution within the domain, which is crucial for accurately predicting erosion phenomena. Various erosion models also help in assessing the impact of these particles under different working conditions.

Jana Yost –

This training gives a clear understanding of sedimentation and erosion effects, but could you explain why it’s necessary to use different erosion models like Finnie, Oka, and McLaury?

MR CFD Support –

The use of different erosion models, such as Finnie, Oka, and McLaury, is necessary to account for various factors that influence erosion. Each model is developed based on different empirical correlations and considers different aspects such as the collision angle, velocity, material hardness, and the characteristics of suspended solids. By employing a range of models, engineers and researchers can compare the predictions and choose the most suitable one for the specific conditions of their project, ensuring accurate and reliable simulation results.

Prof. Russel Schiller II –

I’ve learned new skills thanks to the detailed sedimentation and erosion simulation training. It was intriguing to see how DPM and erosion models can be applied in a real case scenario. Well done MR CFD!

MR CFD Support –

Thank you for sharing your positive experience with our sedimentation and erosion simulation in a shell and tube with ANSYS Fluent software training. We strive to provide useful and comprehensive courses and are glad to hear you found them helpful. Keep up the good work in applying what you’ve learned to real-world situations!

Alan Kuphal –

I was really impressed with how thorough the explanation of the sedimentation and erosion process is outlined in the training! The use of specific erosion models to measure impact provides a clear understanding. I would love to know how effective these simulations are when compared to actual experimental data?

MR CFD Support –

Thank you for your positive feedback on our training resources! Regarding your question on the effectiveness of our simulations compared to actual experimental data: CFD simulations like the ones performed using ANSYS Fluent can be incredibly accurate when properly calibrated and validated against experimental data. They enable us to predict complex fluid dynamics and interactions such as erosion and sedimentation with high fidelity. Users can fine-tune models with real-world data to ensure congruity between simulation predictions and experimental outcomes.

Ms. Laisha Heller –

This is my first time learning about the discrete phase model for CFD analysis. The sedimentation and erosion study you provided was incredibly detailed and thorough. I really like how the DPM captures the particle behavior that might not be evident from a single-phase flow perspective.

MR CFD Support –

Thank you for the positive feedback about our Sedimentation and Erosion training with Ansys Fluent. We’re glad to hear that the detailed explanation of the DPM model provided you with a clear understanding of multiphase flow simulation and its complexity. It’s rewarding to know that our efforts to provide comprehensive training material are appreciated!

Jakayla Runolfsson –

I was really interested by the sedimentation and erosion study. Can you tell me if the simulation could be applied to different materials within the tube, and how might that impact erosion rates?

MR CFD Support –

In the simulation, different materials within the tube would indeed affect the erosion rates. The materials’ properties, such as hardness, ductility, and yield strength, directly influence erosion. The erosion models available in ANSYS Fluent, such as Finnie, Oka, and McLaury, include empirical correlations which take into account these material properties. Thus, a change in material may require recalibration of the erosion model parameters to accurately predict the rate of erosion according to the new material’s characteristics. The provided training helps users understand how to implement these changes in ANSYS Fluent and interpret the results accordingly.

Miss Courtney Fisher –

The details in this training seem extensive and practical. Can you let me know if pre-processing for the DPM simulation is covered in the course, such as particle injection and specific boundary conditions for particles?

MR CFD Support –

Yes, the training covers pre-processing for the DPM simulation, including the setup for particle injection, defining particle materials, and specifying all necessary boundary conditions for particles in the ANSYS Fluent module. This allows you to understand how sediment particles interact with the fluid flow and the consequent erosion effects on the structure.

Kenton Rodriguez –

This training seems thorough, has the sedimentation effect been visualized dynamically, and can we see these changes in erosion over time with the CFD analysis depicted in this product?

MR CFD Support –

Yes, the sedimentation effect is visualized dynamically and you can see the changes in erosion over time. The CFD analysis captures the transient behavior of the particles within the shell and tube system, and the simulation results include visualization of the sediment deposition as well as the erosion effects on the walls of the tube and shell.

Amara Adams –

After completing this training, I feel confident in my ability to analyze sedimentation and erosion processes using ANSYS Fluent. The attention to detail and the comprehensive overview of different erosion models were particularly beneficial. It’s impressive to see the erosion predictions using the Oka and Mclaury models. Thank you for offering this valuable learning experience.

MR CFD Support –

Your positive feedback is greatly appreciated! We are delighted to hear that our training has enhanced your understanding and skills in utilizing ANSYS Fluent for sedimentation and erosion analysis. It is wonderful to know that the detailed explanation of the erosion models proved to be helpful. If you have any further queries or require more assistance, feel free to reach out. Thank you for choosing our training materials.

Miss Kaitlin Stracke DVM –

Wow, the level of detail in simulating erosion using different erosion models is quite impressive! How do different erosion models affect final predictions compared to actual material properties and operational conditions?

MR CFD Support –

Thank you for your positive feedback! Different erosion models take into account varying factors like the collision angle, particle velocity, wall hardness, and material malleability. These factors affect the accuracy of the predictions in relation to the actual materials being used in the simulation and their operating conditions. For instance, the Finnie model is suitable for malleable materials and emphasizes collision angles and velocities. The Oka model includes the wall’s hardness, making it perhaps more precise for studies with harder transmission pipes. Meanwhile, the McLaury model is apt for situations involving suspended solids in fluids, such as water with sand. Therefore, by choosing closer representative erosion models, the predictions are more likely to align with real-life scenarios.