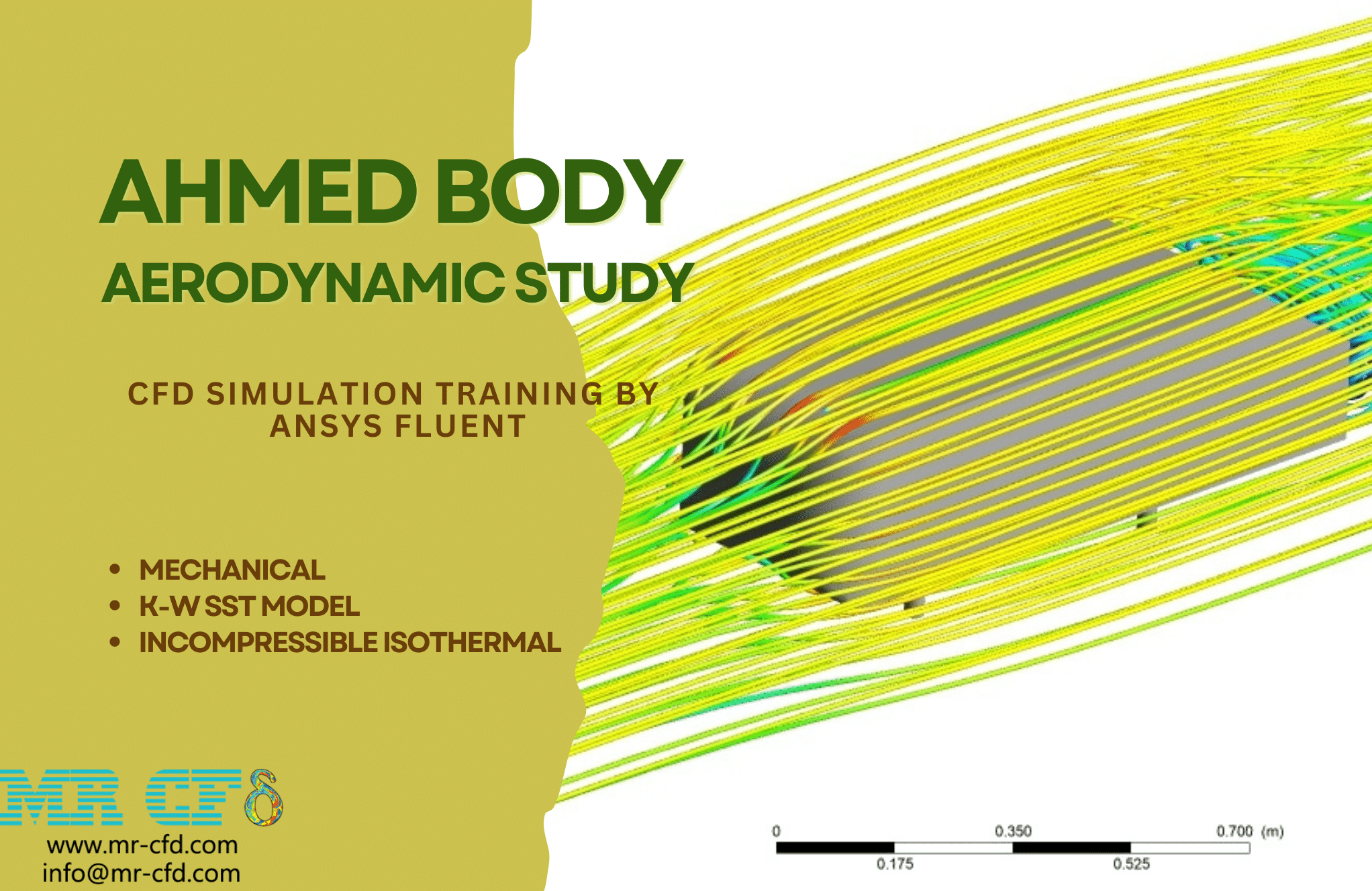

Ahmed Body Aerodynamic Study, ANSYS Fluent Training

Free

This project is going to study an incompressible isothermal airflow adjacent to the famous Ahmed body.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Ahmed Body Aerodynamic Study, ANSYS Fluent, CFD Simulation Training

Description

The Ahmed body is a simplified vehicle model that captures the essential flow features around an automobile. Also, Ahmed’s body allows us to capture aerodynamic characteristics relevant to bodies in the automobile industry.

It’s used to describe the turbulent flow field around a car-like geometry. When the numerical model is validated, it is used to design new car models. To test this geometry for ourselves, in this study, we employ a CFD solver is and then calculate the drag values.

This project is going to study an incompressible isothermal airflow adjacent to the famous Ahmed body geometry. The geometry is a 1-meter car inside a 25-meter wind tunnel. Also, we selected the maximum speed of 20 m/s for the inlet, corresponding to a 72 Km/h car speed.

To study the current problem, one must solve the flow equations in the differential form. Also, we assume the isothermal, incompressible, turbulent condition inside the wind tunnel.

As a numerical study, the initial step towards the modeling is the production of the CAD geometry. We consider the blue face as the inlet of the domain while the red face as the outlet.

For the current problem, we generate a mesh count of 624,482 elements to represent the geometry using ANSYS Meshing. Regarding the quality of the mesh, the maximum skewness of 0.84 with an average of 0.22 is satisfactory. In addition, for an interested reader, we depicted the quality distribution of mesh as below. Also, we added 10 layers for our prism elements to accurately calculate the boundary layer.

Ahmed Body Aerodynamic Study Methodology

The calculation procedure can be started when we import the mesh into the ANSYS FLUENT solver.

In this project, we consider gravity. The flow behavior is steady. The type of this project is Pressure-based.

We used the k-w SST model to simulate the fluid’s turbulence.

Conclusion

After we converge the solution, we could obtain the results through post-processing. Meanwhile, as an assurance of a valid convergence, the drag and Y-plus values were monitored during the solution iterations.

This study decided that the solution is converged when the drag force reached a constant rate, and the residuals were below 10-5 values. Also, the maximum Y-plus value was 60 on the Ahmed body, which shows us that we have efficiently resolved the boundary layer.

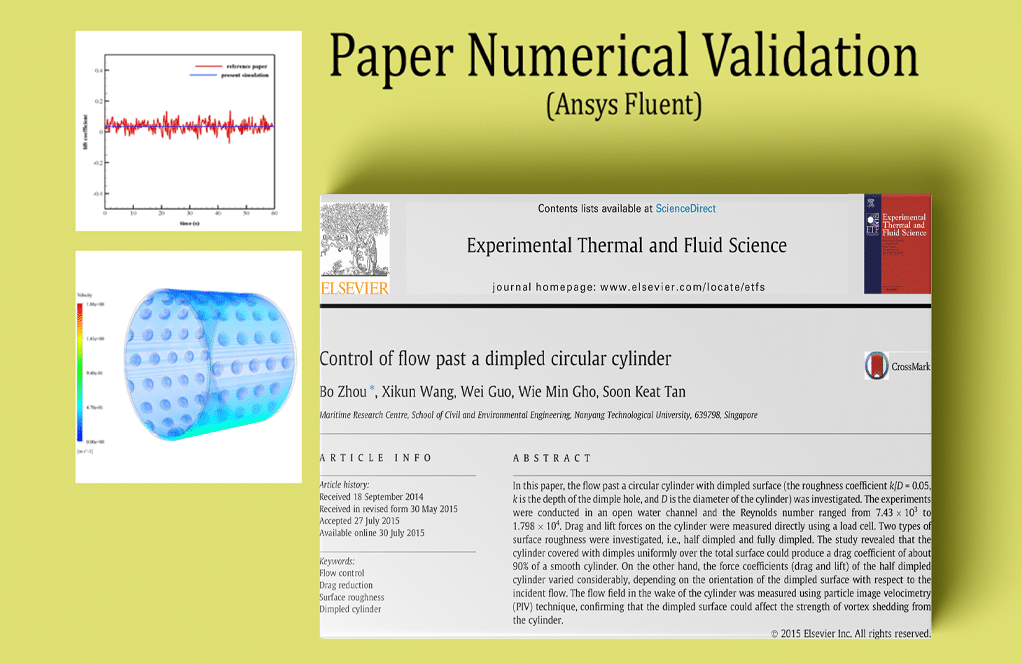

Before going through the results, two important issues must be noted regarding the Ahmed body geometry. Firstly, the Ahmed body geometry is a turbulent benchmark. Ahmed’s body is employed for cases where new turbulent models have been developed, like lid-driven cavity and backward step, and its accuracy is under examination.

For the noted cases, the experimental results of drag, flow separation, and separation angle are compared to the obtained data from the new model implemented inside the CFD code. Therefore, Ahmed body allows us to validate our numerical model.

Secondly, due to the simple geometry of Ahmed body, it could be easily employed for LES/DES simulations, where high-quality elements are required. Thus, Ahmed body could inform us regarding the details of turbulence for automotive applications.

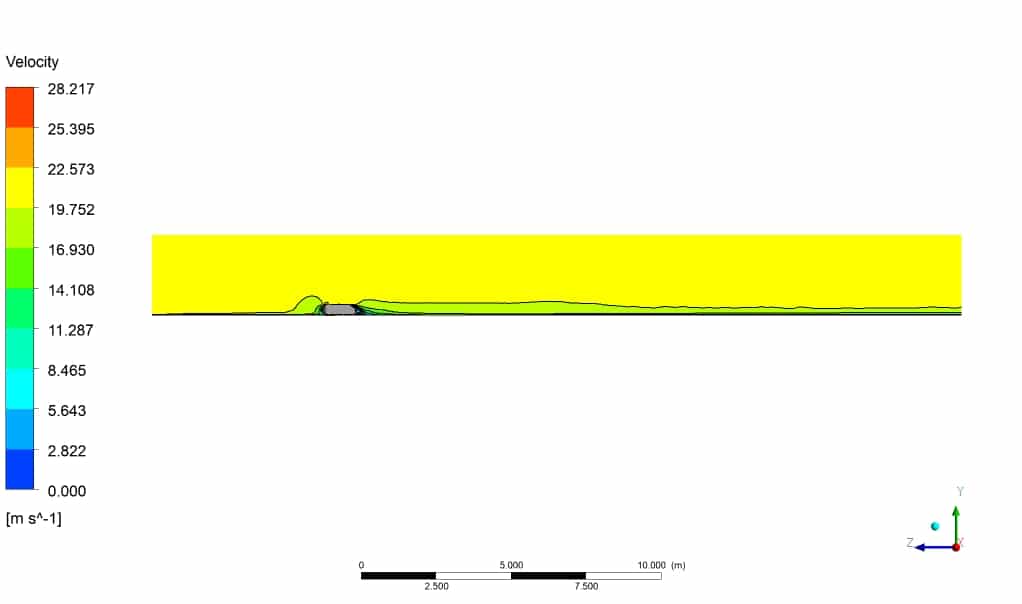

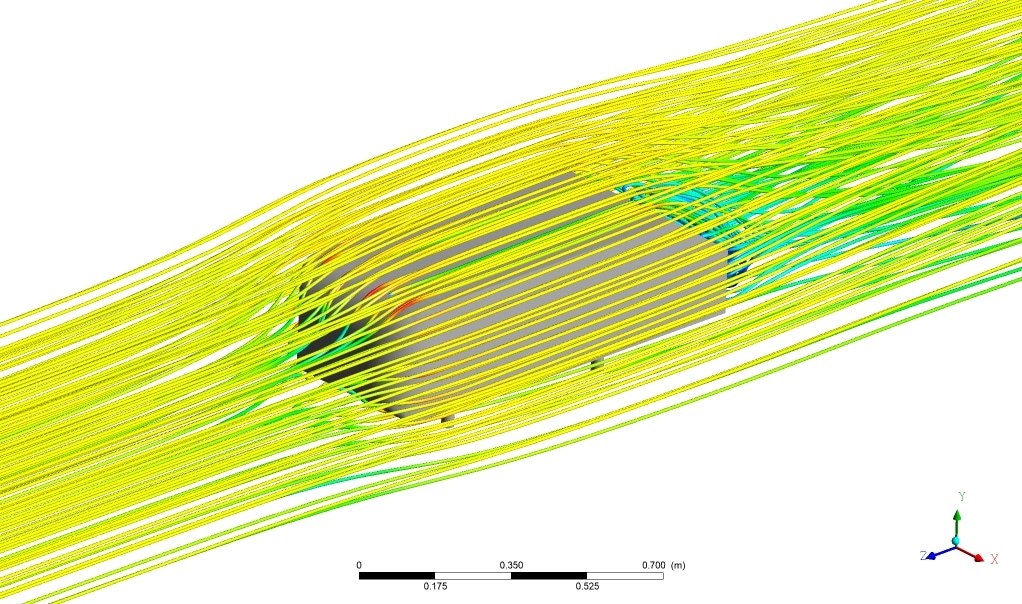

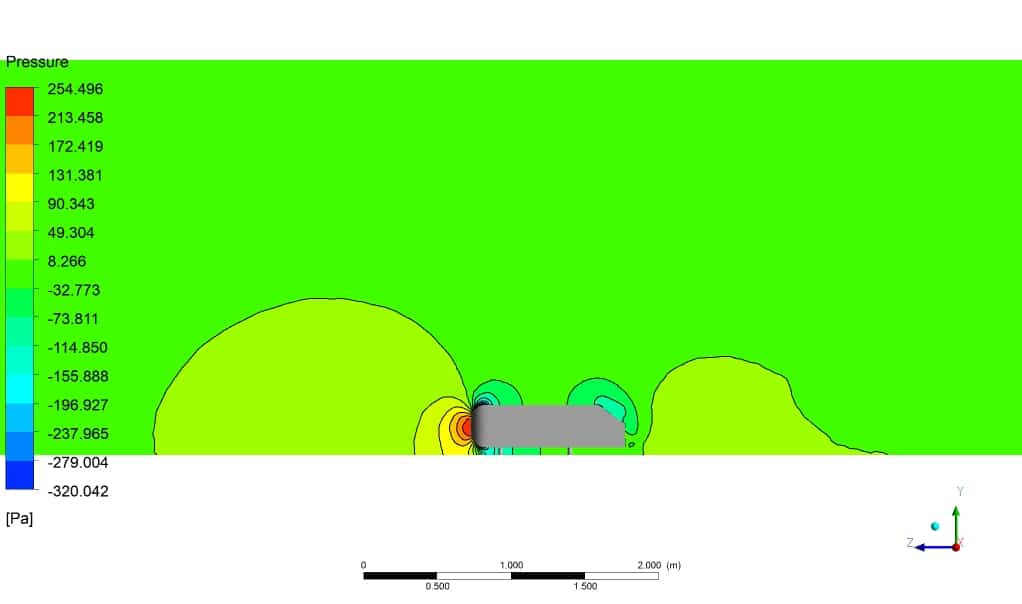

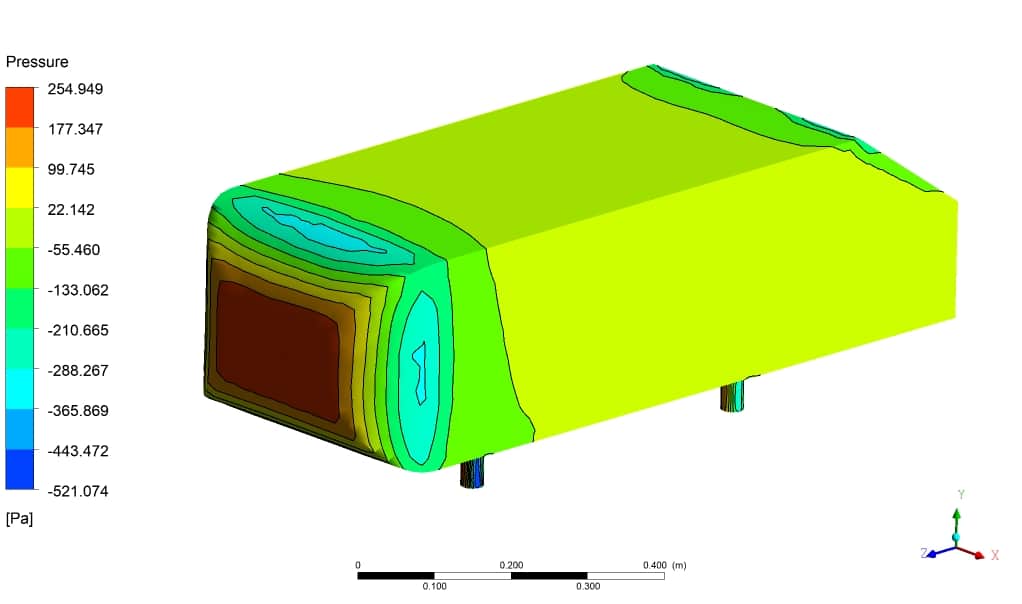

Afterward, the results regarding the pressure and the velocity field are depicted in the below figures. The maximum value of velocity was found at the corners, while the maximum value of pressure was at the middle of the front face, where the velocity was minimum. Also, we represent the streamlines to give much insight into the problem.

Finally, we have found that the drag force is 15.091 (N), which was accurate for a 1-meter car with the noted specifications.

Ezra Champlin –

The training on the Ahmed Body simulation was detailed and insightful. The step-by-step approach, along with clearly identified boundary conditions and turbulence model selection, was very helpful.

MR CFD Support –

Thank you for your positive feedback. We are glad you found the training detailed and helpful for understanding the Ahmed Body aerodynamics! If you have any more questions or need further assistance with CFD simulations, please don’t hesitate to ask.

Davon Medhurst –

I just completed the Ahmed Body Aerodynamic Study with ANSYS Fluent and must say, I am thoroughly impressed with its comprehensive analysis! The quality of the meshing and the information about monitoring the residuals and Y-plus values was particularly helpful. The fact that you can validate aerodynamic properties through simulation that showers the intricate behavior of turbulent flows is immensely powerful. Excellent training material!

MR CFD Support –

Thank you for your kind words! We’re glad to hear that you found our Ahmed Body Aerodynamic Study training material comprehensive and valuable. The ability to monitor and analyze the flow accurately is crucial, and we’re delighted our product could assist with that. Your feedback is truly appreciated, and we look forward to providing you with more quality training experiences. If there’s anything further you’d like to explore or learn about, don’t hesitate to reach out to us.

Hank Boyer –

I am impressed by the comprehensive aerodynamic analysis of the Ahmed body and how fluent the explanation is in the provided description. It seems like a high-quality educational resource for understanding vehicle aerodynamics in CFD!

MR CFD Support –

Thank you for taking the time to review our Ahmed Body Aerodynamic Study using ANSYS Fluent. We appreciate your positive feedback and are glad to hear that you found it to be an insightful and valuable resource. If you have any further questions or need more information, feel free to reach out to our team!

Harvey Pacocha –

I’ve finished the Ahmed Body Aerodynamic Study CFD Simulation training, and I must say the attention to detail, especially on the quality distribution of the mesh and Y-plus values, provided an in-depth understanding of how to set up simulations for automotive applications. Very impressed with the clarity and educational value of the content!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training helped enhance your understanding and provided comprehensive insights into the simulation setup process. Our team works hard to ensure the quality and educational value of our content. Your satisfaction and the knowledge you’ve gained are our top priorities. If there’s anything else we can assist you with, please let us know!

Pamela –

Provide more free tutorials, please.

melika maysoori –

We are glad that this tutorial was useful for you. User satisfaction motivates us to produce more free products.:) Sure.;) Over time, you can see more tutorials in this section.

Reggie Boehm –

This CFD study on the Ahmed body was delightful and educational. It covered the essentials about aerodynamics related to automotive bodies, provided thorough descriptions of methodology, and checks for result validity (like Y-plus and convergence)! Great job!

MR CFD Support –

Thank you for your positive feedback on our Ahmed Body Aerodynamics Study. It’s incredible to hear that you found the study insightful and that it enhanced your understanding of automotive aerodynamics. We work hard to provide comprehensive and educational content, and your comment reiterates that our efforts are appreciated. Stay tuned for more useful simulations and analyses. Your enthusiasm fuels our commitment!

Agnes Buckridge –

I really appreciate how detailed the study on the Ahmed body aerodynamics was, particularly the careful attention to the boundary layers and turbulence modeling. The validation against experimental results speaks to the reliability of the study for real-world applications in the automotive industry.

MR CFD Support –

Thank you for your positive feedback. We are thrilled to hear that our detailed approach to the Ahmed body aerodynamics study met your expectations and that our efforts to validate the data added value to your understanding of automotive aerodynamics. We strive to provide accurate and reliable simulations for practical applications, and your acknowledgment is greatly appreciated.

Milo Treutel –

I just completed the Ahmed Body Aerodynamic Study and it was fantastic! The way the tutorial guides you through the entire process, from meshing to monitoring convergence, really solidifies the concepts. The detailed information on setting up the turbulence model and boundary layers was especially helpful. Thank you MR CFD for such an informative and well-structured training!

MR CFD Support –

We’re thrilled to hear you had a great experience with our Ahmed Body Aerodynamic Study training! It’s wonderful to know the tutorial was clear and helpful for you, especially in understanding the complexities of turbulence modeling and boundary layer setup. Thanks for choosing MR CFD Company’s products, and we’re grateful for your positive feedback!

Emmanuelle Bayer II –

The level of detail in this review of the Ahmed Body Aerodynamic Study is fantastic! I got a strong sense of the comprehensive approach taken to simulate and analyze aerodynamic characteristics. Impressed by how the mesh quality and Y-plus values were considered to ensure accurate boundary layer resolution, and that a constant drag rate served as a convergence criterion. The methodologies employed, including the usage of the k-w SST turbulence model and your presentation of the pressure and velocity fields, streamline visualization, and straightforward reporting of drag force, reflects a profound understanding of CFD applications in automotive design. Great job on this study!

MR CFD Support –

Thank you for your positive feedback on the Ahmed Body Aerodynamic Study! We’re thrilled to hear that the level of detail provided in the CFD simulation and analysis was meaningful and informative. Your appreciation of the mesh quality, Y-plus values, and the establishment of convergence criteria reflects your understanding of the complexities involved in such studies. We’re glad that the methodologies, results, and visual presentations met your expectations and aided in your comprehension of aerodynamic characteristics in automobile-related bodies. Your recognition is highly valued, and it encourages our continued commitment to providing high-quality CFD learning materials.

Gerald Wilkinson PhD –

This training seems very comprehensive! I appreciated learning about the aerodynamics of car-like geometries and how turbulence behaves in these scenarios. The detailed explanation on how to set up the model, choose boundary conditions and assess the mesh quality was particularly useful. The Ahmed body being a benchmark for turbulent models also showed me the significance in automotive aerodynamics. Thanks to this course, I feel I have a solid grounding in evaluating drag and analyzing flow separation for vehicle design. Kudos to MR CFD for a well-structured and informative training program!

MR CFD Support –

Thank you for your positive feedback! We’re glad to know that you found the Ahmed Body Aerodynamic Study valuable and that it enhanced your understanding of vehicle aerodynamics. It’s always our goal to provide comprehensive and practical CFD training that enables our users to confidently apply these skills in real-world scenarios. We appreciate your recognition of the course structure and our efforts to deliver a high-quality learning experience. If you have any further insights or require assistance on any other CFD-related topics, feel free to reach out to us.

Leopoldo Schumm III –

The Ahmed Body Aerodynamics study simulates crucial aspects of car design. Kudos to MR CFD Company for creating a comprehensive and practical training module that couples theoretical knowledge with hands-on CFD skills using ANSYS Fluent.

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that you found the Ahmed Body Aerodynamic study to be comprehensive and practical for understanding car design principles. If you ever have any questions or need further assistance, feel free to reach out to us. We’re here to help enhance your CFD knowledge and skills.

Bradford Hettinger –

The tutorial on the Ahmed Body Aerodynamic study was impressively in-depth. The thorough explanation of the methodology and the extensive details on the setup, mesh generation, and results provided me with a clear understanding of automotive aerodynamics. This has solidified my comprehension of flow separation, drag forces, and the importance of validating CFD models against experimental benchmarks.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you found our Ahmed Body Aerodynamic study to be thorough and informative. We take great pride in creating educational materials that help in understanding complex aerodynamic concepts and their practical applications. Your comprehension and ability to apply these fundamentals are exactly what we aim for with our training products. If there’s anything else you’re curious about or if you have further interest in CFD simulations, don’t hesitate to explore more of our offerings.

Miss Nella Gorczany –

The review was very illuminating, particularly in the explanation and conclusion sections where complex aerodynamic concepts were communicated effectively. It will definitely help beginners step into CFD analysis with a practical understanding.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that you found the review helpful in understanding the aerodynamic concepts through the Ahmed Body study in ANSYS Fluent. It’s our pleasure to assist learners and make CFD analysis more accessible.