Air Gap Membrane Distillation (AGMD), ANSYS Fluent CFD Simulation Tutorial

$220.00 $110.00 Student Discount

- This simulation is about air gap membrane distillation (AGMD) via ANSYS Fluent software.

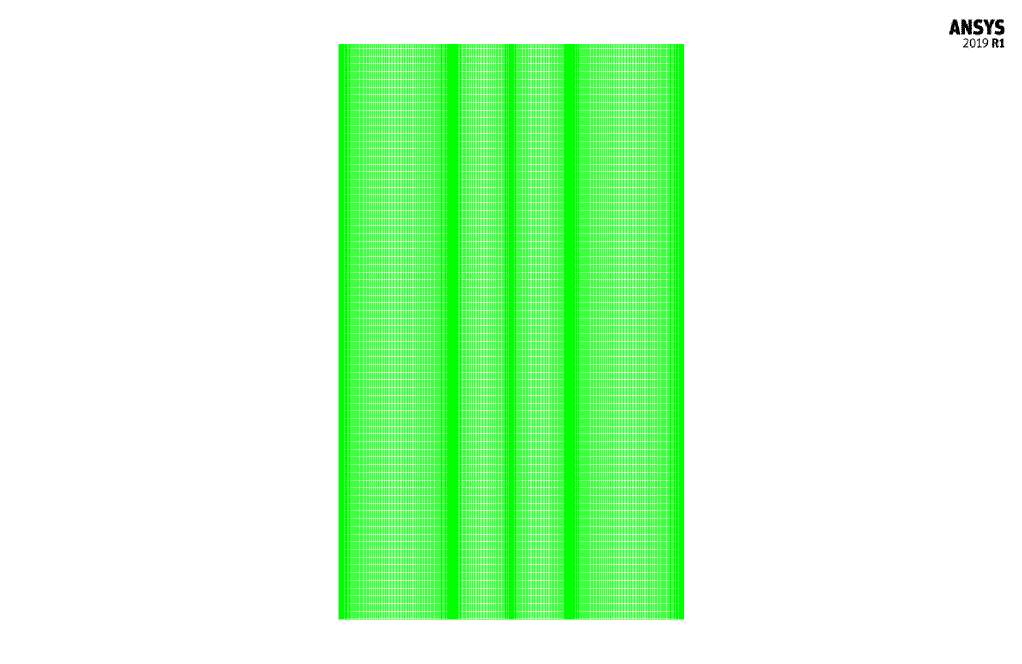

- We have designed the geometry using ANSYS Design modeler software and created the mesh on this geometry using ANSYS meshing software. The mesh type is structured with 150000 cells.

- The VOF (volume of fluid) model has been used to define the multiphase model.

- mass transfer is defined based on the evaporation-condensation mechanism.

- porosity is defined to express the permeability of the porous medium.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This simulation is about air gap membrane distillation (AGMD) via ANSYS Fluent software.

Water desalination systems include two general methodologies: “thermal desalination” and “membrane desalination.” In the “thermal method,” phase exchange occurs to produce fresh water; while in “the membrane method,” specified membranes are used to separate water from impurities.

Membrane distillation (MD) systems combine the thermal and membrane methods. In these systems, both phase exchange occurs, and specified filters are used.

There are different MD systems. In this project, Air-Gap Membrane Distillation (AGMD) is studied.

This AGMD system consists of four zones; including the feed channel, membrane layer, air gap, and cooling channel. Hot water flows in the feed layer, and cold water flows in the cooling layer in the opposite direction. Next to the feed water layer, the membrane layer is placed, and then an air gap is placed next to the cooling water layer.

AGMD performance system is considered in the processing systems category. It means, that in the first step, the water experiences surface evaporation, and in the second step, the pure water vapor condenses on the condensate surface.

Therefore, for simplicity, it is assumed that the hot feed water has already been converted to steam. So, the saturated steam flows in the feed channel to be ready to condense in the air gap section.

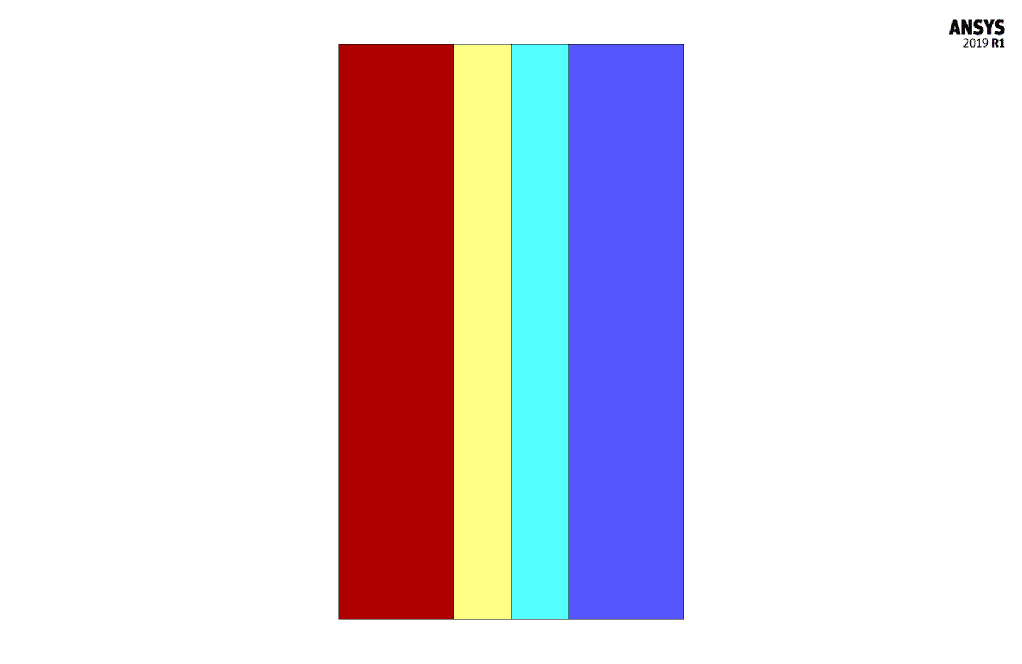

The geometry of the present project is modeled in two dimensions with Design Modeler software.

Then the model meshed with ANSYS Meshing software. The model’s grid is structured, and 150000 cells have been created.

Methodology: Air Gap Membrane Distillation (AGMD)

In this simulation, three different phases are used. The steam inside the system is supposed to turn into water, and condensation occurs. On the other hand, there is also an air gap within the system. So a multiphase flow must be used instead of a single fluid.

The VOF (volume of fluid) model has been used to define the multiphase model. This multiphase model can completely separate different phases from each other and display a distinct boundary between phases.

For the boundary between the water phase and the vapor phase in the system to be clear, the VOF model is the best option.

Air is defined as the primary phase of the model, and water liquid, and water vapor are defined as the secondary phases of the model. When the multiphase model is used, a parameter called volume fraction is provided for the secondary phases of the model to solve their transport equations.

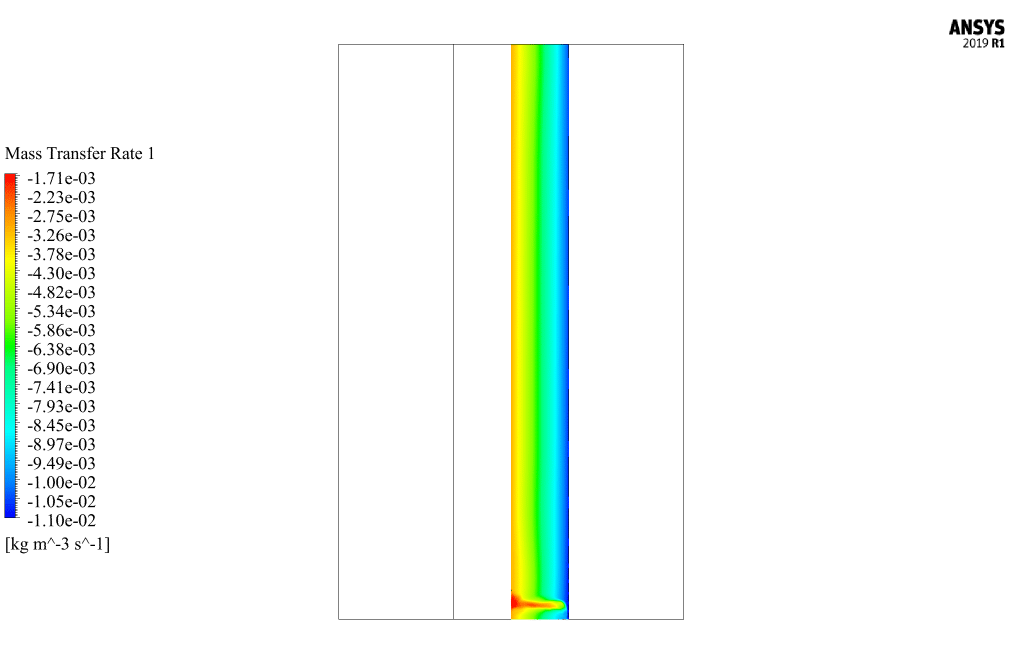

A phase change occurs between the water and vapor phases. So a mass transfer between these two phases is defined. This mass transfer is defined based on the evaporation-condensation mechanism.

This mechanism deals with the phase change process between liquid and vapor. In the evaporation-condensation mechanism, Lee’s equations calculate the mass transfer rate. These equations depend on the saturation temperature and the frequency coefficient of evaporation and condensation.

Also, a porous medium has been used for the membrane part of the system. A parameter called porosity is defined to express the permeability of the porous medium. This coefficient represents the ratio of empty volume to total volume.

Conclusion

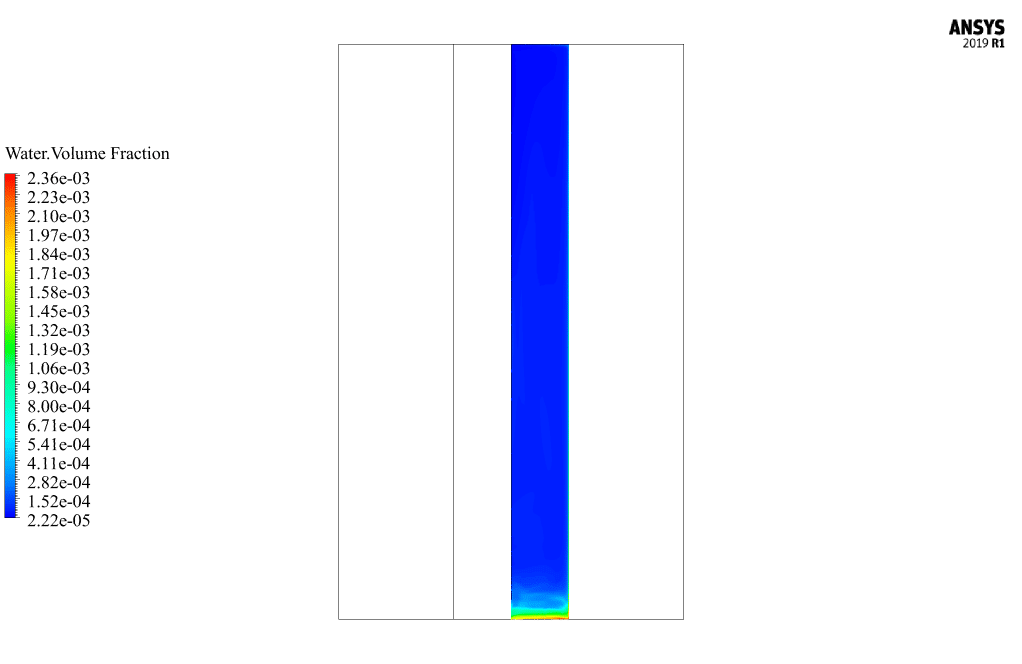

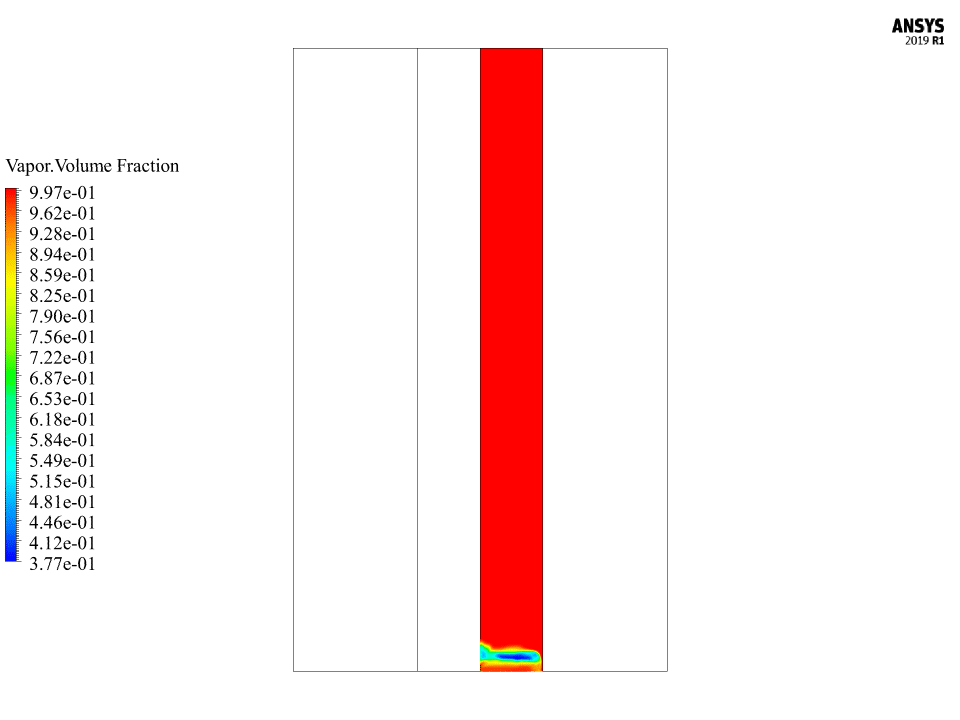

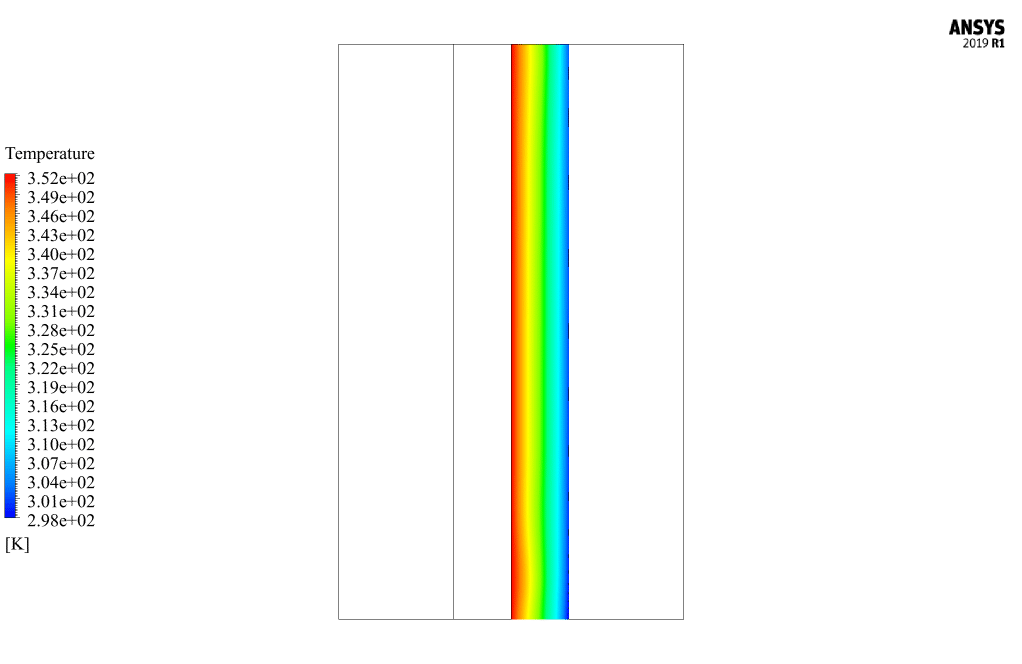

After the end of the simulation solution, the contours related to temperature, phase change rate between water and vapor, and the volume fraction of each of the water and vapor have been obtained.

The results show that the temperature decreases on the cold side of the air gap. The temperature contours show the thermal boundary layer well. The highest condensation or phase change rate occurs in the regions with the temperature drop. The negative sign for the phase change rate indicates the transformation from vapor to liquid phase.

Also, when the volume fraction contour of distilled water is investigated, a film of liquid appears on the cold plate of the air gap. This produced fresh water goes to the bottom of the air gap due to gravity.

The results prove that the current water desalination system works correctly and the membrane distillation mechanism works correctly.

Dr. Einar Johnson –

The product offered by MR CFD for AGMD simulation in ANSYS Fluent looks comprehensive. Does the simulation include temperature-dependent properties for the accuracy of the condensation process?

MR CFD Support –

Indeed, the simulation includes temperature-dependent properties to ensure an accurate representation of the condensation process. The physical properties of the materials involved, especially the saturation temperature, impact the phase change rate calculations, and MR CFD’s product takes this into consideration for reliable results.

Kaden Bartell –

I recently completed the Air Gap Membrane Distillation simulation tutorial, and I have to say, it was incredibly detailed and informative. The step-by-step guidance made the concepts easy to understand and the software became much more approachable. I feel much more confident in running my own simulations now. The attention to detail, especially in setting up the condensation mechanisms and mass transfer, has been particularly helpful.

MR CFD Support –

Thank you for your lovely feedback! We’re thrilled to hear that our AGMD simulation tutorial has been so helpful and has strengthened your confidence in using the software. It’s fantastic to know that the detailed instructions and the focus on key mechanisms like condensation and mass transfer have enhanced your learning experience. Your success is what motivates us to keep providing quality educational material. We appreciate the time you took to share your thoughts, and we look forward to supporting you in your future simulation endeavors!

Vernice Braun –

The tutorial mentioned Lee’s model for mass transfer. Can you provide more details on how Lee’s model is specifically implemented in the simulation setup for AGMD?

MR CFD Support –

In this CFD simulation of AGMD within ANSYS Fluent, Lee’s model has been employed to manage the mass transfer due to phase change between the liquid and vapor phases. To configure Lee’s model in Fluent, saturation temperature under operating conditions and the coefficients associated with evaporation and condensation are input parameters. This exhibits through user-defined functions or preset model settings in Fluent. The calculated mass transfer rate is then incorporated into the momentum, mass, and energy equations for precise representation of the evaporation-condensation dynamics prevalent in the air gap of the membrane distillation process.

Danika Will –

This tutorial increased my understanding of AGMD systems. The detailed explanation helped me grasp the concept of condensation and the role of the air gap. Can you tell me which boundary conditions affect the rate of condensation most critically?

MR CFD Support –

The rate of condensation in AGMD systems is highly influenced by the temperature gradient between the hot feed side and the cold side. Boundary conditions on the hot side, relating to the temperature and pressure of the incoming steam, as well as on the cold side, pertaining to the temperature and flow rate of the cooling medium, are critical in determining the rate of condensation. Further, the operational efficiency of the membrane and clearance in the air gap also play significant roles.

Sammy Bergstrom –

Very detailed explanation! I appreciate that phases are managed individually, which is crucial for capturing the simultaneous vapor water phase transition. Could you tell me how the software handles heat transfer in the air gap specifically?

MR CFD Support –

In the simulation, the heat transfer within the air gap is managed using the VOF multiphase model to simulate thermal interaction between phases. ANSYS Fluent takes into account natural convection driven by temperature differences between the hot vapor and the cold plate, and radiation may also be considered. The software employs a conjugate heat transfer model that calculates the temperature fields in the participating media (air, vapor, and the solid wall of the cold plate) to accurately capture the heat dynamics that lead to condensation in the air gap area.

Roberta Emmerich –

Fantastic tutorial! The step by step process was so clear, and learning about AGMD with ANSYS Fluent was insightful. Adequate coverage of the VOF model and Lee’s phase change mechanism gave a good understanding of the simulation.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear that our tutorial met your expectations and helped clarify the principles behind the Air Gap Membrane Distillation process using ANSYS Fluent. If you have any further questions down the road or need additional clarification, don’t hesitate to reach out.

Dr. Keanu Hoppe –

The tutorial on AGMD desalination was easy to follow. It beautifully illuminated the complexities of the distillation process and the integration of different scientific principles.

MR CFD Support –

Thank you for your generous feedback! We’re glad the AGMD CFD simulation tutorial was clear and instructive. It’s always great to hear that our efforts to explain complex processes in an understandable way are successful. Thanks again for choosing MR CFD’s learning products.

Regan O’Reilly –

I was impressed by the detailed explanation of AGMD process and simulation setup. The combination of the thermal process with a membrane for desalination sounds very efficient.

MR CFD Support –

Thank you for your positive feedback about our Air Gap Membrane Distillation (AGMD) tutorial! We’re delighted to know our detailed explanations on the AGMD process and the step-by-step guidance in the simulation setup met your expectations. Your satisfaction with the efficient depiction of the desalination process and the clear presentation of our simulation method is much appreciated.

Rebecca Auer Sr. –

Great tutorial! As a beginner, could you explain what volume fractions I should be looking at to know if the simulation is running correctly?

MR CFD Support –

In your AGMD simulation, pay attention to the volume fractions of the vapor and the water. A vapor volume fraction close to 1 indicates the presence of steam, and areas where it transitions to lower values reveal condensation into water. Correct simulations typically show a decrease from vapor to water volume fractions across the membrane, with distilled water forming on the cold side of the air gap.

Mr. Thad Schneider DDS –

I’m deeply impressed with the detailed explanation of the air gap membrane distillation presented here. It’s a complex process, and the simulation seems to perfectly capture the temperature gradients and phase changes. Keep up the fantastic work providing such in-depth learning materials!

MR CFD Support –

Thank you for your enthusiastic feedback! We’re thrilled to hear that you find our simulation tutorial on Air Gap Membrane Distillation both informative and detailed. Your support inspires us to continue delivering high-quality educational content. If you have any further questions or need assistance with other topics, please don’t hesitate to reach out to us!

Reginald Pfannerstill –

I’ve used the AGMD simulation learning materials, and it has greatly improved my understanding of the processes involved. I just wanted to express my gratitude for such detailed instructions and crystal-clear explanations. Well done, MR CFD Company, your learning product has been very helpful.

MR CFD Support –

Thank you so much for your kind words and for taking the time to leave us this fantastic review. We’re thrilled to hear that the AGMD simulation tutorial was effective for your learning experience and that the detailed information provided was beneficial to you. We appreciate your feedback, and it encourages us to continue creating high-quality educational materials. If you need any more assistance or have further inquiries in the future, always feel free to reach out. Thanks again!

Dr. Hanna Witting –

The Lee’s equations that calculate mass transfer in the simulation, are they a standard part of ANSYS Fluent, or do they need special user-defined functions to be implemented?

MR CFD Support –

Lee’s equations for mass transfer are a standard feature available in ANSYS Fluent’s evaporation-condensation model. The software comes with predefined functions that can calculate mass transfer based on these equations, eliminating the need for user-defined functions in most cases.

Gideon McGlynn –

The results look very informative! I am curious if the simulation explores the efficiency of the AGMD system based on different operating conditions or membrane materials?

MR CFD Support –

We appreciate your interest in the details of the AGMD simulation! The efficiency of the AGMD system is largely influenced by factors such as operating conditions and the membrane materials used. Our CFD simulation can explore various scenarios by altering input parameters to study the effects on system efficiency. If you have specific conditions or materials in mind, do let us know, and we can discuss the possibilities of incorporating those into a simulation study.

Adrianna Langworth –

I’m impressed with the detailed explanation of AGMD in the tutorial! Has this simulation been validated with any experimental or real-world data?

MR CFD Support –

Thank you for the compliment on the tutorial’s detail regarding Air Gap Membrane Distillation. The CFD simulations adhered to established physical principles and used proven models like the VOF and Lee’s phase change mechanism for accuracy. However, validation against specific experimental or real-world data would depend on benchmarks set by engineers and researchers in the field of water desalination systems. The MR CFD Company often ensures that simulations are as relevant to real-world applications as possible. If you require information on specific validations, please let us know!

Shawn Grant –

I just finished going through the AGMD simulation tutorial, and it changed my perspective on desalination processes entirely. The clarity and detail provided in each step of simulation truly helped me understand the VOF models and the phase change concept. I’m impressed with how the mass transfer was explained using Lee’s equations and how the use of a porous medium for the membrane was elaborated. Seeing the temperature distribution and observing the phase change on the contours was enlightening!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled that you found our AGMD simulation tutorial enlightening and helpful. Understanding the VOF model and phase changes is indeed crucial for conducting an accurate CFD analysis in membrane distillation systems. We’re glad the tutorial was able to provide you with clarity and detail that enhanced your understanding. We strive to create resources that make complex concepts more accessible, and we appreciate hearing that we’ve achieved this with our AGMD tutorial. Should you have any further feedback or need assistance, please don’t hesitate to reach out.

Aron VonRueden –

I recently completed the AGMD simulation tutorial by MR CFD. I must say, the step-by-step instructions were really well thought out and easy to follow! The use of porous media for the membrane and the clarity with which the VOF method was explained to showcase the distinct boundaries during condensation phenomena was excellent. Understanding the phase change mechanism was made simple, even for someone with limited prior experience in multiphase flows. Excited to apply these concepts to my own project!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that the tutorial was beneficial to you and that you found the explanation of the VOF method and phase transition clear and understandable. We take pride in creating educational materials that cater to various experience levels. Good luck with applying these concepts to your project, and please don’t hesitate to reach out to us if you need any further assistance!

Levi Hamill Jr. –

What approach is taken to simulate the condensation process within the AGMD system in ANSYS Fluent?

MR CFD Support –

In the AGMD simulation, condensation is modeled through a mass transfer mechanism between water vapor and liquid water. This phase change is captured using Lee’s model for evaporation-condensation within the VOF framework, where the mass transfer rate depends on the saturation temperature and coefficients of evaporation and condensation.

Polly Sanford –

The simulation of AGMD seems thorough, but could you specify how you determined the appropriate mesh size for this study?

MR CFD Support –

In the AGMD simulation, the mesh size is selected based on a balance between accuracy and computational efficiency. The final mesh of 150,000 structured cells ensures that the flow field and phase change are resolved accurately, particularly around the membrane and air gap zones, which are critical for the distillation process, while keeping the computational cost manageable.

Mr. Candido Leuschke II –

The tutorial mentioned the VOF model for multiphase flow; can you explain how this impacts accuracy compared to single-phase models?

MR CFD Support –

Certainly! The VOF (Volume of Fluid) model provides a distinct interface between the different phases, which is necessary to accurately simulate the interaction of steam, air, and water in membrane distillation processes. A single-phase model would not be able to capture the process of phase change, leading to less accurate results. The VOF model allows for the direct tracking of the liquid-vapor interface and accurately models mass transfer during condensation. This significantly increases the fidelity of simulations dealing with multiphase phenomena like those in AGMD systems.

Garnett Balistreri –

The AGMD simulation is fascinating. One concern I have is how the surface wettability and membrane properties were taken into account? Were any approximations made for these complexities, or were they included in the simulations directly, potentially affecting accuracy?

MR CFD Support –

The surface wettability and membrane properties play a crucial role in the AGMD process. In this simulation, the membrane’s porosity is considered using a porous medium model to account for its permeability. As for the surface wettability, the simulation would use contact angle and surface tension properties within the software environment to model the interaction of water and vapor at the membrane surface. For any advanced interfacial phenomena, additional boundary conditions or user-defined functions might have been implemented. Such considerations are made to increase the simulation’s accuracy and closely mimic the real-world performance of the AGMD system.

Kathlyn Cremin –

What settings do I need to adjust if I want to use a different membrane material in the AGMD simulation?

MR CFD Support –

You would need to modify the properties of the porous medium to match the characteristics of the new membrane material. This involves adjusting the porosity and permeability values in the porous zone settings. Additionally, if the membrane material has different thermal properties, you may need to update thermal conductivity, specific heat capacity, and possibly the mass transfer coefficients depending on how the new material affects the phase change behavior.

Drew Hodkiewicz V –

I’m impressed with how AGMD can efficiently desalinate water. Excellent tutorial!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the tutorial on Air Gap Membrane Distillation (AGMD) using ANSYS Fluent was helpful. We are committed to providing high-quality learning resources. If you have any further questions or need more assistance, feel free to reach out.

Viva Hill –

I truly benefited from the detailed explanation in the Air Gap Membrane Distillation (AGMD) tutorial. The methodology was insightful, specifically the approach to phase changes and mass transfer. Appreciate all the work that went into creating this resource!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our tutorial on Air Gap Membrane Distillation (AGMD) provided you with a clear understanding of the methodologies involved in CFD simulation. It’s our goal to deliver comprehensive and insightful educational materials, and we’re glad that it was beneficial for you. If you have any more questions or need further assistance with your CFD learning journey, feel free to reach out!

Braden Rohan –

I really appreciated the detailed breakdown of the distillation process and the clear explanation of phases involved in AGMD. Brilliant work!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our explanation of the Air Gap Membrane Distillation process was informative and clear. It’s our goal to provide comprehensive insights and if you have any more questions or need further clarification, don’t hesitate to reach out!