Sludge Flow In Centrifugal Pump CFD Simulation

$160.00 Student Discount

- The problem numerically simulates Slurry Flow in Centrifugal Pump using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

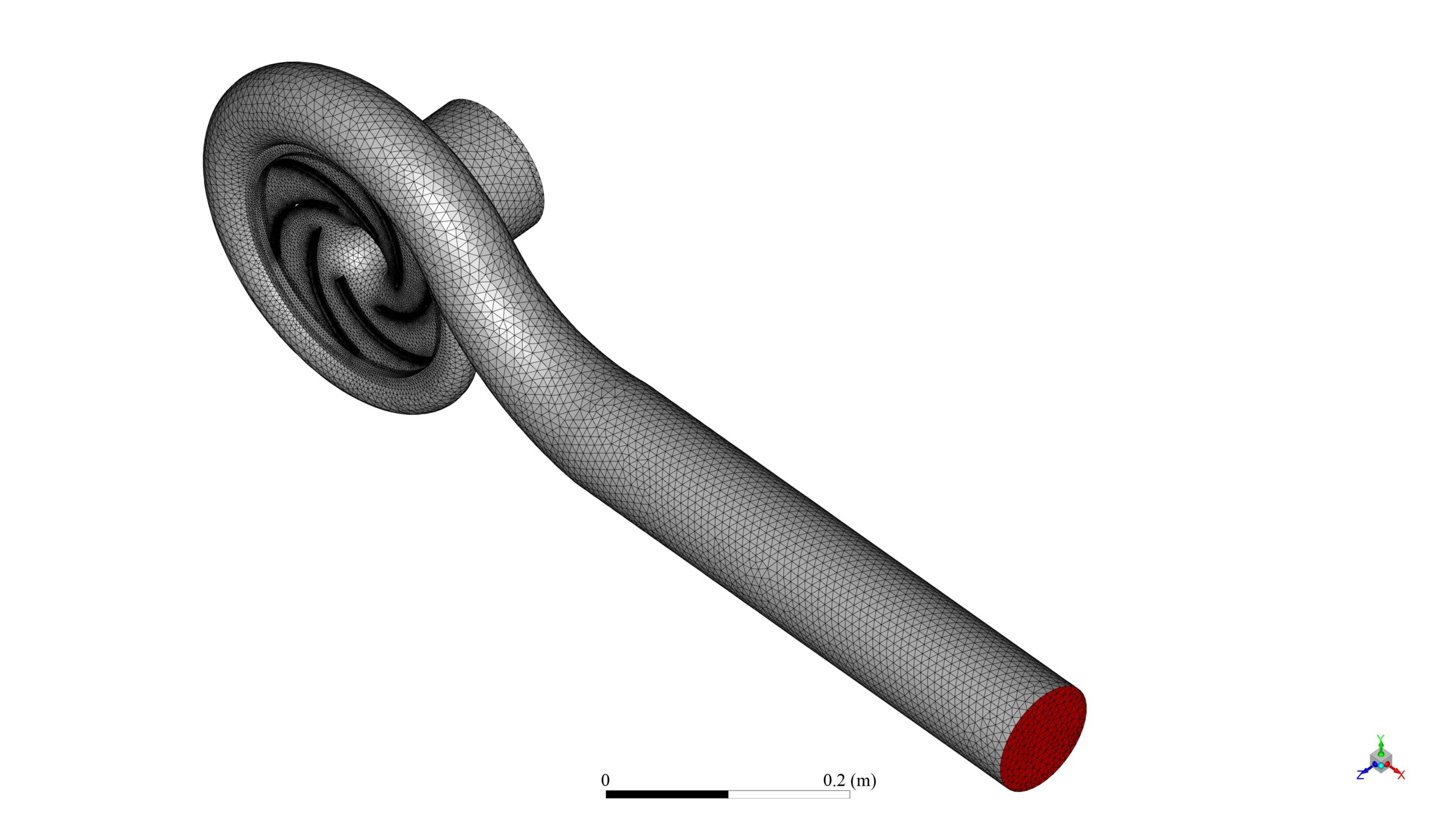

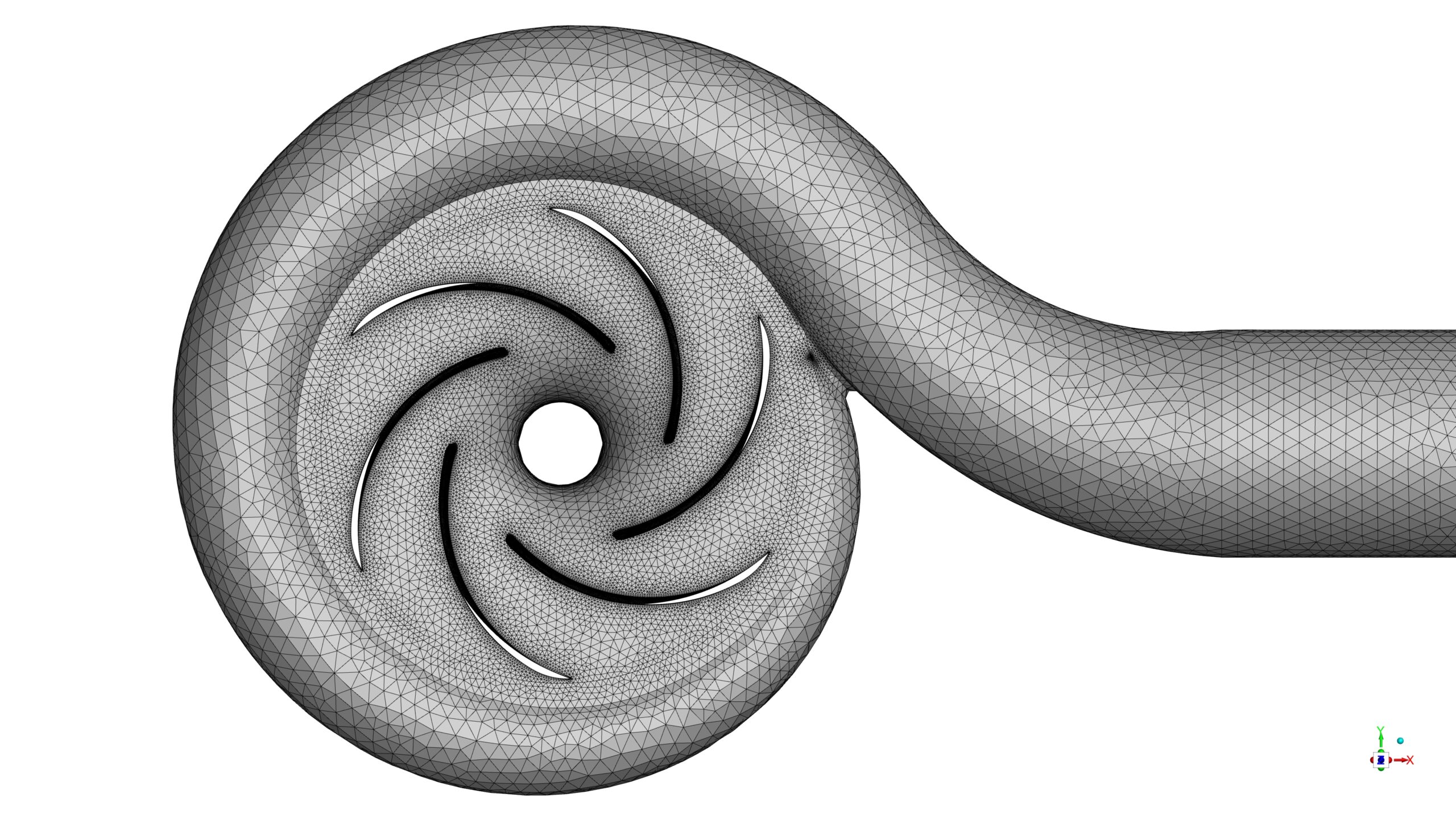

- We Mesh the model with ANSYS Meshing software, and the polyhedra element number equals 1,498,132.

- We use the Frame Motion to define the rotational movement in the rotating zone.

- The Mixture multiphase model is activated to model the effect of solid particles.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Sludge Flow In Centrifugal Pump CFD Simulation, ANSYS Fluent Tutorial

Description

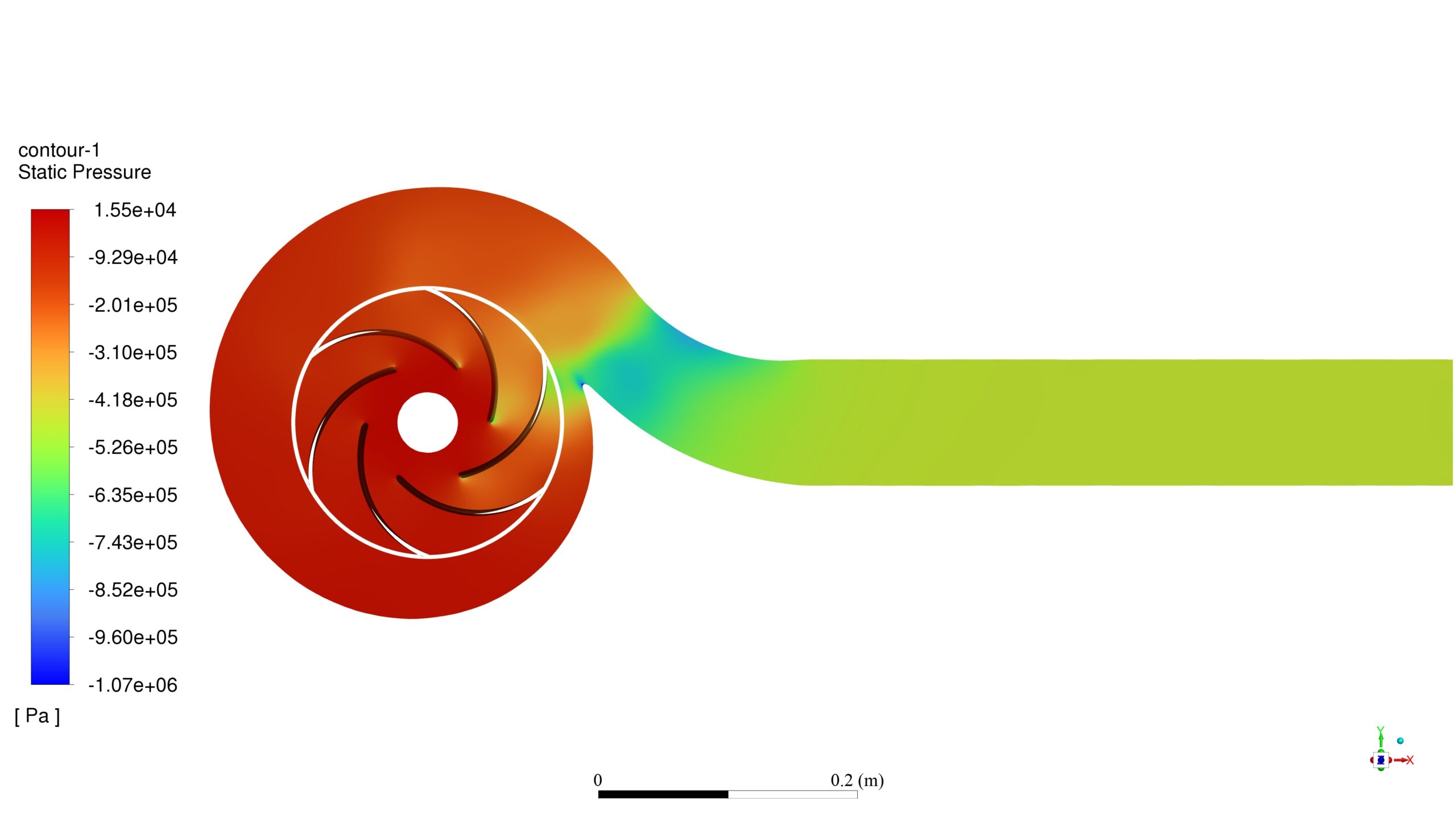

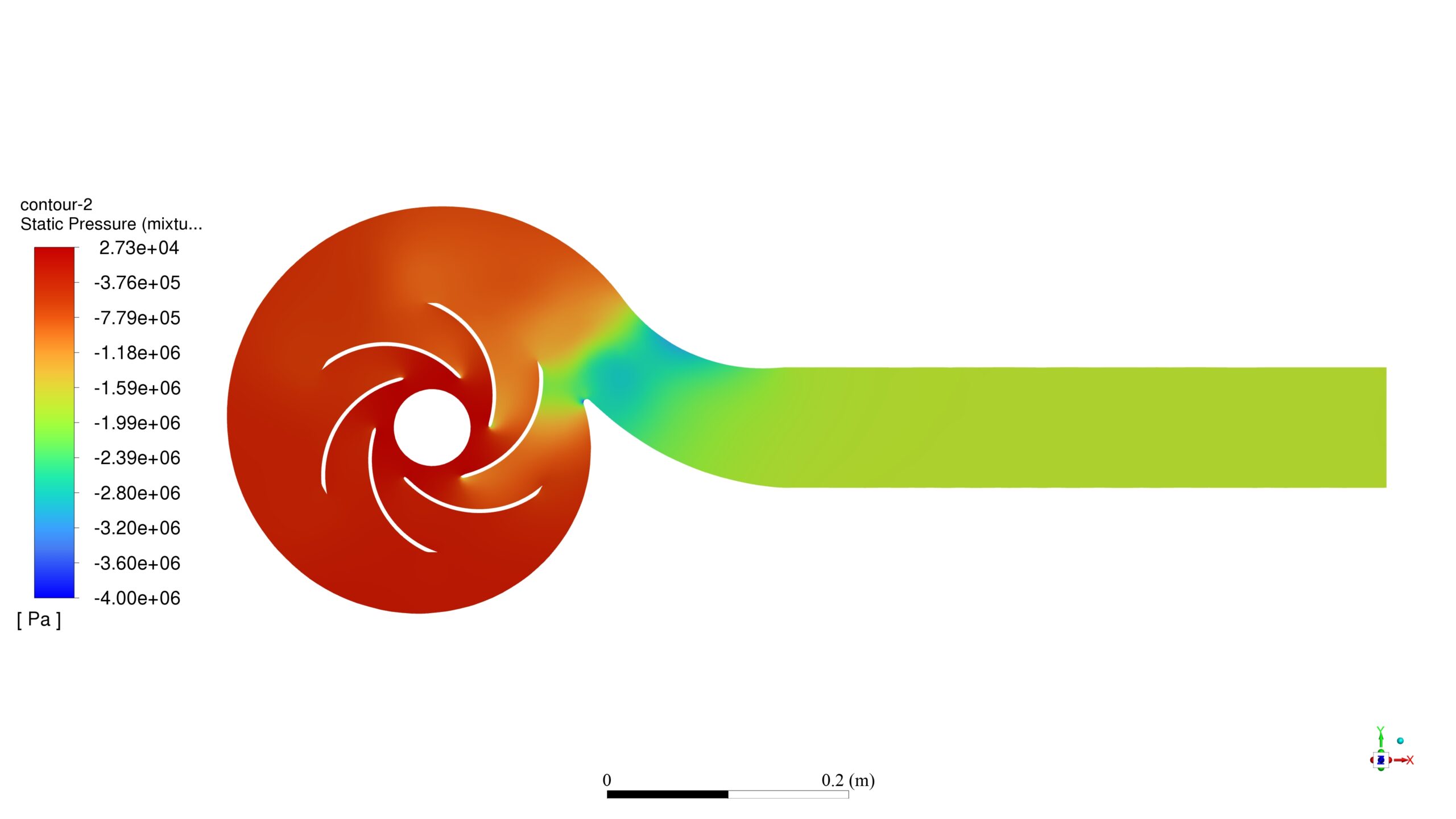

The performance of centrifugal pumps is significantly impacted by the distinctive properties of sludge flow with a particle concentration greater than 50%. The high particle concentration increases the sludge’s viscosity and density, making it harder to pump.

The thickening and weight gain of the sludge causes higher friction losses inside the pump system. Because of the increased resistance, the pump has to work harder to push through the friction and keep the flow rate constant. In addition, sludge with a high particle concentration can severely wear and abrade the impeller and other pump parts.

This product uses ANSYS Fluent software to stimulate the sludge flow inside a centrifugal pump. We perform this CFD project and investigate it by CFD analysis.

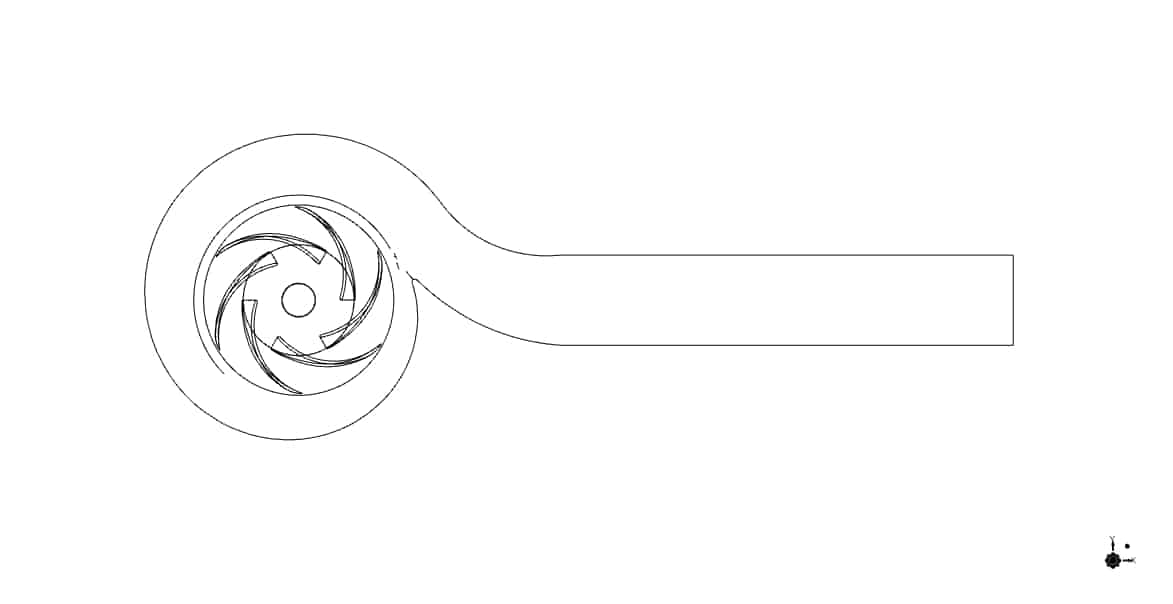

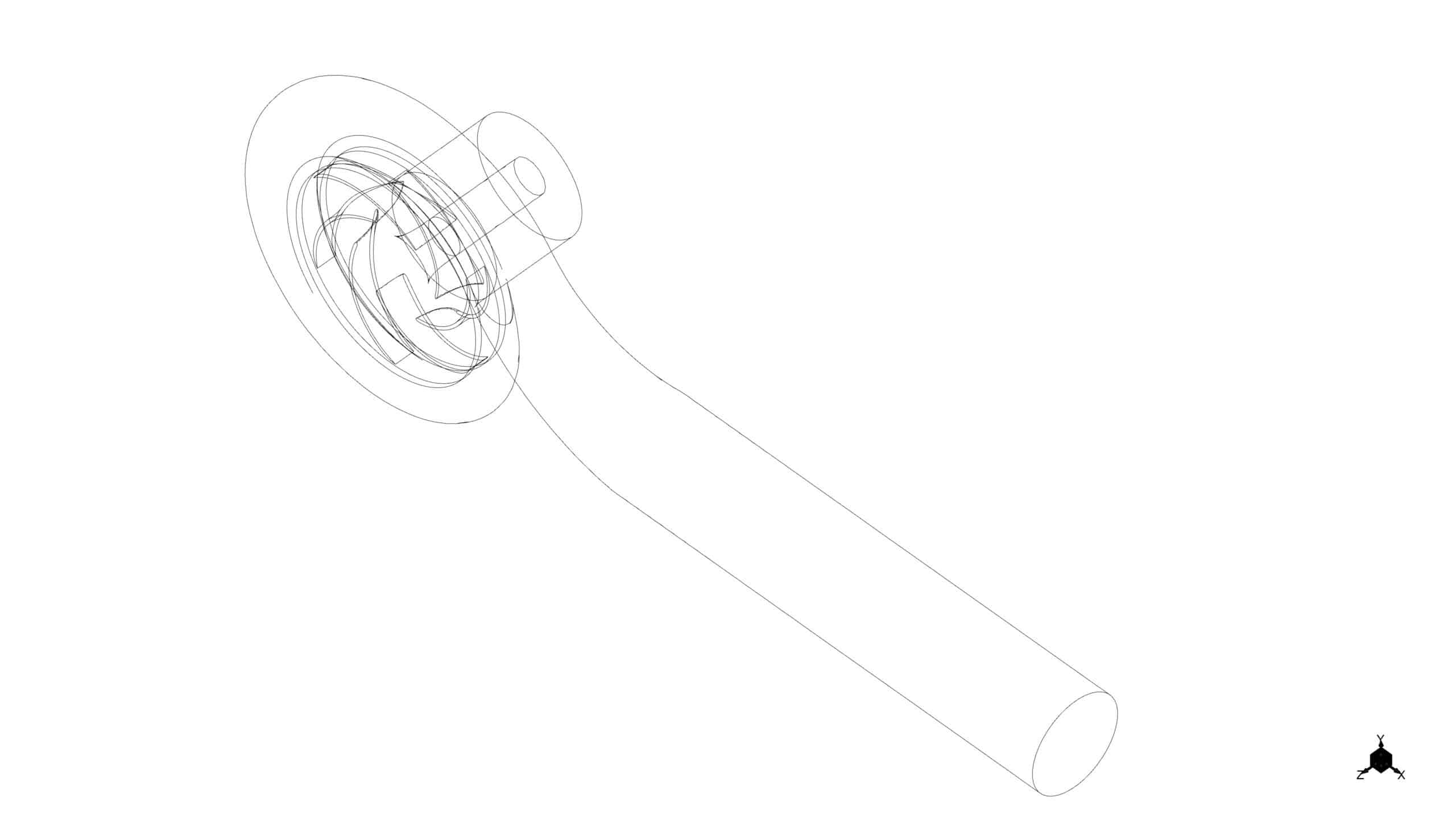

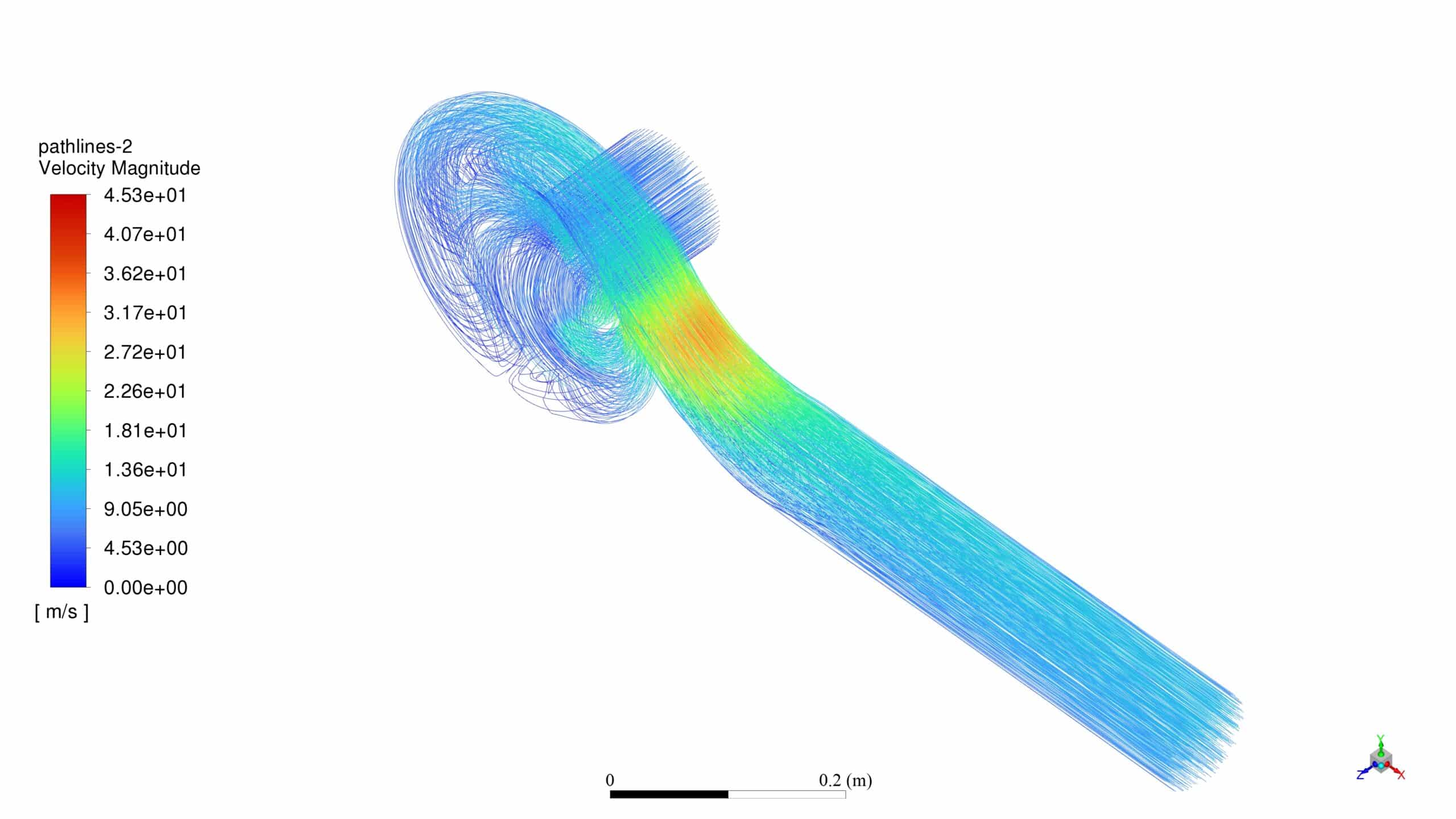

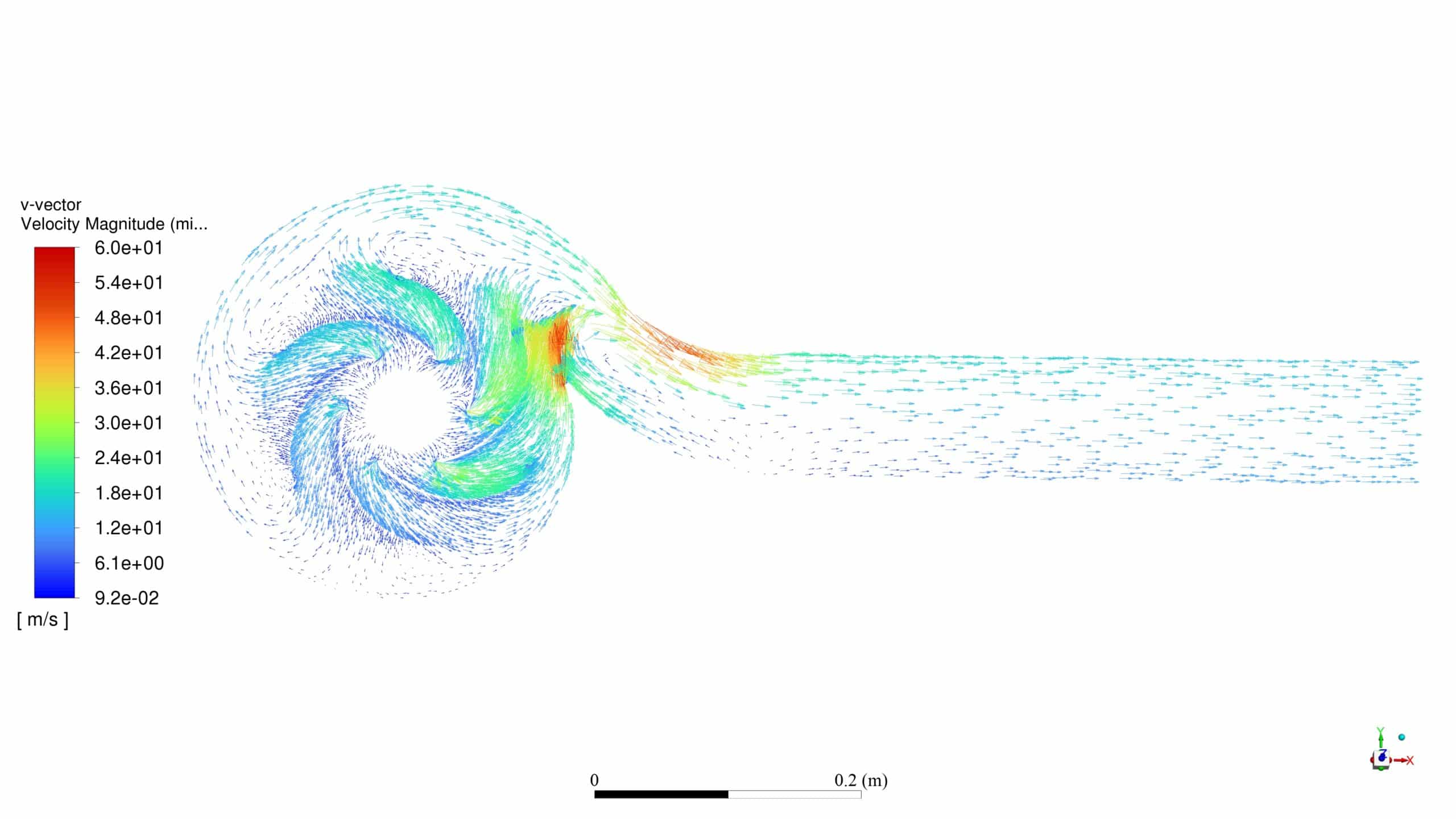

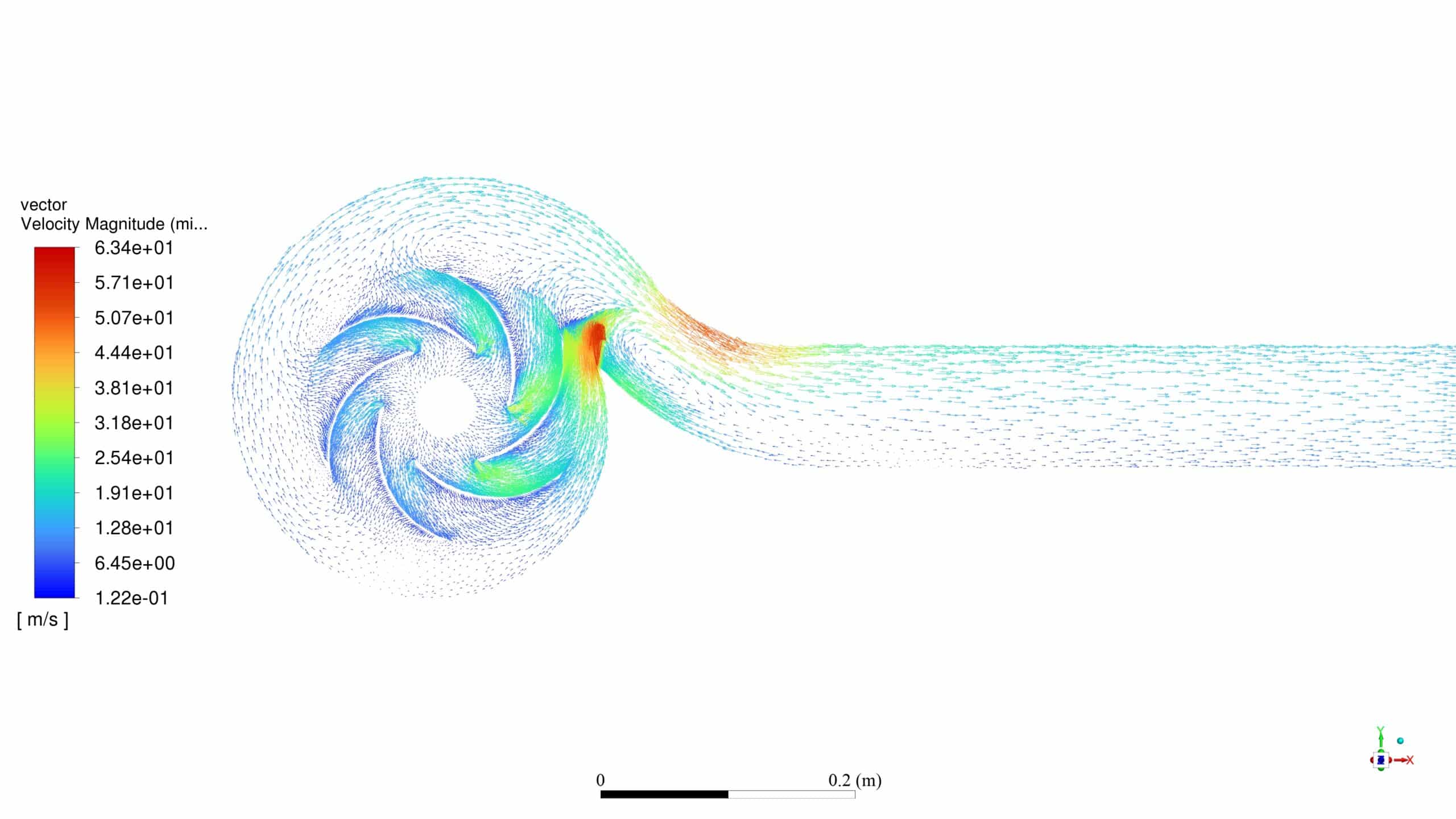

We designed a centrifugal pump in which the computational domain consists of rotating and stationary zones. The flow enters the pump through the stationary part entrance and then turns into the rotational zone. The rotating region of the pump rotates with a rotational speed equal to 1000 rpm then the flow finds its way to the pump outlet.

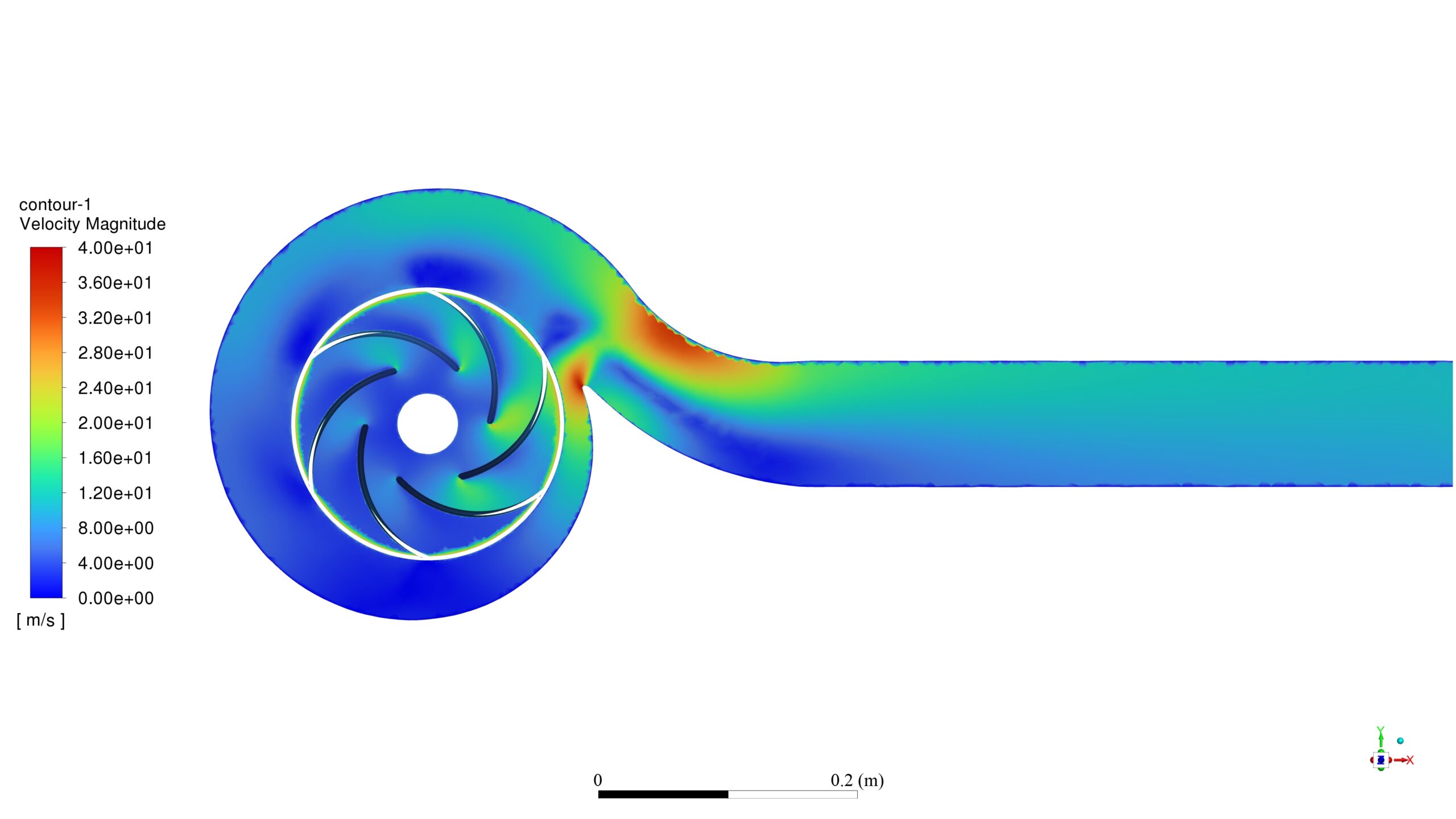

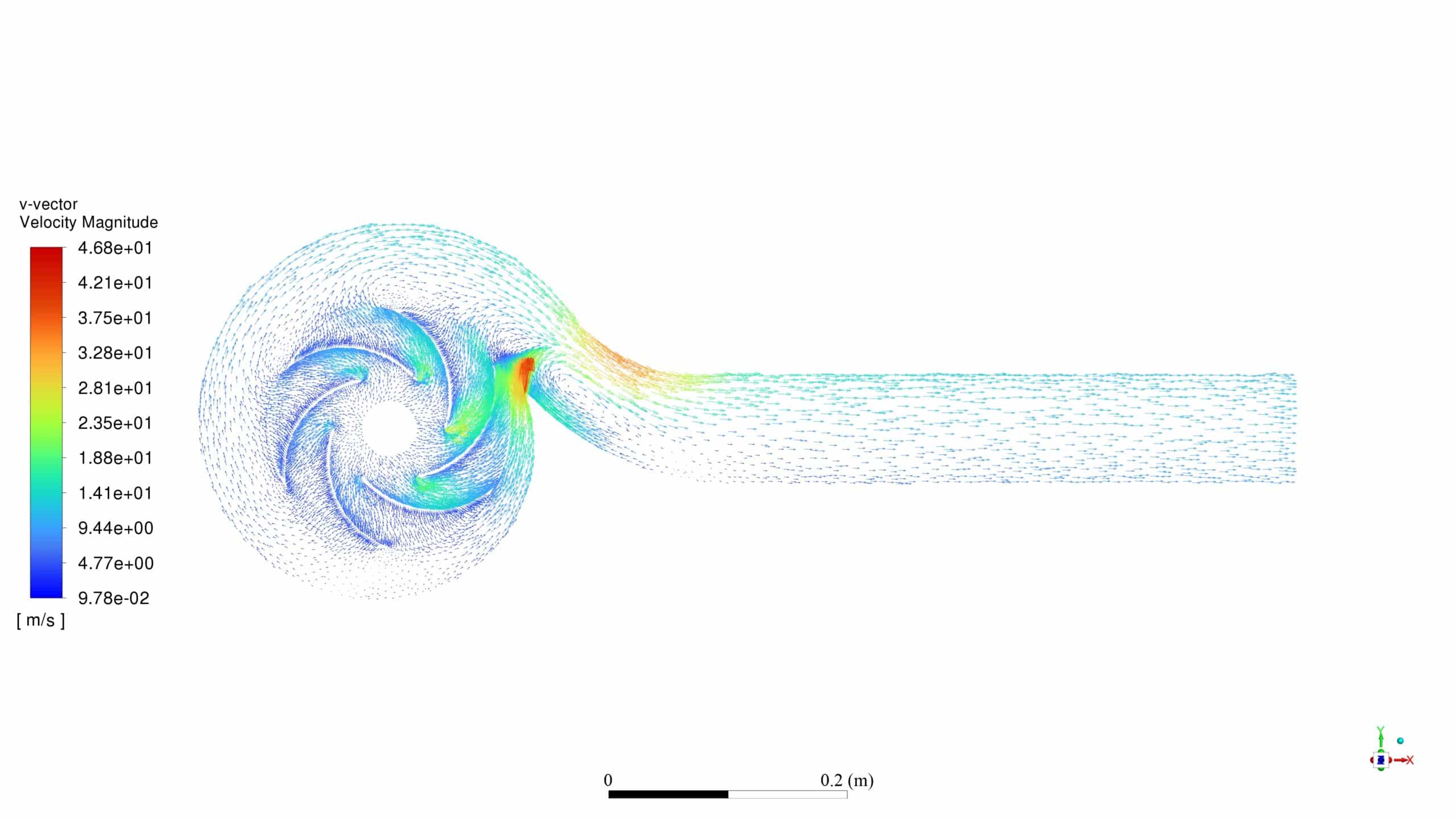

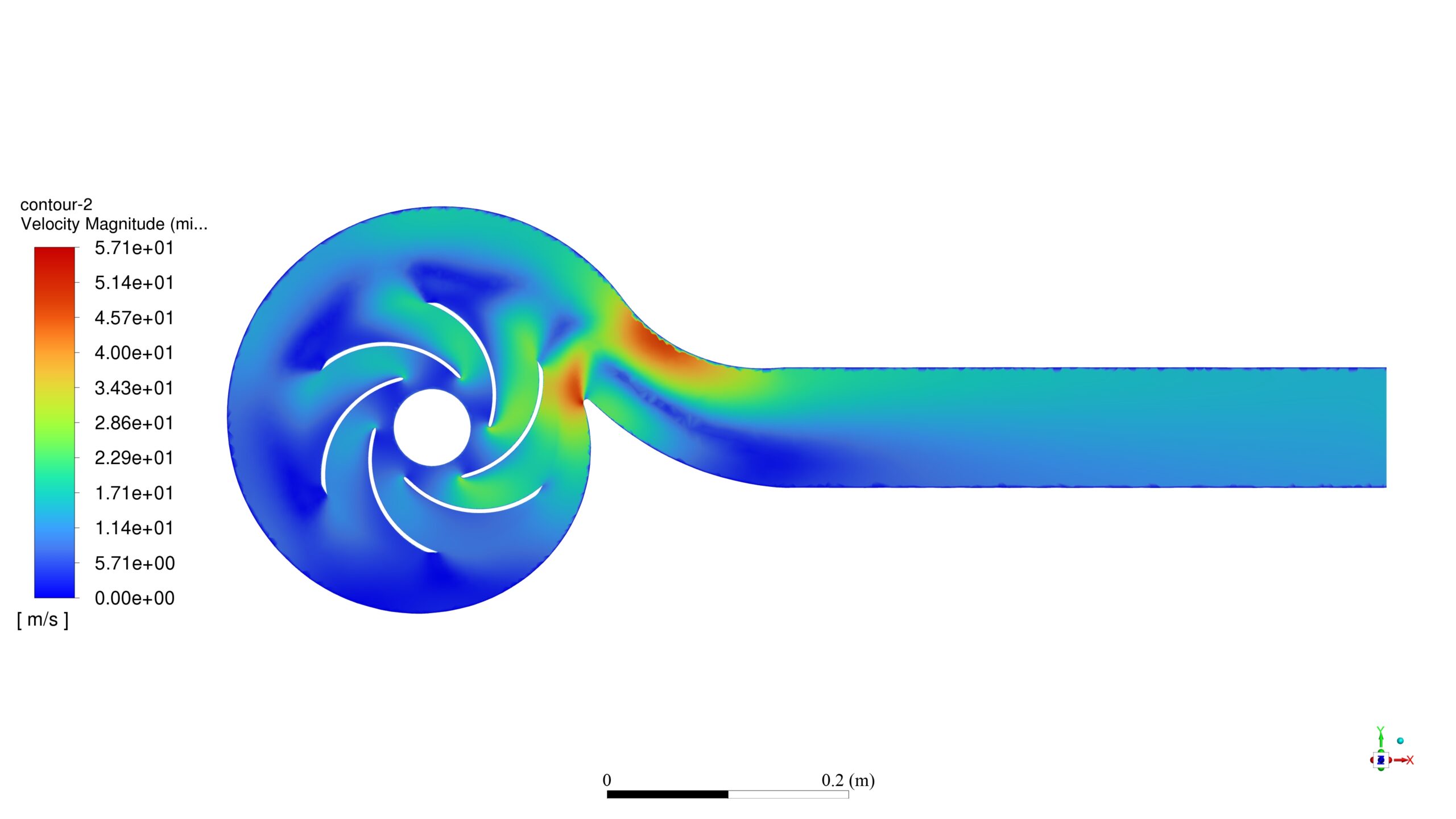

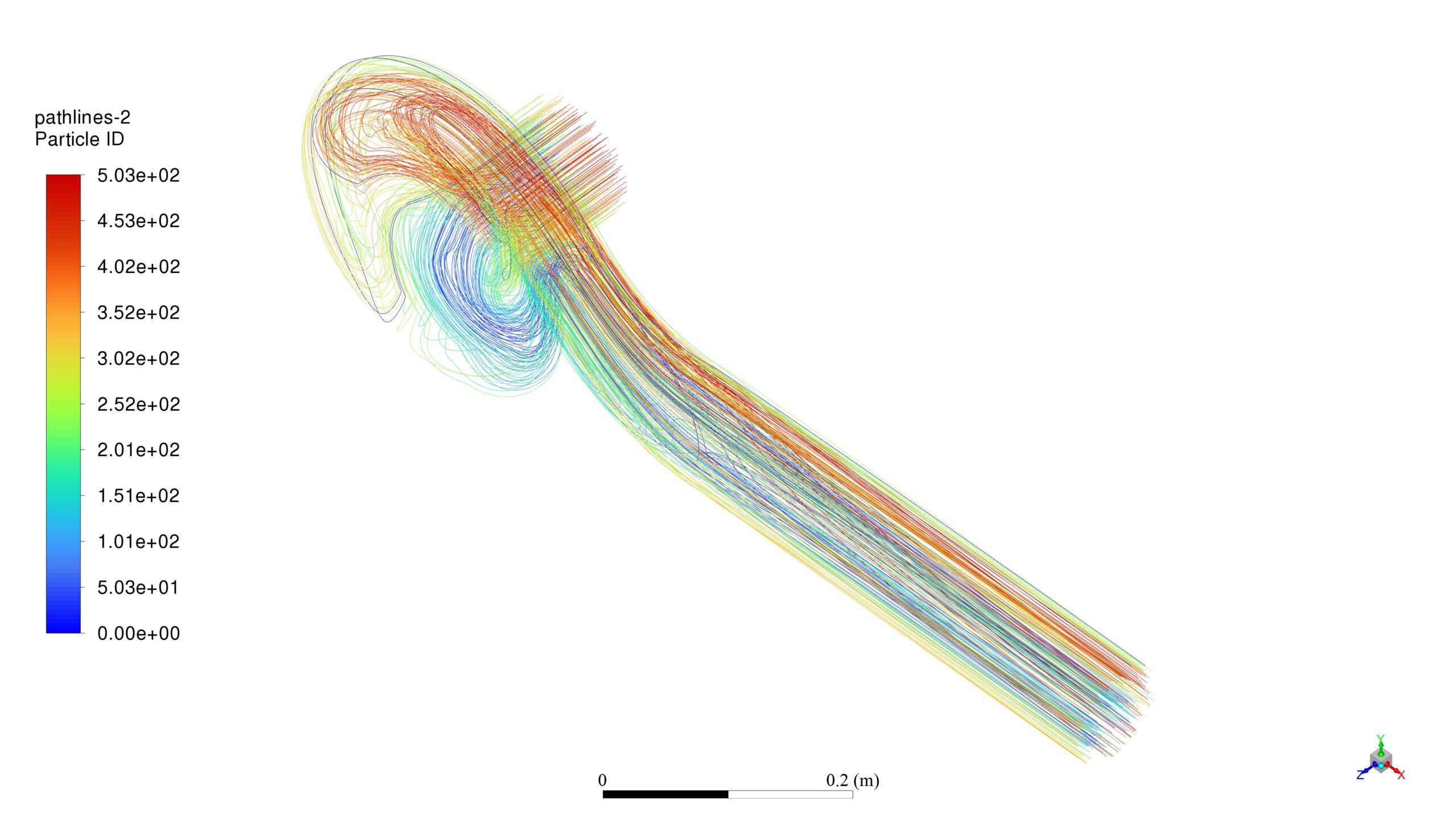

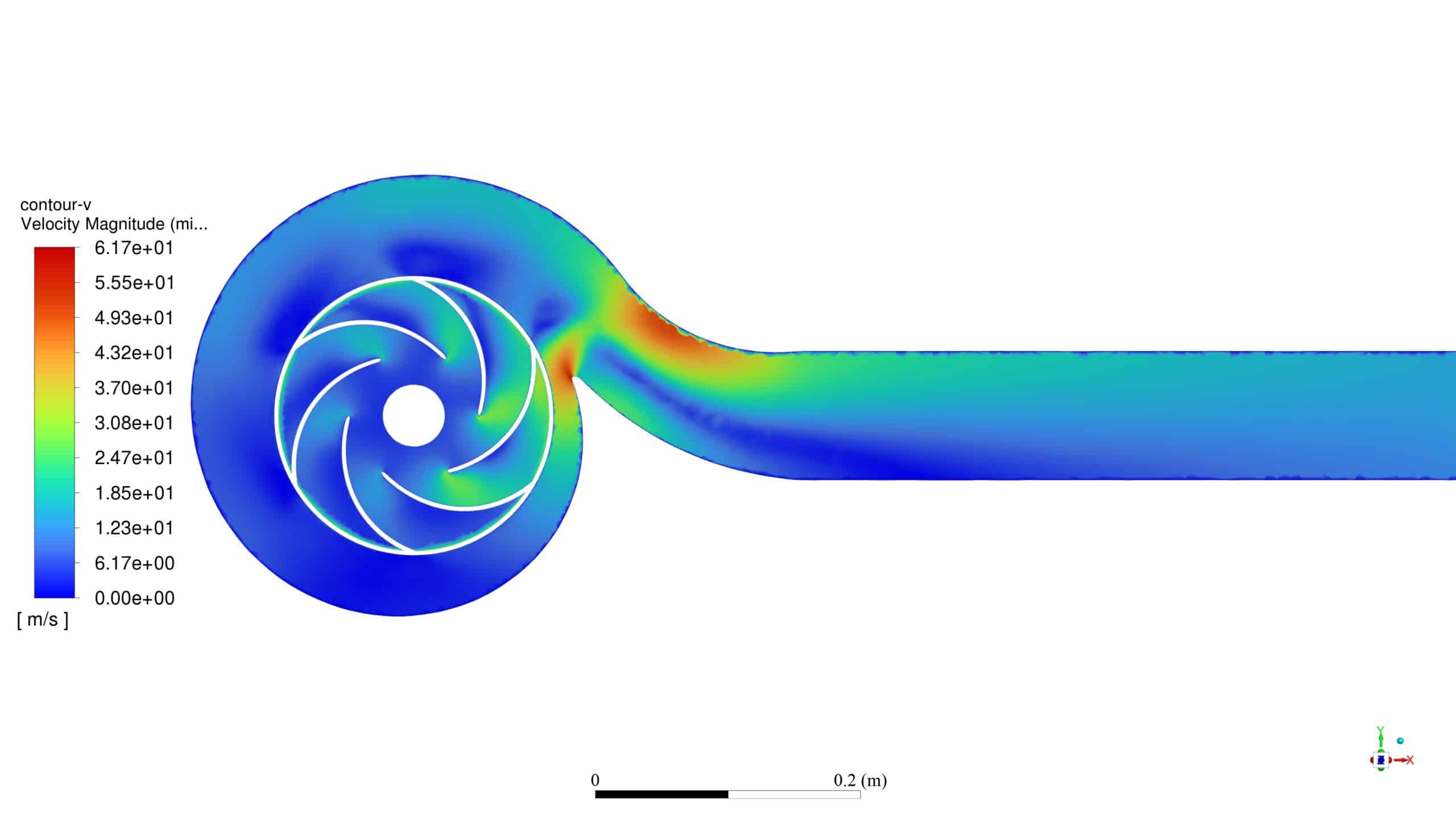

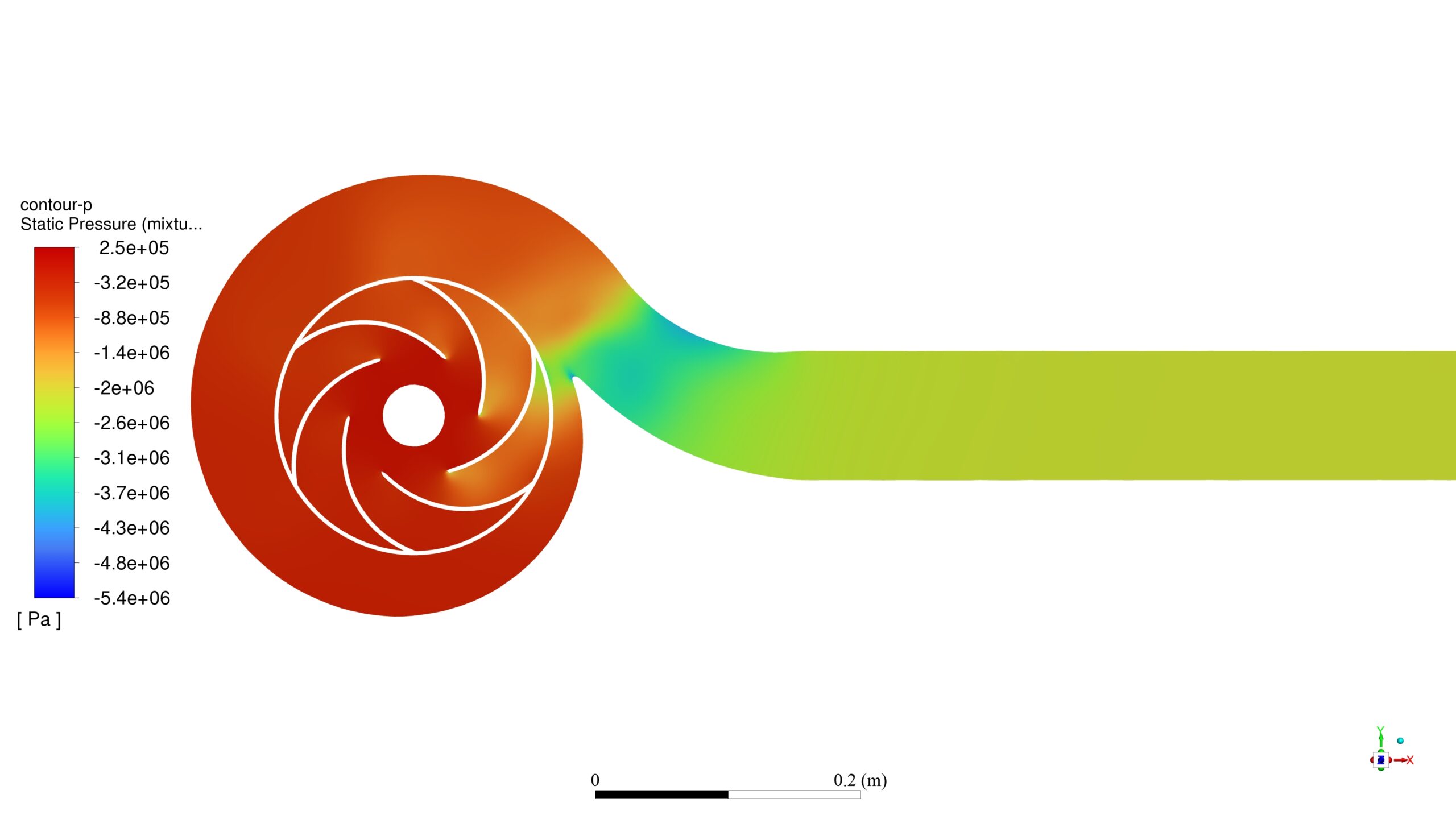

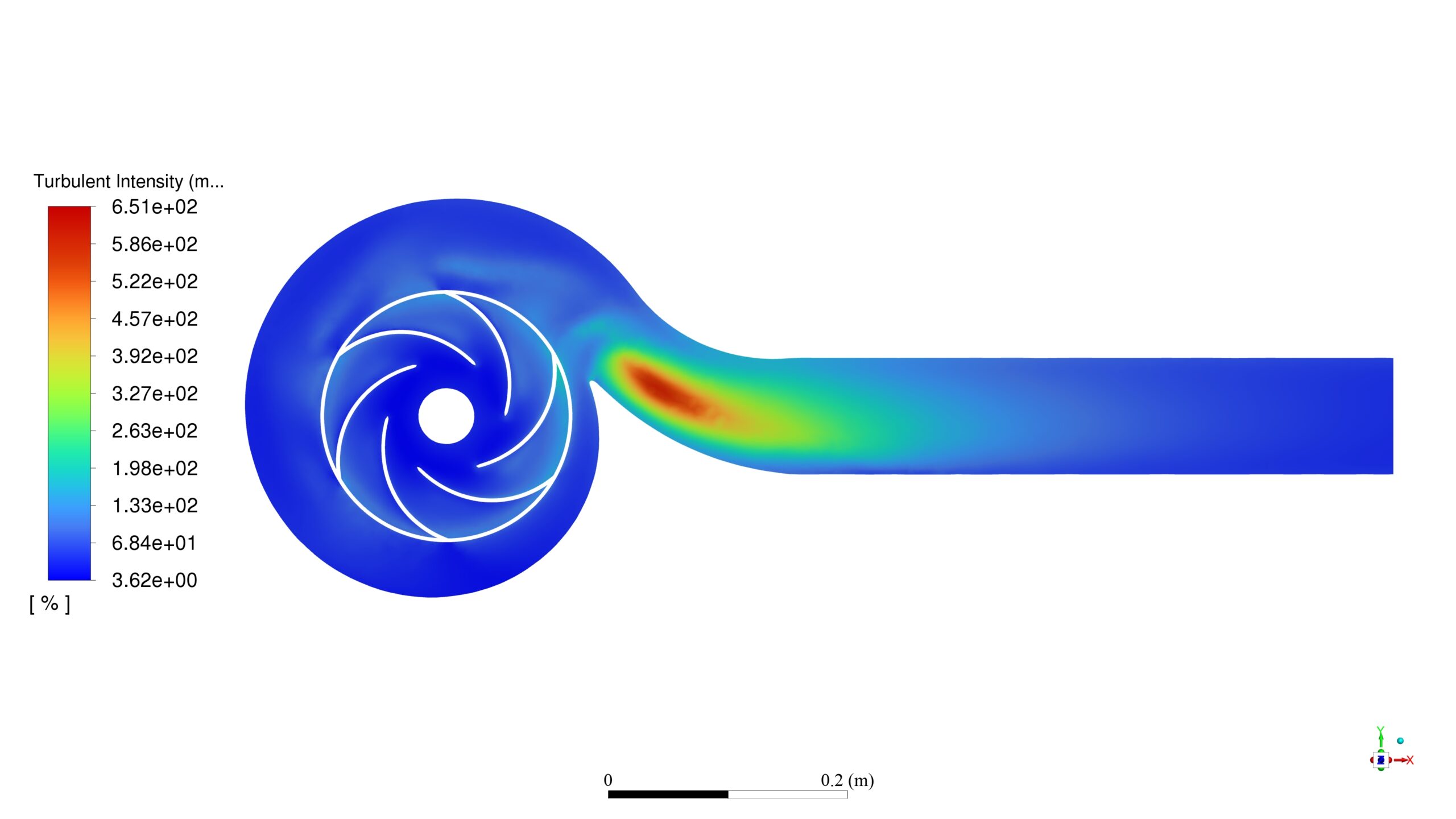

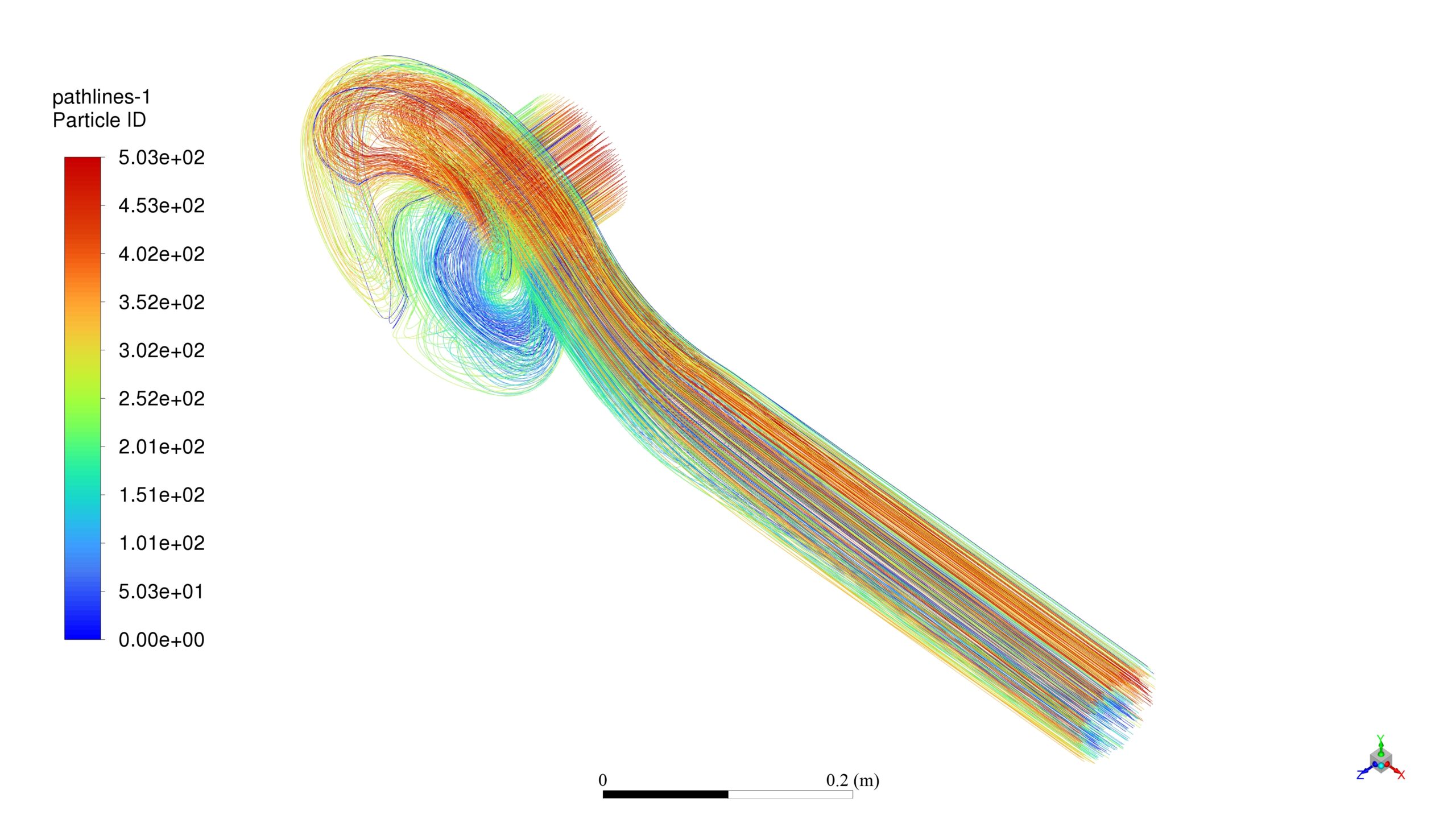

First, we simulated water flow using the SST k-w turbulence model to see the flow behavior through a centrifugal pump, the range of pressure drop, the velocity contour, and the other results, such as streamlines, shown in the results.

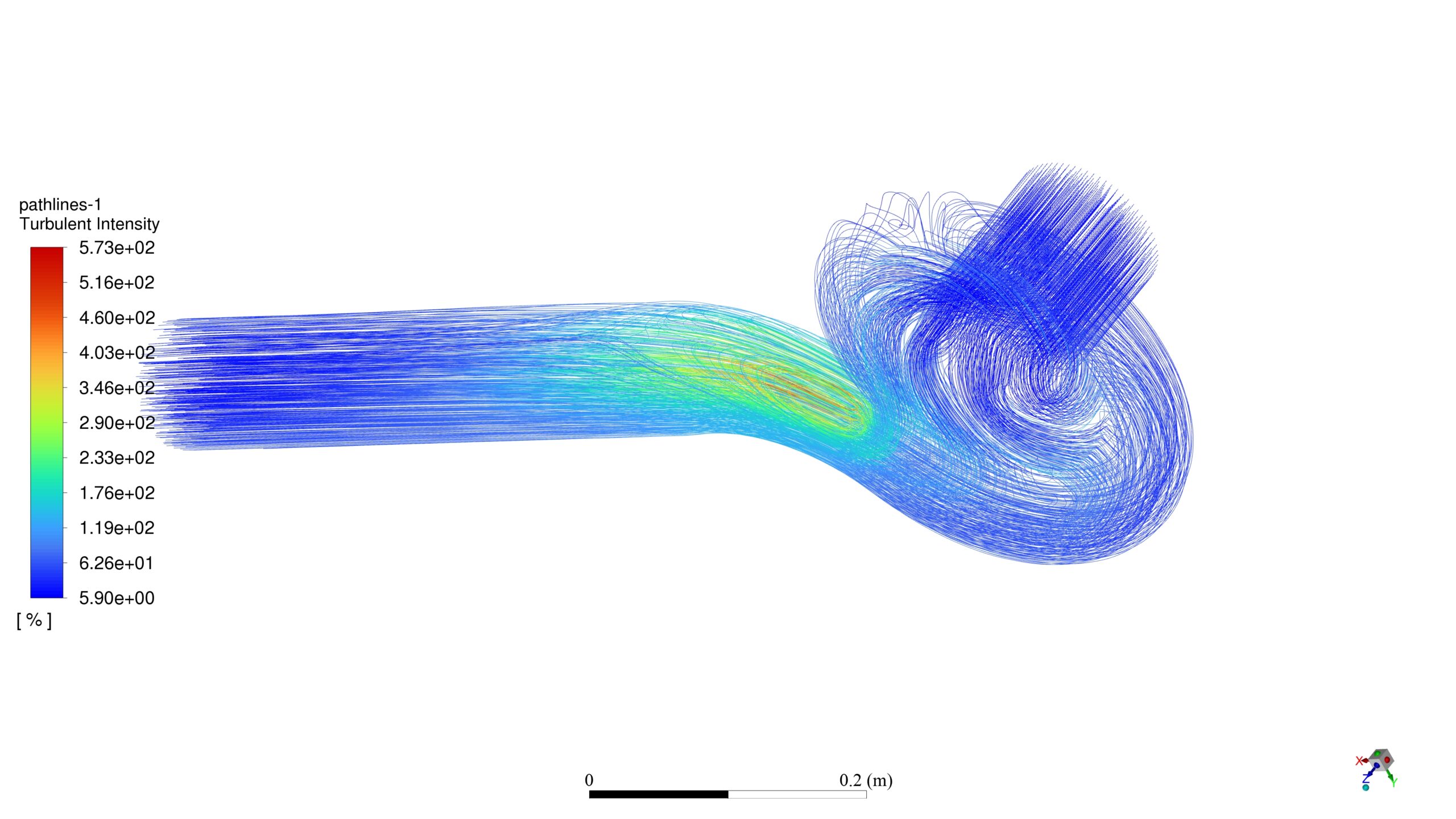

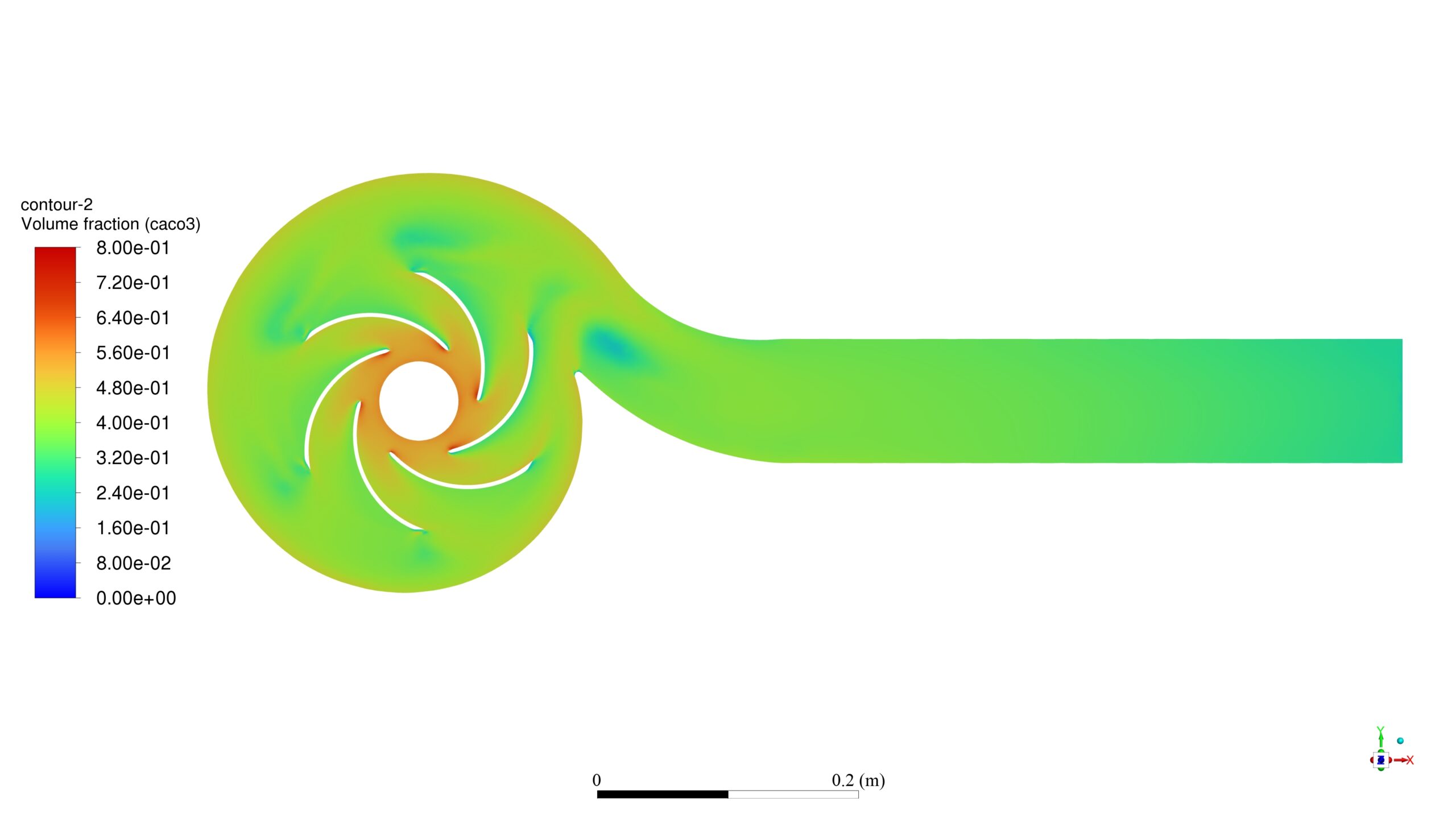

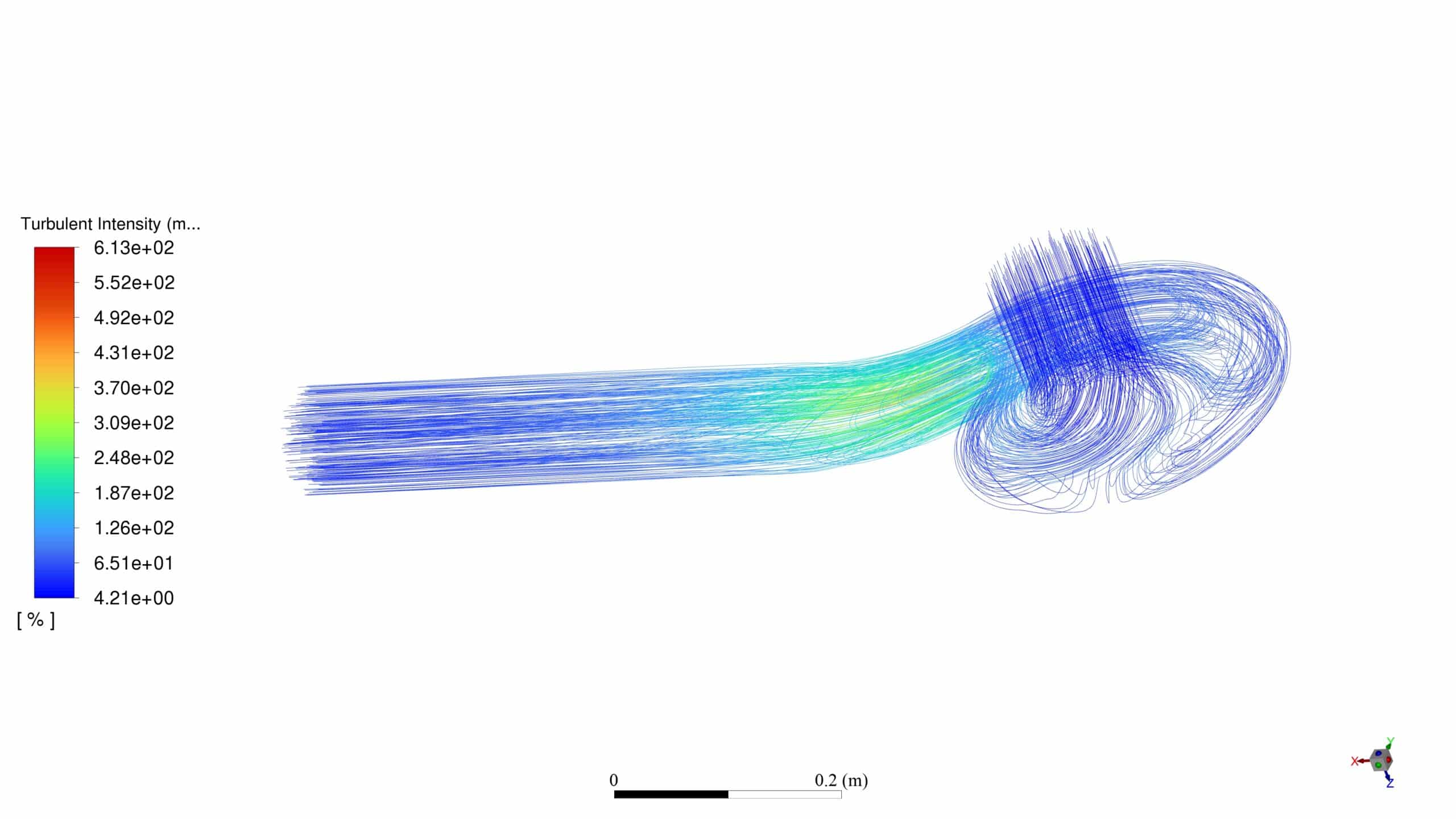

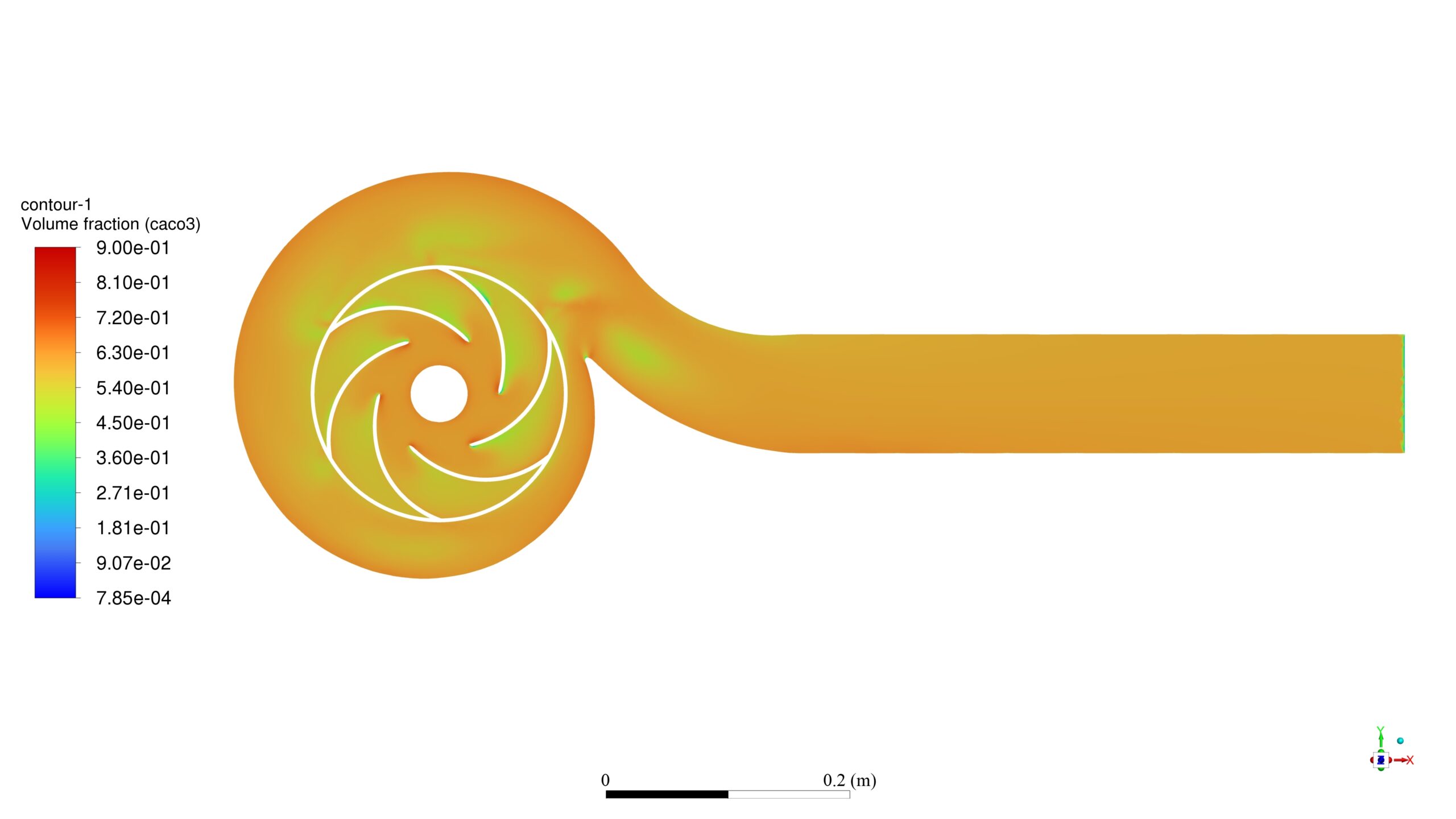

Second, we simulated the sludge flow, including water as the base fluid and calcium carbonate as particles with 50% and 60% concentration, respectively, using a multiphase mixture model, which can account for solid particles suspended in a liquid medium.

We modeled the geometry of the project using Design Modeler software. Then we meshed the model with ANSYS Meshing software. The mesh model is polyhedral, and the number of cells equals 1,498,132.

Sludge Flow In Centrifugal Pump Methodology

In this problem, the mixture model solves the sludge flow by considering water and calcium carbonate as the first and second phases. The Schiller-naumann model is chosen to model the drag coefficient.

Multiple Reference Frames (MRF) model has been applied for the rotation simulation. The diameter of particles is considered equal to 100 µm. The SST k-w turbulent modal is used for both water and slurry flow.

Conclusion

The pressure, velocity, volume fraction and turbulence intensity contours, velocity vectors, and path lines are presented for the pure water and mixture model. These results show the behavior of both water and sludge flow through a centrifugal pump. Also, you can see the effect of increasing sludge concentration on pressure, velocity contours, and turbulence intensity.

Kendrick Ortiz –

I’m impressed with the complexity of the simulation handling particle-laden sludge flow! Can you tell me what effect the rotational speed of the pump had on the particles’ behavior and overall pump efficiency in the simulated environment?

MR CFD Support –

In the simulated centrifugal pump environment, the rotational speed of 1000 rpm influences how these particle-laden sludge flows interact with the pump components. High rotational speeds can lead to increased centrifugal forces acting on particles. This can cause more pronounced wear and erosion on the impeller and also affect the distribution and flow patterns within the pump, potentially leading to uneven particle distribution. Increased internal friction and turbulence can reduce overall pump efficiency at these high concentrations. The simulation provides insight into such effects, helping evaluate the durability and performance of the pump.

Neil Effertz –

This tutorial seems very thorough. Can you please explain how the multiphase mixture model handles the different phases, especially with high particle concentration like in sludge?

MR CFD Support –

The multiphase mixture model used in the simulation handles the multiple phases by treating them mathematically as one fluid with properties that are averaged based on their volume fractions. For the case of sludge with high particle concentration, such as in the simulation, it predicts the behavior of the sludge by considering the interactions between the particles and the base fluid. The density and viscosity of the sludge are determined by the concentration of particles, and the model accounts for solid-liquid interactions through the implementation of effective viscosity models and interphase drag formulations.

Dean Kessler –

This tutorial seems in-depth! Does it also cover how to account for wear and abrasion on the impeller and other parts of the pump due to sludge flow?

MR CFD Support –

Thank you, we’re delighted to hear you’re interested in the intricacies of our tutorial! The main focus of this simulation is to analyze the flow and pressure distribution of the sludge within the centrifugal pump. Wear and abrasion indicators are indeed critical for longevity and performance assessments, but tuning the simulation to predict wear patterns requires advanced modeling, such as discrete-phase or erosion models. The current tutorial is aimed at providing an understanding of the fluid dynamics with solid particle interactions. For wear considerations, additional modules and steps would be necessary which might go beyond the scope of this initial analysis.

Mr. Thad Fisher Jr. –

What are the benefits of using a polyhedral mesh in this particular simulation of sludge flow in a centrifugal pump?

MR CFD Support –

The use of a polyhedral mesh offers better accuracy and convergence speed in the CFD simulation. Polyhedral cells have more faces than tetrahedra or hexahedra, which allows for a more isotropic distribution of points and hence a better approximation of flow gradients within each cell. Additionally, fewer polyhedral cells are needed to fill the same volume compared to tetrahedral cells, which can lead to a reduction in computational cost without compromising the solution quality.

Jeremy Padberg III –

After performing the CFD simulation, were you able to determine the difference in energy requirements for sludge with higher particle concentrations versus lower ones?

MR CFD Support –

Yes, the simulation provided insights into the energy requirements for different sludge concentrations. Higher particle concentrations in the sludge increase the viscosity and density, which leads to greater friction losses inside the pump system, requiring more energy to maintain the desired flow rate.

Selmer Roob –

The tutorial seems quite detailed, and modeling sludge flow is complex. Do you have any additional tips for accurately capturing the interactions between the sludge particles and the pump components?

MR CFD Support –

In our tutorial, we emphasize the critical role of accurately setting particle diameter, density, and volume fraction for the sludge particles. Additionally, selecting the appropriate drag model is essential—Schiller-Naumann in this case—alongside ensuring proper mesh resolution around critical areas such as the impeller to capture the interactions with high fidelity. Boundary conditions should also reflect realistic inflow and rotational speeds. For deeper analysis and specific optimization regarding wear and abrasion, utilizing a Discrete Phase Model (DPM) could benefit in capturing particle trajectories and interactions with the pump walls more precisely.

Bailey Jenkins –

I’m pleased with the level of detail in the sludge flow CFD simulation tutorial. The inclusion of different particle concentrations makes it a practical tool for understanding real-life centrifugal pump issues. I’m also curious about the lifespan of the centrifugal pump when handling highly viscous sludge. Is that discussed in the results or recommendations section of the product?

MR CFD Support –

Thank you for your feedback on our sludge flow CFD simulation tutorial. Regarding your question about the lifespan of the centrifugal pump when handling highly viscous sludge with high particle concentration, the tutorial primarily focuses on the flow behavior and performance analysis. However, the tutorial does highlight the issue of increased wear and abrasion on pump parts due to viscous sludge, which indirectly implicates potential maintenance and lifespan considerations. For a thorough lifespan estimation, additional material wear and fatigue analyses would be required, and this could be considered in an advanced study beyond the scope of this CFD simulation tutorial.

Kian Little –

I found the CFD analysis of sludge flow in a centrifugal pump very informative, especially the impacts of different particle concentrations. The detailed results offer great insights into the performance under challenging conditions. Well done on demonstrating the importance of proper CFD simulations in dealing with complex fluids like sludge.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that you found our CFD analysis of sludge flow in a centrifugal pump both informative and comprehensive. Understanding the behavior of complex fluids in machinery is crucial, and we’re glad our simulations could offer you valuable insights. If there are any more details you’re interested in or another aspect of CFD simulations you’d like to explore, don’t hesitate to reach out! We’re here to help.

William Kub –

This tutorial has provided valuable insights into the behavior of sludge flow through centrifugal pumps. I particularly appreciate the detailed analysis of the impact of particle concentration on pump performance.

MR CFD Support –

Thank you for your feedback! We’re glad you found the insights on the sludge flow behavior and its impact on centrifugal pump performance useful. We always aim to provide comprehensive analyses and conclusions in our CFD simulations and tutorials to aid your understanding and application of CFD in real-life scenarios. Kindly reach out if you have any more questions or need further assistance in your projects.

Jorge Medhurst –

How does this simulation account for the wear and abrasion on pump components due to sludge flow with high particle concentration, and does it provide predictions on the lifespan of the pump parts?

MR CFD Support –

While the simulation provides valuable insights into the flow behavior and pressure and velocity changes within the centrifugal pump due to high-concentration sludge flow, it focuses on the immediate flow dynamics rather than the long-term abrasion and wear predictions. Wear predictions and the impact on component lifespan would require additional analysis that typically encompasses material properties, operating conditions, and potentially a particle tracking model to simulate the erosion wear on the component surfaces.

Okey Langosh –

I’m new to CFD, and after going through this amazing simulation, I was wondering if you could clarify how the Multiple Reference Frames (MRF) model works in simulating the rotation of the centrifugal pump.

MR CFD Support –

The Multiple Reference Frames (MRF) model is a technique used in CFD simulations to handle rotating machinery. In your simulation, one part of your grid (representing the pump’s impeller) is set in a rotating reference frame. This portion rotates at the prescribed speed (in this case, 1000 rpm), while the stationary part of the grid does not rotate. The interaction between the rotating and stationary zones is accounted for in the calculations, which allows the simulation to capture the effects of rotation on the fluid flow without needing to physically move the mesh. This simplifies the computation considerably while still producing accurate results.

Kayley Cartwright –

How does the particle concentration of the sludge affect the pump’s performance and maintenance requirements?

MR CFD Support –

The higher particle concentration of the sludge increases the sludge viscosity and density, leading to greater friction losses within the pump system and more considerable wear on internal parts like the impeller. Maintenance requirements may increase due to the abrasion and the additional energy required by the pump to maintain the flow rate against the increased resistance.