Thermal Effect on Mixing, CFD Simulation ANSYS Fluent Training

$80.00 Student Discount

This project investigates the thermal effect of mixing Glycerin & Water-liquid via ANSYS Fluent, and the results of this simulation have been analyzed.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Thermal Effect on Mixing Problem Description

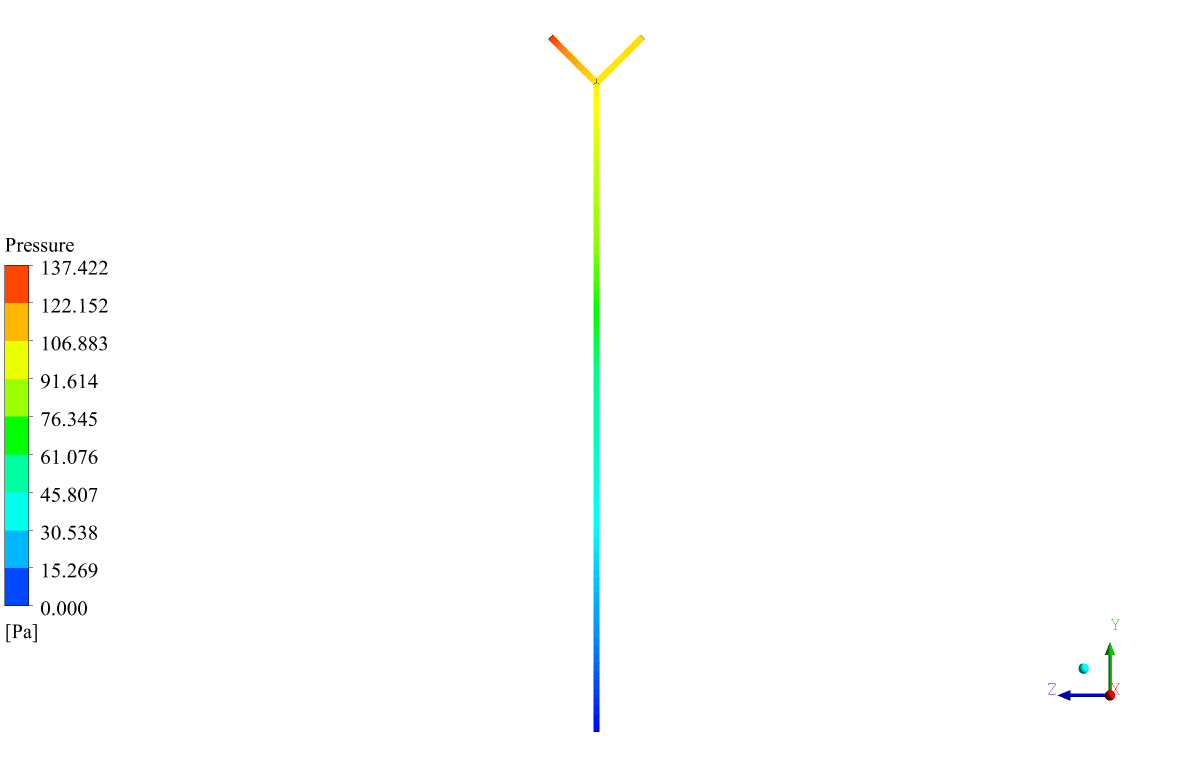

This project investigates the thermal effect of mixing Glycerin & Water-liquid. The study aims to determine the effect of applying heat flux on a Y-shape pipe. First, the problem is solved without any heat flux, and then a different heat flux is applied.

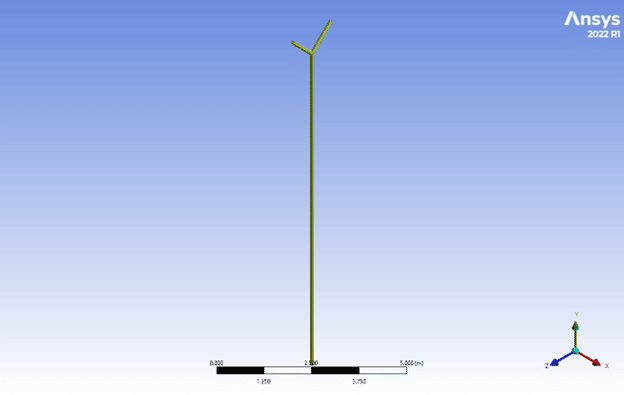

Geometry & Mesh

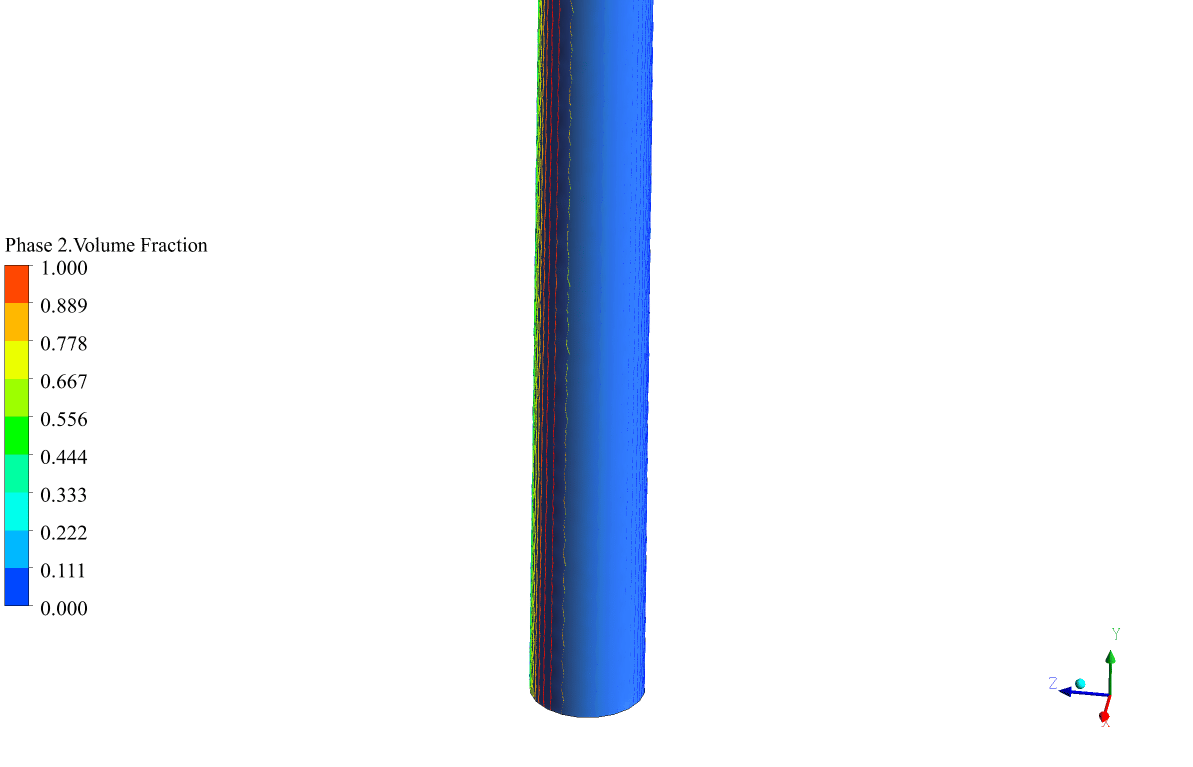

The 3D geometry is designed in Ansys Design Modeler. There are two inlets for water-liquid and glycerin. After getting in contact with each other, they interact 10-meter long pipe. In addition, the mesh grid is carried out using Ansys Meshing software.

CFD Simulation

Several assumptions have been considered, including:

- The simulation is Steady to capture fluid behavior in a steady-state manner.

- The pressure-based solver type was used due to the incompressibility of the working fluid.

- Gravitational acceleration effects were ignored.

The following table represents a summary of the solution:

| Models(Viscous) | ||||

| Multiphase | Volume of Fluid (VOF) | |||

| Formulation | Implicit | |||

| Interface Modeling Type | Sharp | |||

| Number of Eulerian Phases | 2 | |||

| Energy | On | |||

| Viscous | k-epsilon Realizable | Standard Wall Function | ||

| Materials | ||||

| Definition method | Fluent database | |||

| Material name | Water-liquid, Glycerin | |||

| Cell zone condition | ||||

| Material name | Mixture | |||

| Boundary condition | ||||

| Inlet-1 | Type | Mass-flow-inlet | ||

| Phase-1 | ||||

| Mass flow rate | 0.15 m/s | |||

| Phase-2 | ||||

| Mass flow rate | 0 | |||

| Inlet-2 | Type | Mass-flow-inlet | ||

| Phase-1 | ||||

| Mass flow rate | 0 | |||

| Phase-2 | ||||

| Mass flow rate | 0.15 m/s | |||

| Outlet | Type | Pressure outlet | ||

| Guage Pressure | 0 | |||

| Wall

Wall inlet-1 Wall inlet-2 |

Type | Wall | ||

| Thermal Condition | Heat Flux | |||

| Solver configuration | ||||

| Pressure-velocity coupling | Scheme | Coupled | ||

| Spatial Discretization | Gradient | Least squares cell-based | ||

| Pressure | PRESTO | |||

| Momentum | First-order upwind | |||

| Turbulent kinetic energy | First-order upwind | |||

| Turbulent dissipation rate | First-order upwind | |||

| Volume Fraction | Compressive | |||

| Initialization | Initialization methods | Standard Initialization | ||

| Run calculation | Number of Iteration | 2000 | ||

Thermal Effect on Mixing Results

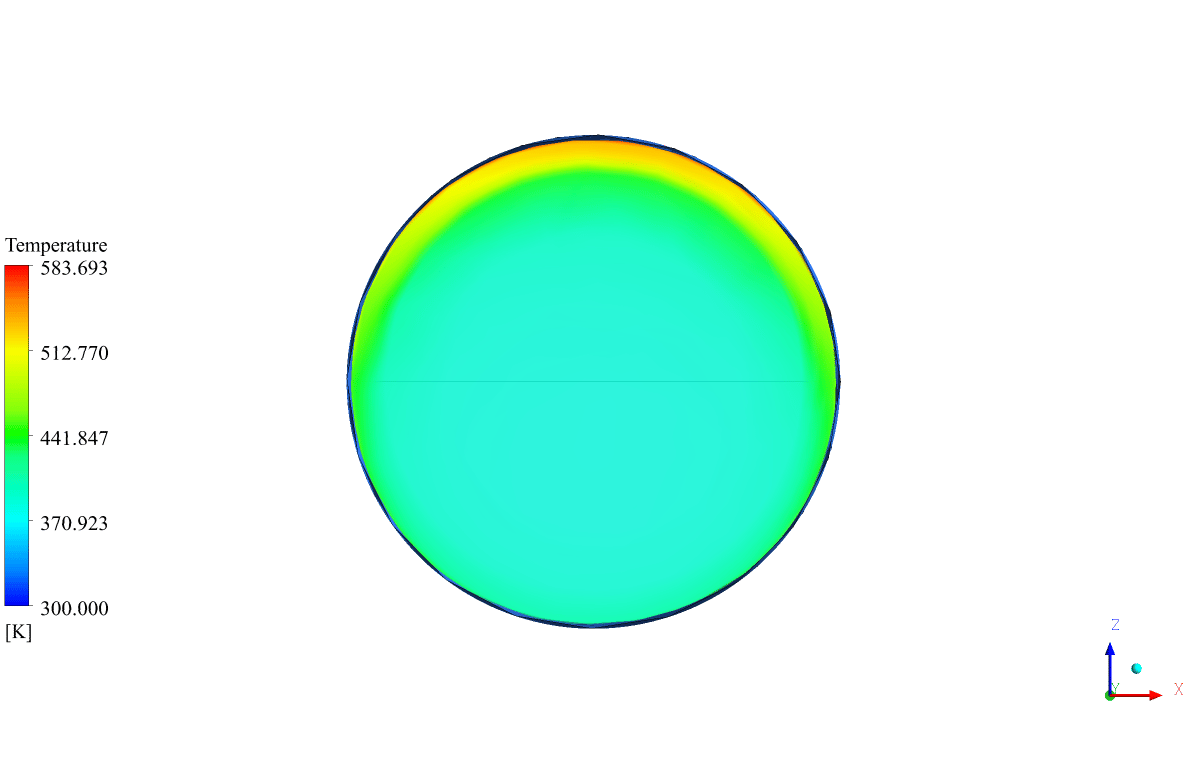

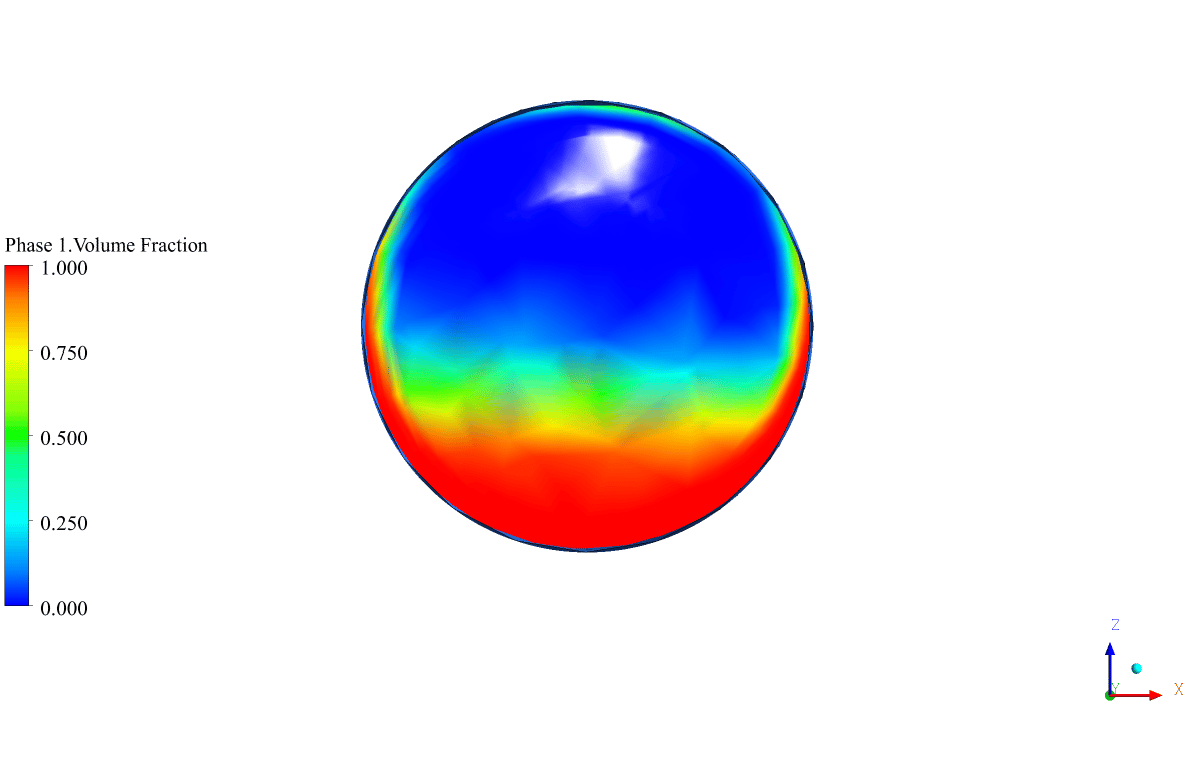

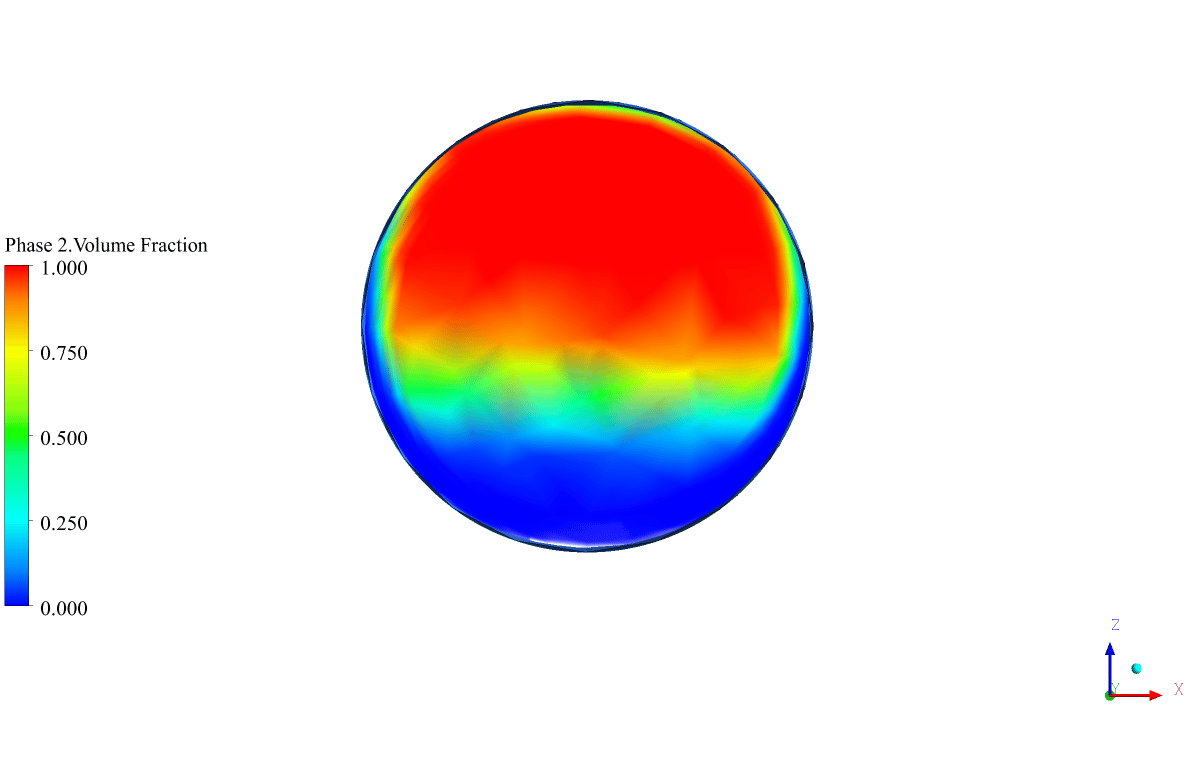

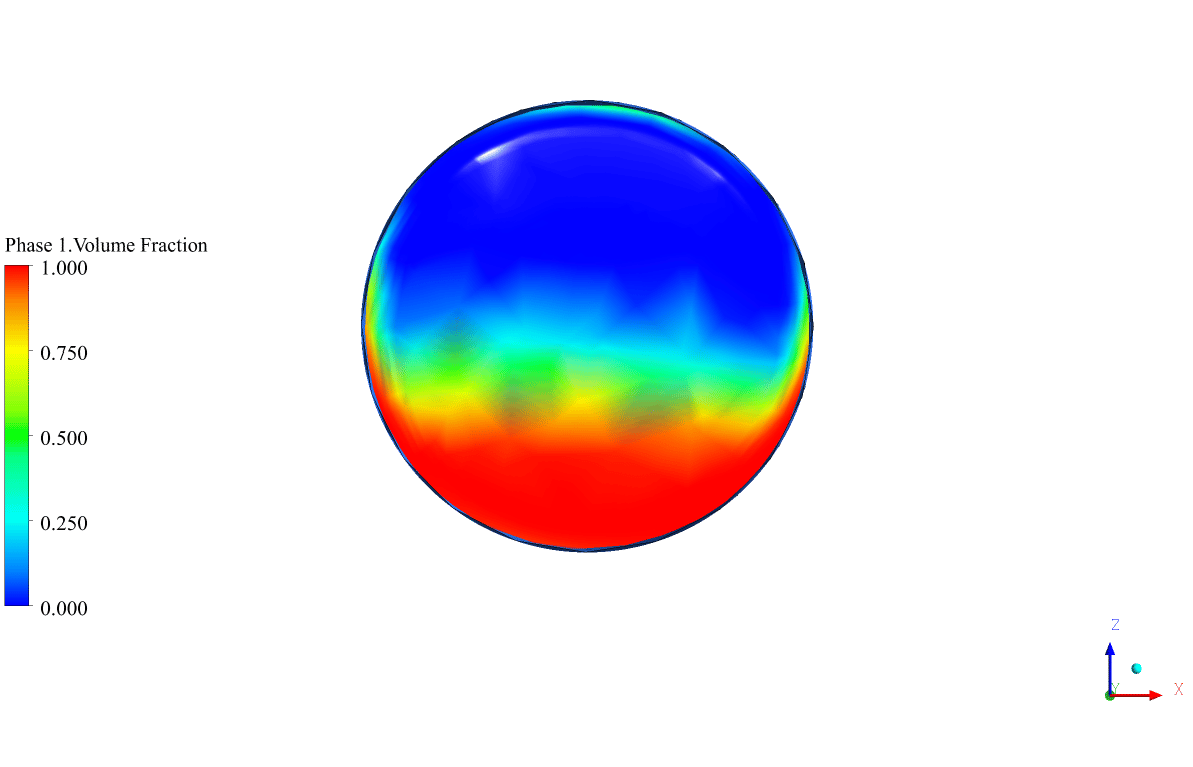

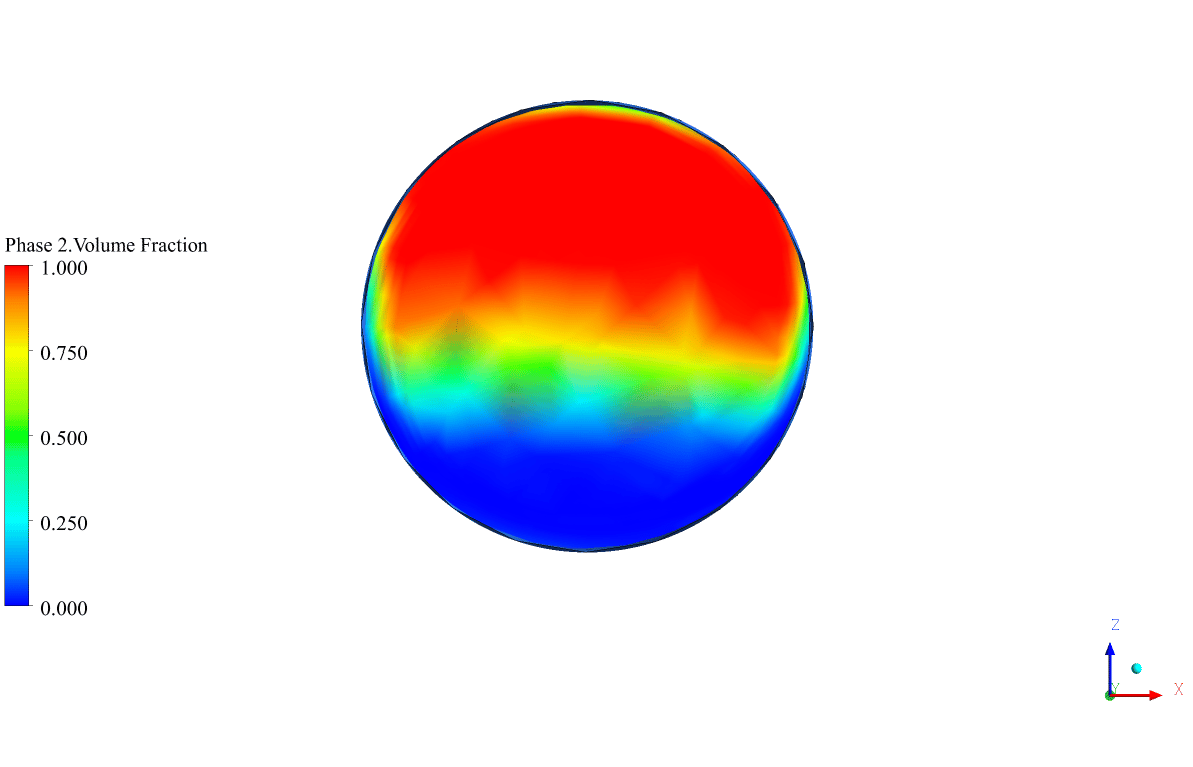

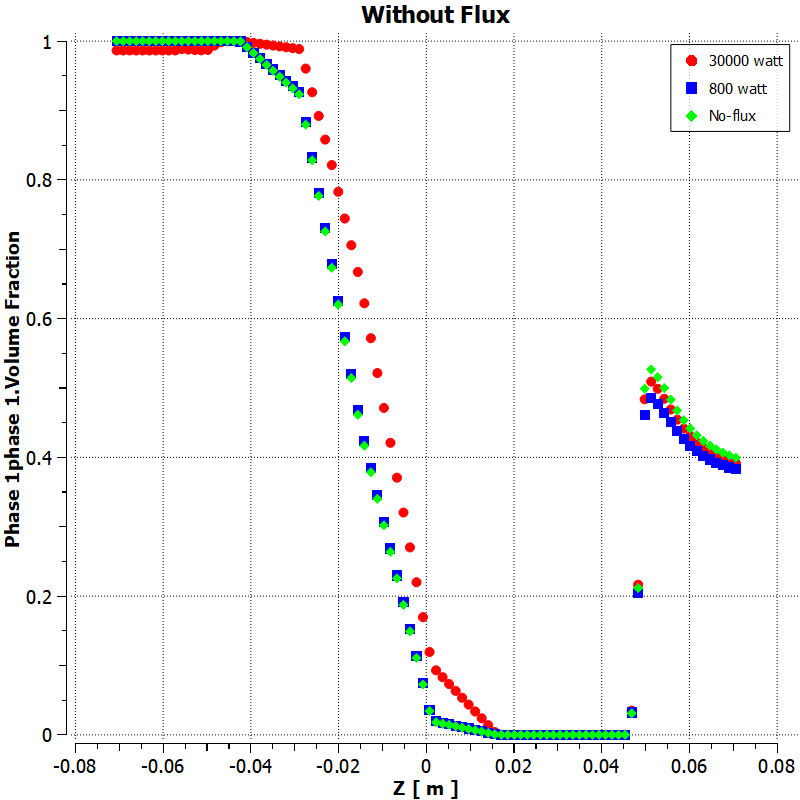

After the simulation, 2-dimensional contours of both volume fractions are extracted. Plus, a plot indicating the volume fraction of phase 1, which is water-liquid, through the centerline of the outlet, is shown below. Indeed, the viscosity of glycerin is highly dependent on temperature, as illustrated in Fig.3. Applying a heat flux on pipe walls increases the temperature and decreases the glycerin viscosity. As a result, it has less surface interaction (viscous forces) and resistance through water-liquid and causes better mixing (see Fig.4). The plot shows that by applying 30000-watt heat flux, the volume fraction of water liquid gets higher at each point which illustrates the presence of water where it was not before. Moreover, The contours show that, due to the low thermal conductivity of glycerin, the temperature of central points remains approximately constant. In other words, by using a highly conductive fluid, the impact of thermal conditions on mixing would be more impressive.

Mr. Junius Feeney Jr. –

Beyond the initial contour results, could you provide more details on how the changes in viscosity from the heat flux affected the overall fluid flow beyond the mixing?

MR CFD Support –

The changes in viscosity due to applied heat flux considerably affect the overall fluid flow dynamics. As glycerin’s viscosity decreases with increased temperature, the fluid flow becomes more turbulent and the interaction between glycerin and water intensifies. This reduction in viscous force allows for a smoother mixture as the fluids can move more freely. Enhanced turbulence also promotes better thermal mixing, leading to a more uniform temperature distribution in the downstream flow. Admins could provide further insights using additional simulation data such as flow velocity vectors, turbulence intensity, and perhaps thermal distribution plots for a more comprehensive view.

Shaun Schneider –

I am pleased with the thorough CFD analysis on the thermal effects impacting glycerin and water mixing. The use of heat flux to illustrate changes in the mixing quality was particularly interesting. Can you describe how the viscosity change of glycerin resulting from the applied heat affects the overall mixing process in simpler terms?

MR CFD Support –

As the heat is applied to the pipe walls, the glycerin, which is originally quite thick, becomes thinner or less viscous. This reduction in viscosity causes the glycerin to mix more easily with the water. Think of it like stirring honey that’s been warmed up – it swirls and blends much better with other liquids than when it’s cold and more solid.

Luciano Padberg –

I enjoyed how the application of heat flux was demonstrated to affect the mixing process of Glycerin and Water. This detailed simulation work led to a deeper understanding of fluid behavior influenced by temperature changes. Great training material!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our simulation on the thermal effect on mixing provided valuable insights. Your understanding of the intricacies in fluid dynamics is the exact outcome we hope to achieve with our training material. Thank you for choosing our product for your learning experience.

Jasper Murray –

I’ve noticed that you’ve applied different heat fluxes; could you explain how the different levels of heat flux affect mixing behavior, particularly in relation to both viscosity and temperature changes between glycerin and water?

MR CFD Support –

The application of different heat flux levels leads to variations in the temperature profile within the flow. As the heat flux increases, the temperature of the pipe wall rises, directly affecting the viscosity of the glycerin due to its temperature-dependent physical properties. A higher temperature typically results in a lower viscosity for glycerin, making it less viscous and more capable of mixing with water. The reduction in viscosity increases mixing efficiency as the viscous forces inhibiting flow and mixing are reduced, allowing for better intermingling between the glycerin and water molecules. Conversely, since water has a relatively constant viscosity compared to glycerin, the impact of heat on water’s mixing behavior is less pronounced. Thus, higher heat flux promotes better mixing, reflected in the increased volume fraction of water throughout the Y-shape pipe. However, as glycerin has low thermal conductivity, heat does not distribute evenly, leading to more significant temperature variations across different regions within the mix, particularly near the center where temperature changes are minimal.

Maymie Schmitt –

The review of the Thermal Effects on Mixing training was fascinating and helpful! The simulation intricately covers the influence that heat flux has on the mixing of glycerin and water-liquid in a Y-shaped pipe. I especially appreciated the detailed explanation of the changes in viscous forces and the resulting improvement in mixing, corroborated by contours and plots. The results clearly exhibit the significant role temperature plays in altering viscosity and enhancing the process. Would definitely recommend this to anyone looking to understand multiphase flow and heat transfer nuances in fluid dynamics simulations.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the ‘Thermal Effect on Mixing’ simulation insightful. It’s great to see that our focus on providing a clear understanding of thermal influences in fluid dynamics is having a positive impact. We appreciate your recommendation and are always here to support your journey in learning about multiphase flow and heat transfer simulations. Should you have further interest or inquiries in the future, don’t hesitate to reach out. Happy simulating!

Jarret Keeling –

I would like to compliment on how comprehensive the project for the Thermal Effect on Mixing seems. The level of detail in meshing, boundary conditions, solver configurations, and result analysis is admirable. Is the full report with all the simulation records available for purchase, and if so, how can I go about acquiring it?

MR CFD Support –

Thank you for your kind words! We’re glad you find our Thermal Effect on Mixing CFD Simulation comprehensive and informative. Yes, the full report with all simulation details is available for purchase. Please visit our website or contact our sales team, and they will assist you in acquiring the full project documentation, including all necessary simulation files.

Jannie Bogan –

I learned so much from the ‘Thermal Effect on Mixing’ CFD simulation training! The step-by-step process was comprehensive and easy to follow. I’m curious, does the training include any troubleshooting tips for common issues that may arise during simulation?

MR CFD Support –

The training that you are referring to, ‘Thermal Effect on Mixing,’ is designed to take you through a steady-state simulation that investigates the thermal effect of mixing glycerin and water. While troubleshooting is an important aspect of any simulation work, typically, such simulations focus primarily on setup and analysis. Should any common issues arise, they are usually addressed in dedicated troubleshooting materials or sections within the training. For specific instances, you might find additional resources or contact technical support services provided by MR CFD Company. If you’re facing any particular issues or have questions regarding the simulation setup, we would be happy to assist you.

Colleen Lebsack –

The simulation study on thermal effects in the mixing of glycerin and water is impressive. Your explanation of the methodology and results is very thorough. The heat flux’s role in improving mixing due to reduced glycerin viscosity was particularly interesting.

MR CFD Support –

Thank you for your kind words! We are pleased to hear that you found the simulation study on the thermal effect on mixing glycerin and water useful and informative. It’s great to know that the role of heat flux in enhancing the mixing process caught your attention. We constantly strive to provide thorough and comprehensible training materials. If you have any more questions or need further assistance, please don’t hesitate to reach out to us.

Reanna Bartoletti I –

The training was extremely informative, carefully detailing each step of the process!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the training helpful and informative. If you have any further questions or need additional learning materials, don’t hesitate to reach out to us. We’re here to support your continuous learning journey.

Miss Lilliana Denesik –

The explanation was very clear. I didn’t know that temperature could have such an impact on the mixing process. Great to see how applied heat flux can improve mixture homogeneity!

MR CFD Support –

We’re delighted to hear you found the simulation results insightful. It’s indeed fascinating how temperature plays a crucial role in fluid dynamics, especially in mixing processes. Thank you for taking the time to appreciate our training product. If you have further interest or questions in our simulations or trainings, please don’t hesitate to ask.

Mr. Tyrique Daniel –

I was impressed with the clarity of the results showing the impact of heat on glycerin viscosity. Can you provide a little more insight into why using a highly conductive fluid would make thermal conditions have a greater impact on mixing?

MR CFD Support –

Of course! When a fluid has higher thermal conductivity, it means that heat can transfer through it more effectively. As heat is applied to the pipe walls, a highly conductive fluid will respond more quickly, and the heat will distribute more evenly throughout the fluid mass. This can help balance temperature gradients, which in turn can reduce the viscosity more uniformly, leading to enhanced mixing. Using fluids with better heat transfer capabilities allows the energy from the heat flux to alter flow properties more drastically compared to fluids like glycerin, which have lower thermal conductivity. Thus, the type of fluids and their thermal properties play a critical role in mixing efficiency when external heat is applied.

Gordon Fahey –

I’m curious about how the heat flux was varied in the simulation – was it changed uniformly along the pipe or just in specific sections? And how was it ensured that the result was not affected by initial transient thermal gradients but rather by the steady-state condition?

MR CFD Support –

In the simulation, the heat flux is generally applied uniformly along the walls of the Y-shaped pipe to maintain consistency in the experimentation. However, to ensure the results reflect the steady-state condition and are not affected by initial transient thermal gradients, the simulation was run for a sufficient number of iterations (2000 as stated). This practice allows the flow to develop fully and reach a thermally steady state where the thermal gradients due to initial conditions have dissipated. Measurements and reporting are carried out after the flow and thermal conditions have stabilized.

Ms. Bailee Will I –

I bought the ‘Thermal Effect on Mixing, CFD Simulation ANSYS Fluent Training’ and went through it. The training was exceptional in clarity and helped me understand the importance of temperature in fluid interactions. Nicely done!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear you found our training on the thermal effect on mixing in ANSYS Fluent helpful and clear. Understanding temperature influences in fluid dynamics is crucial, and we’re glad we could assist in your learning journey. Your satisfaction with our training materials is our top priority. If you have more questions or need further assistance in the future, please don’t hesitate to reach out.

Aylin Skiles Sr. –

Just a word of appreciation for the comprehensive training module. The thermal effect on mixing glycerin and water using ANSYS Fluent sounds remarkable. Such a deep dive into technical aspects like heat flux impact, VOF model, and mesh handling helps build fundamental CFD knowledge. I’m impressed with the thoroughness of the simulation setup and the clarity in the presentation of results. Well done!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the training module comprehensive and educational. Understanding the interplay between heat flux and fluid dynamics is essential, and we’re glad the course clarified these aspects for you. Your feedback inspires us to continue creating high-quality CFD training content.

Prof. Santina Fahey PhD –

I am impressed with how this training deals with the complexities of thermal effects on mixing glycerin and water. The results clearly show how applying heat flux impacts the viscosity and promotes better mixing.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that our training on the thermal effect on mixing Glycerin & Water-liquid met your expectations and provided clear insights into how heat flux influences the mixing process. If you need further assistance with any of our training materials, feel free to reach out. Your success with our products is our utmost priority!

Doug Smith –

I am greatly impressed by the detail captured in the thermal effects on mixing of glycerin and water. The analysis of viscosity changes and the way heat flux facilitates better mixing are truly insightful. The visualization of results through figures and plots adds great value to the understanding of the simulation outcomes.

MR CFD Support –

Thank you so much for your kind words and recognition of the level of detail in our Thermal Effect on Mixing CFD Simulation using ANSYS Fluent. We are thrilled to hear that the information and visuals were helpful in understanding the impact of heat on fluid mixing. We always strive to provide comprehensive and illustrative learning products, and your feedback validates our efforts.

Kiarra Raynor V –

What a fascinating analysis on the effects of thermal conditions on mixing glycerin and water-liquid! The detailed breakdown of the modeling steps and results really showcases how heat flux can change the viscosity and subsequently influence the mixing dynamics. Well presented!

MR CFD Support –

Thank you so much for your kind words! We’re glad to hear that you found the analysis fascinating and well-presented. It’s inspiring to know that our efforts to explain how thermal effects influence mixing have been appreciated. If you have any further questions or need more information on CFD simulations, feel free to reach out to us!

Reese Bogan –

The results look fascinating. Just one clarification: Does applying higher heat flux beyond 30000 watts change the mixing efficiency significantly, or does it reach a point of diminishing returns?

MR CFD Support –

Thank you for your positive feedback and interesting question! Yes, applying a higher heat flux could potentially further decrease the viscosity of glycerin and promote better mixing. However, there is indeed a point where the increase in mixing efficiency will see diminishing returns due to limitations imposed by other factors such as flow rates and the physical design of the mixing apparatus. To fully understand this relationship, one would need to run additional simulations at higher heat flux values to observe the effects.

Joesph Wintheiser –

The results clearly show that by applying heat flux, mixing is improved, but I’m curious how much computational time this simulation took?

MR CFD Support –

The computational time for a simulation like this can vary based on several factors, including the complexity of the geometry, the details of the mesh, the computational power available, and the convergence criteria set for the simulation. However, with the stated number of 2000 iterations and given the setup detail, it may take several hours on a standard workstation. For the most accurate information, you would need to refer to the specific simulation log details or the MR CFD team can provide an approximation based on their experience with similar simulations.

Miss Josianne Beatty –

I was thrilled to see the clear visualization of the mixing process. The changes observed with the application of heat flux on the mixing efficiency were particularly fascinating. Could you explain how the surface interaction decreases as the glycerin’s viscosity reduces due to heat?

MR CFD Support –

When heat flux is applied, the glycerin’s temperature rises, resulting in a decrease in its viscosity. Lower viscosity means the glycerin has less internal resistance and is more fluid. This reduction in viscous forces allows it to mix more readily with water, improving the overall mixing efficiency in the Y-shaped pipe.

Ronny Altenwerth –

I found the detailed setup and results of the thermal effect on mixing simulation fascinating. The mixing behavior in the Y-shaped pipe was very clear, and the contours provided me with excellent visual feedback on the process. Great work!

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the simulation details and results helpful and easy to visualize. Your feedback is greatly appreciated, and it motivates us to continue providing high-quality CFD training products. If you have any further questions or need assistance with any other simulations, please don’t hesitate to reach out.

Prof. Ignacio Buckridge –

I must say I’m personally intrigued by the detailed analysis of the thermal effect on mixing glycerin and water this simulation provides. The results clearly illustrated how the applied heat flux positively affected the mixing process due to the reduced viscosity of glycerin. Fluent database to define material properties, employing Viscous k-epsilon Realizable models, and PRESTO for pressure discretization particularly offer the precision required for this complex interaction! Kudos to MR CFD for structuring this comprehensive training module. Each step builds up the user’s understanding, from defining boundary conditions to analyzing results—at every step, I felt in command of the process.

MR CFD Support –

Thank you for taking the time to leave such a detailed and positive review! We are thrilled to hear that you found our training content on the thermal effect of mixing glycerin and water insightful and easy to follow. Your grasp of the significant aspects demonstrates the effectiveness of our training module. We’re glad you appreciated the use of Fluent database for material properties and the comprehensive structure of the simulation steps. It’s reviews like yours that reassure us we are on the right track in providing quality educational resources. Thank you for choosing MR CFD, and we hope to continue being a part of your learning journey!

Mikayla Morar –

The project was very interesting! It really helped me understand how heat flux can affect the mixing process. The visuals were very clear, and the comparison between the cases with and without heat flux provided an excellent learning experience. Thank you for such a well-explained simulation study.

MR CFD Support –

Thank you for your kind words and positive feedback! We are thrilled to hear that our training on the thermal effect on mixing has enhanced your understanding of the process. It’s our pleasure to provide clear and informative simulations that are useful to our customers. Should you have more questions or need further assistance in future studies, please don’t hesitate to reach out. Happy learning!

Mack Dooley –

This product review is shining! It absolutely clarified the complex relationship between heat flux and fluid dynamics within a mixed system. Grateful for the insight provided on the impact of viscosity and thermal conductivity on mixing efficiency.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the simulation results were enlightening and gave you valuable insights into thermal effects on mixing glycerin and water. It’s always rewarding to know when our training products make a positive impact.