Tank Filling CFD Simulation, 3-phase, ANSYS Fluent Training

$80.00 Student Discount

In this project, Tank Filling with three phases (VOF) has been simulated and the results have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Tank Filling Project Description

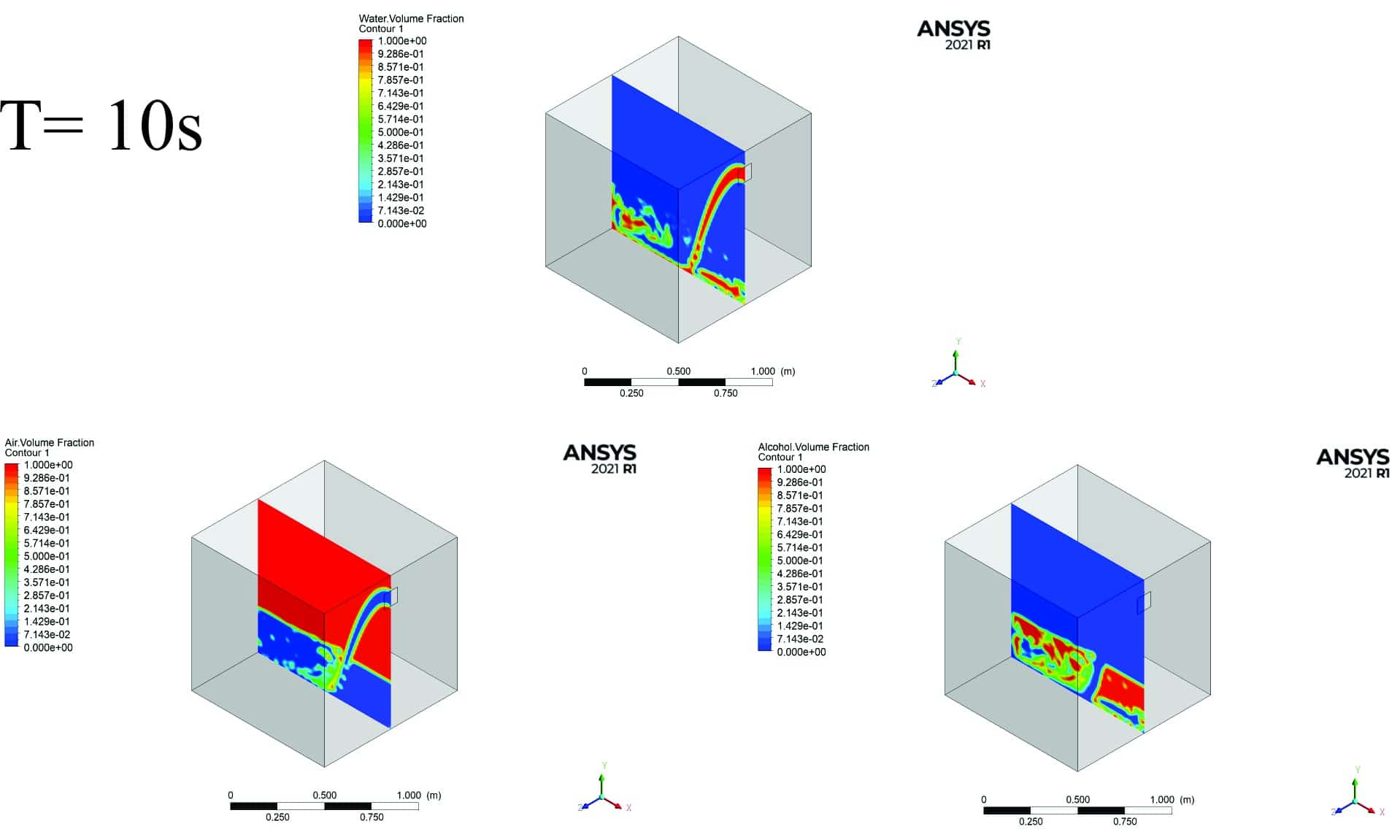

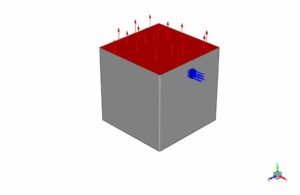

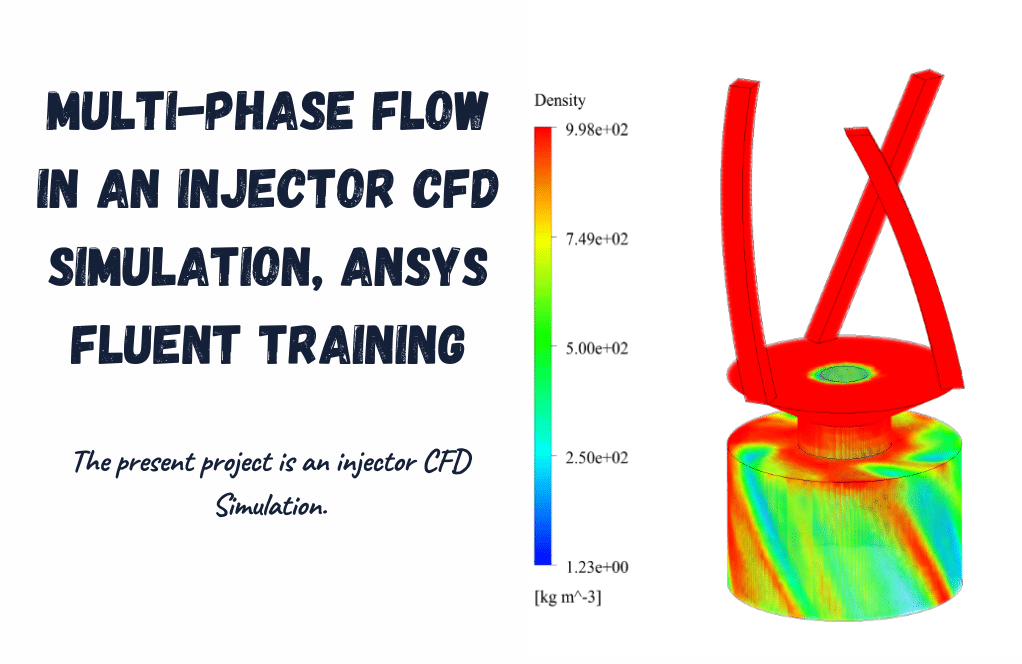

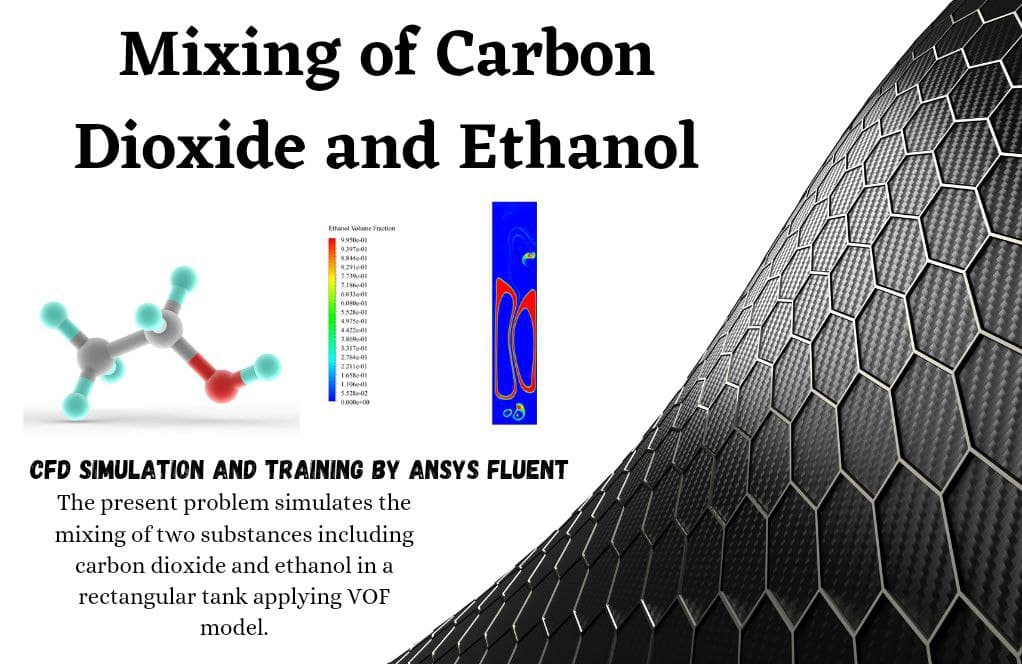

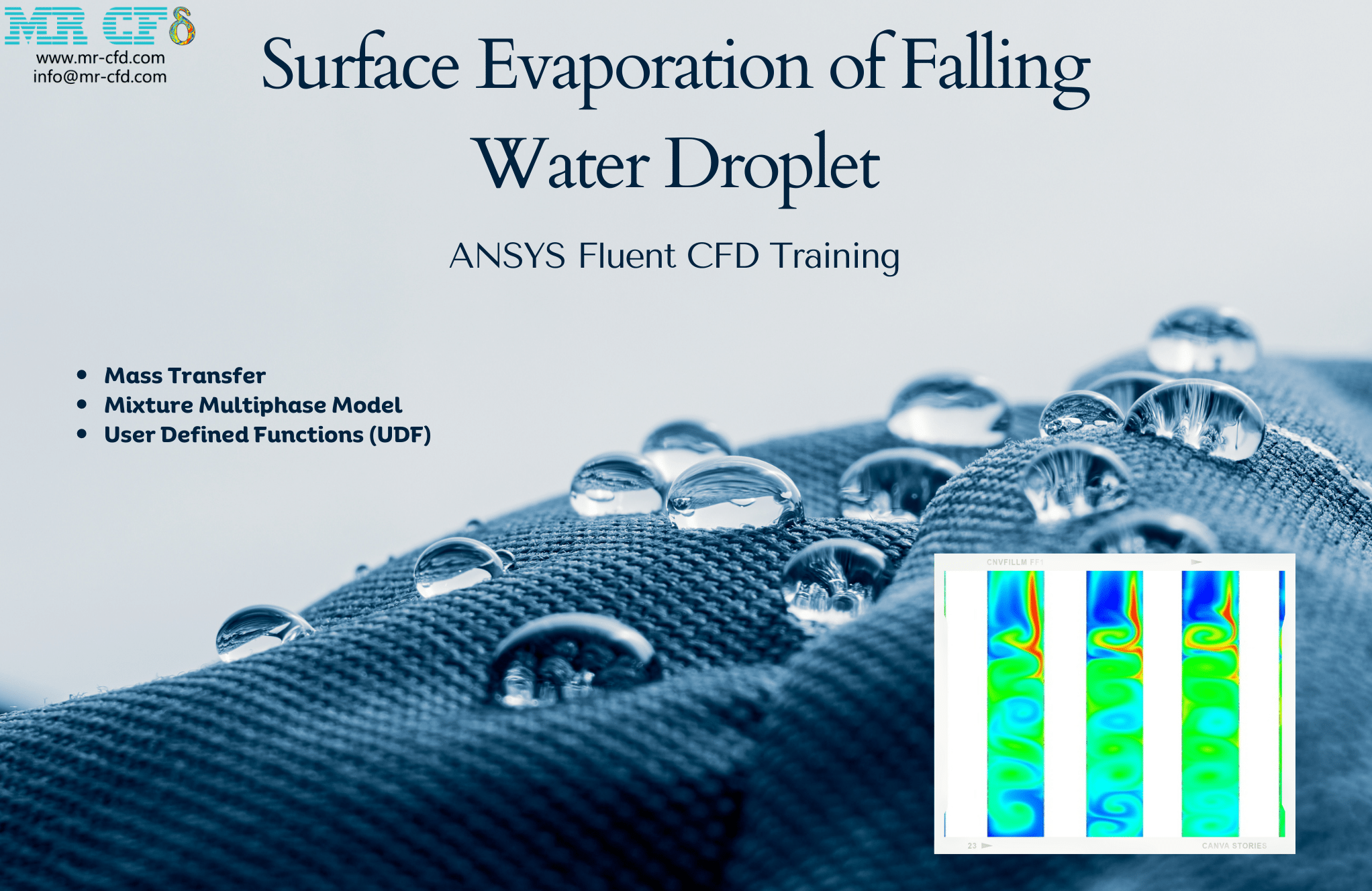

The current project simulates the tank filling by Ansys Fluent software. The goal of many operations in the chemical industry is to separate the components of a solution or mixture from each other or to obtain a pure substance from a combination of two or more components. In this Tank Filling simulation, using the VOF (volume of fluid) method, the interaction of three phases, including water, alcohol, and air was investigated. For this purpose, the effect of shear forces on the boundary between the phases was applied by applying surface stresses between the two phases. Water enters the domain through a 10 cm side valve at a speed of 1 m / s, and the interaction of the phases was investigated by comparing different contours.

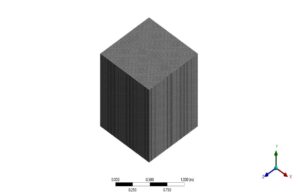

Geometry & Mesh

The computational domain was designed using Design Modeler software, and its dimensions were a cube with a side of 1 meter. A square valve with a side of 10 cm in the wall was designed to allow water to flow into the domain. In the beginning and before starting to solve the problem, there was 40 cm of alcohol in the bottom of the container

.

Ansys Meshing software was used for grid generation, and the type of problem elements was structured. Also, the total number of elements was about 421,000.

Tank Filling CFD Simulation

To simulate the present model, several assumptions are considered, which are:

- Due to the incompressibility of the flow, the pressure-based solver method has been selected.

- The simulation is transient.

- The gravity effect is considered equal to -9.81 m.s-2 on Y-axis

- All thermodynamic properties of fluids, including density, were assumed to be constant.

The VOF (Volume of Fluid) model is used to simulate non-mixing biphasic flows and is generally used to simulate the interface of two fluids. In other words, the VOF model will be highly efficient when the goal of the simulation is to study the interface between two fluids. In the software, the equations of each phase were solved discretely along with the RANS and turbulence equations.

The following is a summary of the steps for defining the problem and its solution:

| Material Properties | |||

| Water | |||

| Amount | Fluid properties | ||

| 998.2 | Density (kg/m3) | ||

| Alcohol | |||

| Amount | Fluid properties | ||

| 790 | Density (kg/m3) | ||

| Air | |||

| Amount | Fluid properties | ||

| 1.225 | Density (kg/m3) | ||

| Multiphase | |||

| Homogeneous model | VOF (volume of fluid) | ||

| Number of Eulerian phases | 3 (water-alcohol-air) | ||

| Interface modeling | sharp | ||

| Formulation | Explicit | ||

| Phase interaction | |||

| Fluid type | Surface tension coefficient (N/m) | ||

| Water-air | 0.072 | ||

| Alcohol-water | 0.043 | ||

| Air-alcohol | 0.022 | ||

| Boundary Condition | |||

| Type | Amount (units) | ||

| Velocity inlet | 1 m/s | ||

| pressure outlet (gauge pressure) | 0 pa | ||

| Cell zone condition | |||

| Fluid | mixture | ||

| Turbulence models | |||

| K-epsilon | viscous model | ||

| Realizable | K- model | ||

| Standard wall functions | Wall function | ||

| Solution methods | |||

| SIMPLE | pressure velocity coupling | ||

| PRESTO | pressure | spatial discretization | |

| Second-order upwind | momentum | ||

| First-order upwind | turbulent kinetic energy | ||

| First-order upwind | turbulent dissipation rate | ||

| Volume fraction | Geo-reconstruct | ||

Tank Filling Results

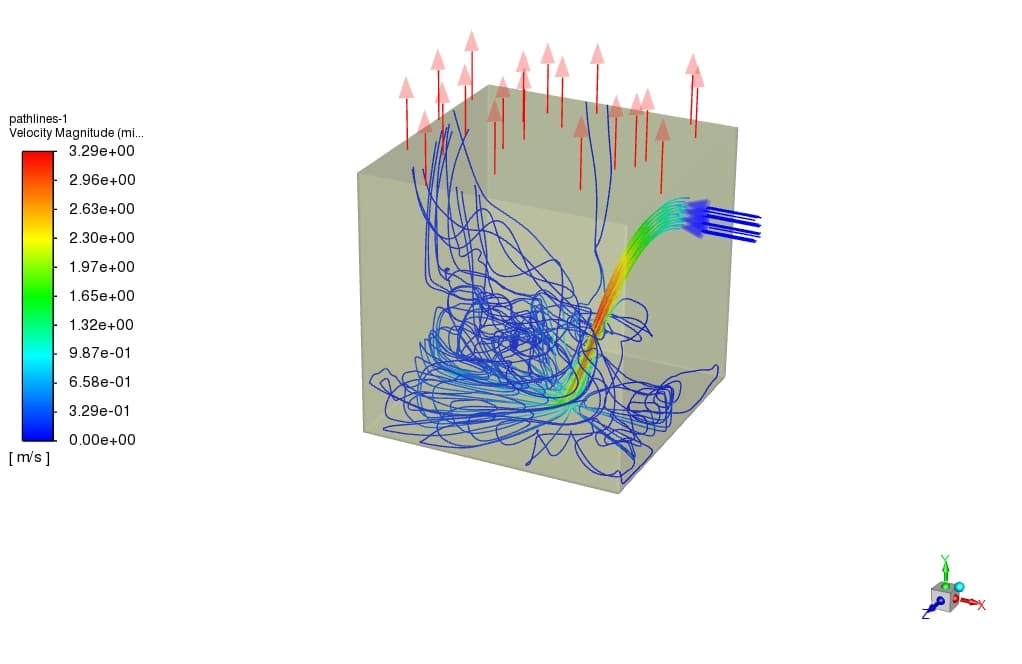

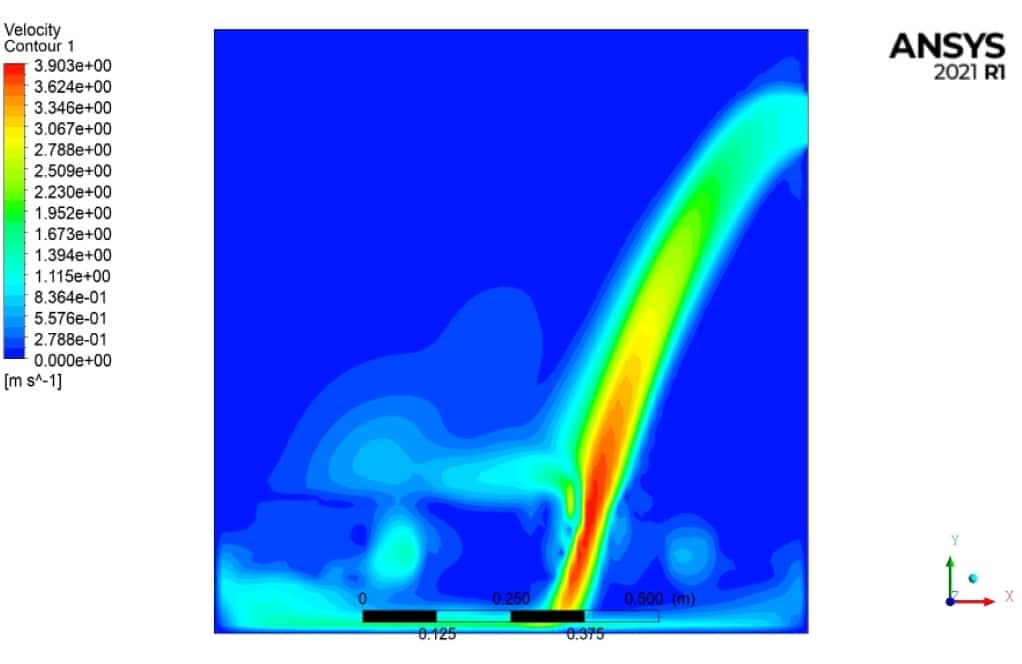

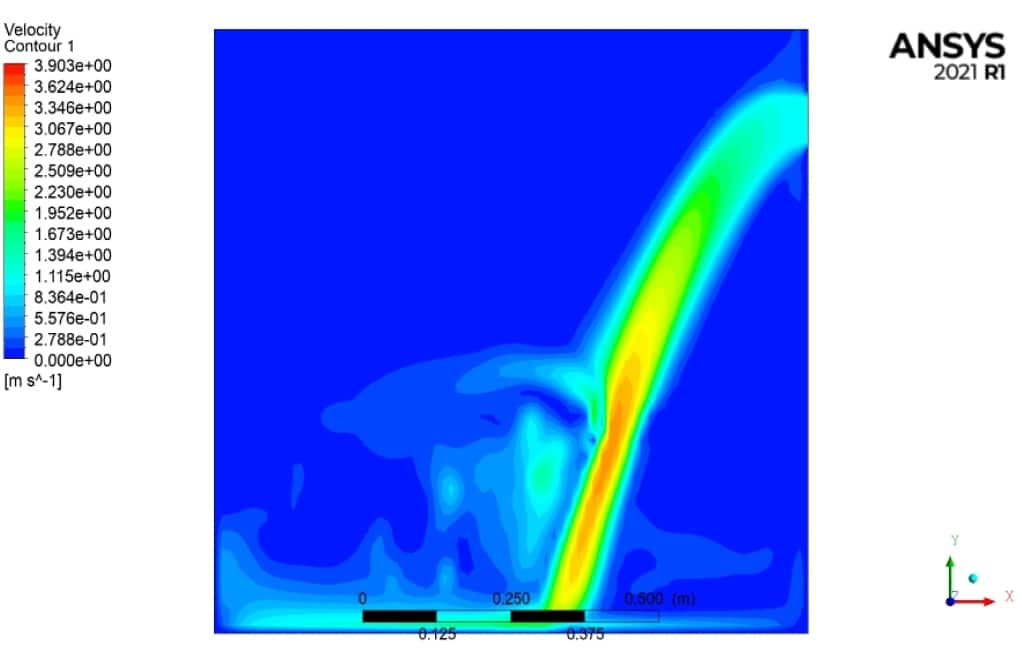

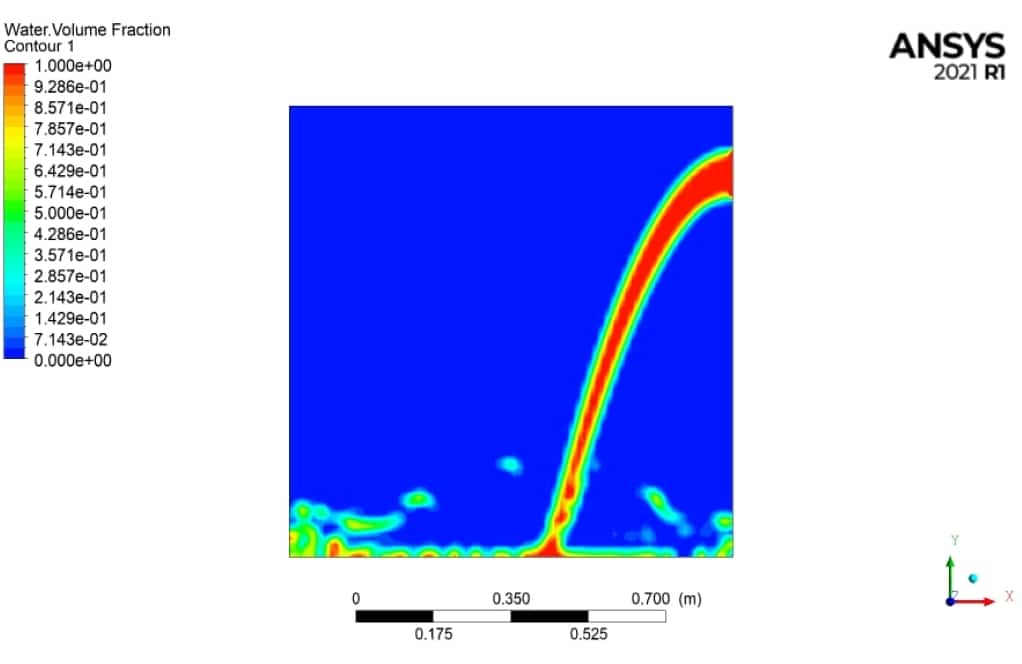

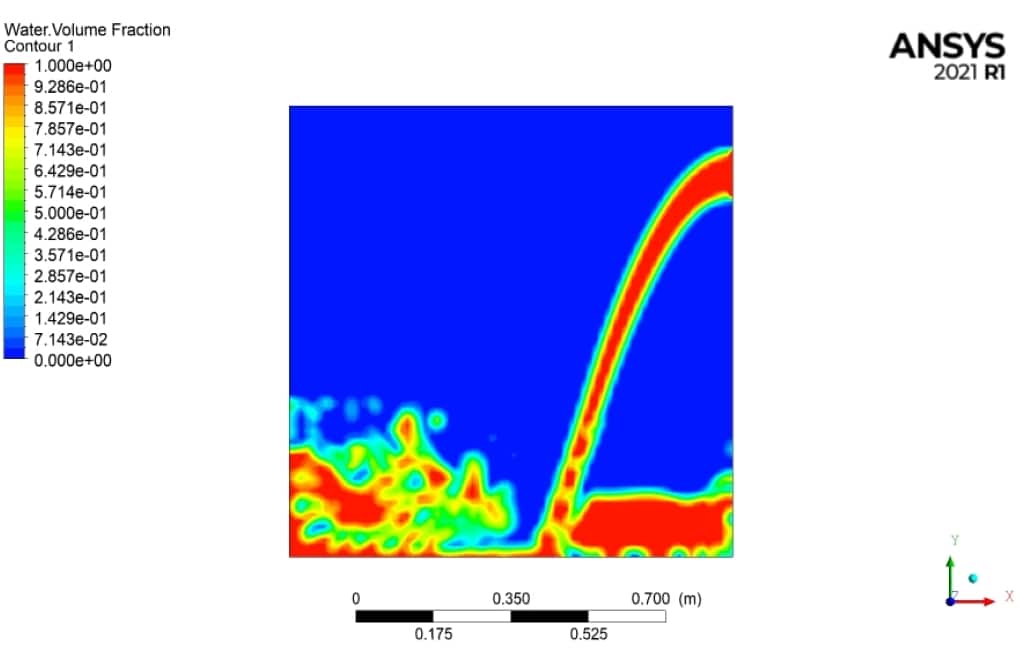

In this section, first, the velocity counters at 1 and 15 seconds after solving were given below. As can be seen in the attached animation, as the volume of water in the tank increases, the alcohol phase moves upwards, and due to the non-mixing of water and alcohol, the separation operation can be performed by placing a drain valve under the tank.

Tevin Haag –

I was pleased with the detailed explanation of the tank filling simulation. Will I be able to apply this training to a four-phase system with different fluids?

MR CFD Support –

Thank you for your feedback! I’m glad to hear you found the three-phase tank filling simulation useful. While this specific training focuses on a system with water, alcohol, and air, the core principles of VOF modeling and the steps you’ve learned can indeed be applied to a simulation with four phases. You’d need to account for the additional phase interaction properties, update the boundary conditions accordingly, and ensure that the mesh is refined enough to capture the interfaces between all fluids involved.

Ms. Vesta Hoppe –

I was really impressed with the precision of the interactions between water, alcohol, and air in the Tank Filling CFD simulation. The clear definition of boundaries and smart application of the VOF methodology serve as a great learning resource for understanding multiphase flow.

MR CFD Support –

Thank you for your kind review! We’re thrilled to hear that the Tank Filling CFD simulation met your expectations. It’s always reassuring to know that our efforts to provide detailed and precise simulations contribute to a deeper understanding of complex processes like multiphase flows.

Winnifred Rosenbaum –

This course made my understanding of the VOF model so much clearer! It simplified the concept of phase interactions in a multicomponent system.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our Tank Filling CFD Simulation course made the VOF model clear and easy to understand. Our aim is to simplify complex concepts, and your feedback reaffirms the work we’re doing. We appreciate your support!

Rudy Heller I –

I was fascinated by the multiphase aspect of the simulation. Could you clarify how each fluid’s temperature impacts the simulation and whether it’s taken into account in the VOF method?

MR CFD Support –

In the VOF model for this tank filling simulation, the primary focus is on the interaction between the fluid phases, which includes their densities and surface tensions as mentioned in the project description. The temperatures of the fluids are typically important if the simulation includes heat transfer or if temperature variations substantially affect the fluid properties like viscosity or surface tension. However, in this simulation, all thermodynamic properties, including density, are assumed constant, which implies that temperature effects are not a primary concern. Thus, the temperature of each fluid does not play a substantial role in this simulation model, as the separation is primarily due to differences in density and surface tension between water, alcohol, and air, rather than temperature-based stratification or mixing.

Martina Ritchie Jr. –

Did the simulation investigate how different temperatures affect the interaction between water, alcohol, and air?

MR CFD Support –

According to the information provided in the project description, the effects of temperature on the interaction between the three phases were not investigated. The simulation focused on the separation process based on density differences under the assumption of constant thermodynamic properties, including density.

Bobbie Dibbert MD –

I’m delighted with how the simulation applied real conditions to a multicomponent system. The visual output must be fascinating! Thanks for offering such a comprehensive learning tool.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled that our simulation’s ability to model real conditions and provide visual insight was valuable to you. Your appreciation truly motivates us to keep providing quality simulations for in-depth learning experiences.

Alta Carroll –

I am delighted with the precision of the three-phase separation simulation. The visualizations of the shear force impacts and phase interfaces were especially informative. It helped me grasp the fundamental separation processes in the chemical industry. Great job on illustrating complex phenomena in such a straightforward manner!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation has been helpful and provided clarity on such intricate concepts. It’s wonderful that the visual representations enhanced your understanding of separation processes. We appreciate your positive feedback and look forward to providing you with even more insightful products!

Major Reinger –

I’m really impressed with the level of detail in the project description. It provides a thorough understanding of the simulation process. The inclusion of specifics such as the VOF method, mesh generation, boundary conditions, and even the results indicates a high-quality training product. Well done on creating an effective educational tool for understanding the complex dynamics of multi-phase flows in a tank filling scenario.

MR CFD Support –

Thank you so much for your positive feedback! We’re glad to know the product effectively delivered the intricacies of the simulation process and that you found the educational material comprehensive and helpful. Your appreciation really motivates us to continue creating high-quality CFD training materials. If you have any more questions or need further assistance in the future, don’t hesitate to reach out!

Marian Jerde II –

I really appreciated the clear presentation of material properties for each fluid phase. It made understanding the multiphase interaction within the tank more tangible.

MR CFD Support –

Thank you for your kind words! We’re pleased to hear that the detailed presentation of material properties enhanced your understanding of the multiphase interactions. If you need further clarification or information on any aspect of the simulation, feel free to reach out. Your insights are invaluable to us!

Eldred Keeling –

Fantastic learning material! This comprehensive project thoroughly elucidated the liquid-liquid and liquid-gas phase interactions during tank filling. Observing the separation operation was particularly insightful.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the Tank Filling simulation project was insightful and that you appreciated learning about phase interactions with the VOF method in ANSYS Fluent. If you have any further questions or need more information on our training materials, feel free to ask!

Mrs. Amelia Sauer I –

I just finished the Tank Filling CFD Simulation course, and the detailed insights on the interaction of three phases using the VOF method were thoroughly covered. Great course for understanding multiphase flow in industry applications!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Tank Filling CFD Simulation course valuable and that it contributed to your understanding of multiphase flow. We appreciate you choosing our learning products and hope to assist you in your future learning endeavors as well.

Lynn Pfannerstill –

This product seems fascinating! The attention to detail appears robust, but I had one query: what was the deciding factor for choosing the Realizable K-epsilon model over other available models for turbulence in this scenario?

MR CFD Support –

The Realizable K-epsilon model was chosen due to its ability to handle a wide range of turbulent flows with better accuracy in predicting the rates of strain and rotation. Its formulation also provides reliable simulations of the flow’s interaction with the tank boundaries, which is critical for the assessment of shear forces and phase separation in this tank filling scenario.

Mckenna Price –

The detailed simulation, can you explain which part of the tank filling results would help in optimizing the drain valve placement at the bottom to enhance separation?

MR CFD Support –

The simulation results related to the behavior of the alcohol phase as the tank fills would be crucial in optimizing the drain valve placement. Observing the alcohol’s upward movement when the water volume increases provides insight into the separation dynamics, which could inform decisions on the optimal position for the drain valve to maximize the efficiency of the separation process.

Melvina Marvin –

I was particularly impressed by the clear separation achieved between water and alcohol in the tank filing simulation using the VOF method. The presentation of the simulation results, such as the velocity counters and the phase movement animations, demonstrated a comprehensive understanding of the process. Excellent work on visualizing the phase interactions and effects of surface tension.

MR CFD Support –

Thank you for your positive feedback on the Tank Filling simulation! We are glad you appreciated the clarity of the separation process and the visual elements in the presentation of our results. It’s our goal to produce detailed and understandable CFD simulations. If you have any further questions or another topic you’re interested in, please let us know.

Morgan O’Hara –

I’m really impressed with the detail of this simulation for the Tank Filling CFD. Great job on displaying the interaction of the phases!

MR CFD Support –

Thank you for your kind words! We’re glad to hear you are impressed with the simulation. We aim to provide detailed and accurate analyses in our CFD simulations. If you have any more questions or need further clarification on any part of our training materials, please don’t hesitate to ask.

Albina Boyle –

Everything sounds well-detailed, but does the simulation also show how the phase separation occurs over time, not just at 1 and 15 seconds?

MR CFD Support –

Yes, the simulation includes a full transient analysis. Phases (water, alcohol, air) can be tracked in motion as the tank fills up, which helps to understand and visualize the separation process throughout the simulation timeline, not just at the specific time instances mentioned.

Sally Rohan –

The simulation results are fascinating! Could you please explain how the separation operation is enhanced by gravity in this system compared to no gravity conditions?

MR CFD Support –

Gravity plays a critical role in enhancing the separation of different phases in a tank filling simulation like this one due to differences in density. It creates a buoyant force that causes the lighter phase (alcohol) to rise and the heavier phase (water) to settle at the bottom. Without gravity, this natural separation due to buoyancy would not occur, and separating the phases would require alternative methods, such as centrifugation or additional mechanical systems. In this simulation, gravity ensures a passive and energy-efficient separation process, further illustrating the innovative capacity of CFD to model practical industrial operations.

Mr. Tre Kessler –

Loved this training on the Tank Filling CFD Simulation! The step-by-step explanation and use of VOF for three phases was outstanding. It helped me understand multiphase flow simulation much better.

MR CFD Support –

We’re thrilled to hear that the Tank Filling CFD Simulation training met your expectations and was helpful in furthering your understanding of multiphase flows! Thank you for your kind words, and we look forward to providing you with more quality learning materials.