Surface Evaporation of a Falling Water Droplet, ANSYS Fluent CFD Training

$180.00 Student Discount

- The problem numerically simulates the surface evaporation of a falling water droplet using ANSYS Fluent software.

- We design the 2-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 94800.

- We perform this simulation as unsteady (Transient).

- We use the Mixture Multi-Phase Model to define droplets inside the air.

- We use a UDF to define surface evaporation as the Mass Transfer rate between water and air.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This simulation is about the surface evaporation of a falling water droplet via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

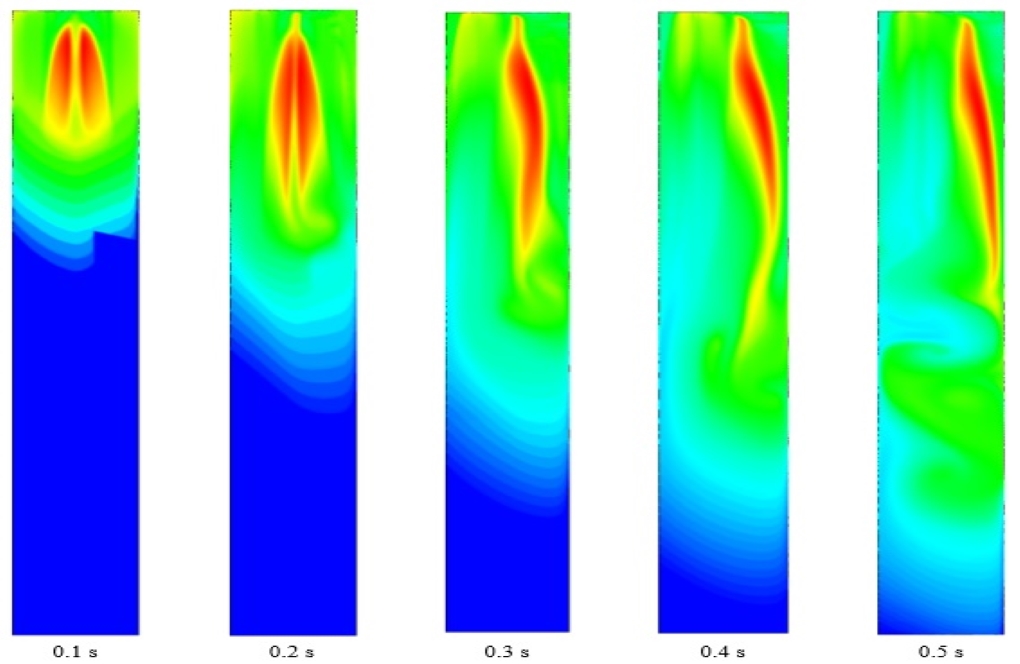

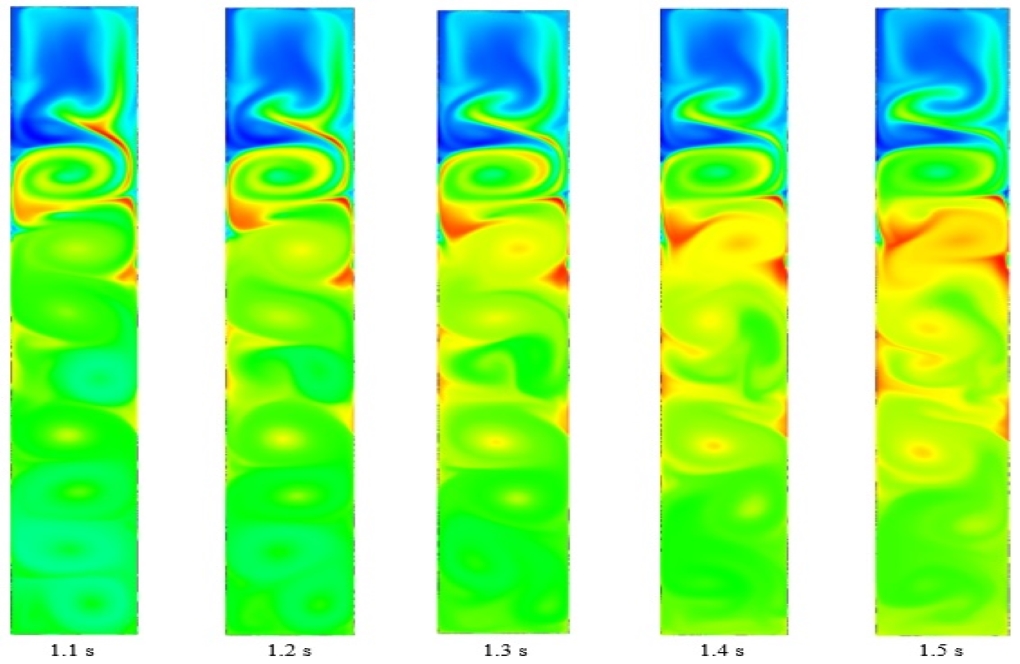

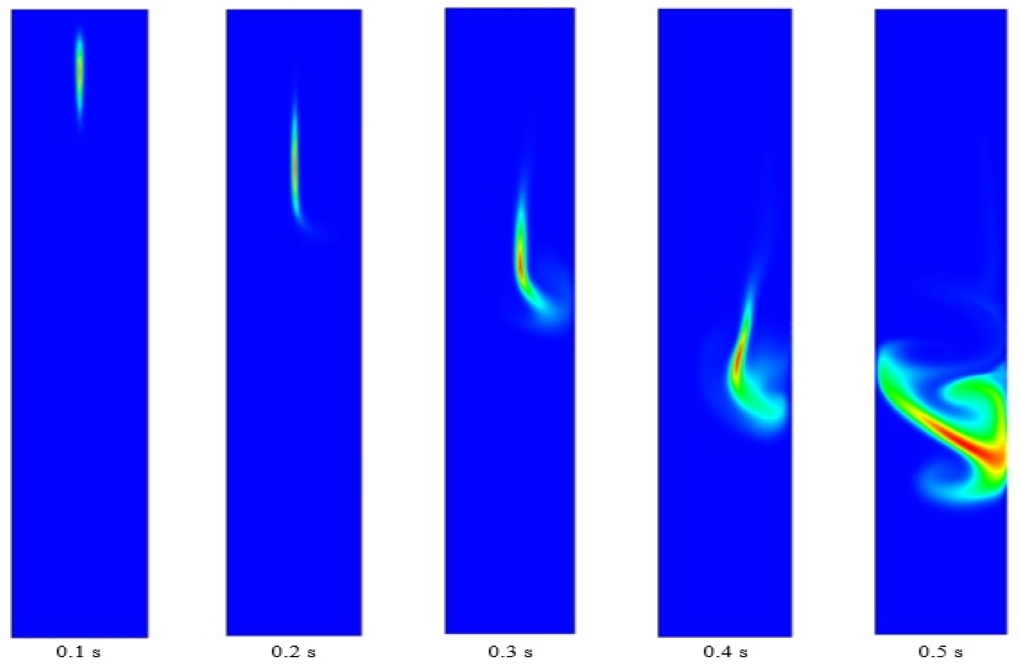

In this project, the surface evaporation process of a water droplet into the air space is investigated. The purpose of the simulation is to investigate the droplet behavior during the falling and the amount of vapor produced in the air due to the water surface evaporation.

The time taken to process the downward movement of water within the air space is assumed to be 12 seconds. No external factor as a boundary condition affects the drop, and the downward movement is based solely on the force of gravity.

The geometry of the present model is drawn by Design Modeler software. The model is then meshed by ANSYS Meshing software. The model mesh is structured, and 94800 cells have been created.

Surface Evaporation Method

In this simulation, there are three phases of water, air, and vapor in the computational area. Therefore, the Multiphase model is used to model the primary phase of air and the secondary phases of water and water vapor.

The Mixture model is used to define the multiphase model. This model is more complex than VOF and mixture models. As water droplets evaporate in space, the phenomenon of mass transfer between the two phases of water and vapor should be used.

As the evaporation of the present model is not boiling, we use surface evaporation. The major difference between boiling and surface evaporation is that boiling occurs when the water temperature reaches saturation temperature.

In contrast, surface evaporation can occur at a lower temperature than the saturation temperature, and it happens at the surface temperature of the liquid. We use the Evaporation-Condensation type mass transfer to define surface evaporation, whereas, in the present model, we use the UDF code to define surface evaporation.

Surface Evaporation Result

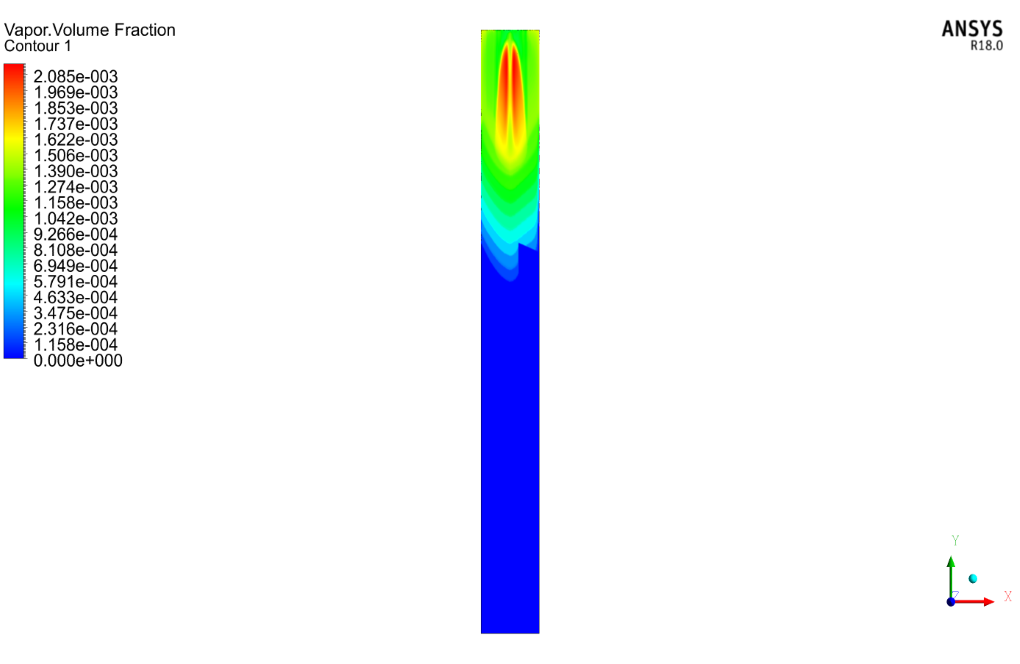

After simulation, the contours of temperature, velocity, and pressure are obtained. Also, contours of mass fraction of water, air, and vapor are obtained. After simulation, the contours of temperature, velocity, and pressure are obtained.

Also, contours of mass fraction of water, air, and vapor are obtained. The contours show that the water droplet is moving downwards due to gravity. After moving downwards, the droplets gradually evaporate to the surface, and as a result, the vapor is generated.

Mrs. Mina Lynch –

Can this simulation be customized to model the evaporation of other types of droplets?

MR CFD Support –

Yes, we can accommodate your desired simulations. Please share more details about your specific requirements.

Demetris Steuber –

I really enjoyed learning how the evaporation process of a water droplet is simulated during its fall. The concepts were explained clearly, and helped me understand the interplay of temperature, pressure, and phase changes in a dynamic environment.

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that our training on Surface Evaporation of a Falling Water Droplet using ANSYS Fluent was informative and easy to understand. We strive to deliver clear explanations of complex concepts. If you have any further questions or need more information on similar topics, feel free to reach out!

Ms. Sadye Gutmann IV –

How does the simulation model the evaporation process?

MR CFD Support –

The simulation uses the mass transfer model in ANSYS Fluent to simulate the evaporation process. It takes into account the heat and mass transfer between the water droplet and the surrounding air.

Tatyana Kemmer II –

The product description was comprehensive and helped me understand almost everything, but I’m wondering about the vapor production. How is the amount of vapor produced in the air calculated in this simulation?

MR CFD Support –

In this simulation, the amount of vapor produced in the air from the evaporating water droplet is calculated using the mass transfer mechanisms enabled by the Mixture model. By defining the phases of water, air, and vapor, and specifying the Evaporation-Condensation mass transfer type, along with implementing the UDF code for surface evaporation, the simulation tracks the amount of water that transitions from the liquid phase into vapor. The contours of mass fraction for each phase, particularly the vapor, provide a quantitative insight into the rate and total amount of vapor produced throughout the simulation duration.

Dr. Claire Jacobi DDS –

The simulation on surface evaporation of a falling water droplet seems very comprehensive. I was impressed by how the water behaviour during fall and the subsequent vapor generation were depicted in the contours. The application of the Multiphase and Mixture models sounds quite sophisticated!

MR CFD Support –

Thank you for your positive feedback. We’re glad you found the simulation and its depiction through contours comprehensive. It’s always our aim to provide detailed and sophisticated models that help enhance understanding of such complex phenomena in CFD analysis.

Dr. Enola Weber PhD –

The learning materials on surface evaporation were really comprehensive and work well for beginners too! The UDF coding part was explained perfectly, allowing me to grasp how to implement surface evaporation practically.

MR CFD Support –

Thank you for your kind words! It’s wonderful to hear that our materials on surface evaporation and the use of UDF coding in ANSYS Fluent were helpful and accessible to you. We always strive to explain complex concepts in an easy-to-understand manner. Keep up the good work with your CFD simulations!

Alvera Weimann –

This tutorial on the surface evaporation of a falling water droplet was so enlightening! The comprehensive exploration of how the evaporation takes place and generating the contours for the mass fraction of different phases was splendid. Kudos to the team for crafting such a detailed and informative CFD project!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to know you found the tutorial enlightening and informative. Our team takes pride in creating simulations that are not only detailed but also easy to understand. We’re glad the efforts put into the CFD project on surface evaporation were appreciated, and it’s wonderful to know that the content was up to your expectations. If there’s anything else you’d like to learn about or get assistance with, feel free to reach out!

Scot Davis IV –

I really appreciate how the surface evaporation process of a water droplet has been simulated. The execution of a UDF code for defining surface evaporation seems quite advanced. All these details helped me understand the phenomenon much better!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear you found the simulation informative and understandable. Our goal is always to provide practical solutions and clear insights, and we’re glad to have achieved that with the surface evaporation training. Your enthusiasm really motivates us!

August Turcotte –

I’m impressed with the level of detail in the simulation of the water droplet’s evaporation. It’s fascinating to learn how gravity and evaporation are balanced in this scenario. Well done on capturing the phenomenon accurately within the simulation results.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the simulation study both detailed and insightful. Capturing the subtle balance between physical forces in a realistic manner is a key goal of our simulations, and we appreciate your recognition of our efforts. Stay tuned for more interesting CFD projects!

Marty Conroy –

The way how droplet evaporation is visualized in the results is fascinating. I appreciate details such as the separation of water, air, and vapor, and providing insights into their interactions and the evaporation process of a water droplet. The training material seems well-constructed and appears to offer a deep understanding of fluid dynamics in a simple evaporation scenario. The use of UDF for defining surface evaporation adds depth to the study, and the results’ contours must be quite informative.

MR CFD Support –

Thank you for your detailed compliment on our Surface Evaporation of a Falling Water Droplet, ANSYS Fluent CFD Training. We’re pleased to know that the visualization and the depth of the study meet your expectations and that you appreciate the complexity and quality of the work presented in the material. Your feedback is invaluable, and we hope that our products continue to enhance your knowledge and experience in CFD analysis.

Maud Waters –

Are there any additional visual aids, like video or animation, to show the sequence of evaporation of the water droplet during the 12-second simulation?

MR CFD Support –

Our training includes detailed visualizations, including contours of temperature, velocity, pressure, and mass fractions. Although animations are not directly mentioned in the description, it is common for such CFD simulations to feature animations that illustrate the dynamic processes of simulation over time. If one is available for this specific simulation, it’ll be a valuable asset to truly understand the dynamics of the evaporation over the 12-second time frame.

Mr. Chandler Schulist –

I appreciated the fine details provided in the surface evaporation training. The in-depth explanation of the physical phenomenon and multiphase modeling was enlightening.

MR CFD Support –

Thank you for your kind words. We’re glad to hear that our training on surface evaporation of a falling water droplet using ANSYS Fluent provided you with a clear and thorough understanding of the topic. Your satisfaction with our educational content is extremely important to us!

Russ Prosacco V –

I’m truly impressed with how this training captured the detailed process of a water droplet’s surface evaporation during free fall. Your approach to illustrating the intricacies of multi-phase flow simulations is both educational and fascinating to visualize. Kudos to MR CFD for providing a well-structured and understandable training module that delves into such complex phenomena. The use of UDF for surface evaporation in ANSYS Fluent was particularly insightful.

MR CFD Support –

Thank you for your kind words. We’re delighted to hear that you found our training module on the surface evaporation of a falling water droplet informative and comprehensible. At MR CFD, we strive to make complex CFD concepts more accessible and engaging. Your appreciation encourages us to continue creating quality educational content. If you have any further insights or need assistance, please don’t hesitate to reach out!

Sadye Batz IV –

I’m really impressed with how this training emphasized real-world applications and intricate scientific concepts like surface evaporation. The thorough investigation and the use of UDF code seem like they could provide detailed insights into droplet behavior. It feels like participants could gain a strong understanding of multiphase flows through this experience.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the training met your expectations and provided you with valuable insights into the complex phenomena of surface evaporation and multiphase flows. Your understanding and appreciation of these details signal to us that we are on the right track in delivering high-quality CFD education. If you have further inquiries or require assistance in utilizing the knowledge gained, please feel free to reach out.

Lyla Terry –

I’m thoroughly impressed with the simulation of the surface evaporation process for a falling water droplet. It’s fascinating to see the interplay between phases and the realistic representation of the evaporation dynamics during the droplet’s descent. Kudos to the team for executing such a detailed and informative analysis!

MR CFD Support –

Thank you for your positive feedback. We are glad to hear that you appreciated the detailed analysis of the falling water droplet and its surface evaporation. Our team strives to deliver comprehensive and informative simulations, so your satisfaction means a lot to us!

Devonte Feil –

What is the benefit of using CFD for analyzing the evaporation process?

MR CFD Support –

CFD allows for detailed analysis of the evaporation process, providing insights into the heat and mass transfer phenomena that cannot be easily obtained through experiments.

Aurore Gulgowski –

The training material for the surface evaporation CFD training was immensely informative! The explanation of the mass transfer process and the use of the UDF for evaporation modelling provided a hands-on experience with the software’s capabilities. After working through the examples, I feel much more confident in setting up my own simulations involving multiphase flow and evaporation phenomena.

MR CFD Support –

Thank you for your positive feedback on our Surface Evaporation of a Falling Water Droplet CFD training. We’re thrilled to hear that our materials have bolstered your confidence in managing complex simulations involving multiple phases and evaporation. It’s incredibly rewarding to know that the detailed explanations and examples facilitated a valuable learning experience for you. We remain committed to providing high-quality educational content to support our learners in advancing their CFD analysis skills. If you have any further questions or require assistance with future simulations, please don’t hesitate to reach out!

Prof. Terry Skiles –

The multimedia resources helped me visualize the complex dynamics of the water droplet evaporation. The detailed temperature, velocity, and pressure contours clarified the interaction between phases. Excellent training for understanding multiphase flows with surface evaporation.

MR CFD Support –

Thank you for your positive review. We always strive to provide comprehensive resources that make complex concepts easier to understand. We’re glad that the training assisted you effectively in grasping the intricacies of multiphase flows and surface evaporation. Your feedback is greatly appreciated!

Toy Hartmann –

I’m fascinated by how the software handles the phase transition between liquid water and vapor. Can you please explain a bit more about how the evaporation-condensation mass transfer model is set up in ANSYS Fluent for this case?

MR CFD Support –

In ANSYS Fluent, the evaporation-condensation mass transfer model for this case is handled via the user-defined function (UDF) to specifically define surface evaporation conditions. The model enables the measurement of the rate of mass transfer from the liquid water droplet to the vapor phase, capturing the dynamics of surface evaporation without boiling, which occurs at lower temperatures. The UDF accounts for environmental variables, and physical properties, and allows precise control over how mass transfer is managed in the simulation to accurately replicate surface evaporation of falling droplets.

Vincenzo Kertzmann V –

The clarity and detail in the description are impressive, highlighting both the methodology and results beautifully. This conveys a deep understanding of the surface evaporation simulation for a falling water droplet using ANSYS Fluent, which is certainly insightful for learners. The simulation’s achievement in showing evaporation and generation of vapor clearly demonstrates the product’s effectiveness for visualization and analysis of complex multiphase interactions. Great stuff!

MR CFD Support –

Thank you for your kind words! We’re so glad to hear that the training for the Surface Evaporation of a Falling Water Droplet using ANSYS Fluent was both clear and useful for you. We take pride in providing detailed and practical CFD training, and it’s wonderful to know it has helped deepen your understanding of multiphase flow simulations. We appreciate you taking the time to share your positive experience!

Shannon Bayer –

The description of the surface evaporation CFD training was enlightening. Your skillful handling of the multiphase model has provided clear insights into the behavior of droplets under gravity and evaporation processes. Impressive work includes defining mass transfer between phases and using the UDF code for accuracy in simulation results.

MR CFD Support –

Thank you so much for your kind words and appreciation! We’re thrilled to hear that you found the surface evaporation CFD training helpful and insightful. It’s always our goal to deliver clear and thorough understandings of our simulation processes. Your feedback motivates us to continue providing high-quality training and support. If you have any further questions or need more assistance, feel free to reach out to us. Thank you for choosing our services!