Brake Disk Heat Transfer CFD Simulation, ANSYS Fluent Tutorial

$60.00 Student Discount

- The problem numerically simulates the heat transfer process in brake disks using ANSYS Fluent software.

- We design the 3-D model by the Gambit software.

- We Mesh the model by Gambit software, and the element number equals 32884.

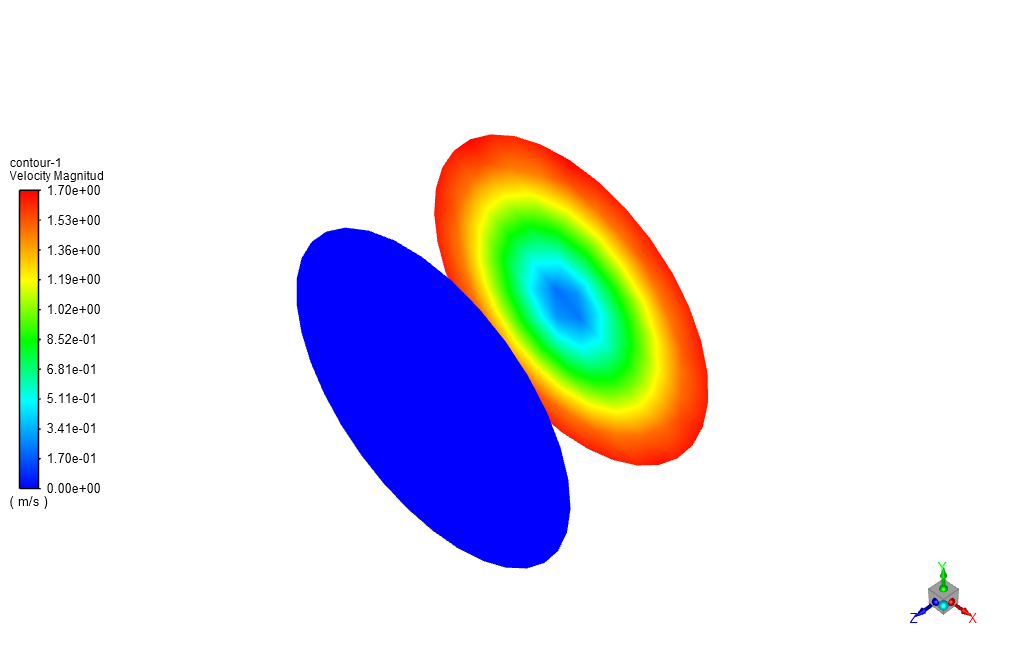

- We have two disks, including the Stationary wall and the Moving wall.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

In this project, the heat transfer process in brake disks is simulated, and the simulation results have been investigated using ANSYS Fluent software.

The present model is designed in 3-D using the Gambit. The geometry is related to a brake disk whose temperature increases due to the friction force applied to it because of braking.

The meshing of this present model has been generated by Gambit software. The total cell number is more than 32884.

Brake Disk Methodology

Disks are one of the most widely used components in the industry. The study of the disks’ performance and their rotation’s effect on each other has always been considered by design engineers in mechanics.

The heat generated by the rotation and the friction created at the point where the disks come in contact with each other has adverse effects on the body and reduces their life.

Simulation of brake disks, the study of the phenomenon of heat generated, the heat transfer from the discs to each other, and their surroundings are among the most important issues discussed in the industry.

In this project, ANSYS Fluent software simulates the heat transfer process in brake disks. “Disk2” has a rotating motion with a rotational velocity of approximately 343rpm. The rotating motion of Disk 2 has been applied to it using the moving wall option.

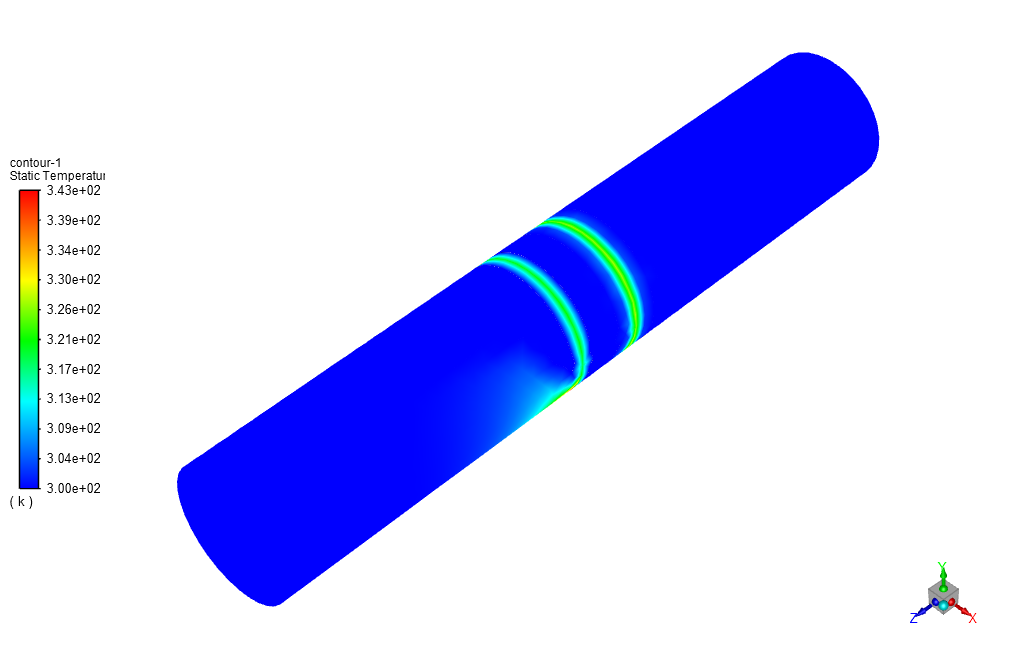

The existing disks have the same temperature equal to 343 K. since “Disk1” is stationary, it will cause “Disk2” to slow down and exert friction.

The Laminar model is used to solve fluid flow equations, and the energy model is also activated to calculate the temperature distribution inside the computational domain.

Brake Disk Conclusion

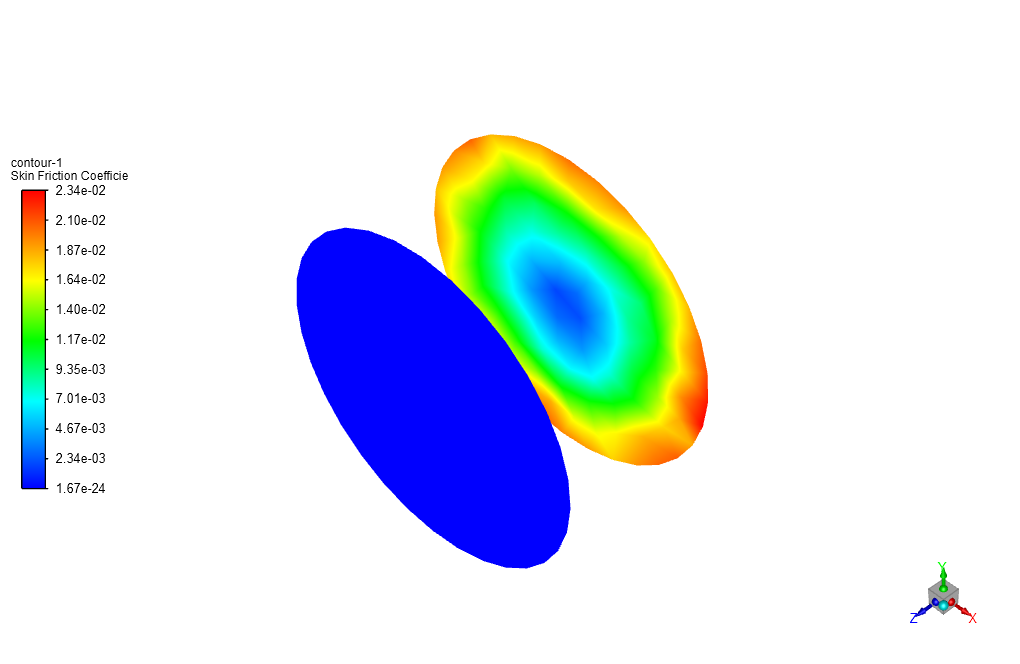

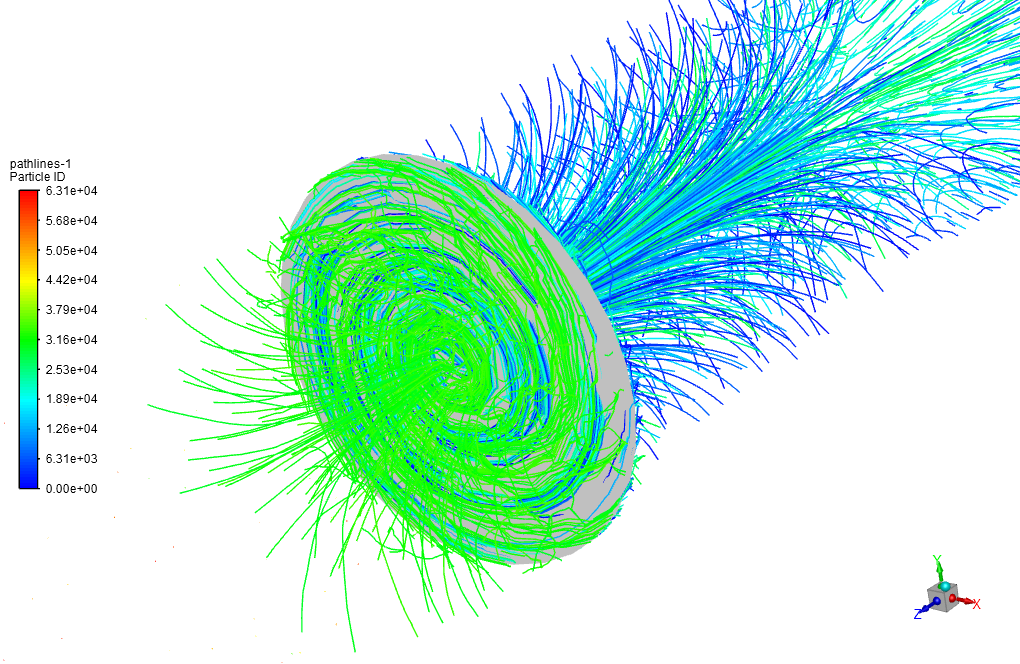

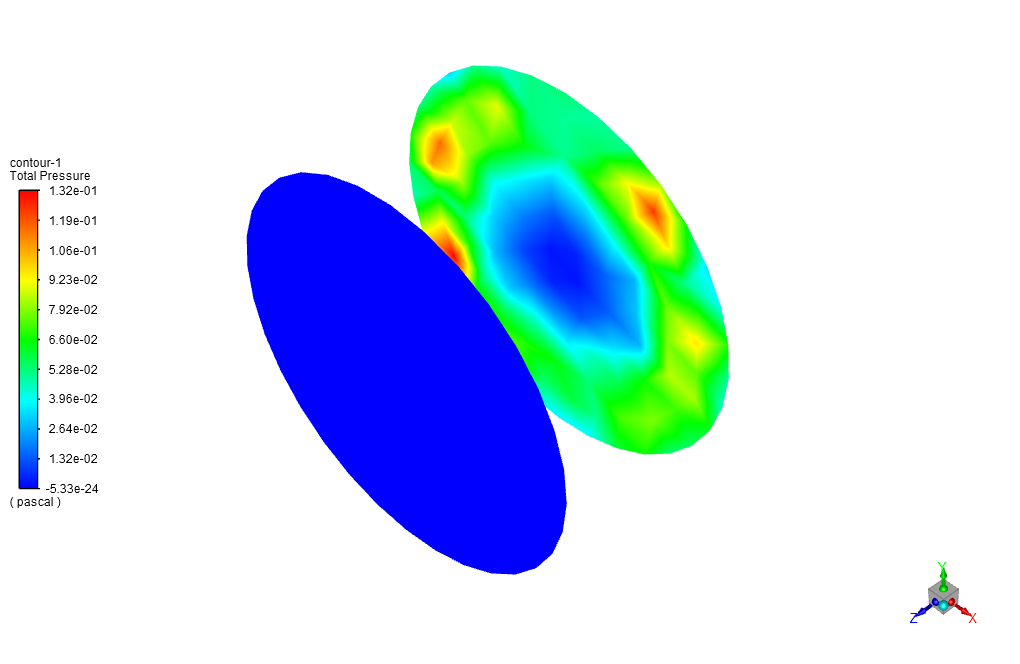

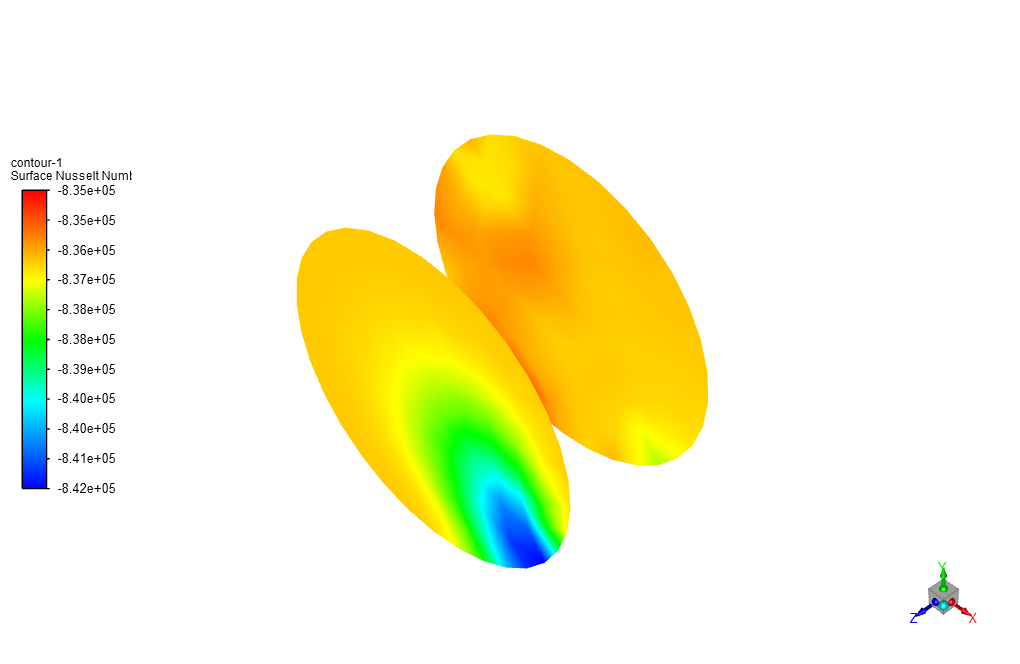

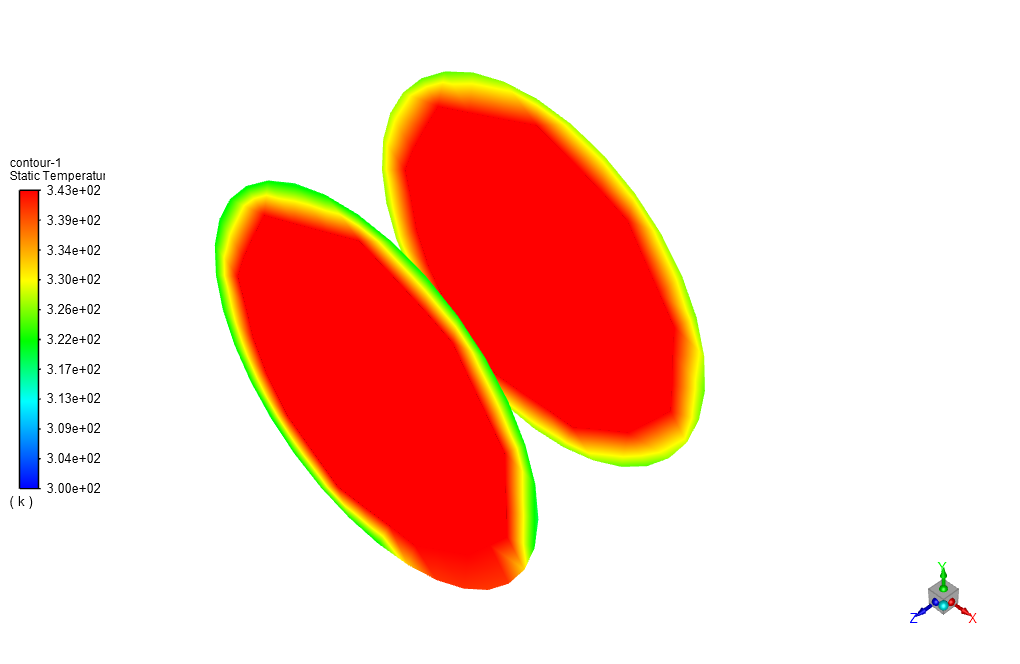

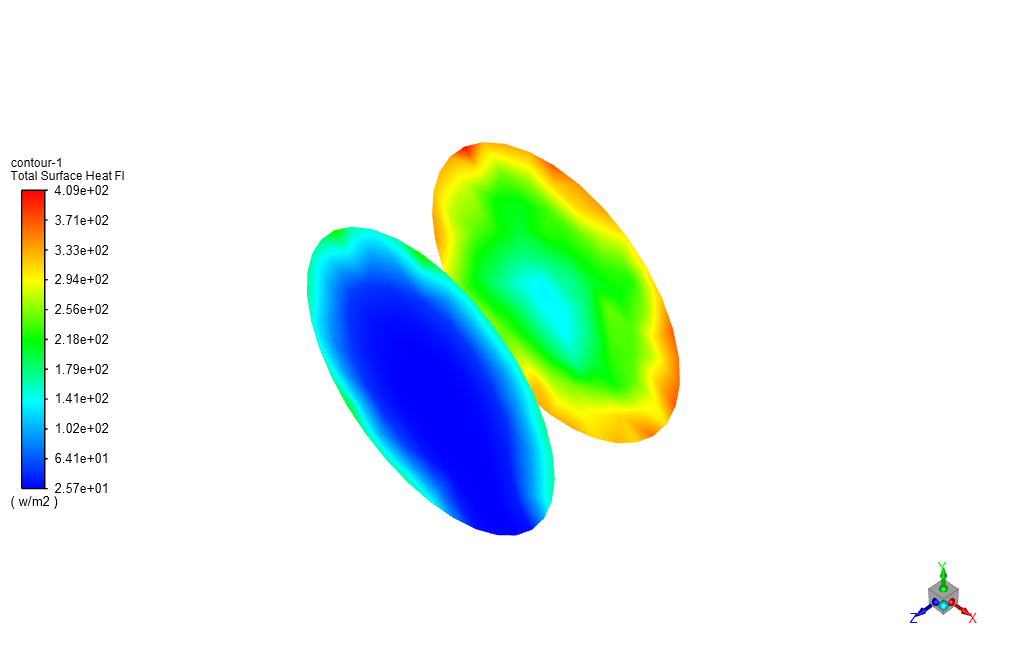

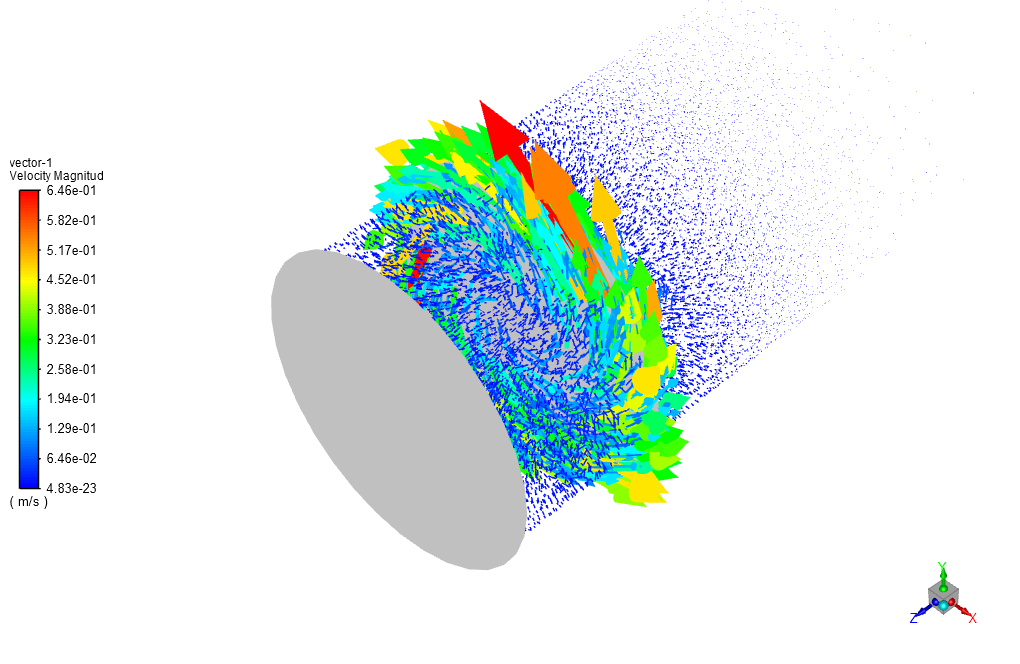

After the simulation, two- and three-dimensional contours related to pressure, temperature, skin friction coefficient, etc., are obtained.

For instance, as seen in the temperature contour, the fluid and disk temperatures are increased due to the friction imposed on them. Furthermore, in the streamline and velocity vector results, the rotating motion of Disk 2 is visible.

Mona Baumbach –

The tutorial was meticulous and thorough. Learning the step-by-step process helped me understand the heat transfer in brake disks effectively!

MR CFD Support –

Thank you for your kind words! We’re really glad to hear that our tutorial was helpful to you. If you have any more questions or need further assistance, don’t hesitate to reach out!

Ivory Mueller –

The tutorial was very informative and I learned a lot about braking systems and simulation. Kudos to the team for such a detailed guide.

MR CFD Support –

We are delighted to hear that you found the Brake Disk Heat Transfer CFD Simulation Tutorial valuable and educational. Thank you so much for your positive feedback and for taking the time to compliment our product. We always strive to provide comprehensive and useful materials for our users.

Magali Kunde –

I recently went through the ANSYS Fluent Tutorial for Brake Disk Heat Transfer and was impressed by the depth of the tutorial content. The step-by-step processes helped me to thoroughly understand the intricacies of simulating heat transfer in brake disks.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the tutorial helpful and that it enhanced your understanding of heat transfer simulation in brake disks. We are always here to provide substantial learning materials to empower our users in their simulation endeavors.

Savannah Hills –

I’m really impressed with the clarity and detail of temperature contours in the brake disk simulation. It really showcased the heat distribution resulting from friction!

MR CFD Support –

Thank you for your compliment! We are glad that the temperature contours provided clear insight into the heat distribution across the brake disks during the simulation. We strive to deliver detailed analysis in our products, and we appreciate your positive feedback!

Edwina Green –

The detailed visualization of brake disk heating and cooling during operation in your simulation tutorial is outstanding. The rotational effects can be clearly seen, and how they influence temperature changes is fascinating. Keep up the excellent work in providing such insightful tutorials!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the simulation tutorial on brake disk heat transfer insightful and clarity on the visualizations useful. Understanding the thermal behavior of brake disks is crucial for safety and performance, and we aim to provide the best learning experience. If you have any more questions or need further assistance, always feel free to reach out!

Lawson Schinner –

I’m truly impressed by the level of detail in the temperature and movement analysis of the brake disk using ANSYS Fluent. The results showing how efficiently the heat is dissipated during braking provide a deep understanding of the brake disk’s heat transfer characteristics. Excellent tutorial!

MR CFD Support –

Thank you for your positive feedback! We are glad you appreciate the detailed analysis and found the tutorial effective. Understanding the heat transfer in brake disks is crucial for performance and safety, and we’re happy to know our tutorial served its purpose well. If you need further assistance or more tutorials, feel free to reach out!

Clementina Bergnaum –

I recently purchased the Brake Disk Heat Transfer CFD Simulation, ANSYS Fluent Tutorial. It had excellent guidance throughout! The visuals in the tutorial were clear, and the step-by-step process was very easy to follow. Learned so much about heat transfer on brake disks!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that the tutorial was clear and educational. It’s great to know that our efforts to create an easy-to-follow guide with helpful visuals paid off. If you have any more questions or need further assistance, please feel free to reach out!

Sonny Roob –

I’m thrilled with how the ANSYS Fluent tutorial demonstrates heat transfer during braking—it’s so detailed! Seeing the increase in temperature caused by friction on the contours was totally fascinating.

MR CFD Support –

We’re glad to hear that you found the tutorial on Brake Disk Heat Transfer using ANSYS Fluent insightful and informative! It’s wonderful that the detail provided and the visual contours enhanced your understanding of the heat generation due to friction. Thank you for your positive feedback!

Dr. Jessy Mitchell Jr. –

The tutorial on Brake Disk Heat Transfer was superbly detailed. It really helped me understand the complex phenomenon involved in braking systems and heat dissipation. The clear steps taken to explain the motion setup and friction application are particularly useful for a project I’m undertaking. Kudos to the team for creating such an in-depth and practical guide.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our Brake Disk Heat Transfer tutorial was helpful for your project. Our aim is to provide detailed and practical guides that can be applied in the real world. If you ever have any more questions or need further assistance in your projects, don’t hesitate to reach out. We wish you the best for your undertakings!

Alexzander Nicolas –

The images in the tutorial were extremely informative. With the step-by-step guidance, I fully grasped the brake disk simulation and the visual results were just as insightful as the written data.

MR CFD Support –

We are thrilled to hear that the tutorial’s images and step-by-step instructions were beneficial for you. Your grasp of the brake disk heat transfer simulation is important to us, and we appreciate the time you’ve taken to provide this positive feedback. Thanks for choosing our tutorial!

Javier Maggio –

The tutorial was incredibly detailed and comprehensive. It was particularly helpful to learn how disk temperature rises due to friction in a braking scenario. The contours made it easy to visualize the temperature distribution and flow movement.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the tutorial was helpful and that the visual representations of temperature distribution and velocity vectors were clear and informative. Your understanding of the heat transfer in brake disks is crucial, and we’re glad the detailed explanations contributed to your learning experience.

Aylin Willms –

I’ve stepped into the world of CFD recently, and the analysis of heat transfer in brake disks using ANSYS Fluent is fascinating! Your tutorial managed to present complex engineering concepts in a straightforward manner, which was really helpful. Really impressed by your work, and looking forward to trying more tutorials!

MR CFD Support –

We’re delighted to hear that our Brake Disk Heat Transfer CFD Simulation in ANSYS Fluent was beneficial to you, especially as you’re new to the field of CFD! Thank you for taking the time to share your positive experience. Knowing that our tutorials assist in simplifying complex concepts is incredibly motivating. We can’t wait to continue supporting your learning journey with our other tutorials!

Shayna Goodwin –

The tutorial for the Brake Disk Heat Transfer CFD Simulation was very informative. It gave me a clear understanding of how to set up and simulate the heat generation and transfer due to friction in braking systems. The step-by-step approach made the complex physics more manageable.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our Brake Disk Heat Transfer CFD Simulation tutorial met your expectations and provided you with a clear understanding of the simulation process. Our goal is to deliver comprehensive and informative tutorials to help users like you successfully conduct complex simulations. If you have further questions or need additional assistance, don’t hesitate to reach out.

Althea Cummings –

The description of this project was very detailed, and the process fascinates me! I’d like to know if the material properties of the disk affect the outcome of the heat transfer simulation significantly.

MR CFD Support –

Yes, material properties such as thermal conductivity, specific heat capacity, density, and emissivity play a critical role in the outcome of heat transfer simulations. In brake disk simulations, materials with high thermal conductivity are preferred as they can dissipate the heat generated by friction more effectively, reducing the risks associated with overheating.

Abigayle Hoppe –

The tutorial was exceptional in outlining the setup and outcomes. The temperature distribution results nicely showed how heat transfer works in braking systems, which deepened my understanding.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our Brake Disk Heat Transfer tutorial was instrumental in enhancing your understanding of heat transfer in braking systems. If you have any more feedback or need further insights, feel free to ask. Your positive experience is very important to us!

Neva Hudson –

The tutorial was insightful! I was able to follow along and replicate the heat transfer process on brake disks. The part where the Laminar model was used made a lot of sense for the flow conditions in my simulation. Kudos!

MR CFD Support –

Thank you for your positive feedback! We’re really glad to hear that our Brake Disk Heat Transfer CFD Simulation tutorial was helpful and that you could apply it successfully. If you have any more questions or need further assistance, feel free to reach out!

Alvera Berge –

I’m thoroughly impressed with the Brake Disk Heat Transfer CFD Simulation using ANSYS Fluent. The step-by-step methodology adopted made it easy to follow through with the various stages of simulation, from the initial geometry set-up right up to the analysis of results. The intricate meshing with a total cell number of more than 32884 cells ensures accurate capture of thermal gradients and fluid flow oddities around the braking surfaces. Moreover, the successful application of a rotating wall to mimic the rotating brake disk is commendable. This tutorial is invaluable to engineering professionals and students looking to deepen their understanding of brake disk thermal dynamics in real-world applications.

MR CFD Support –

Thank you for your wonderful review! We are pleased to hear that you found the Brake Disk Heat Transfer CFD Simulation tutorial valuable and user-friendly. Your recognition of the details like the comprehensive meshing and the application of motion using the moving wall option is much appreciated. It’s always our goal to deliver helpful and thorough educational content to our users. Should you have more inquiries or need further assistance, feel free to reach out!

Louie Grant –

The tutorial for the brake disk simulation seems very informative. The visual results are particularly helpful to understand the heat distribution. Thanks for the comprehensive guide!

MR CFD Support –

Thank you for your review! We’re delighted to hear that the brake disk heat transfer tutorial was informative and helped to clarify the heat distribution process. Customer satisfaction is our priority, and we are pleased that our visual aids made the concepts clear. If you have any more questions or need further assistance, please don’t hesitate to reach out!