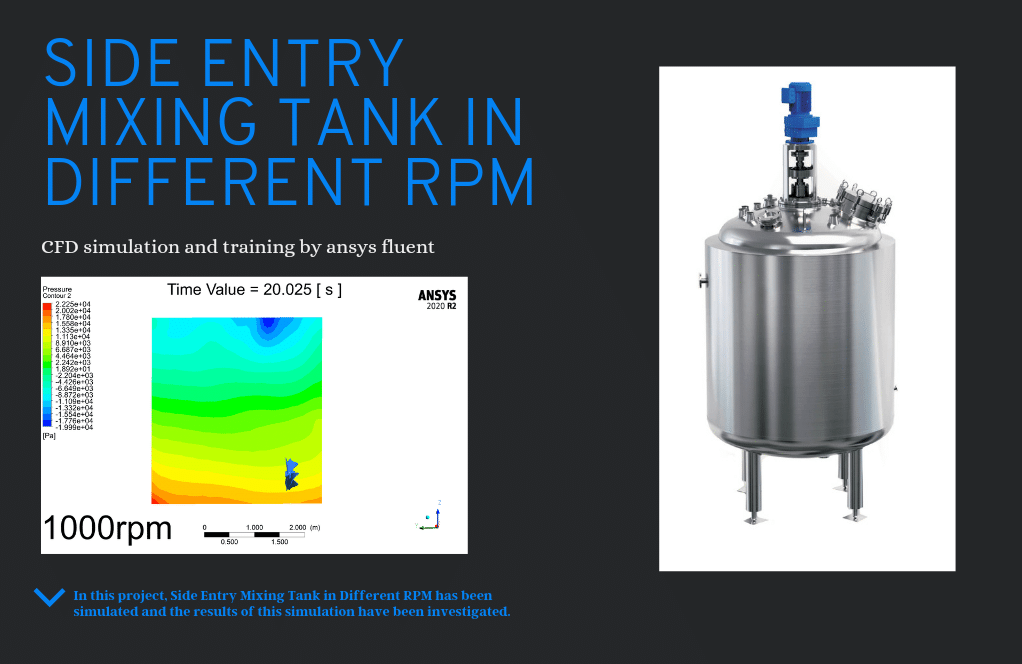

Side Entry Mixing Tank in 3 Different rotational speeds, Ansys Fluent CFD Simulation Training

$180.00 Student Discount

In this project, Side Entry Mixing Tank in Different RPM has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description

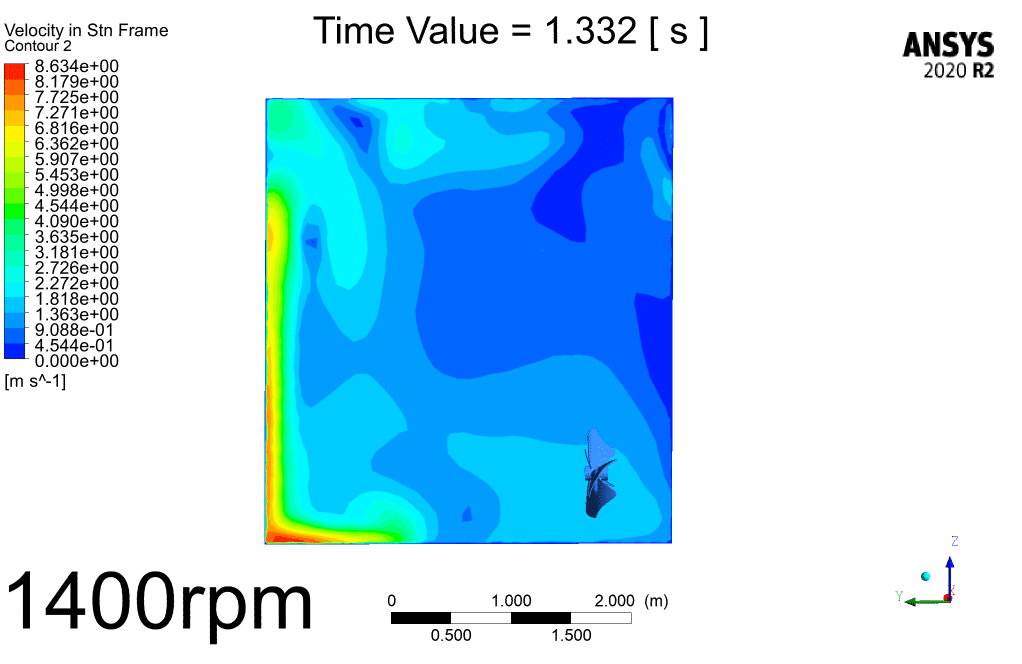

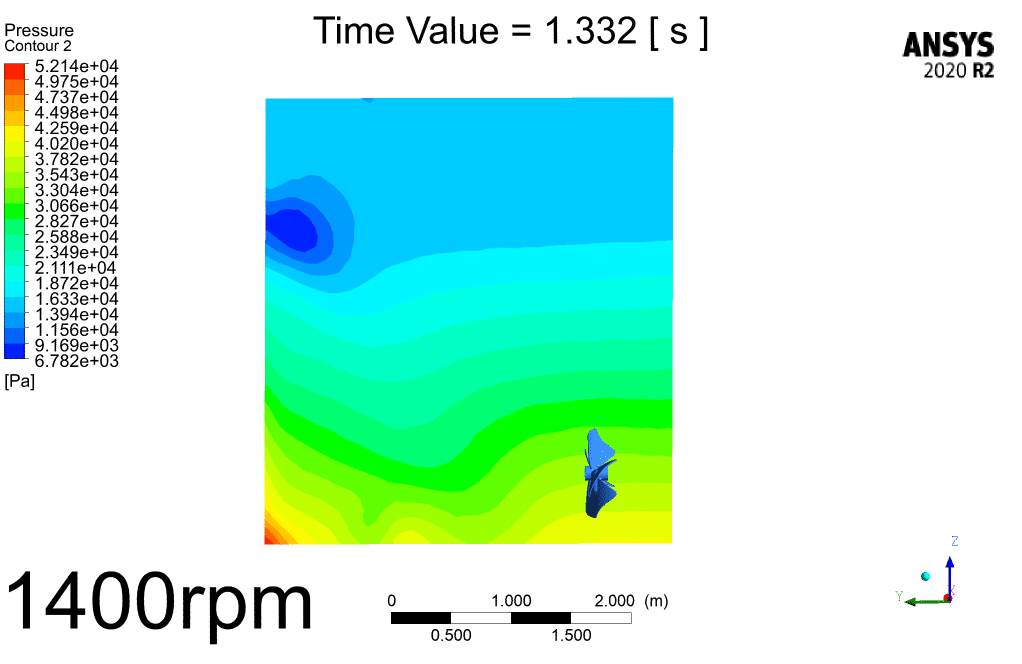

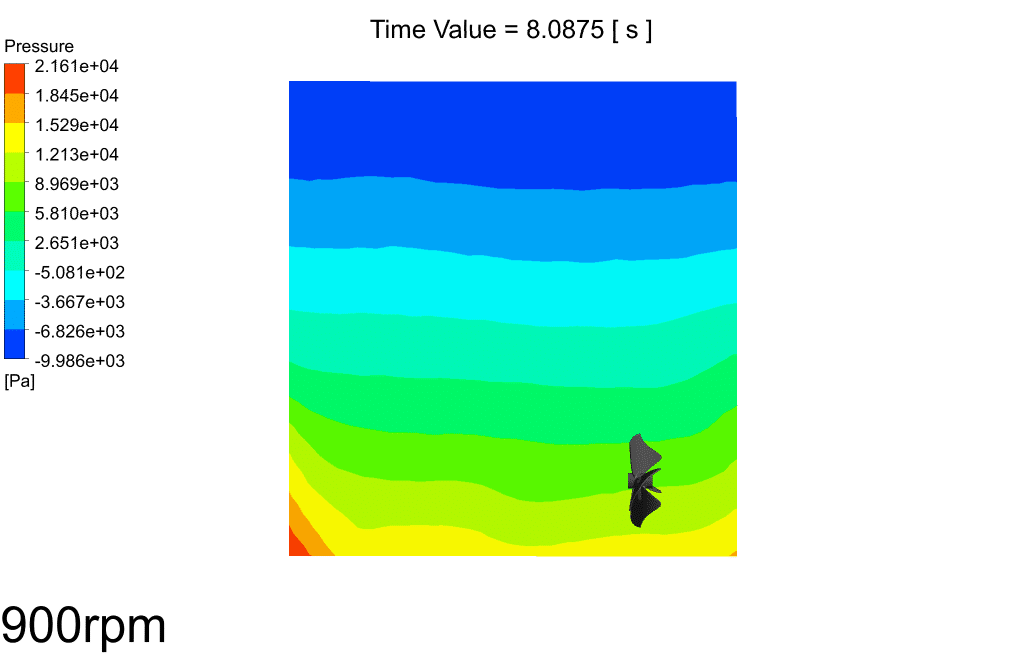

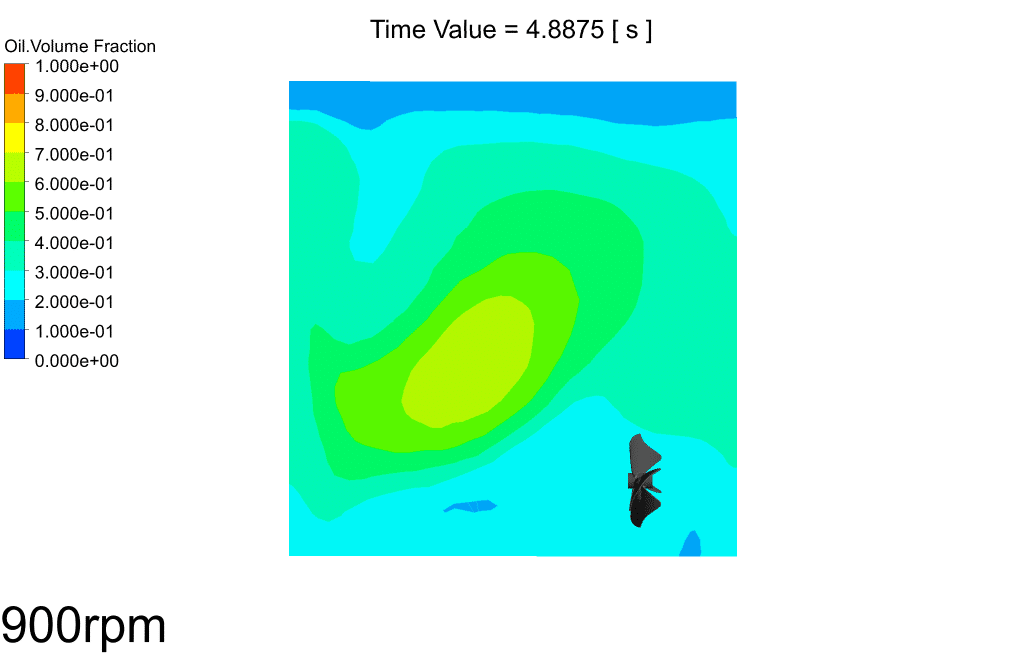

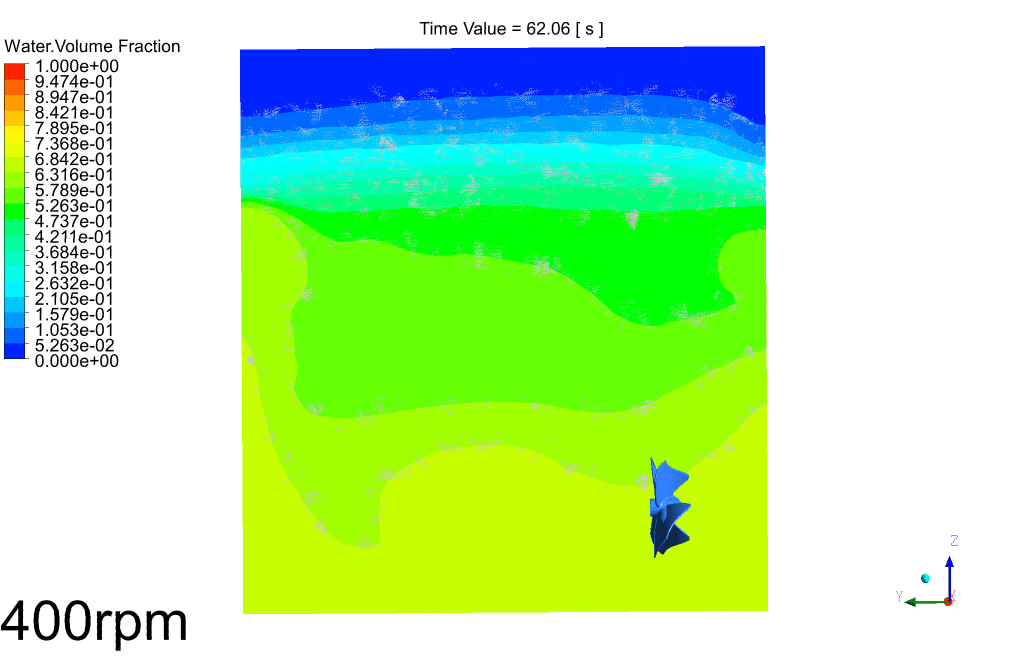

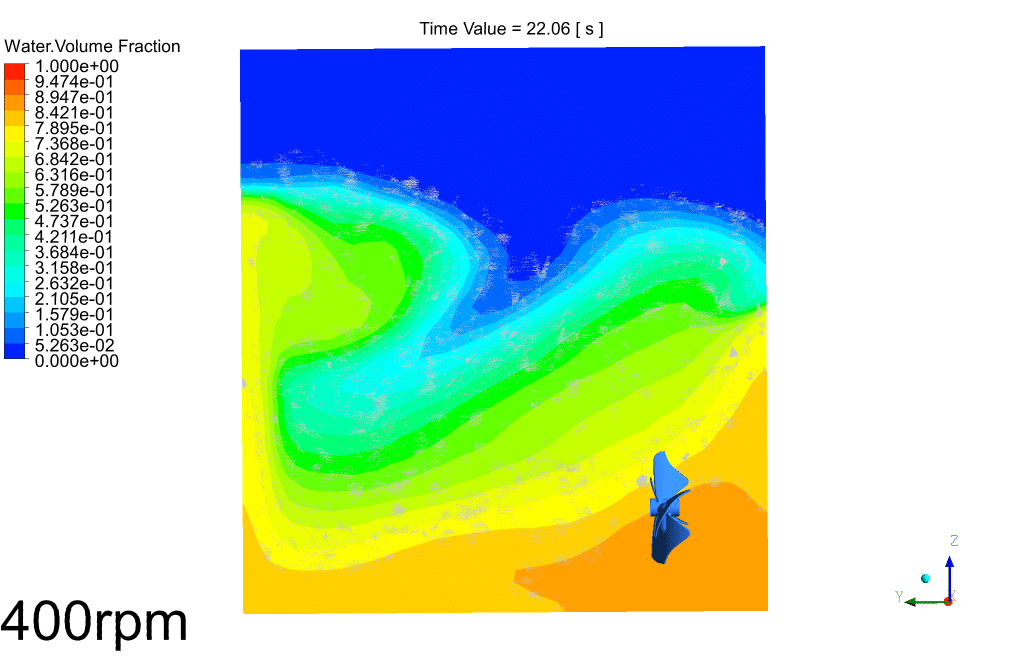

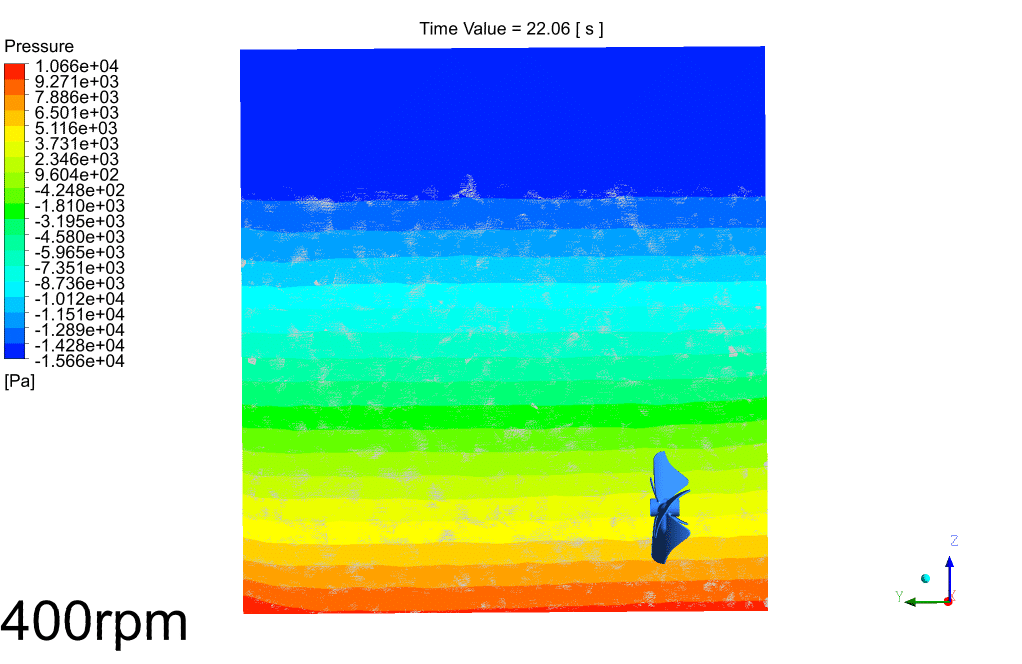

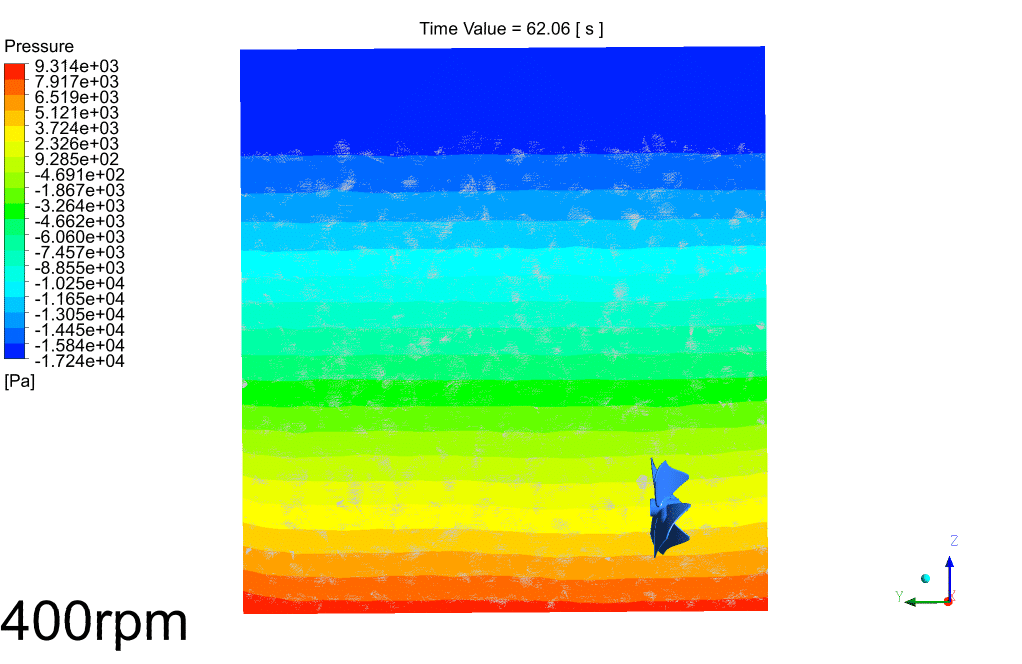

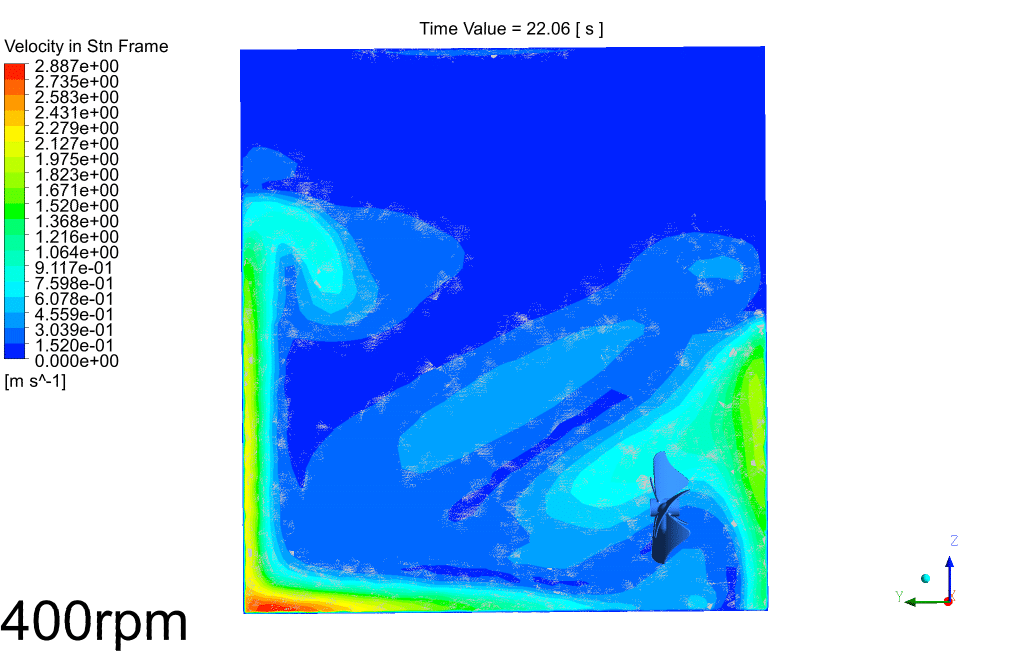

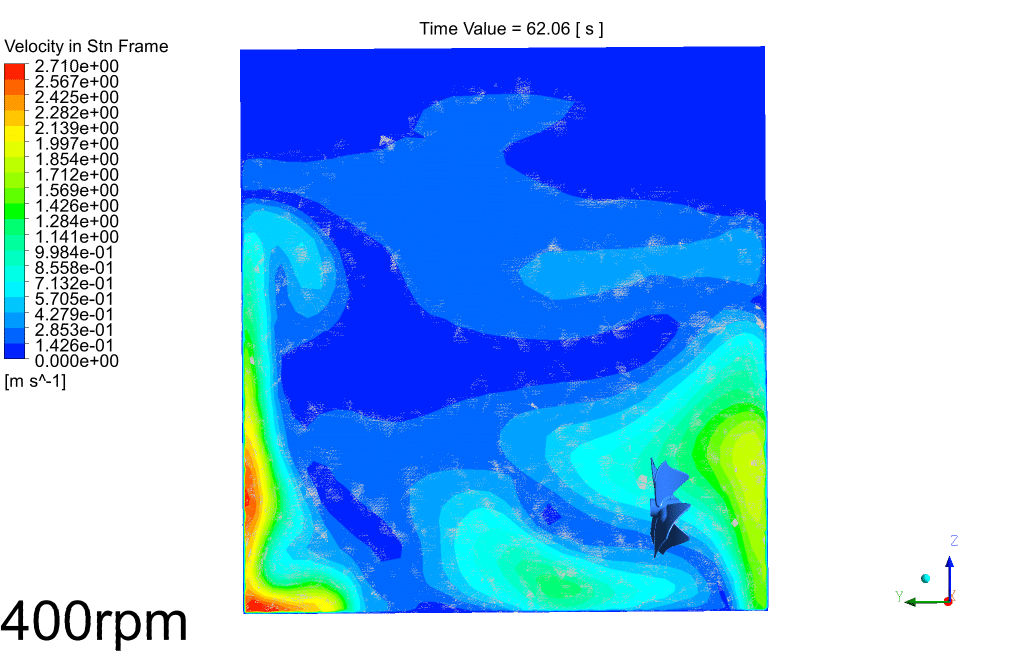

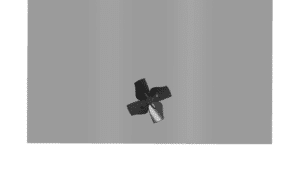

In this project, Side Entry Mixing Tank in Different RPM has been simulated by Ansys Fluent Software. which has been done by the CFD numerical simulation method by Ansys Fluent software, a mixing tank has been simulated. The mixing process is essential in many industries; for example, in the oil and gas industry, water deposition causes much damage to storage tanks, which causes corrosion, leakage, and perforation of the source. Side mixing blades are used to prevent these events because in most positions, due to space limitations, the blade can not enter the tank from above. This simulation is performed at different rotational speeds of 400 and 900 and 1400 rpm with the mesh motion method.

Geometry & Mesh

The three-dimensional geometry of this project is designed with Spaceclaim software. The length of the computational area is 400 cm, the width is 400 cm, and the height is 375 cm.

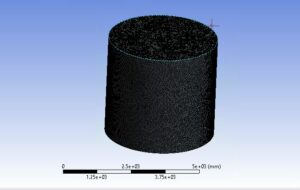

ANSYS Meshing produces the grid of the computational area, and the number of elements is 933102, which is made of relatively small grid elements.

Side Entry Mixing Tank CFD Simulation

To simulate this acoustic project, several assumptions are considered:

- We perform a pressure-based solver.

- The simulation is unsteady (Transient)

- We consider the gravity (-9.81 m^2/s) in the z-direction.

The following table represents a summary of the defining steps of the problem and its solution:

| Viscous | k-epsilon | |

| k-epsilon model | standard | |

| near-wall treatment | standard wall functions | |

| Multiphase | VOF | |

| Phase 1 | air | |

| Phase 2 | oil | |

| Phase 3 | water | |

| Boundary conditions | ||

| Wall | Wall Motion | Stationary wall |

| Frame motion | On | |

| Fluid | Rotational velocity | Case1: 400 rpm & Case2: 900 rpm & Case 3: 1400 rpm |

| Methods | ||

| Pressure-Velocity Coupling | simple | |

| Pressure | PRESTO | |

| momentum | second-order upwind | |

| turbulent kinetic energy | first-order upwind | |

| turbulent dissipation rate | first-order upwind | |

| Initialization | ||

| Initialization methods | Standard | |

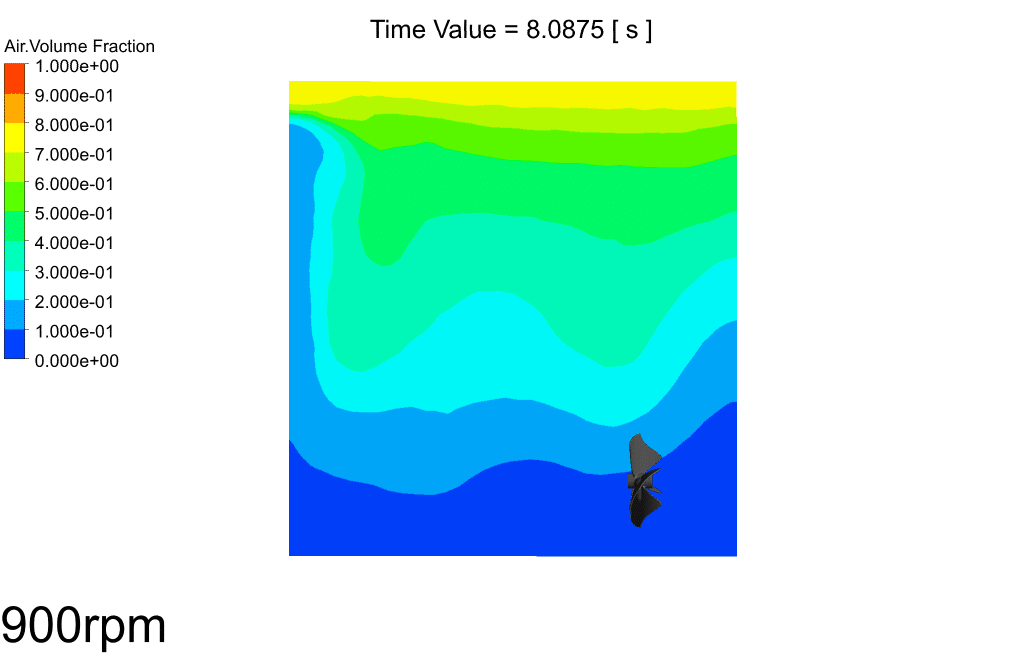

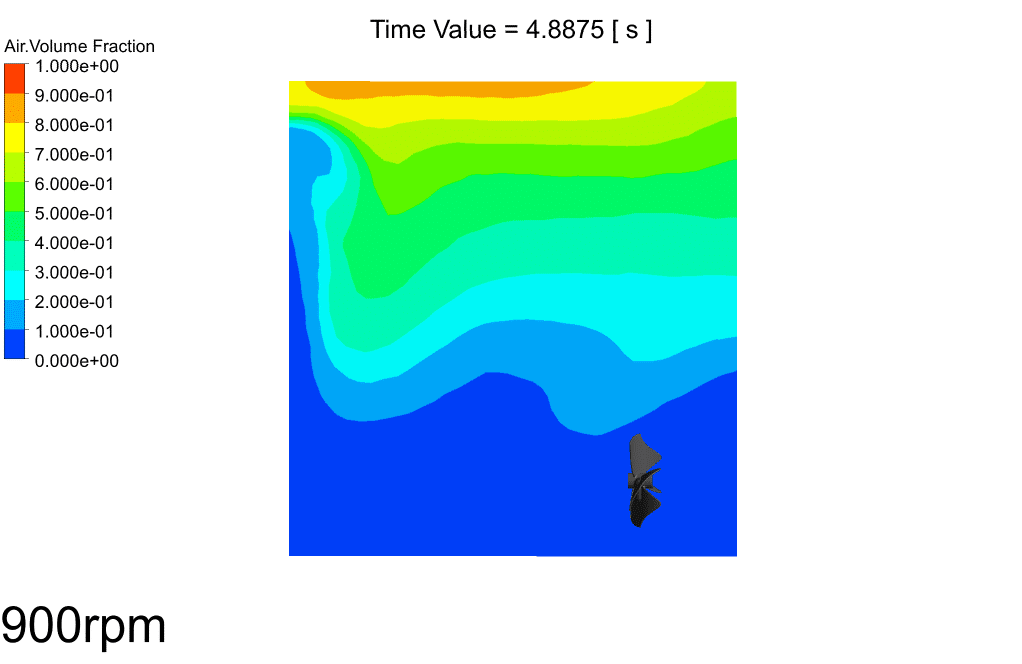

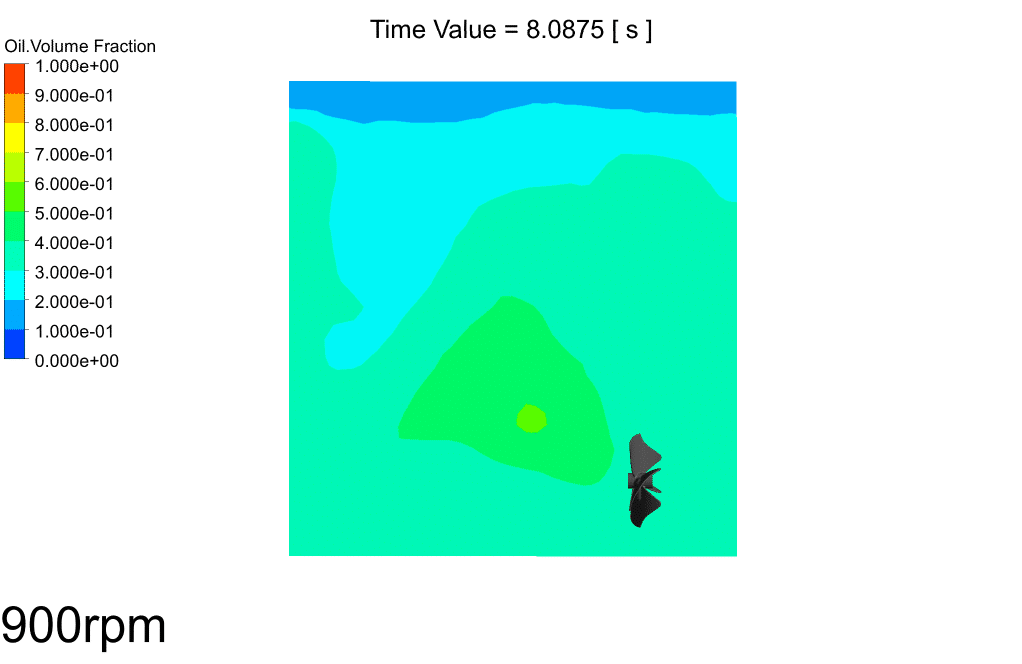

Side Entry Mixing Tank Results

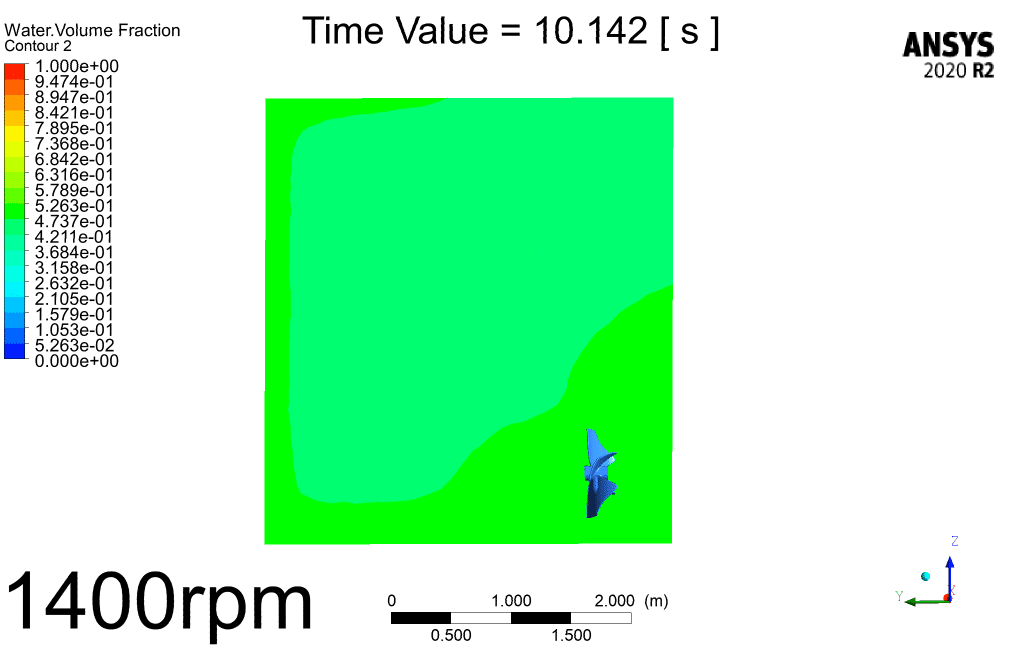

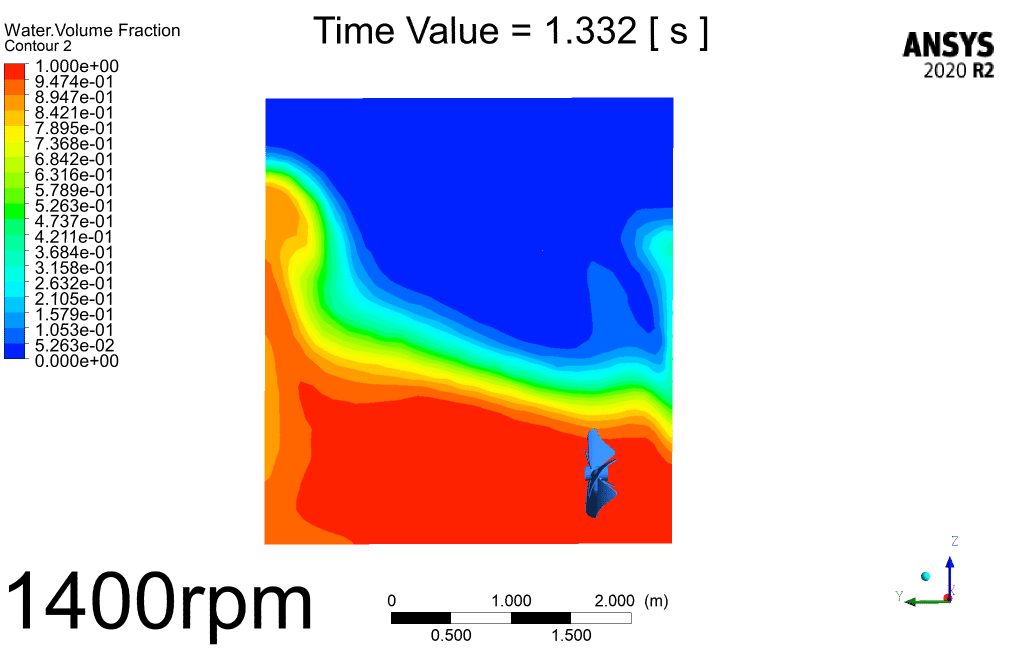

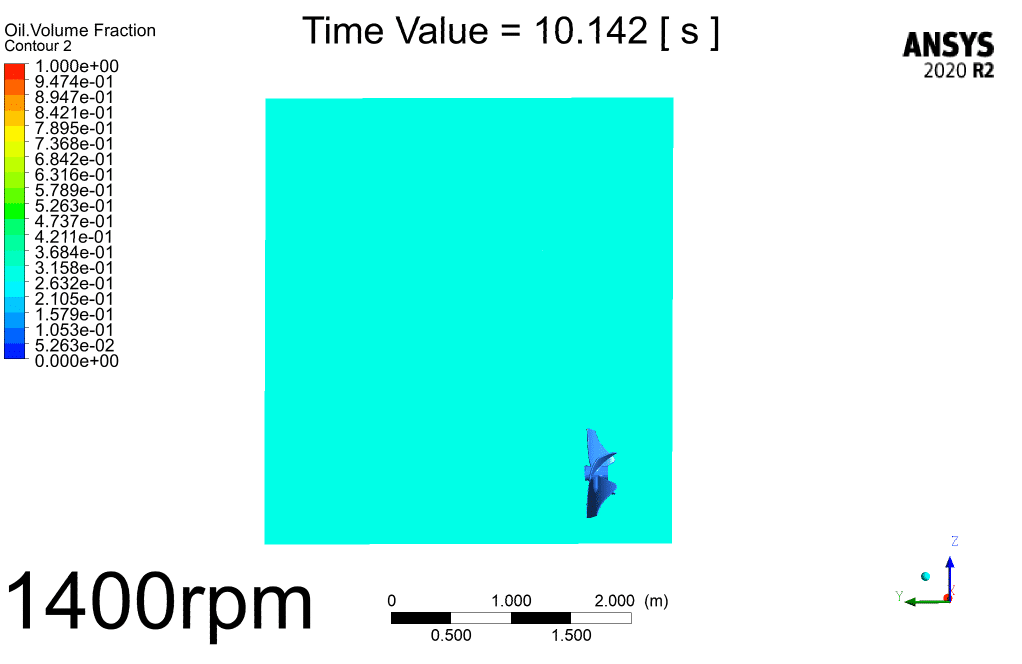

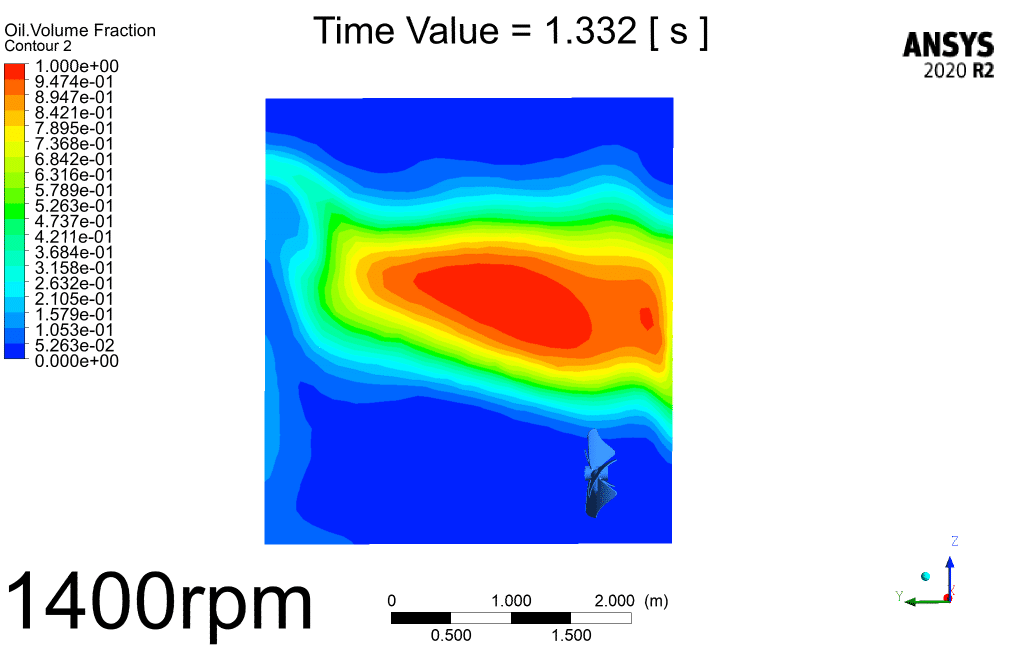

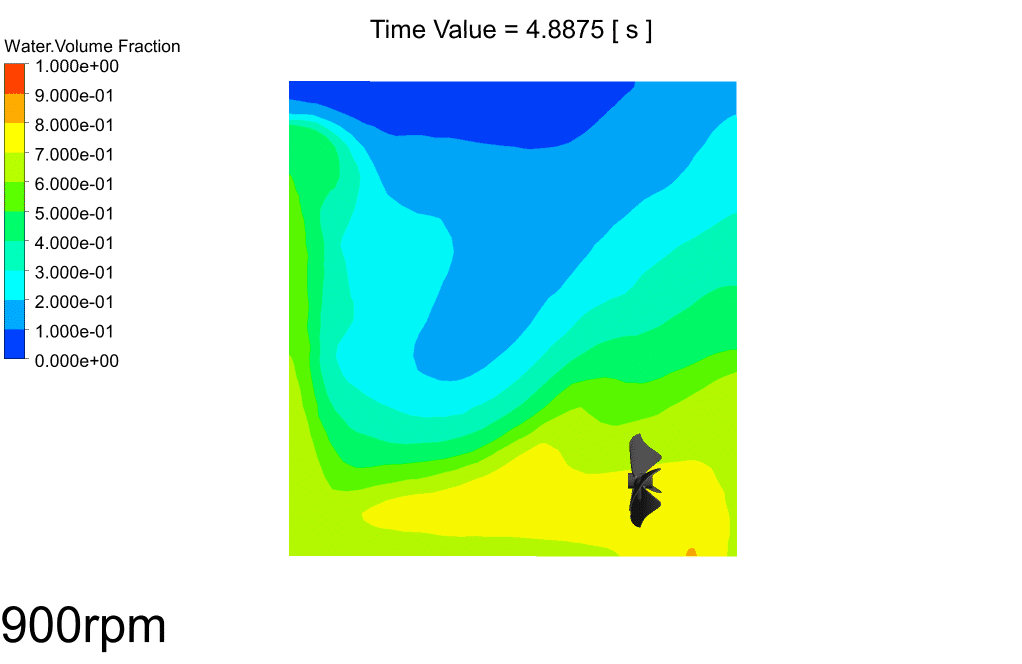

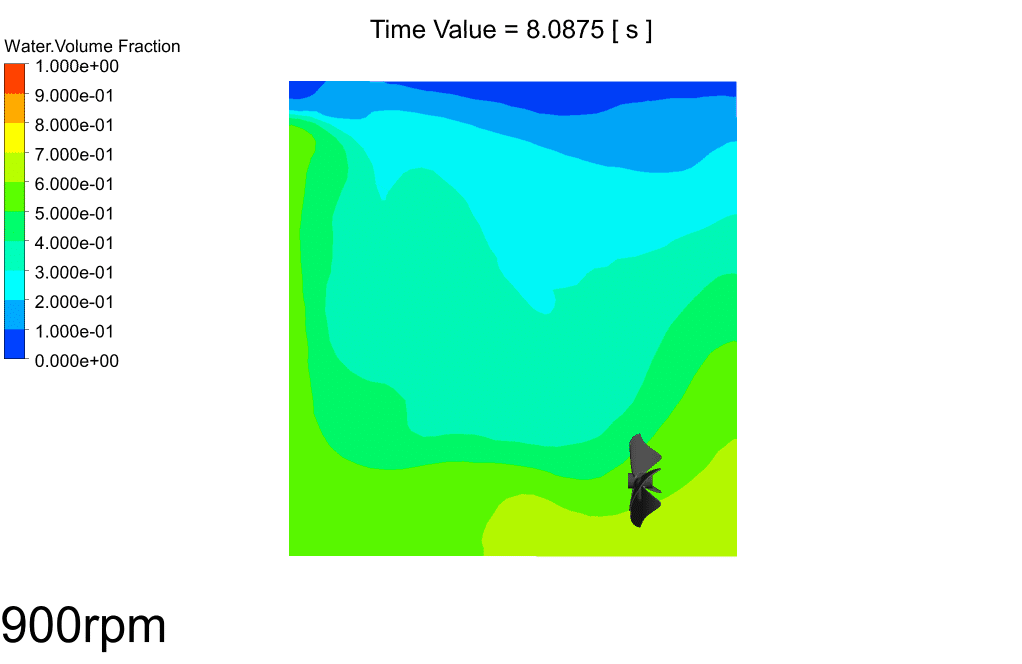

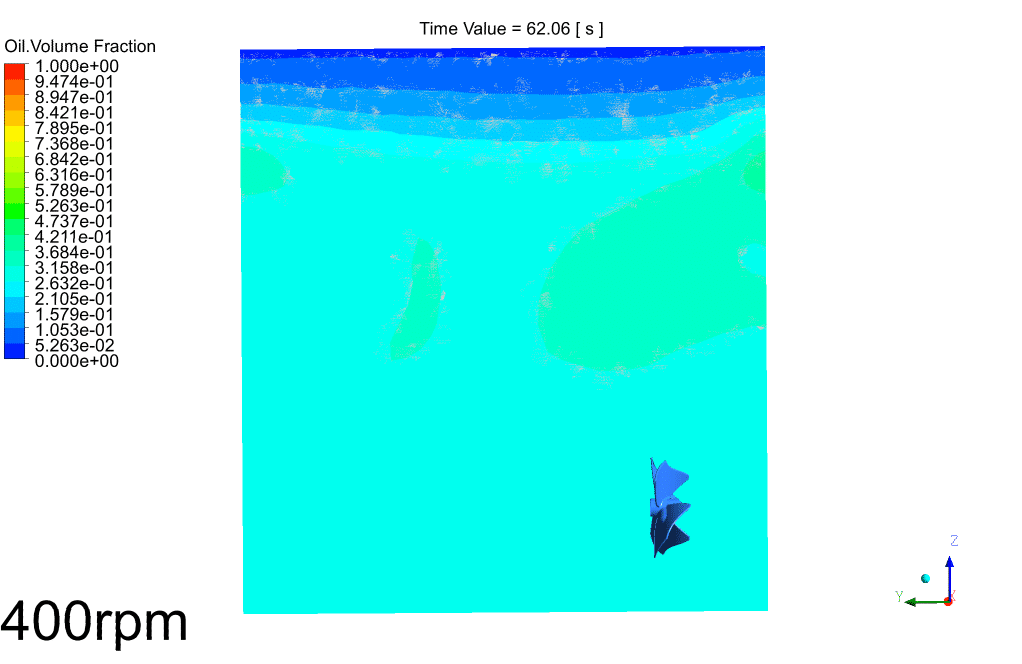

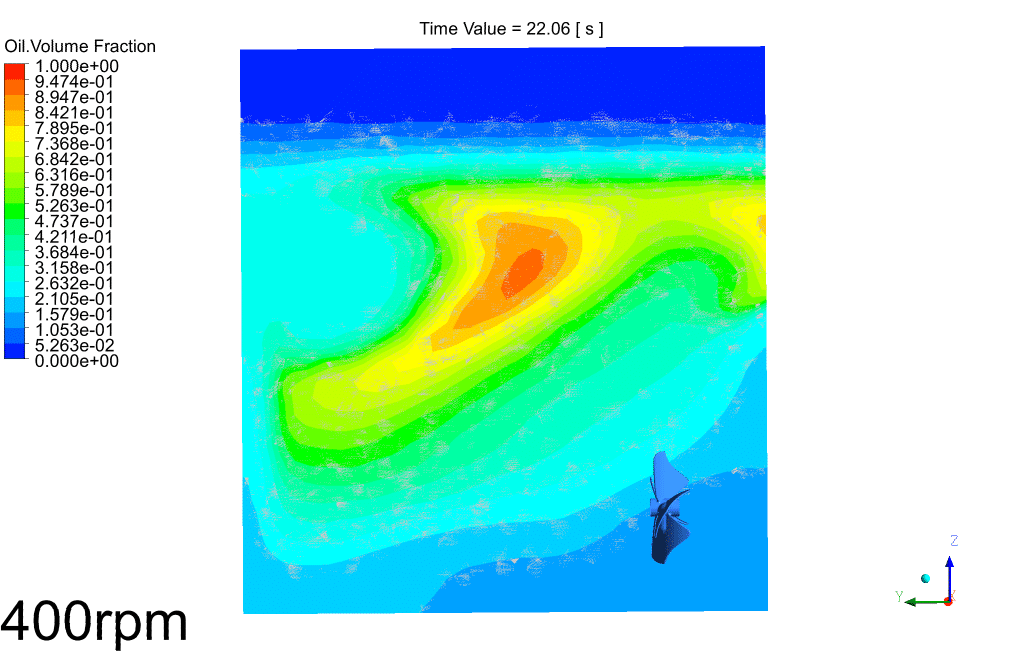

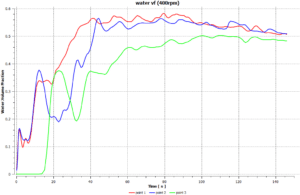

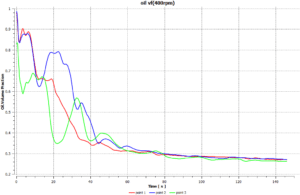

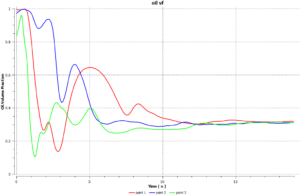

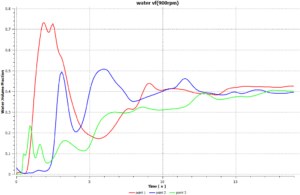

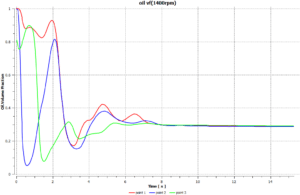

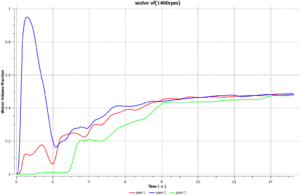

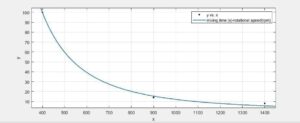

In this simulation, the mixing tank contains water and oil, in which water settles to the bottom of the tank due to its higher density. We mixed the tank’s contents using a side mixer that rotates at 1400, 900, and 400 rpm. We want to get the perfect mixing time for each item. We checked the complete mixing criterion using three sensors placed in different positions of the tank and plotting the volume fraction of oil and water for all three points overtime on the chart. According to these charts, the mixing time is 100 seconds for 400 rpm, 14 seconds for 900 rpm, and 8 seconds for 1400 rpm

Given this trend, it is clear that increasing the rotational speed to a certain extent (here 900 rpm) is very useful for us and reduces the mixing time considerably, but increasing it too much has little effect on the mixing time And we can ignore it and naturally our cost of choosing an engine will be reduced

Prof. Ora Prosacco –

I am thrilled with the clarity of the results across different RPMs for the Side Entry Mixing Tank simulation. It is particularly impressive how the increased rotational speed to 900 RPM drastically reduces the mixing time compared to 400 RPM, whilst further increases above 900 RPM show diminishing returns on mixing efficiency. This insightful outcome must be incredibly beneficial for optimizing industrial processes with respect to equipment selection and operational costs.

MR CFD Support –

Thank you for taking the time to leave such a positive review! We’re glad to hear that you found the simulation results informative and valuable for industrial applications. It’s great to know our product is helping customers understand and optimize their processes more effectively. Your feedback is highly appreciated, and we are delighted that our simulation training has met your expectations.

Dr. Brenna Olson –

Very impressed with the level of detail in the Side Entry Mixing Tank training simulation! Seeing the different rotational speeds and their effects on the mixing process brought the theoretical aspects to life!

MR CFD Support –

Thank you for the positive feedback on our Side Entry Mixing Tank CFD simulation training! We are delighted to know that the details provided in the simulation have been effective in demonstrating the practical applications of rotational speed variations and have enriched your learning experience. Your satisfaction is our top priority.

Fiona Ledner –

I’m impressed with your versatile analysis of different RPM on the mixing efficiency. The precision in determining the perfect mixing times is crucial for optimizing industrial processes.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you find our analysis of the mixing tank at different rotational speeds useful and precise. Optimizing industrial processes is a focus for our simulations, and it’s great to know our efforts resonate with you. If you ever need any more detailed information or have more feedback, feel free to reach out to us.

Annabel Dietrich –

I’m thrilled with how thorough your training material on Side Entry Mixing Tanks with various rotational speeds was! The steps were clear and the CFD simulation method really clarified how different speeds can impact the efficiency of the process.

MR CFD Support –

Thank you so much for your kind words! We’re extremely pleased to learn that you’ve found the training material on the Side Entry Mixing Tank simulation comprehensive and informative. Your feedback is highly appreciated, and we’re glad our efforts could provide valuable insights into the important parameters affecting mixing efficiency.

Granville Huels II –

I’m intrigued by the simulation’s practical application. Do you have a visual guide available to showcase how the rotational speeds affect the mixing process?

MR CFD Support –

We appreciate your interest! Unfortunately, as a response system, we don’t have the facilities to directly provide visual materials, but MR CFD Company typically provides visual results and detailed observations within their training products. You may find related images or possibly videos demonstrating fluid dynamics at various rotational speeds directly on their website or included in the course materials upon purchase.

Mazie Parisian –

I’m impressed with how the simulation demonstrates the relationship between rotational speeds and mixing time. Great analysis showing that beyond a point, a higher speed doesn’t significantly impact mixing efficiency.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our analysis on the effects of rotational speeds on mixing times was insightful and helpful to you. Your feedback is greatly appreciated, and we’re glad the CFD simulation training was able to convey the complexity of mixing processes effectively.

Marlin Klein –

The project beautifully depicts the dependence of mixing efficiency on rotational speed. I was particularly impressed with the strategic placement of sensors to track the mixing process. It seems like a thoroughly comprehensive study.

MR CFD Support –

Thank you for your positive feedback on the Side Entry Mixing Tank simulation project. We strive to ensure our simulations are comprehensive and articulate to provide a deep understanding of such phenomena. We’re thrilled to hear that you recognized and enjoyed the level of detail, including our sensor placement strategy for monitoring the mixing process!

Maxwell Luettgen –

I’m impressed by the clarity of your simulation results showing the impact of different rotational speeds on the mixing process. Could you please detail the criteria used to determine the perfect mixing time?

MR CFD Support –

Thank you for your appreciation! The perfect mixing time was determined by placing three sensors at various points inside the tank. These sensors monitored the volume fraction of oil and water over time. The mixing time was deemed complete when the observed volume fractions at all three sensor locations stabilized and became uniform, indicating a homogeneous mixture.

Mr. Murphy Franecki DVM –

Your comprehensive details on the Side Entry Mixing Tank CFD simulation are fantastic! I learned a lot about how varying the rotational speed impacts the mixing time, which is vital for optimizing industrial processes. The clear explanation of your simulation setup and the specific rotational speeds that were analyzed really made it easy to understand the effectiveness of side mixing blades. Plus, the consideration of rotational speed concerning cost-efficiency is a valuable point for industry applications. Thank you for a well-executed analysis!

MR CFD Support –

Thank you for the kind words and positive feedback! We’re delighted to hear that our Side Entry Mixing Tank CFD simulation training has provided you with valuable insights. Your appreciation motivates us to continue delivering high-quality learning materials. If you have any further questions or need more information, feel free to reach out. Happy simulating!

Clara Cole –

The information on how the mesh motion method is applied at different RPMs helped me tremendously. Thank you for the detailed steps on setting up the multiphase and boundary conditions as well!

MR CFD Support –

We are thrilled to hear that our simulation of the Side Entry Mixing Tank at different rotational speeds provided the clarity needed for your understanding. Your appreciation for the detailed setup instructions and mesh motion application dismisses any doubt about the thoroughness of your learning. Thank you for choosing our training materials, and we look forward to your continued satisfaction with our products!

Dr. Cydney Goldner MD –

The detailed analysis of the Side Entry Mixing Tank CFD simulation showcases a thorough understanding of different rotational speeds’ impacts. I’m amazed at how the simulation captures the effects of changes in rpm so vividly.

MR CFD Support –

We appreciate your positive feedback! It’s great to hear that the simulation provided clear insights into the dynamic behavior of mixing tanks under various conditions. If you need further information or assistance, please don’t hesitate to reach out.

Dr. Neha Lockman –

Outstanding training material! The detailed explanation of the setup and results for different RPMs provides valuable insights for understanding the mixing process in the storage tanks. It is clear that a lot of thought went into making this experience as close to the real-world scenario as possible.

MR CFD Support –

Thank you for your positive review! We’re thrilled to hear that our Side Entry Mixing Tank CFD Simulation Training has been helpful and that you appreciate the detailed setup and analysis. We always strive to provide realistic and thorough training materials. If you have any more feedback or require further learning materials, feel free to reach out.

Prof. Kathryn Rutherford –

The detailed explanation of the different rotational speeds and their effects on mixing is excellent. It really helps in understanding how changing certain parameters can optimize the process.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our comprehensive CFD simulation training has enhanced your understanding of process optimization. Your satisfaction with our learning products is our top priority. If you have any further questions or need assistance, feel free to reach out!

Yvette Schimmel –

Your training helped me understand mixer dynamics really well. The progression of simulation at different RPMs was clear, and the charts were particularly insightful!

MR CFD Support –

Thank you for the positive review! We’re glad to hear that our training materials on the Side Entry Mixing Tank simulation were insightful and that the charts aided in your understanding of the mixing dynamics. We always strive to provide clear and comprehensive explanations oriented to practical applications. Should you have any more questions or require further learning materials, don’t hesitate to get in touch!

Hipolito Stark –

The final results indicate a decrease in the mixing time as the RPM increases. Could you provide more detail on how the mixture uniformity was assessed and determined?

MR CFD Support –

Absolutely! The mixture uniformity was determined through numerical sensors placed at various locations in the tank. The volume fraction of oil and water was recorded over time, allowing us to observe the rate of mixing. Additionally, by examining both transient behavior and established mixture uniformity at timed intervals, it was possible to ascertain when the mixture reached a homogeneous state at each rotational speed.

Eric Runte –

I’m thrilled with the detailed explanation of the Side Entry Mixing Tank simulation! It was useful to see the practical applications, especially how the different RPM values impact the mixing time.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that the simulation was helpful and provided you with a clear understanding of how rotational speeds affect mixing efficiency. We’re committed to delivering practical and educational content that meets our customers’ needs. If there’s anything else you’d like to explore, don’t hesitate to reach out or check our other offerings!

Andre Luettgen MD –

Where are the sensors located in the tank, and how do they measure the perfect mixing time?

MR CFD Support –

The sensors in the tank are located at different positions to accurately measure the concentration of oil and water throughout the mixing process. They record the volume fraction of oil and water overtime, and perfect mixing time is determined by analyzing when the sensor readings indicate a uniform mixture across all sensors. The faster the approach to a homogeneous mixture, the more efficient the mixing process at a given rotational speed.

Sabryna Lynch –

This training seems quite comprehensive. I am interested to know, how does changing the rotational speed affect the simulation time and computational resources required?

MR CFD Support –

Increasing the rotational speed of the mixer does make the simulation more complex and could potentially increase the computational resources and simulation time required due to the higher number of interactions at each time step. However, it primarily depends on the capabilities of the solver and computational setup utilized in ANSYS Fluent.