Single Slope Solar Still, Paper Numerical Validation, ANSYS Fluent CFD Simulation Training

$480.00 Student Discount

- The present problem simulates the surface evaporation process within a solar desalination system using ANSYS Fluent.

- We design the 2-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 8200.

- The present project is validated by a reference article.

- We perform this simulation as unsteady (Transient).

- We use the Mixture Multi-Phase model to define air, water and vapor.

- We used a UDF to define a mass transfer between water and vapor, based on surface evaporation.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates the surface evaporation process within a solar desalination system using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

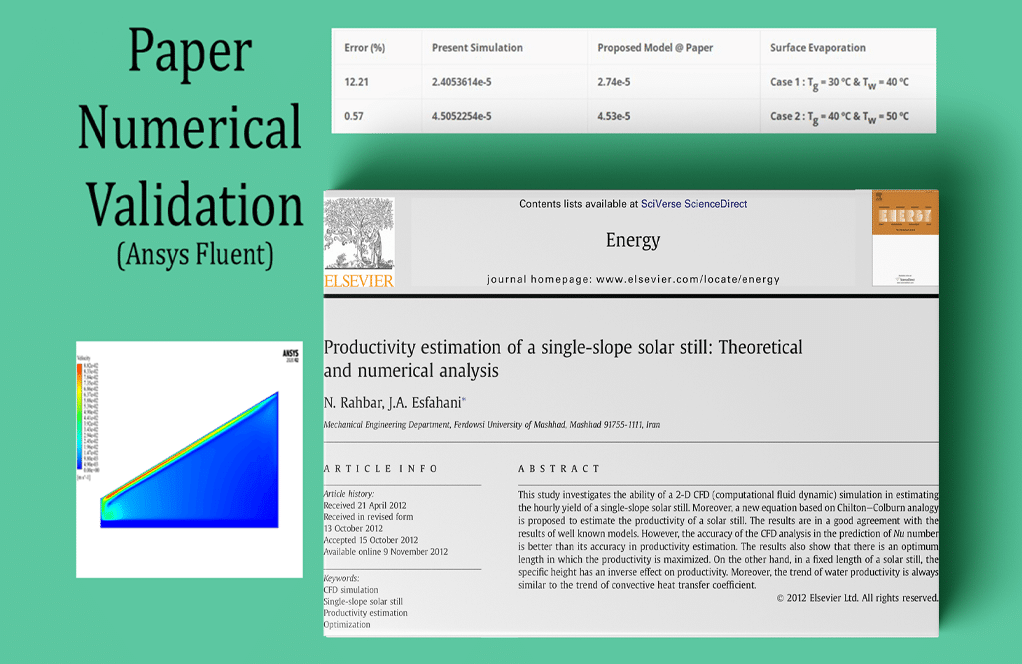

This simulation is based on the information of a reference article [Productivity estimation of a single-slope solar still: Theoretical and numerical analysis], and its results are compared and validated with the results in the article.

In general, evaporation is a surface process that occurs at any temperature on the liquid surface. In this simulation, single slope solar still is designed in which a certain amount of water with a certain height is present.

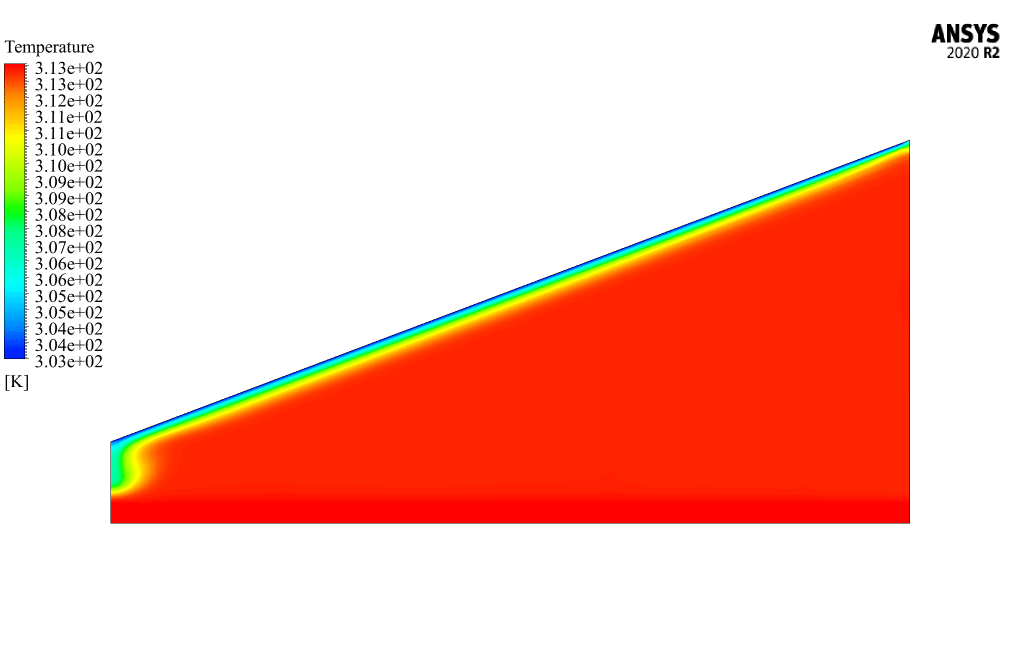

The sloping surface of the solar still is made of glass and is responsible for heat transfer from the sun to the water surface. The surface of the water rises as it receives heat from the solar radiation passing through the glass, resulting in surface evaporation.

The present model is designed in three dimensions using Design Modeler software. The present model is related to single slope solar still.

The length of the chamber is equal to 0.98 meters, and the height of the vertical wall of the chamber is equal to 0.47 meters so the angle of the sloping surface of the chamber is equal to 19 degrees.

The meshing of the model has been done using ANSYS Meshing software. The mesh type used for this geometry is structured, and the element number is 8200. Also, due to the nature of this project, the transient solver has been used.

Surface Evaporation Methodology

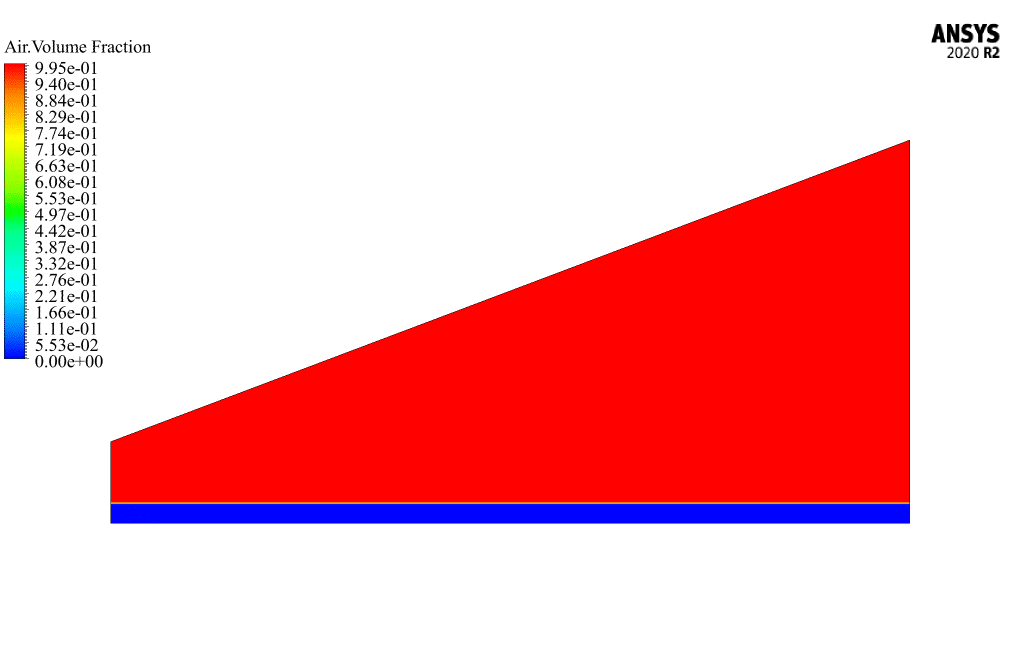

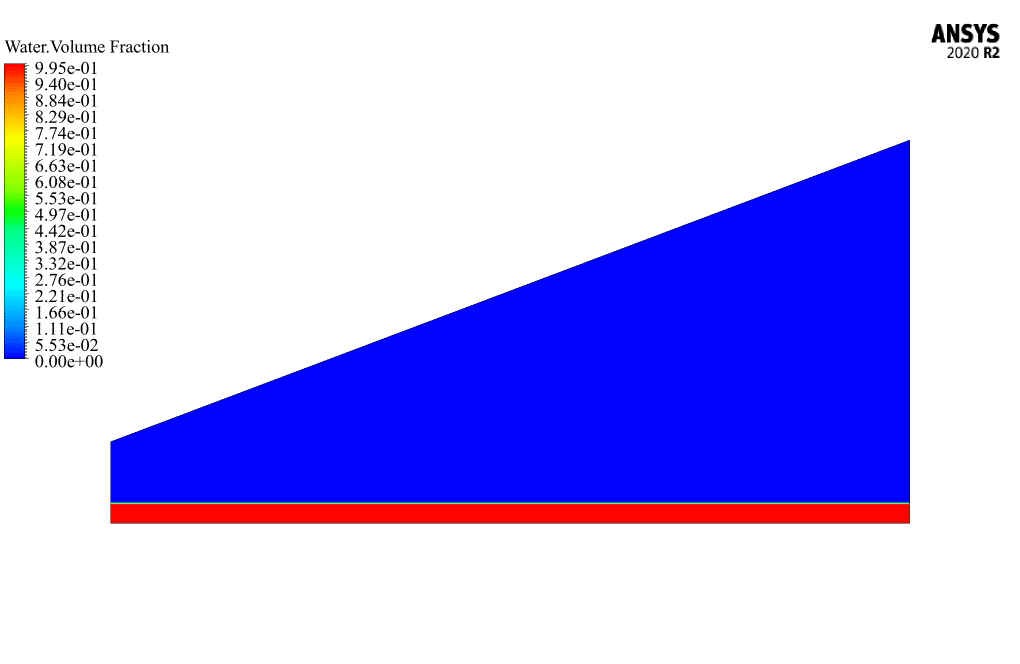

Initially, there is a certain water level inside the chamber where the static airflow is located. As the system starts, the water surface evaporates, and water vapor mixes into the air inside the solar still.

Therefore, to define three phases simultaneously, including liquid water, air, and water vapor, the multiphase mixture model must be used; Because in this three-phase current, the boundary of separation and differentiation between different phases is unclear.

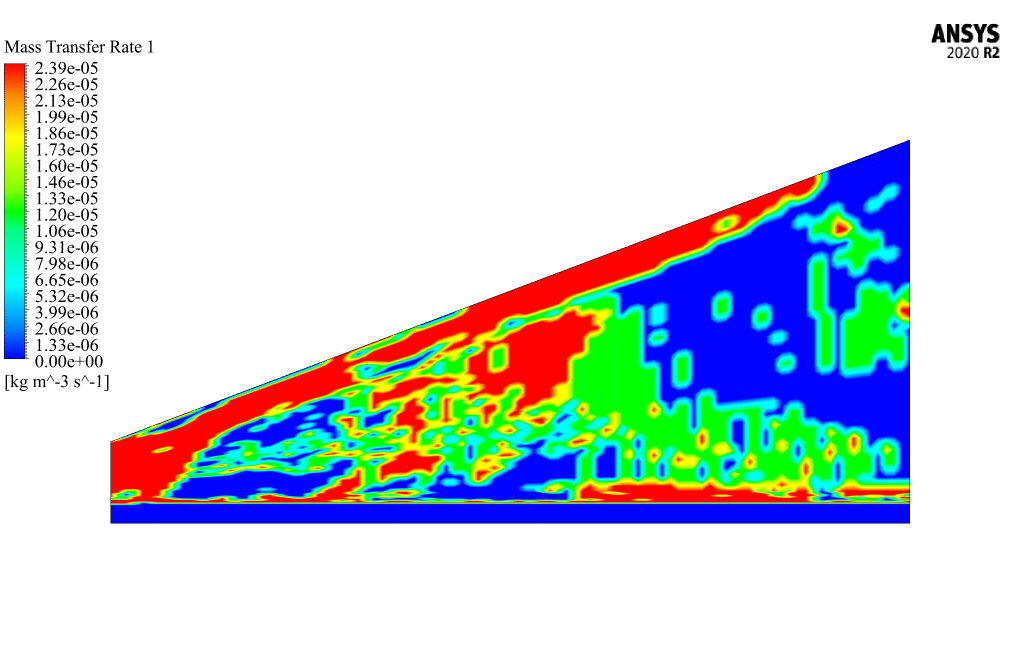

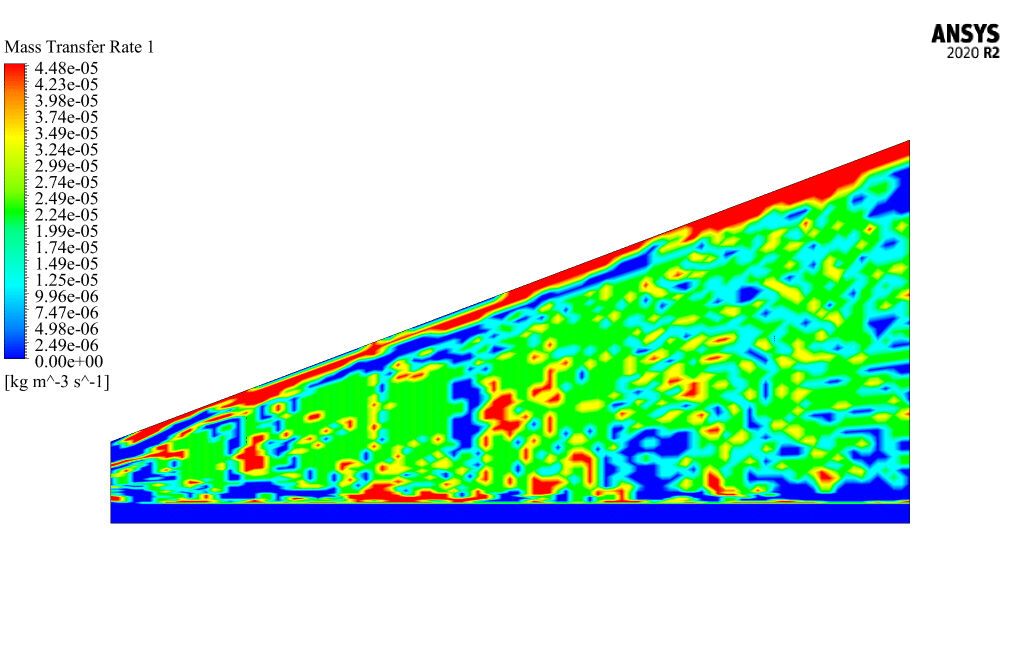

Mass transfer is used to define the phase change process between liquid water and water vapor; A UDF function is used to define the surface evaporation process.

Also, to define the amount of heat caused by solar radiation, it is assumed that the glass wall has a constant temperature due to solar radiation. According to the article information, this simulation has been done in two different modes, and its results have been compared with the results of the article.

In the first case, the initial temperature of the water is equal to 40 ° C, and the constant temperature of the glass is equal to 30 ° C. In the second case, the initial temperature of the water is equal to 50 ° C, and the constant temperature of the glass is equal to 40 ° C.

Surface Evaporation Conclusion

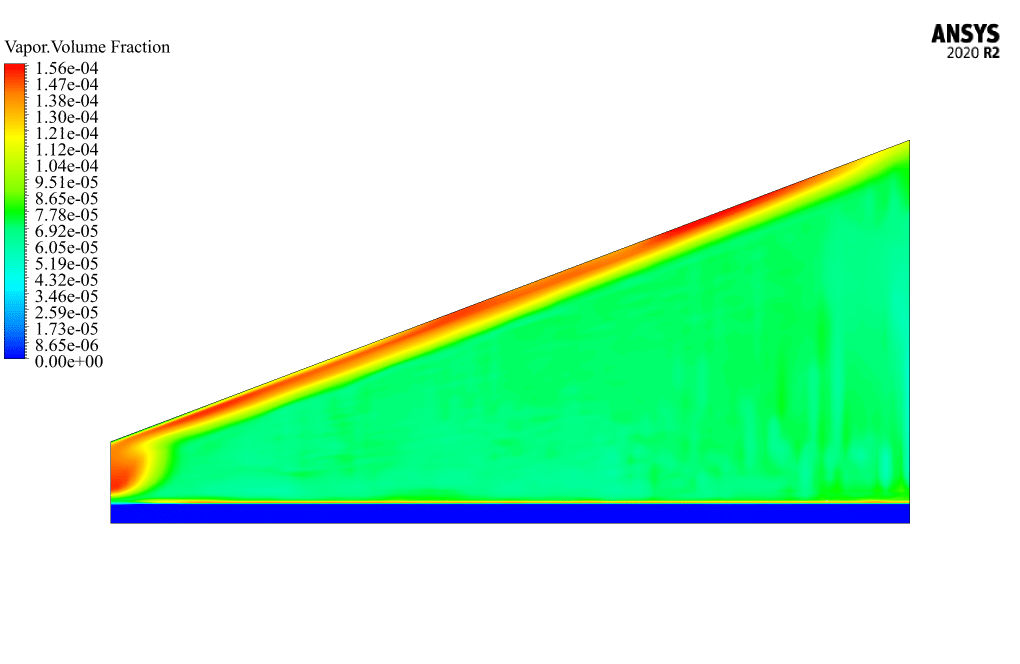

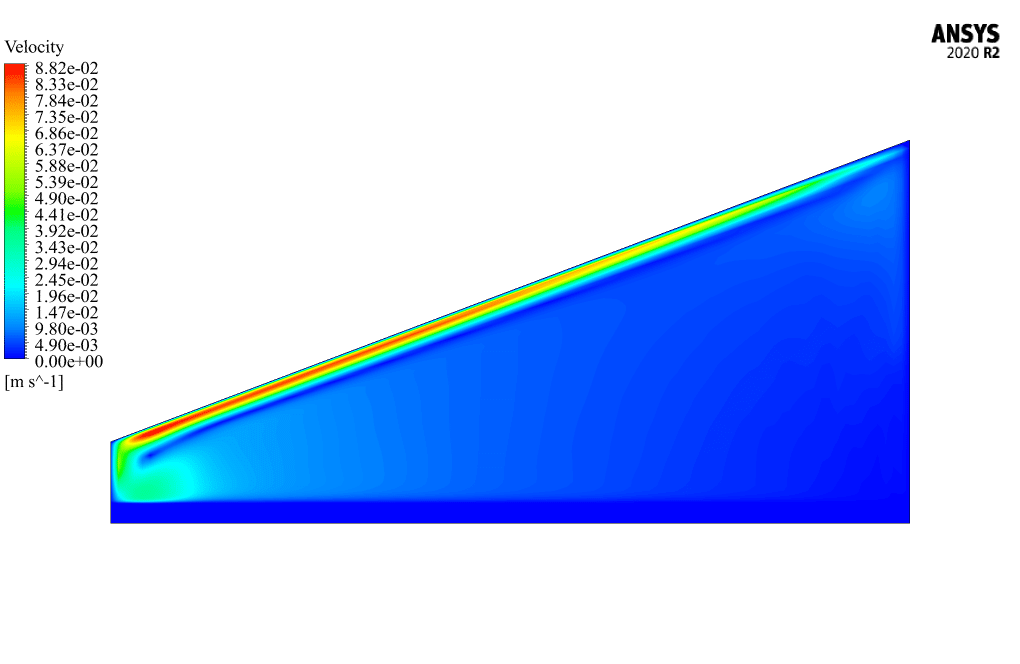

At the end of the solution process, two-dimensional contours related to temperature, velocity, and mass transfer rate between two phases (surface evaporation rate), air volume fraction, liquid water volume fraction, and water vapor volume fraction were obtained.

As seen from the contours, the water surface in the solar still chamber evaporates over time. As a result, water vapor occupies part of the space above the water surface inside the chamber.

The validation of the present simulation is based on the results of Table 3 of the mentioned paper. The amount of surface evaporation rate in the two simulations is compared and validated with the model evaporation rate presented by the paper.

This value of the evaporation rate represents the maximum value of the mass transfer rate between the two phases of liquid water and water vapor.

In the first case, the glass temperature equals 30 ° C. The water temperature is equal to 40 ° C, while in the second case, the glass temperature is equal to 40 degrees Celsius, and the water temperature is equal to 50 degrees Celsius.

| Error (%) | Present Simulation | Proposed Model @ Paper | Surface Evaporation |

| 12.21 | 2.4053614e-5 | 2.74e-5 | Case 1 : Tg = 30 ºC & Tw = 40 ºC |

| 0.57 | 4.5052254e-5 | 4.53e-5 | Case 2 : Tg = 40 ºC & Tw = 50 ºC |

Bart Stracke Sr. –

Having followed the process outlined in this training for the Single Slope Solar Still and achieving results relatively close to the theoretical paper, has made the complex concepts much clearer. The excitement of the accurate simulation results compared to the mentioned paper adds a ton of value. Well done to the MR CFD team for putting together such a comprehensive learning aid!

MR CFD Support –

Dear user, we are absolutely delighted to hear that our Single Slope Solar Still ANSYS Fluent CFD Simulation Training has clearly explained the concepts and provided you with the satisfying experience of obtaining accurate simulation results. Your kind words are greatly appreciated, and we thank you for taking the time to leave such a positive review. We strive to deliver top-quality educational content and it’s gratifying to know that we’ve hit the mark for you. Thank you for choosing MR CFD!

Brigitte Langworth –

I am truly amazed by the level of detail and the adherence to scientific methods demonstrated in this simulation. It is fascinating to see how accurate computational model validations can get when compared to theoretical and numerical analyses. This insight will be immensely beneficial to anyone working on or studying solar desalination systems!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you find the simulation detailed and scientifically accurate. It is always rewarding to know that our products are being well received and that they contribute meaningful value to the work and understanding of our customers. If you have any more thoughts or need further assistance, don’t hesitate to reach out.

Prof. Cathrine Mante –

I was blown away by how precise the simulation results were with the numerical data from the article. It’s impressive how well the surface evaporation rate in both cases approached the proposed model values. Great use of the multiphase mixture model to simulate this complex process!

MR CFD Support –

Thank you for your review! We’re pleased to hear that you are satisfied with the accuracy of our CFD simulation in relation to the theoretical data. Our team strives to provide high-fidelity simulations that can be beneficial for research and industrial applications. If you need any further guidance or have another project in mind, do not hesitate to reach out to us.

Dalton Wisoky –

The simulation technique for this solar still CFD project is very well laid out. The detailed methodology and thoughtful approach to comparing numerical results with those presented in a referenced paper provide a high level of confidence in the simulation’s validity.

MR CFD Support –

Thank you for appreciating our efforts in conducting a thorough and precise CFD analysis. We strive to deliver accurate and validated results to ensure our simulation techniques are reliable and helpful. Your feedback motivates us to maintain high standards in our CFD training products.

Neva Medhurst –

This CFD course seems quite informative and practical. I was particularly impressed by how the theoretical knowledge and quantitative estimations from the reference article were substantiated through dedicated numerical simulations. How accurate would you say these simulation results were when compared to the article’s outcomes?

MR CFD Support –

We’re glad to hear that you found the CFD course informative and valuable. The comparison of the simulation results to the predictions made in the reference article demonstrate an agreeable level of accuracy, with notably low error percentages — 12.21% for Case 1 and 0.57% for Case 2. It highlights the reliability of our simulation framework and our commitment to providing results that practitioners and learners can trust for their analytical needs. Thank you for acknowledging the practicality of this analysis in the realm of solar desalination study.

Erick Mante –

My single slope solar still simulation procedure went smoothly, wonderfully illuminating the effects of different temperatures on evaporation rates. I can truly visualize the practical applications of this method in solar desalination. Glad to see theory and practice align so well!

MR CFD Support –

We’re thrilled that our CFD simulation for the single slope solar still has provided clarity and met your educational needs. We are particularly happy to know that the alignment between practical application and theory was evident in your experience. Thank you for sharing your positive feedback!

Jennie Skiles –

The training showcasing the simulation of the surface evaporation process in a solar desalination system was enlightening. The systematic comparison with the results from a reference article helped solidify my understanding and trust in the method demonstrated.

MR CFD Support –

Thank you for your positive feedback! We’re glad to know that the validation process we included in our training gave you confidence in the simulation and that it was helpful in enhancing your understanding. It’s always our goal to deliver clear and precise educational material. We appreciate you taking the time to share your experience.

Prof. Haylee Windler Jr. –

This training was incredibly detailed and highly educational. Learning about the validation of numerical models against theoretical results deepened my understanding of CFD significantly, paving the way for me to undertake my projects with greater confidence. Everything about this session, from the setup of the initial temperature conditions to observing how solar radiation affects evaporation, was enlightening. I especially appreciated the comparative study, which puts a nice perspective on accuracy and error margins. Great job!

MR CFD Support –

Thank you so much for your kind words. We’re delighted to hear that the CFD session on single slope solar stills met your expectations and that it has helped bolster your confidence for future projects. Knowing that the comparative study added value to your learning experience is very rewarding for us. Should you have any more inquiries or need further assistance in your CFD journey, please feel free to reach out. Thank you once more for choosing our training!

Wilfrid Bahringer –

The details in this review of the solar still simulation showcase how meticulous the validation process was against the theoretical and numerical data in the reference article. I especially appreciate the clear delineation of the different scenarios simulated and the temperature settings for each. Well done!

MR CFD Support –

Thank you for the positive feedback on our Single Slope Solar Still CFD Simulation Training! We take pride in ensuring our simulations are accurate and closely validated against reliable research. Your recognition of the detailed work put into this process is greatly appreciated!

Ashton Franecki –

The course on simulating a single slope solar still exceeded my expectations. The step-by-step approach made complex concepts easily digestible, especially on how the multiphase mixture models are used to simulate surface evaporation. I am impressed by how well the simulation results agreed with the numerical values from the paper.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that you found the course approachable and that it helped you understand complex simulation concepts. We always strive to provide accurate simulations that correlate well with academic and practical research, and your satisfaction with the results validates our efforts. We appreciate your commendation!

Lula Osinski –

The learning material was excellent. The comparative study of the solar still’s productivity was particularly enlightening. The step-wise explanation of solar heat transfer through the glass was engaging and understandable. Great job drawing parallels to the reference paper’s outcomes, hence enhancing the credibility of the simulation. This intricate combination of theoretical knowledge and practical application skills was exactly the kind of resource I needed.

MR CFD Support –

Thank you for your kind words and for acknowledging the effort put into making the simulation as informative and accurate as possible. We are delighted to hear that the comparison with the reference paper provided added value. Seeing our work help others in their learning pursuits is the best outcome we could hope for. We appreciate your support!

Arnaldo Grady –

I’m very impressed with the accuracy of the CFD simulation against the paper’s results—it shows strong validation for surface evaporation rates. How were you able to achieve such a close match?

MR CFD Support –

Thank you for your kind words! Accuracy in our simulations is a top priority. To achieve such a close match, we meticulously calibrated our model using the data supplied in the reference paper. We carefully set up initial and boundary conditions, and employed the same assumptions as in the study. By implementing a user-defined function (UDF) for surface evaporation, we were able to fine-tune the simulation of phase changes. Furthermore, structured meshing contributed to the precision of our results. It was through meticulous attention to detail and validation processes that we ensured such accuracy.

Janessa Miller V –

This training module sounds comprehensive and the validation against scholarly works is impressive! The detail provided makes it a valuable resource for anyone looking to grasp the nuances involved in CFD simulations for solar water desalination systems. Kudos to the team for creating such a well-documented and educational product!

MR CFD Support –

Thank you for your kind words! We strive to deliver high-quality educational content and are delighted to hear that you appreciated the level of detail and validation in our Single Slope Solar Still simulation training. If you need further learning materials or support, don’t hesitate to reach out!

Prof. Marcelo Smitham –

The training product made the complex process of setting up the simulation for a solar still very approachable. It closely followed the referenced academic article and translated theoretical concepts into practical steps in ANSYS Fluent with great clarity.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our training product effectively communicated the complex aspects of the solar still simulation aligned with scholarly research. Your satisfaction with how the theoretical knowledge was conveyed and implemented practically is greatly appreciated.

Stewart Marquardt –

I was really impressed with the level of detail in this simulation. The ability to simulate different temperature settings and see the resulting evaporation rates is fascinating. It must have taken a lot of patience and skill to set up such a validated model. Kudos to your team for accomplishing an in-depth analysis and providing valuable insights through CFD.

MR CFD Support –

Thank you so much for your kind words! We take great pride in our work and strive to provide detailed and accurate simulations. We’re glad that the level of detail in the Solar Still simulation impressed you. Our team appreciates your recognition of the effort that goes into setting up and validating these models. Feedback like yours is incredibly rewarding. Thank you for choosing our training for your CFD analysis needs!

Colby Ankunding –

The provided CFD simulation training for single-slope solar still was excellent and very informative. The comparison with the theoretical models was especially helpful for understanding the accuracy of the simulation. Keep up the great work!

MR CFD Support –

Thank you for your positive feedback! We’re delighted that you found the solar still simulation training helpful and informative. We take pride in providing accurate and useful comparisons to support learning and understanding. If you ever have more questions or need further assistance, we’re always here to help!

Jermey Goyette –

The structured mesh used in the simulation has a total of 8200 elements. Considering the complexity of evaporation, is this mesh sufficiently fine to capture the necessary details for accurate results?

MR CFD Support –

The total number of elements used in the mesh for this simulation was deemed sufficient based on the geometry and scales involved within the computational domain. It is designed to provide an optimal balance between computational efficiency and the level of detail required to capture the essential phenomena occurring in the evaporation process of the single slope solar still.

Holly Powlowski –

The results and detailed procedure used in this simulation are incredibly useful. I am particularly impressed with how well the simulation aligns with the referenced academic article, offering a rigorous numerical validation. The use of structured mesh to achieve precision and the application of UDF for phase changes reflect a high level of expertise. Great job on providing thorough insights and evidence for evaporation rates under different temperature conditions!

MR CFD Support –

Thank you so much for your kind words and feedback. We strive to provide accurate and reliable simulations that are well-aligned with academic research, and we’re glad to hear that this has been reflected in our work with the Single Slope Solar Still simulation. Your recognition of our attention to detail and methodology is greatly appreciated. If you have any more questions or need further assistance, feel free to reach out.