Step Solar Still by Solar Ray Tracing, Species Transport

$220.00 Student Discount

- The problem numerically simulates the Step Solar Still by Solar Ray Tracing using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

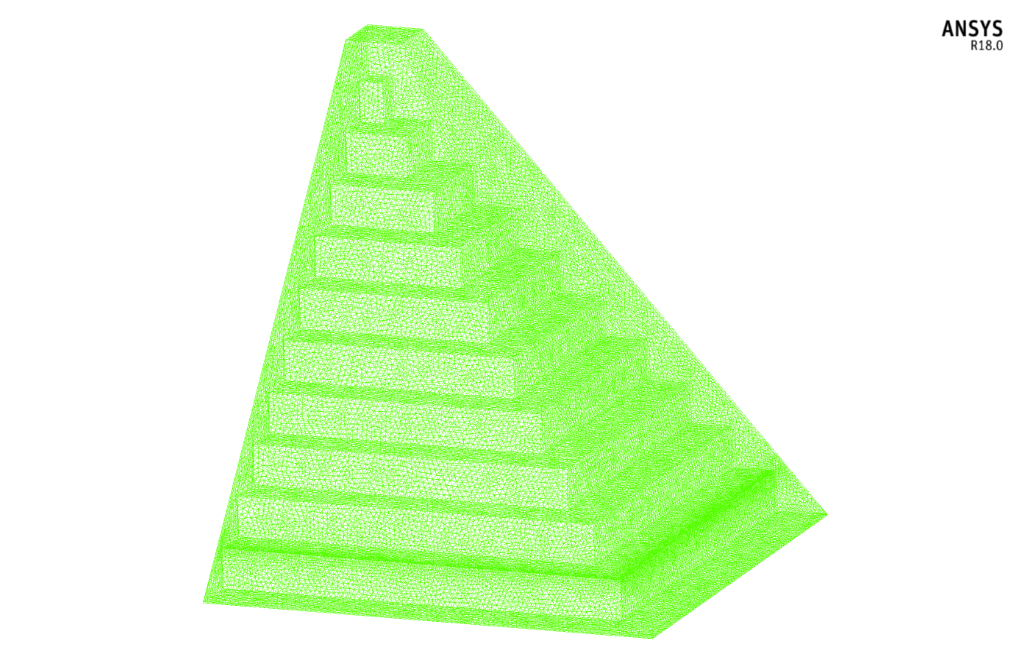

- We Mesh the model by ANSYS Meshing software, and the element number equals 809037.

- We use the Species Transport model to define water and vapor.

- The Solar Ray Tracing model is used to apply the heat absorbed by the sun.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Step Solar Still by Solar Ray Tracing, Species Transport Model, ANSYS Fluent CFD Simulation Training

The present study investigates the performance of a step solar desalination unit by ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The present model consists of a small chamber with a sloping glass surface on both sides and steps within it, where saline water flows on the surface of these steps.

Solar radiation heat transfer passes through the glass to the surface of the water in the enclosure to evaporate the water surface on the steep walls. The resulting vapor meets the cold glass surface and undergoes a distillation process.

Pure water from hot vapor distillation moves down the slope of the glass plate and discharges as pure water.

The present model is designed in three dimensions using Design Modeler software. Since the geometry is symmetric, only one-quarter of the geometry is modeled. This quadrilateral geometry consists of two sloping glass and steps carrying water flow.

The meshing of the model has been done using ANSYS Meshing software. The element number is 809037.

Methodology

To convert the saline water into fresh water, it should be turned into vapor; then, by condensing it, fresh water is obtained. The distillation devices normally comprise a sloped glass layer placed on top of the device and a stepped platform for storing saline water that will be distilled.

The glass layer acts as a hard substrate and a transparent layer that allows sun rays to enter the device. The heating process for obtaining vapor from saline water is generally done using the heat absorbed from solar rays in the distillation devices.

Next, the generated vapor can be condensed into fresh water by rising and colliding with the glass substrate, which acts as a cold surface. Hence, the solar ray tracing model is enabled to simulate the heat absorbed by the sun.

Also, the species transport model is activated to simulate the two phases of water and vapor inside the designed distillation system. It should be mentioned that this method assumes a mixture of water and vapor inside the chamber interior and does not simulate distilled water flow.

In fact, at the beginning of the simulation, the space inside the chamber is filled with vapor only; the bottom plane of the chamber is considered the surface of the water, and since the water evaporates on the surface, it is assumed that the surface consists of vapor.

Constant values of 1.00314⨯10-5 m2/s and 0.0002 kg/ms are considered for the mass diffusion coefficient and the thermal diffusion coefficient, respectively, to convert water into vapor and vice versa.

It is also assumed that the sloping plate where the steam collides is composed only of vapor. It is also assumed that the ambient air temperature is 311.75K with a heat transfer coefficient of 25W/m2K.

The stepped platform containing saline water is assumed only to absorb heat with no transmissivity, while the glass substrate is assumed to have maximum transmissivity with no absorbance.

Gravity has been enabled in the Y direction, and the incompressible ideal gas model accounts for the density difference between water and vapor.

Step Solar Still Conclusion

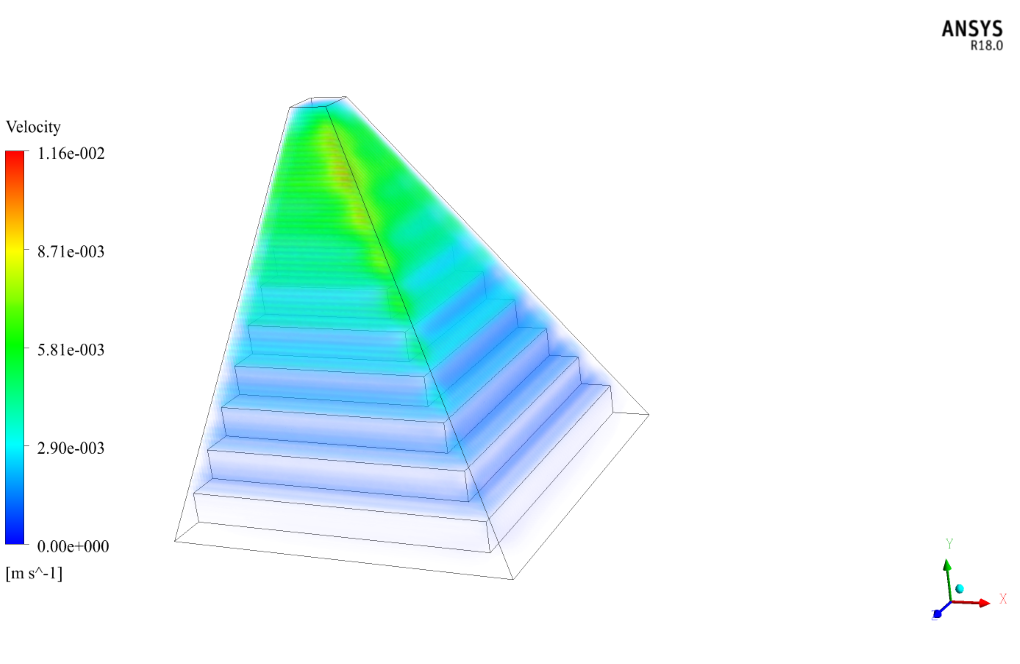

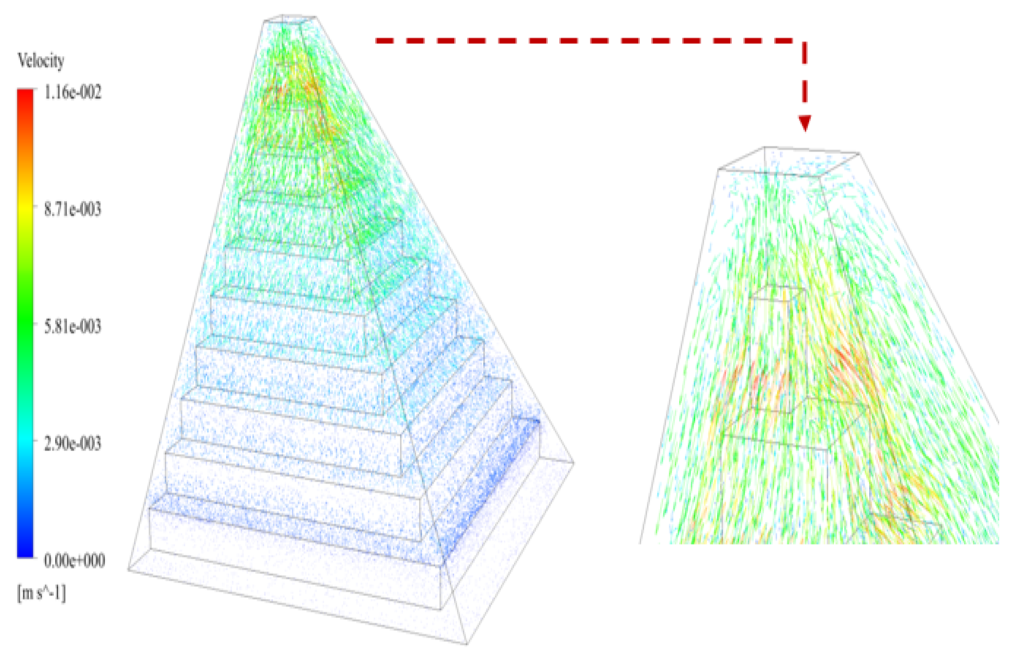

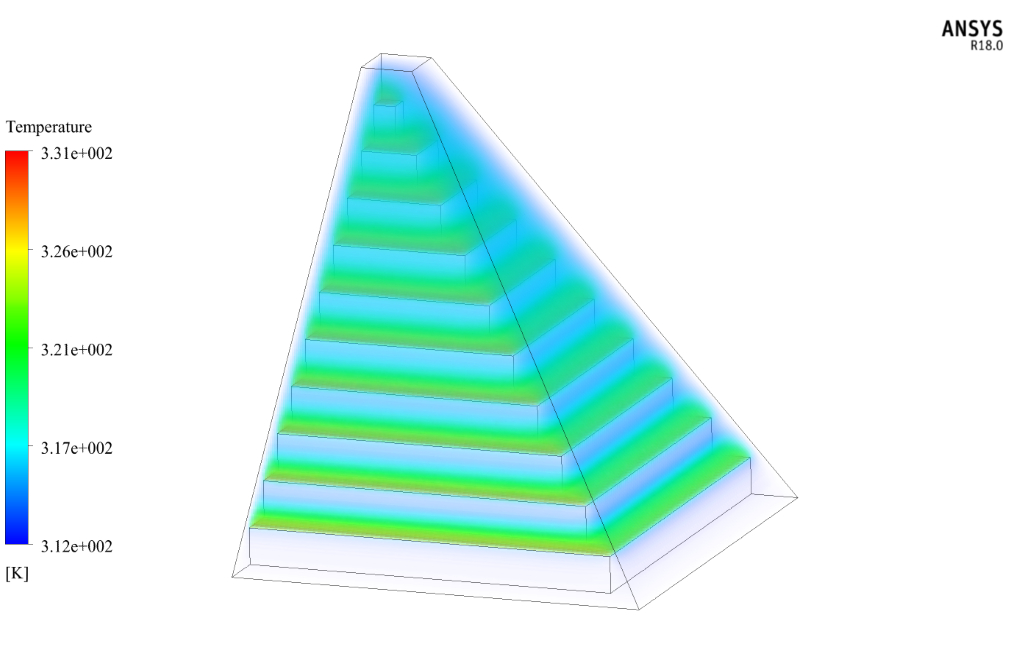

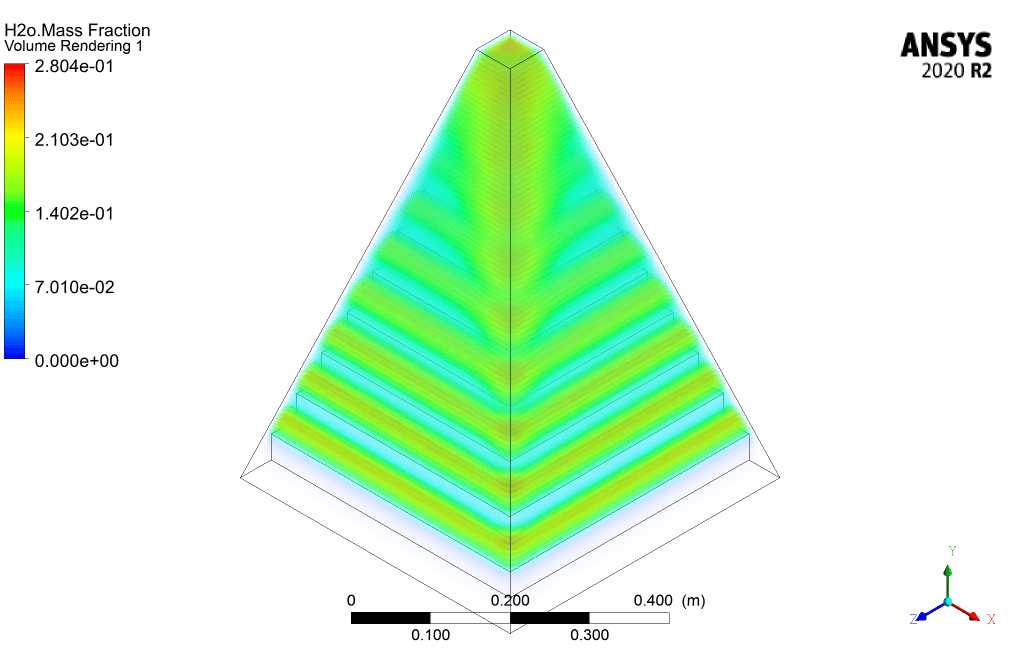

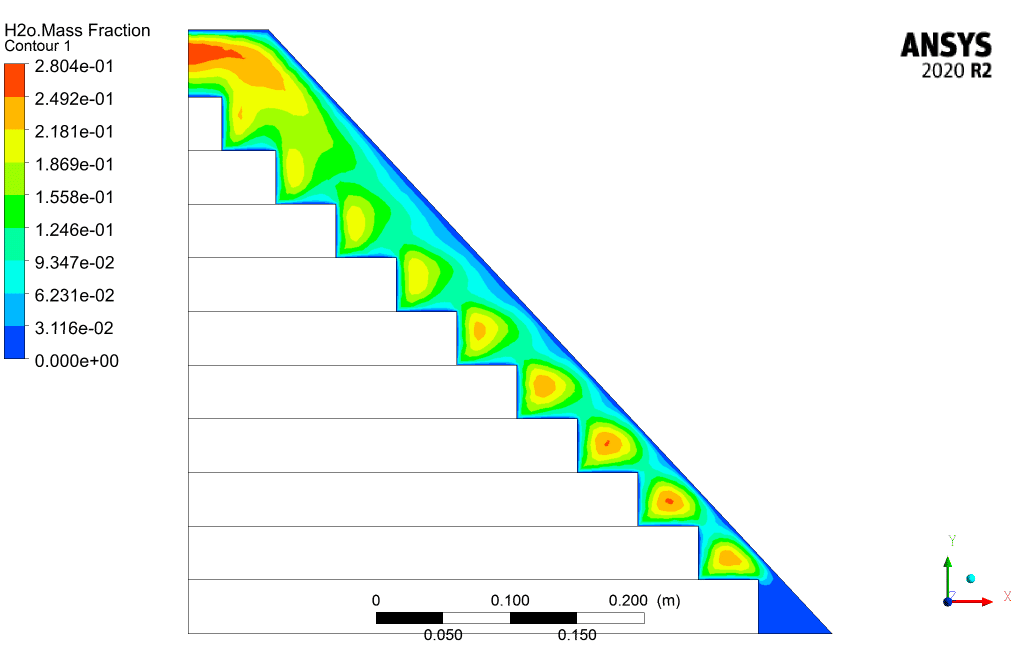

At the end of the solution process, three-dimensional contours related to the velocity, temperature, velocity vector, and species mass fraction inside the distillation device are obtained.

The contours related to velocity and its vectors show how the generated vapor rises within the distillation device to hit the top sloped glass surface.

Also, by viewing the 3D temperature contour, it can be easily observed that the temperature of saline water on the stepped platform has increased, making it evaporate.

Meanwhile, the temperature of the glass layer is cold enough to cause the vapor to condense and then slip to the lower part of the distillation device, where the freshwater is collected.

Also, by viewing the species mass fraction contour, it can be seen that the mass fraction of water is equal to one on the stepped platform and glass substrate. At the same time, the water volume fraction value decreases inside the distillation system space, indicating that vapor is forming there.

Heber Gerhold PhD –

How does the simulation manage the heat transfer process within the solar still?

MR CFD Support –

The simulation uses the energy equation to model the heat transfer in the solar still. This equation takes into account conduction, convection, and radiation, providing a comprehensive description of the heat transfer process.

Ava Roberts –

Is it possible to utilize this simulation to enhance the design of a step solar still?

MR CFD Support –

Yes, the simulation can provide valuable insights into the effects of various design parameters on the performance of the solar still, which can be used for optimization purposes.

Kade Streich –

The 3D contours helped me visualize the process effectively. The performance must be highly enhanced by the heat transfer coefficient and sun ray simulation you’ve mentioned. Thank you for facilitating an easier understanding of solar desalination.

MR CFD Support –

Thank you for your positive feedback on our Step Solar Still by Solar Ray Tracing, Species Transport model! We are glad to hear that the 3D contours effectively aided your understanding of the solar desalination process and that you appreciate the attention to detail in our simulations. If you have further interest or queries regarding CFD analysis, feel free to reach out. We’re committed to providing high-quality tools that help ease the learning curve for complex processes like this!

Althea Schmeler –

The process explanation in this review makes the understanding of the step solar still simulation crystal clear—exceptionally detailed and insightful data, which seems to give a full snapshot of the methodology and the anticipated results from the analysis.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the detailed description provided a clear understanding of the step solar still simulation using ANSYS Fluent. Your compliment is greatly appreciated, and we’re pleased to know that our learning product has met your expectations.

Dr. Kennedy Jakubowski –

The product enlightened me on CFD simulations for solar distillation – magnificent educational material indeed. I’m taken aback by the detailed explanation and the results showcasing the temperature and vapor formation. Really gives insight on sustainable water purification!

MR CFD Support –

Thank you for the positive feedback! We are thrilled to hear that our simulation training on step solar still utilizing solar ray tracing and species transport has provided you with valuable insights and a deeper understanding of sustainable water purification methods. Your appreciation for the details and results in the training means a lot to us. We strive to create instructive and practical learning experiences, and it’s rewarding to know when they make a difference. Thank you for choosing MR CFD for your learning pursuits.

Gilbert Wyman –

Fantastic resource for understanding the step solar still design process using ANSYS Fluent! The description of the methodology involved in solar ray tracing and species transport is particularly impressive. Seeing how vapor flow, temperature variations, and water condensation are simulated gives me insights that were directly applicable to my project on solar distillation. Great work!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our step solar still simulation training has provided valuable insights for your solar distillation project. If you have any further queries or need assistance with any other simulations, feel free to reach out to us.

Grayson Balistreri –

The tutorial was incredibly detailed and made it much easier to understand solar desalination. The step-by-step guidance through the modelling process was particularly helpful!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training helped clarify the process of solar desalination for you. It’s great to know that the detailed steps in the simulation modelling guided you well. Your satisfaction with our learning product is very important to us.

Adalberto Hickle –

I’m thoroughly impressed with the methodology used in the Step Solar Still simulation. Seeing how saline water can be turned into fresh water using sunlight is fascinating. The detail included in the CFD simulation, from the sloped glass to the temperature and velocity contours, demonstrates how thoughtfully the process has been designed to track and enhance the condensation and collection of pure water. Outstanding work in showing the transformation within that chamber. It’s like watching nature’s desalination process, but in a much more controlled and efficient environment!

MR CFD Support –

Thank you for your kind words! We are pleased to see that you appreciate the intricacies of our CFD simulation for the Step Solar Still. Our team has worked diligently to replicate the natural desalination process in a way that is both realistic and informative through our simulation. We’re glad the result has captured your interest and provided valuable insights. Thank you for choosing our learning product and taking the time to express your satisfaction!

Prof. Stewart Mitchell –

I am impressed by the thoroughness of the solar still CFD simulation study using ray tracing and species transport. The contours related to temperature and species mass fraction provide such crisp visuals that one can easily marvel at the intricate process of evaporation and condensation detailed in the model. Truly, a well-executed and insightful investigation into the performance of a step solar desalination unit.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that you appreciate the detail and clarity of the simulation results. Our aim is always to provide comprehensive and accurate insights to help understand complex systems, and your recognition of this effort is highly encouraging. If you have any further questions or need assistance with similar projects, do not hesitate to reach out to us.

Claire Kris IV –

As indicated by the species mass fraction contour, how is the mass fraction of water being segregated from vapor in the system? Can you elaborate on the functioning there?

MR CFD Support –

The species transport model allows for the differentiation between the water and the vapor based on the mass fraction in this simulation. On the stepped platform and glass substrate, the mass fraction of water is set to one because these surfaces are in direct contact with liquid water. As the water evaporates due to the heat absorbed from the solar rays, the water turns into vapor, and its mass fraction in the vapor phase will be less than in the liquid. Within the chamber, the mass fraction decreases, signifying that more vapor is forming. Functionally, when this vapor comes in contact with the cooler glass surface, it condenses back into water which has a mass fraction of one as pure distilled water which is then collected.

Mrs. Melyna Reynolds III –

Can this simulation predict the productivity of the solar still?

MR CFD Support –

Yes, the simulation provides insights into the temperature and humidity distribution, as well as the rate of evaporation and condensation, which can be used to predict the productivity of the solar still.

Ardith Wyman –

The training material was well-structured and led me through all steps of the simulation process. I appreciate the detailed explanation of the methodology, particularly the solar ray tracing and species transport models. Furthermore, the clear outline of the cold condensation phenomena on the glass surface was enlightening.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the course content was effectively structured and informative. It’s great to know that the explanations on solar ray tracing and species transport provided in the training have contributed to your understanding of the simulation process. If you have any further questions or need additional guidance, please feel free to reach out.

Mrs. Alfreda Towne II –

How does this simulation model the evaporation and condensation processes?

MR CFD Support –

The simulation uses the mass transfer model to simulate the evaporation and condensation processes. This model is based on the principle of conservation of mass and takes into account the temperature and humidity conditions inside the still.

Sam Leffler DVM –

The course content sounds comprehensive, but does it come with support materials or tutorials for beginners in CFD to make the most out of it?

MR CFD Support –

Our Step Solar Still CFD simulation training is designed to cater users of different levels, including beginners. It comes with detailed instructional materials and tutorials to ensure that even those new to CFD can follow along and fully grasp the simulation process and concepts presented.

Peter Becker –

This product receives an excellent review from me! The step solar desalination unit study using ANSYS Fluent is an exciting application of CFD. I’m deeply impressed with how solar ray tracing and species transport models are integrated for convincingly simulating the conversion of saline water to freshwater through vaporization and condensation processes. The attention to realistic conditions, like accounting for solar heat transfer through a sloping glass plane and having a stepped chamber for the saline water is thoughtfully crafted. The detailed outcome of temperature, velocity, and species mass fraction contours demonstrated that the software effectively captures the generation and movement of vapor resulting in the collection of fresh water. Kudos to MR CFD Company for providing such hands-on learning experiences that help us visualize and comprehend complex physical phenomena with greater clarity.

MR CFD Support –

Thank you for your thoughtful and detailed complement! We are grateful for your positive feedback and thrilled to hear that our Step Solar Desalination Unit study with ANSYS Fluent has met your expectations. It’s our pleasure to provide products that deliver nuanced and practical insights into complex systems. We look forward to continuing to support your learning experience with our CFD training materials and simulations.

Frederik Ledner –

I truly appreciate the comprehensive functionality of the step solar still simulation and how effectively it captures the distillation process using solar energy. The integration of species transport modeling is especially impressive, allowing for an in-depth analysis of vapor formation and condensation.

MR CFD Support –

Thank you for your positive feedback on our step solar still simulation and its detailed analysis. We’re delighted to hear that you found the species transport modeling to be a valuable feature for understanding the complexities of solar distillation. Your appreciation means a lot to us!