Packed Bed CFD Simulation with Catalyst Particles, ANSYS Fluent

$100.00 Student Discount

- This project simulates a Packed Bed with catalyst Particles, modeled as heat source in ANSYS Fluent.

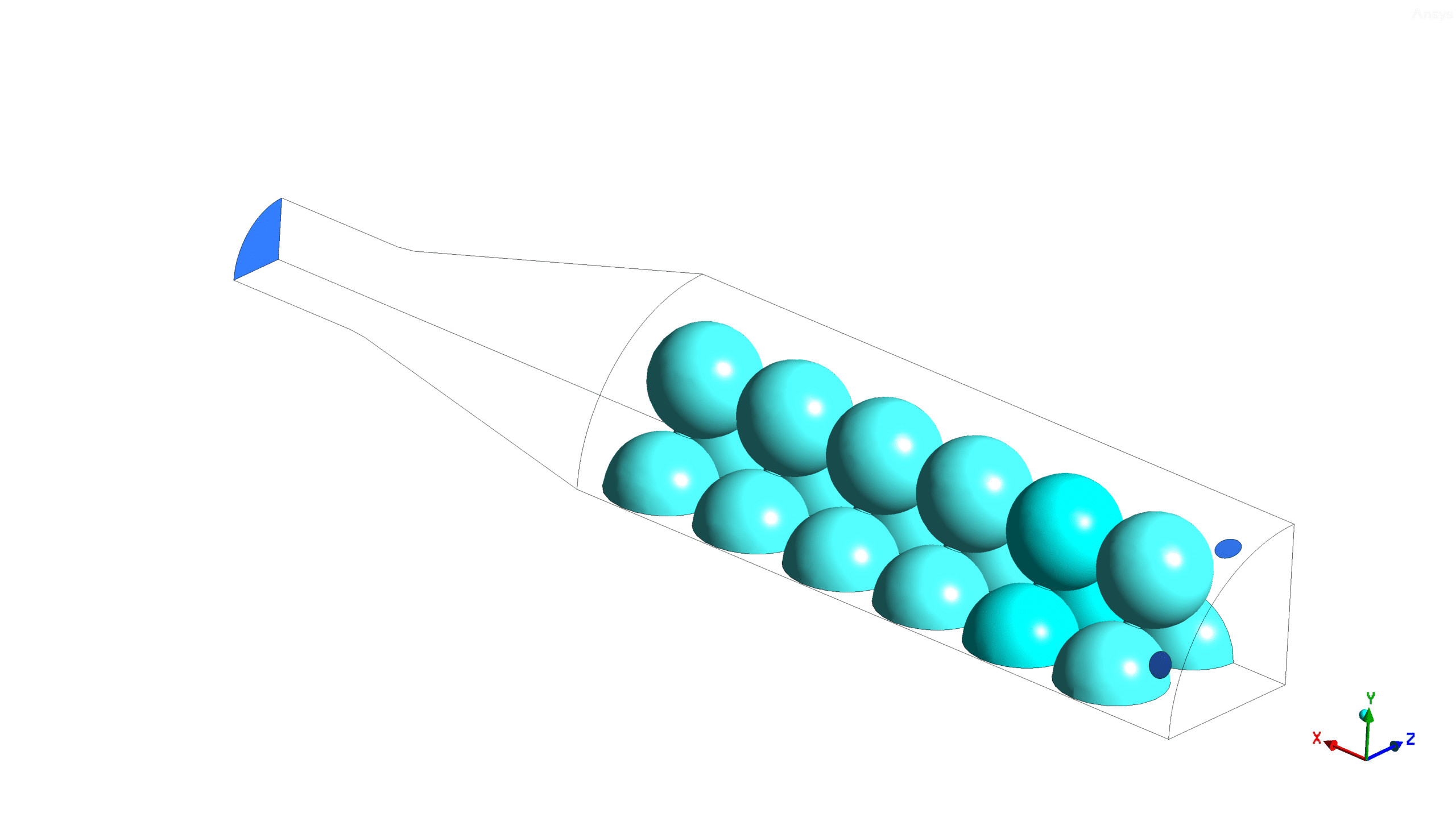

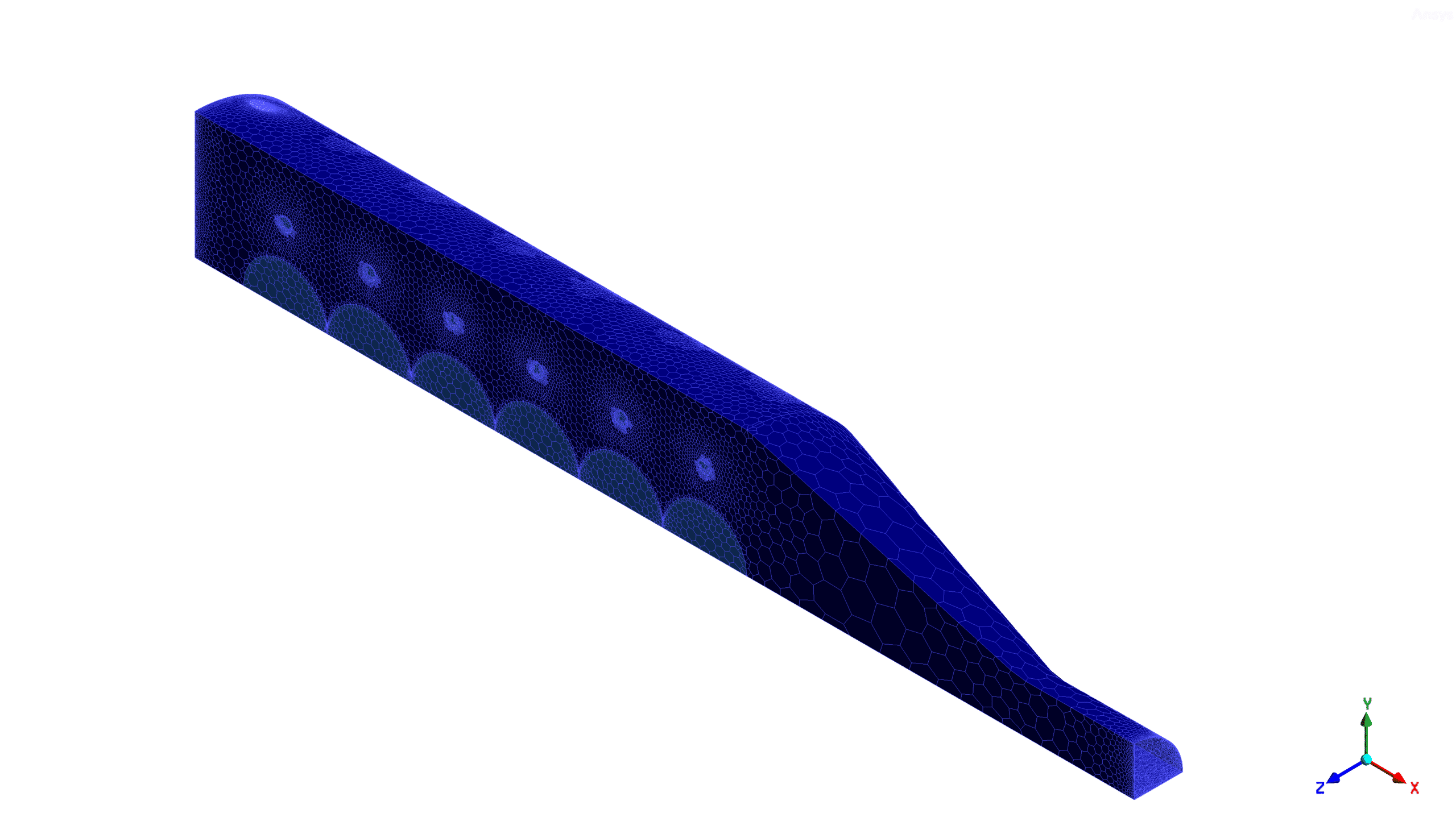

- The geometry is designed in Design modeler then meshed in ANSYS Meshing with 252,565 polyhedral cells.

- RNG k-ε model is activated as turbulence model.

- The radiation is taken into account in heat transfer with DO model.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

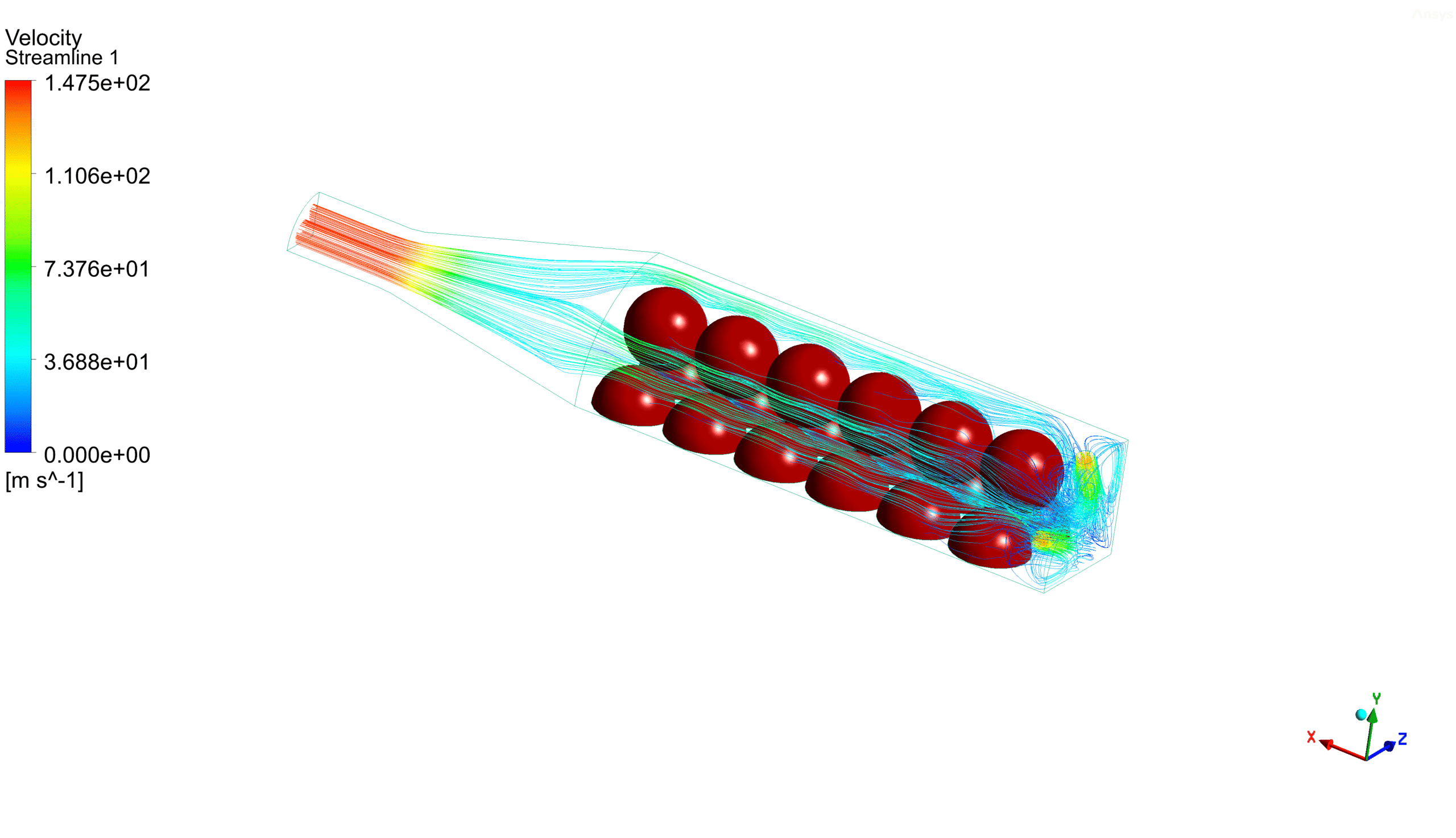

This project simulates a packed bed with Catalyst Particles using ANSYS Fluent software in which the particles are modeled as heat source. A packed bed reactor typically consists of a cylindrical vessel filled with catalyst particles that are often spherical in shape. The size of these spheres can vary depending on the specific application. The geometry of the model is designed in Design modeler then meshed in ANSYS Meshing with 252,565 polyhedral cells.

Methodology

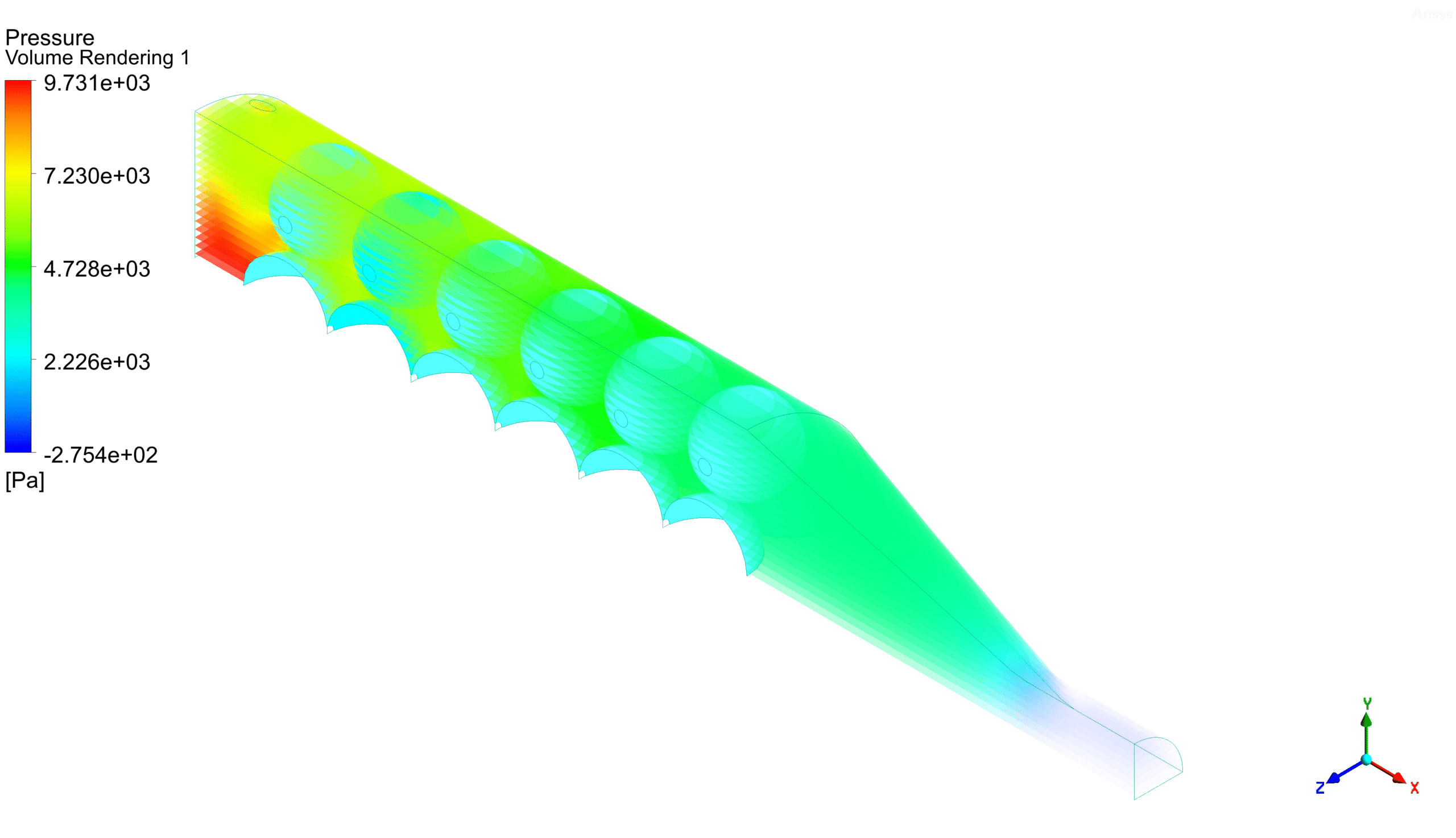

The spheres’ material is considered as quartz and the simulation has been carried out steadily with RNG k-ε model, as turbulence model. The inlet flow rate and the temperature are 0.0125 [kg/s] and 298.15 [K] . We considered solid spheres as heat sources in which each rows of them has different amount of heat in cell zone conditions. Two walls of the packed bed named as wall cavity and wall back cavity have constant flux of 1,999,969.13 and 37,473.8 [w/m2] respectively, but the back wall is considered as transparent with mixed thermal condition. Also due to high temperature of heat sources, the radiation is taken into account in heat transfer and the applied model for its simulation is DO.

Conclusion

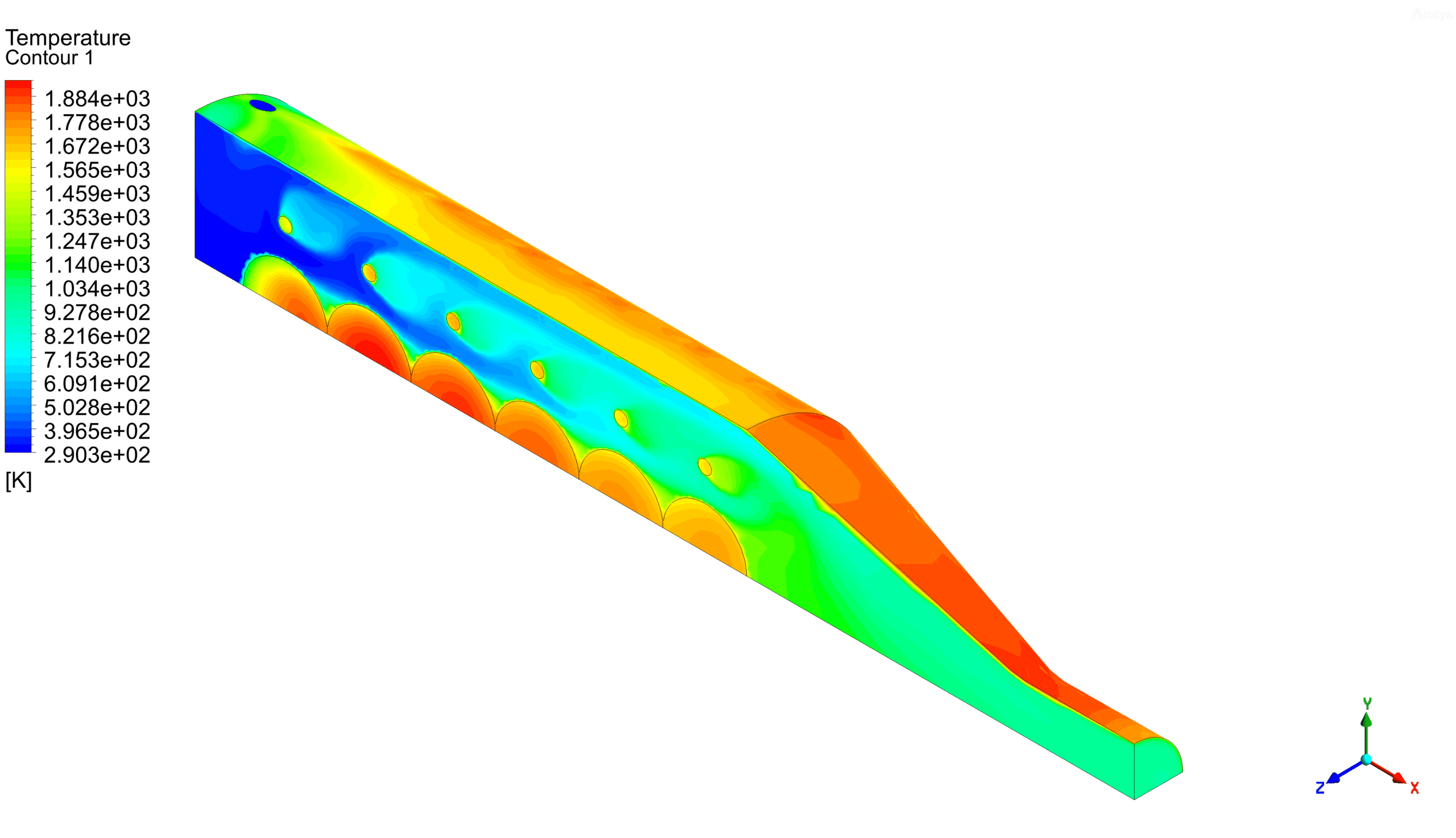

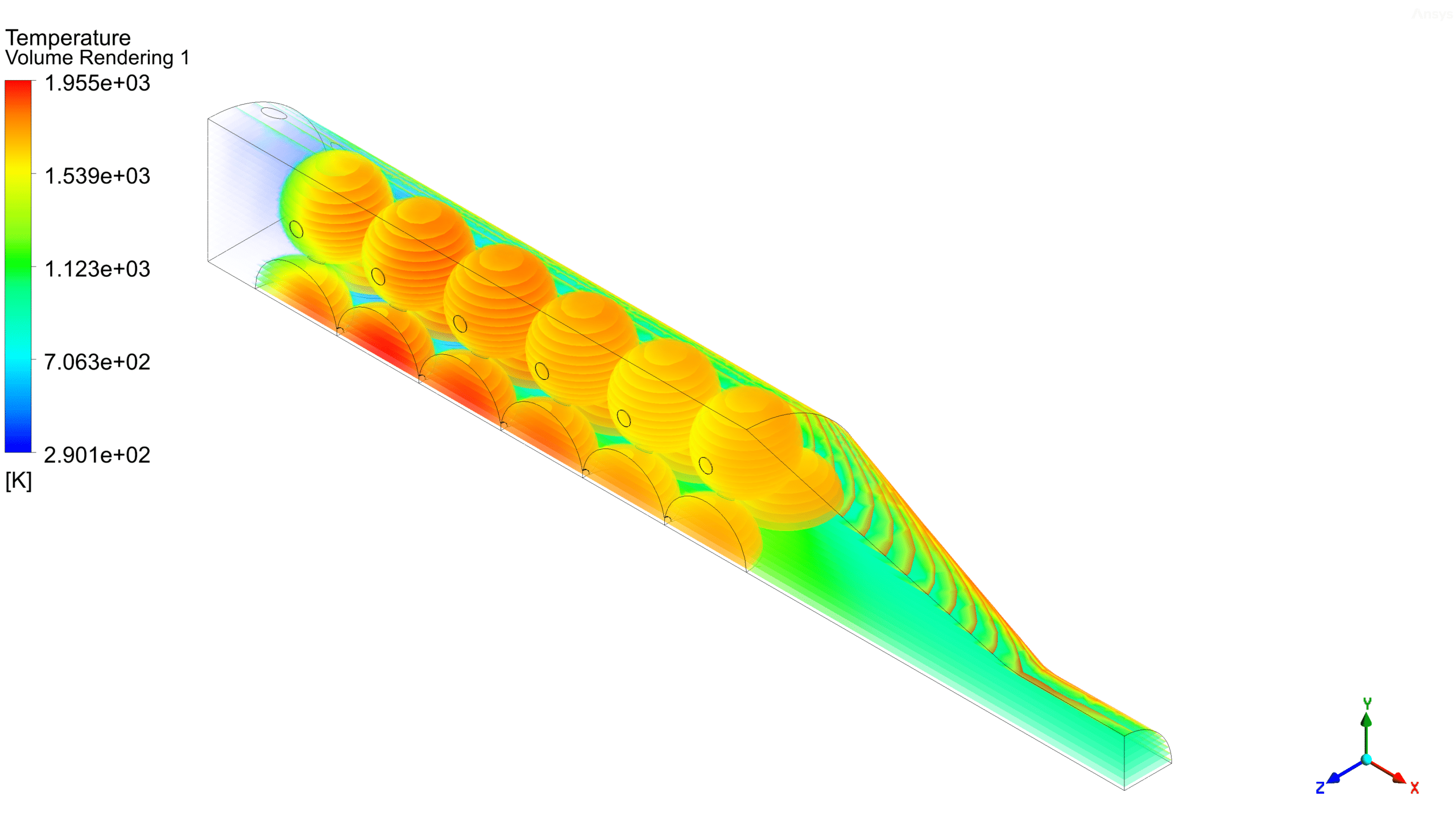

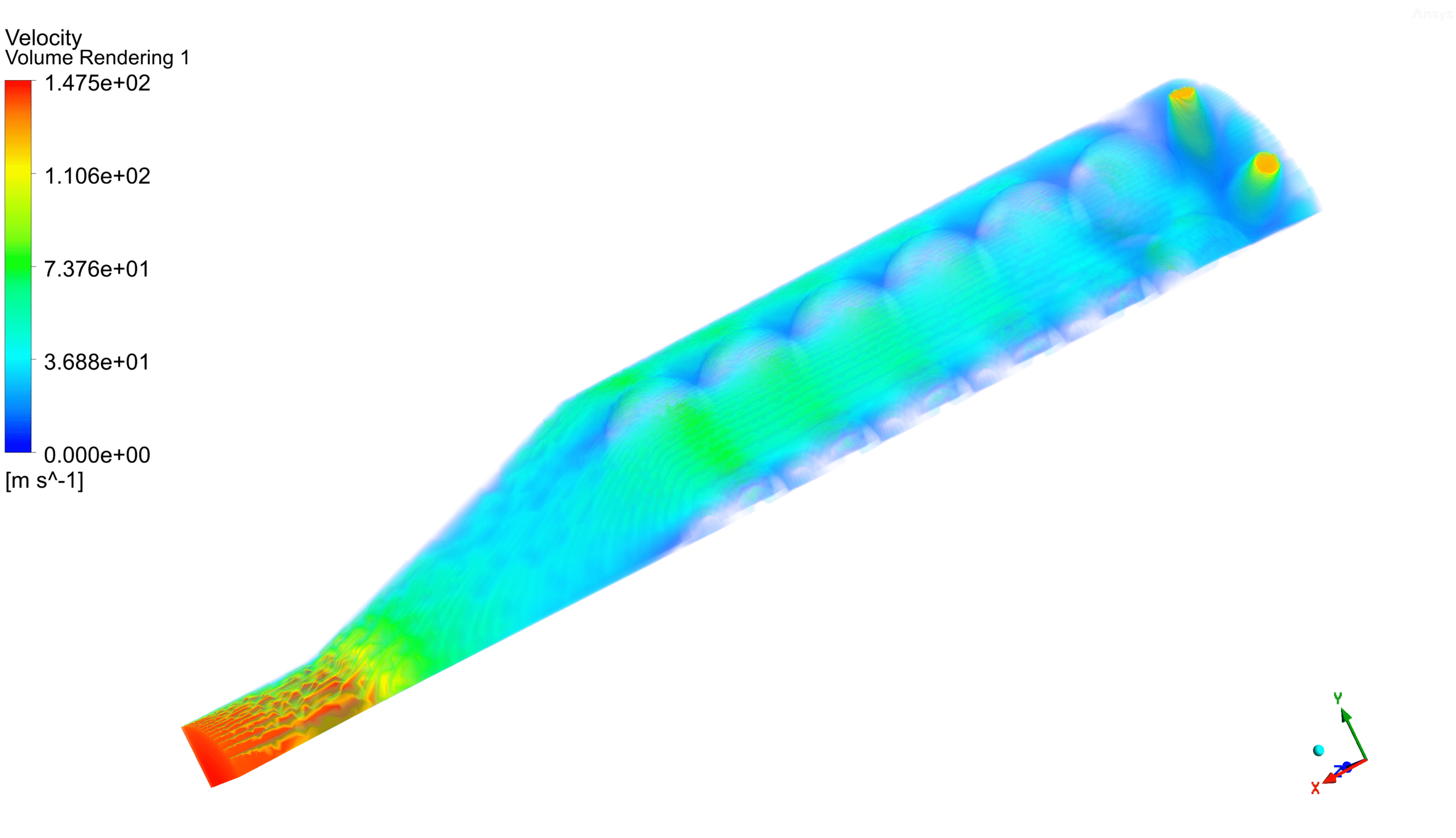

The volume renderings for temperature show how it distributes in the domain according to the all convection, conduction and radiation mechanisms. The air enters the domain via two inlets with 298.15[K] then its temperature increases to 998.131 [K]. Also the higher temperature of the spheres, cause of being heat source, is shown obviously in the contours.

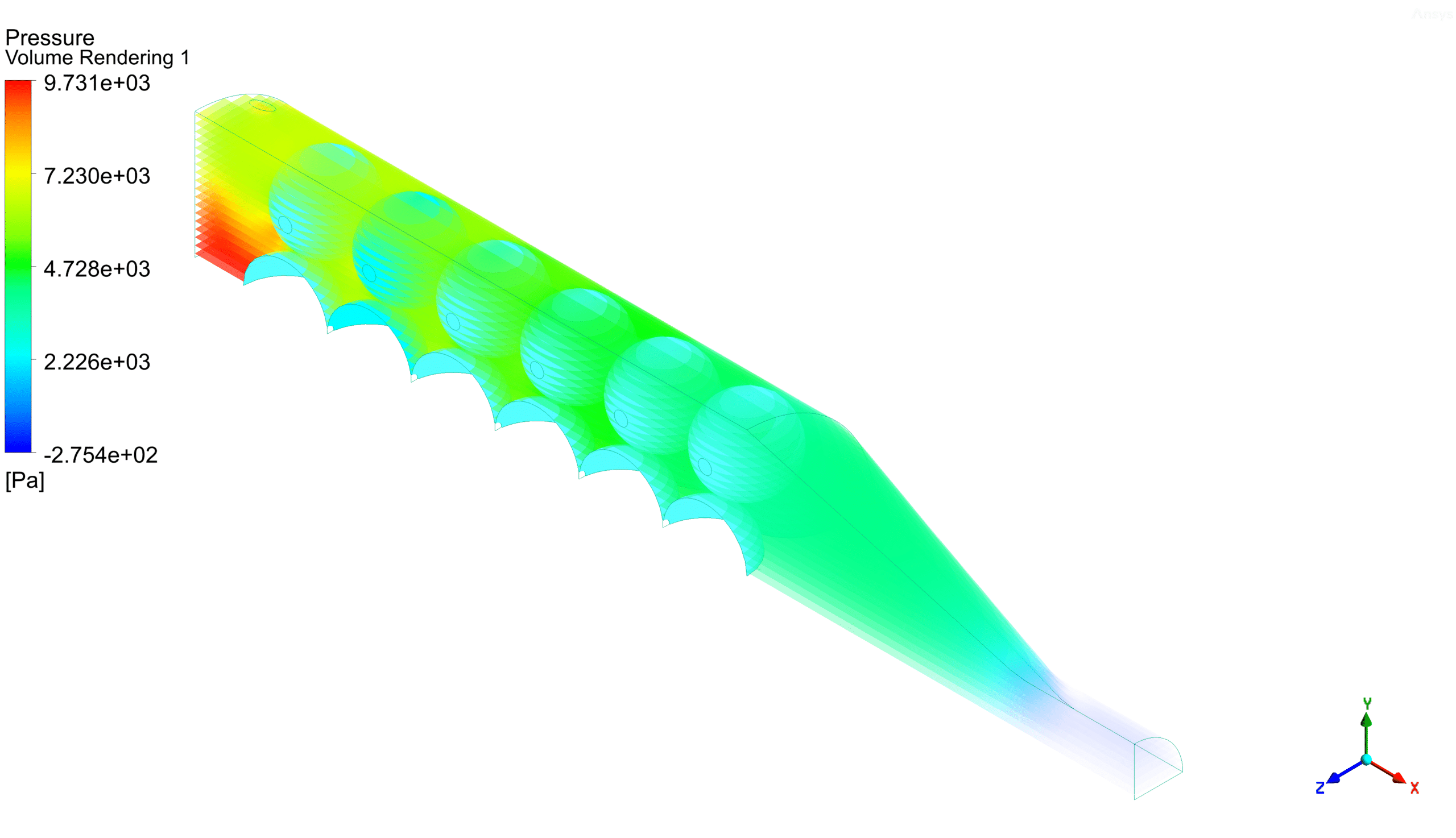

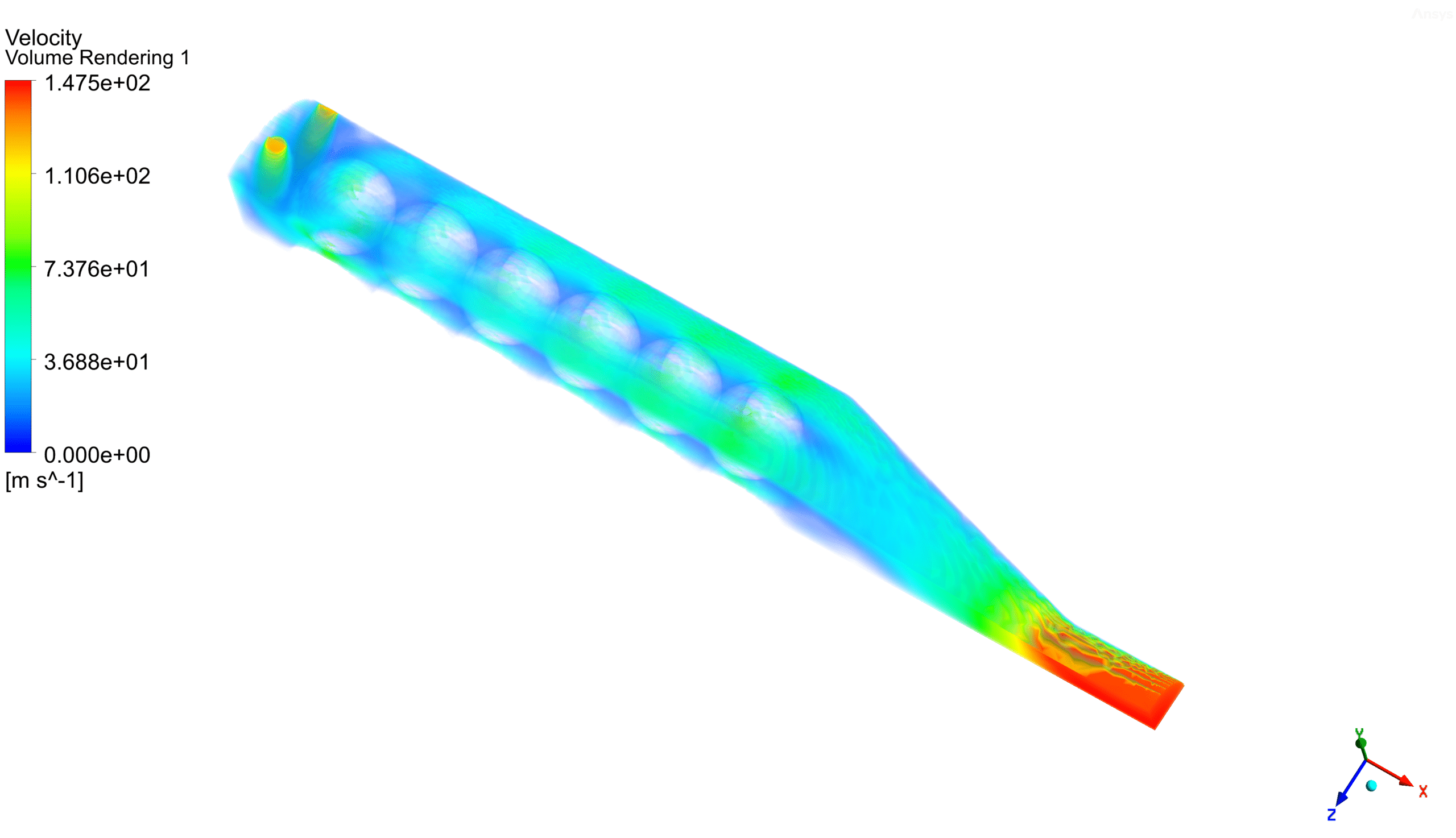

Additionally the streamline of the flow, the pressure and velocity volume renderings are presented. For instance the streamline show how the air flows among the spheres making contact with them, as the base physics in the problem, then exits the domain.

Reviews

There are no reviews yet.