Water infiltration into a porous concrete block, ANSYS Fluent Simulation Training

$120.00 Student Discount

- The problem numerically simulates Water infiltration into a porous concrete block using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 623464.

- We perform this simulation as unsteady (Transient).

- We use the Porous medium to study water infiltration into a porous concrete block.

- We use the VOF Multi-Phase model to define two-phase flow inside a concrete block.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This simulation is about water infiltration into a porous concrete block via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

In this modeling, a cube block is designed as a Porous medium. The water flow enters it from a circular section at the bottom of the block. After passing through the porous material, it leaves the upper section of the block.

The inlet water flow has a relative pressure of 5 bar or 500,000 pascals; Therefore, a pressure inlet boundary condition is used at the block input. It is also assumed that only air inside the block is in the initial state, and water flow penetrates it.

The present work investigates the amount of water infiltration into this porous block over time. Therefore, the current problem is solved as unsteady and time-dependent.

The geometry of the present model is drawn by Design Modeler software. This model consists of a cubic block with a side of 0.15 with a circular inlet for flow entry in the bottom with a diameter of 0.07 m.

The model is then meshed by ANSYS Meshing software. The model mesh is structured, and 421875 Hex cells have been created.

Method

In this simulation, the Porous option is used in the cell zone conditions. The porous medium defined in the block has a porosity coefficient equal to 0.01; This means that the ratio of empty space to the block’s total volume is equal to 0.01.

It is also assumed that only air inside the block is in the initial state, and water flow penetrates it. Therefore, the Multiphase Model is used to define a two-phase flow consisting of water and air.

The two-phase VOF (volume of fluid) model is used in this simulation to define air as the primary and water as the secondary phase. Since the phase separation boundary is completely distinct, the Volume of Fluid (VOF) model is used. The sharp type in interface modeling has been used to determine the behavior at the boundary between two phases.

Conclusion

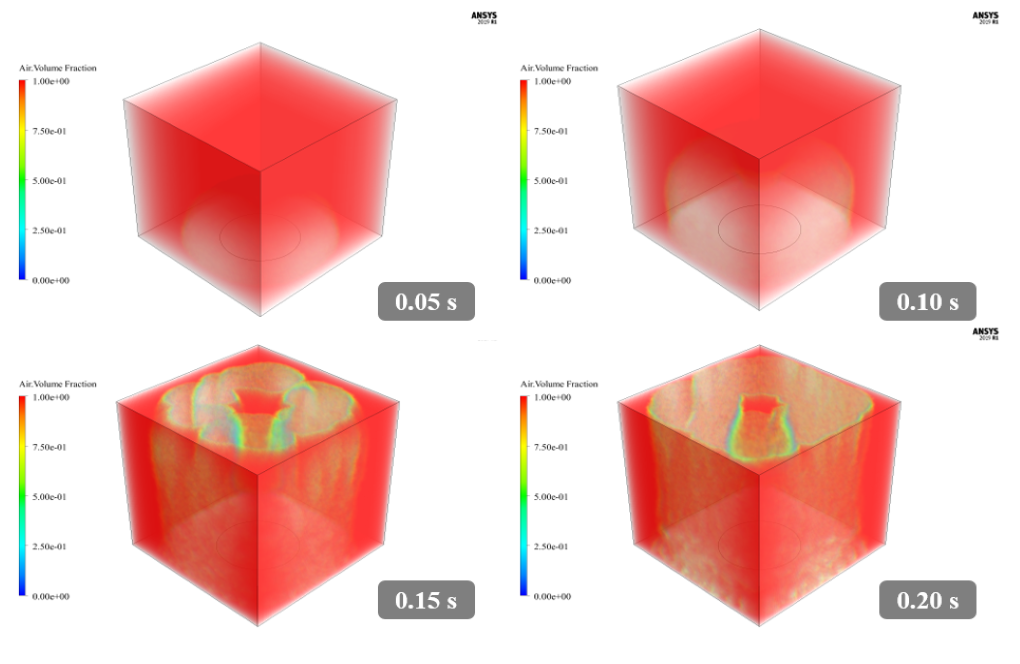

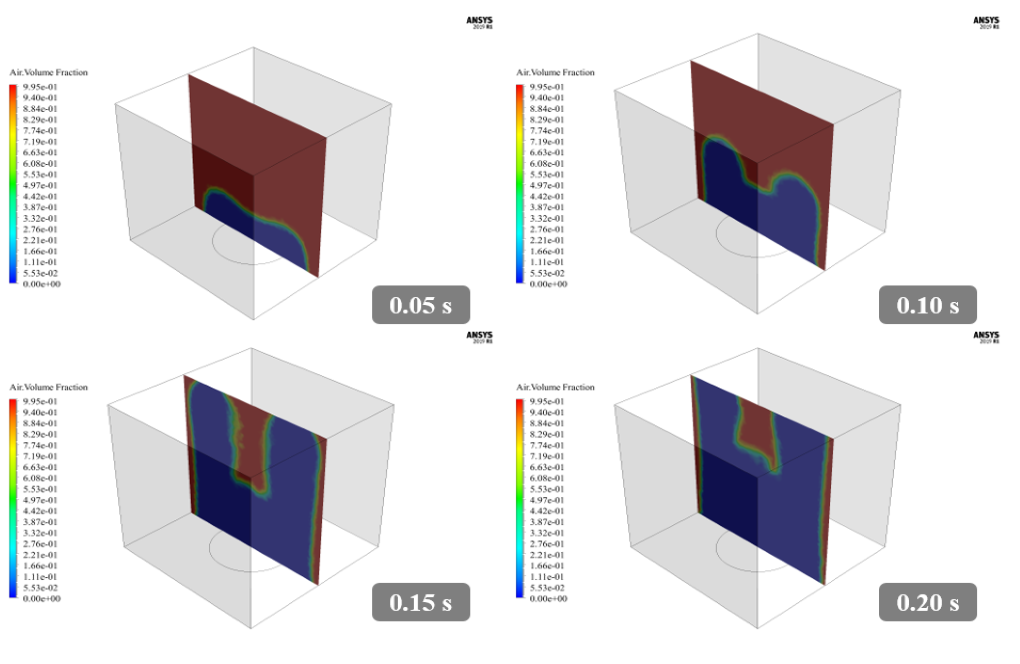

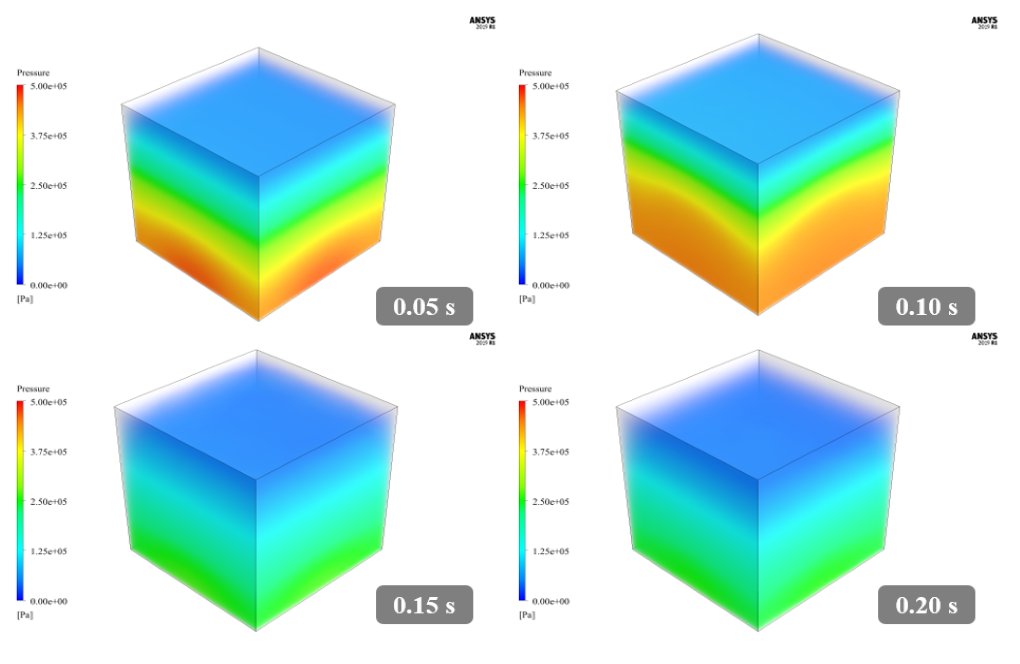

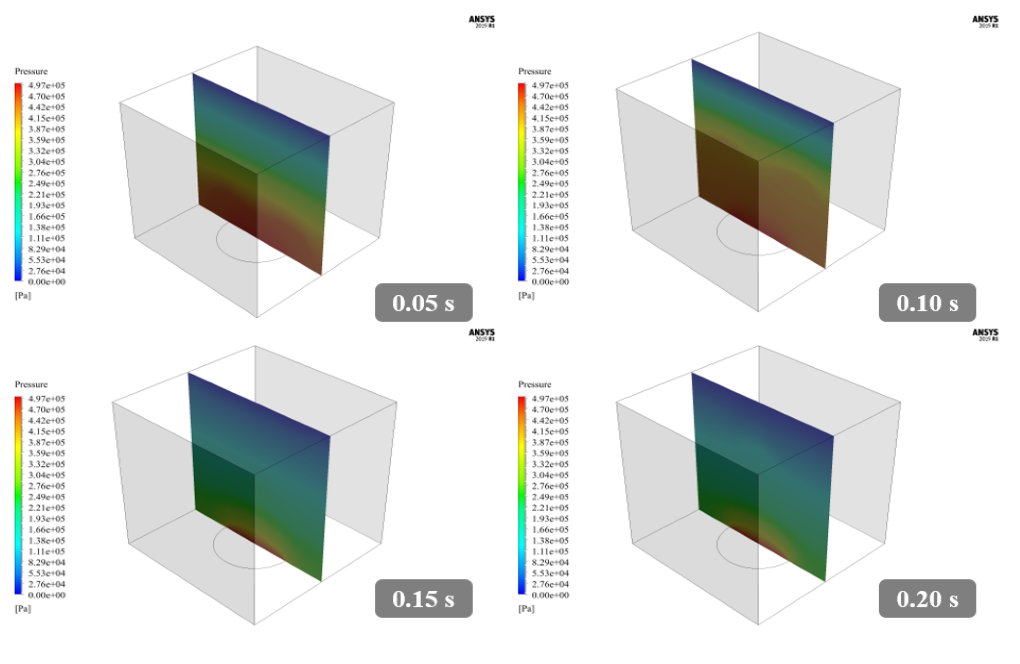

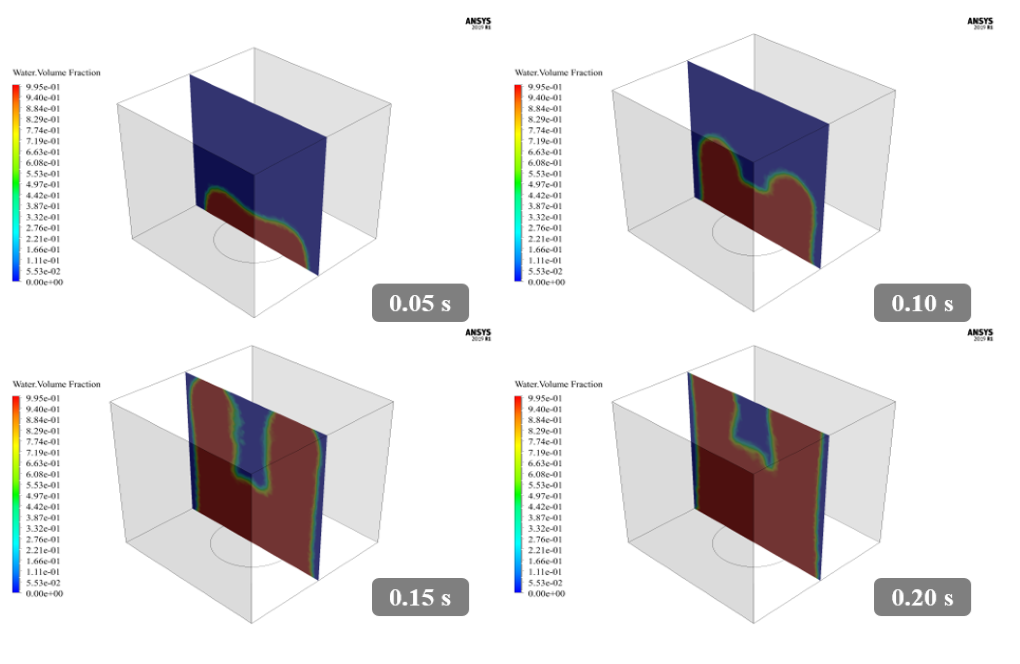

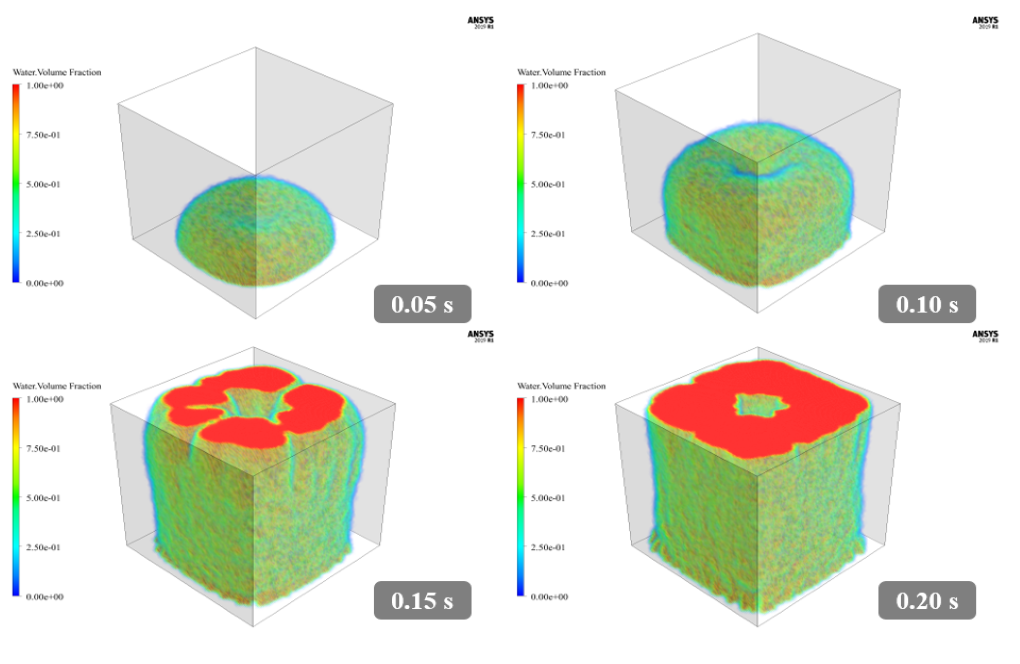

After simulation, two-dimensional and three-dimensional contours of pressure and water and air volume fraction are obtained. These contours were obtained at different times in a time interval of 0.2 s.

It can be seen from the figures that over time, the infiltration rate of water flow inside the block increases. It is also observed that the water flow decreases with pressure by moving inside the porous block due to a porous medium’s effects.

Miss Violette Wolf DVM –

Can the simulation model the effect of different block geometries?

MR CFD Support –

Yes, the simulation can model different block geometries. We can adjust the geometry based on the specific dimensions of your concrete block.

Lonzo Toy –

Can the simulation handle different types of fluids?

MR CFD Support –

Absolutely! The simulation can be adjusted to handle different types of fluids. We can modify the fluid properties, such as viscosity and density, based on your specific requirements.

Kamron Steuber –

How does the simulation handle the multiphase flow in the block?

MR CFD Support –

The simulation uses the Volume of Fluid (VOF) model to handle the multiphase flow in the block. This model can accurately capture the interface between the water and air.

Drake Gislason MD –

I’m impressed by the capabilities of simulating multiphase flow through porous media! Can you tell me if buoyancy effects were considered in this simulation, and how they would impact the results?

MR CFD Support –

In this CFD project, the VOF (volume of fluid) model is primarily focusing on tracking the interface between the water and air phases in the porous concrete block. Buoyancy effects can indeed impact such a simulation. They typically cause water to rise through the porous medium and can create a more realistic pattern of infiltration. If buoyancy effects were considered in this simulation, it can cause the water to disperse in a less uniform manner, potentially leading to more realistic modeling of the behavior of fluid within the porous block. The changes in pressure contours and volume fraction over time would then also be influenced by these buoyancy effects. If they were considered, it would be indicated under the gravity settings or within the body force terms in the simulation setup.

Prof. Jack Mante DDS –

Can the simulation handle different types of fluids?

MR CFD Support –

Absolutely! The simulation can be adjusted to handle different types of fluids. We can modify the fluid properties, such as viscosity and density, based on your specific requirements.

Ms. Magnolia Lueilwitz –

The explanation on the porosity coefficient was particularly insightful. It helped me understand the significance of the ratio of empty space in the model. Fantastic work on detailing the processes!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the information on porosity coefficient helpful. If you have any more questions or need further clarification, we’re always here to help. We sincerely appreciate your review and are glad you are satisfied with our simulation training product.

Pauline Schaden –

I was so impressed with how realistic the infiltration rate of the CFD simulation was for this porous concrete block. It truly highlighted the effectiveness of ANSYS Fluent in showcasing the interaction between water and the porous material.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation effectively demonstrated the capabilities of ANSYS Fluent and provided a realistic depiction of water infiltration into a porous concrete block. Your feedback is greatly appreciated!

Marian Mitchell –

The CFD simulation training product for water infiltration into a porous concrete block has been fantastic for visualizing the process and understanding how pressure and porosity affect fluid movement. The detailed explanation helped to grasp the concept of the VOF model, and the structured mesh creation with ANSYS Meshing software was particularly impressive.

MR CFD Support –

We’re delighted to hear that you found the training product useful and informative. It’s great to know that our detailed approach and the simulation’s visualizations were helpful in understanding the complex processes of fluid dynamics in porous materials. Thank you for the positive feedback!

Liliane Bartell –

I found the simulation quite insightful. The water and air volume fraction contours demonstrated the temporal evolution of infiltration effectively. Could you provide more detail on how the porosity coefficient impacts the infiltration rate in your simulation?

MR CFD Support –

Thank you for your positive feedback. In our simulation, the porosity coefficient impacts the infiltration rate by defining how much of the block volume is empty space that can be filled with water. A lower porosity coefficient means less available space for the fluid, which generally translates to a slower infiltration rate due to the increased resistance against the fluid flow within the pores. As you pointed out, this effect is clearly observable in the simulation as the pressure drops across the porous medium, indicating resistance to flow propagated by its structure.

Connie Herzog –

I am particularly interested in how the VOF model represents the interface between water and air accurately in this porous media scenario. Could you elaborate on how the sharp interface technique in the VOF model contributes to the fidelity of the simulation?

MR CFD Support –

The sharp interface technique in the VOF model is designed to capture the interface between two immiscible fluids, like water and air in this case, with high accuracy. It uses a specific algorithm that ensures minimal smearing of the interface. This means the boundary between the water and air phases is calculated with a higher resolution, which allows for a detailed and realistic representation of the phases as they infiltrate and interact within the porous concrete block. In this simulation, the sharp technique contributes to the fidelity of the results by ensuring that the phase distribution is depicted with clarity, allowing for accurate observation and analysis of the water infiltration process over time.

Miss Yoshiko Becker –

The training materials were very detailed, and the simulation data gave a clear picture of the infiltration process. Loved how the porous concrete block’s behavior was illustrated as the water penetrated over time.

MR CFD Support –

Thank you for your positive feedback! We’re very happy to hear that our simulation training materials were helpful and that the visualizations of the water infiltration process met your expectations.

Nya Reichert I –

I appreciated the detailed explanation in your simulation training for ‘Water infiltration into a porous concrete block’. The use of porosity coefficient and structured mesh to emulate the water movement within the block was enlightening. I could follow along with the setup and understand why certain conditions were chosen, which greatly enhanced my learning experience!

MR CFD Support –

Thank you for your positive feedback on the ‘Water infiltration into a porous concrete block’ simulation training. We’re glad to hear that the detailed explanations of the simulation’s setup and the choices of various parameters were beneficial to your understanding. Your success with our training program is our top priority, and we appreciate you taking the time to share your learning experience with us.

Roselyn Stiedemann –

Can this type of simulation be extended to simulate oil infiltration in porous media, like in oil reservoir scenarios?

MR CFD Support –

Yes, this simulation approach for water infiltration in porous concrete can be adapted to model oil infiltration in similar porous media, such as oil reservoirs. The same basic principles and methodology apply, but the fluid properties would need to be adjusted to reflect those of oil, and possibly the porosity and permeability characteristics of the medium could be different to reflect a reservoir’s geological properties.

Dr. Barton McLaughlin –

I had such a great time working through the simulation for ‘Water infiltration into a porous concrete block’ using ANSYS Fluent. The methodology was clear, and the prescribed steps were easy to follow. It was fascinating to watch the water penetrate the porous block over time, and the presentation of results via two-dimensional and three-dimensional pressure contours, alongside water and air volume fraction contours, helped solidify my understanding of the complex phenomena modeled.

MR CFD Support –

We are pleased to hear that your experience with our ‘Water infiltration into a porous concrete block’ ANSYS Fluent simulation training was positive. It’s great to know that the clarity of the methodology and results helped you gain a thorough understanding of the water infiltration process. We thank you for your kind words and hope that you will find our other simulation trainings equally beneficial!

Mr. Erling Beer –

Really impressed by how detailed the simulation of water infiltration into a porous concrete block is. The ability to track the water movement over time and see the effect of the porous medium on the water pressure provides valuable insights for real-world applications.

MR CFD Support –

Thank you for taking the time to share your experience. We are thrilled to hear that our ANSYS Fluent simulation for water infiltration into a porous concrete block met your expectations and provided the detailed insights you were looking for. Your feedback is greatly appreciated!

Isaac O’Reilly –

Can you please explain how the simulation accommodates changes in water infiltration over time?

MR CFD Support –

In this simulation, changes in water infiltration over time are accommodated by solving the problem as unsteady and time-dependent. The Multiphase VOF (volume of fluid) model within ANSYS Fluent tracks the interface between the water and air, allowing the simulation to capture the advancing water front as it moves through the porous block. The porous medium’s properties, such as porosity and permeability, influence the flow behavior, and this is factored into the calculations at each time step.