Brake Disk System Conduction Heat Transfer, ANSYS Fluent Simulation Training

$140.00 Student Discount

In this project, the heat conduction of a brake disk system is modeled and simulated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Brake Introduction

Brake is among the most widespread units with the non-stationary friction. We use braking friction systems for damping the kinetic energy of the rotational or translational motion of masses by friction forces. By braking, one can decrease the velocity of relative sliding to zero or the given value. In the course of operation of braking units, parameters like velocity, temperature, friction-wearing characteristics of materials vary greatly.

Project description

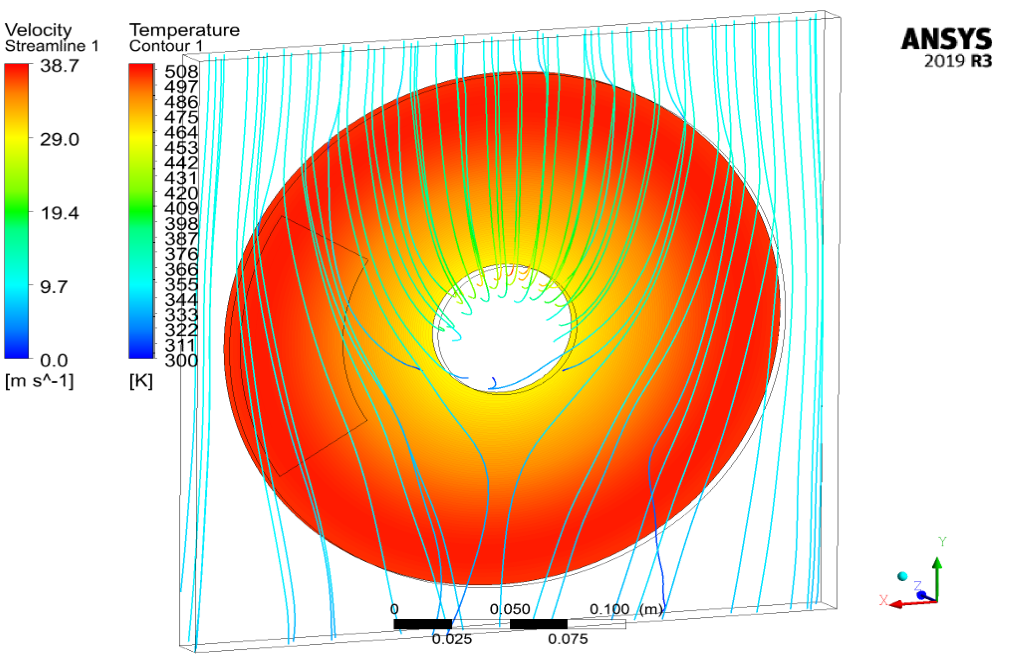

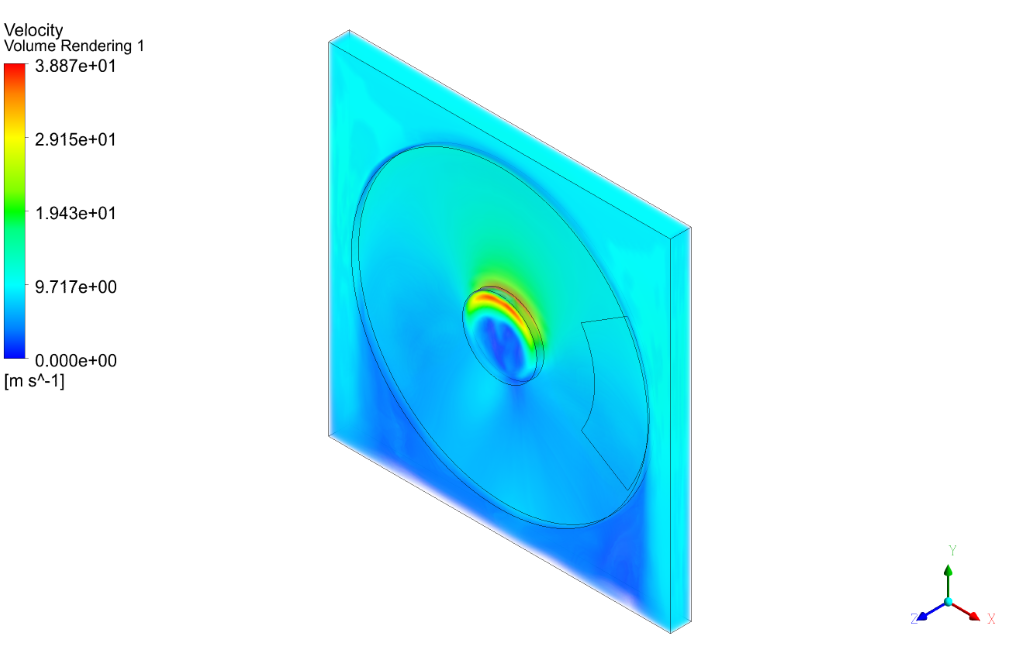

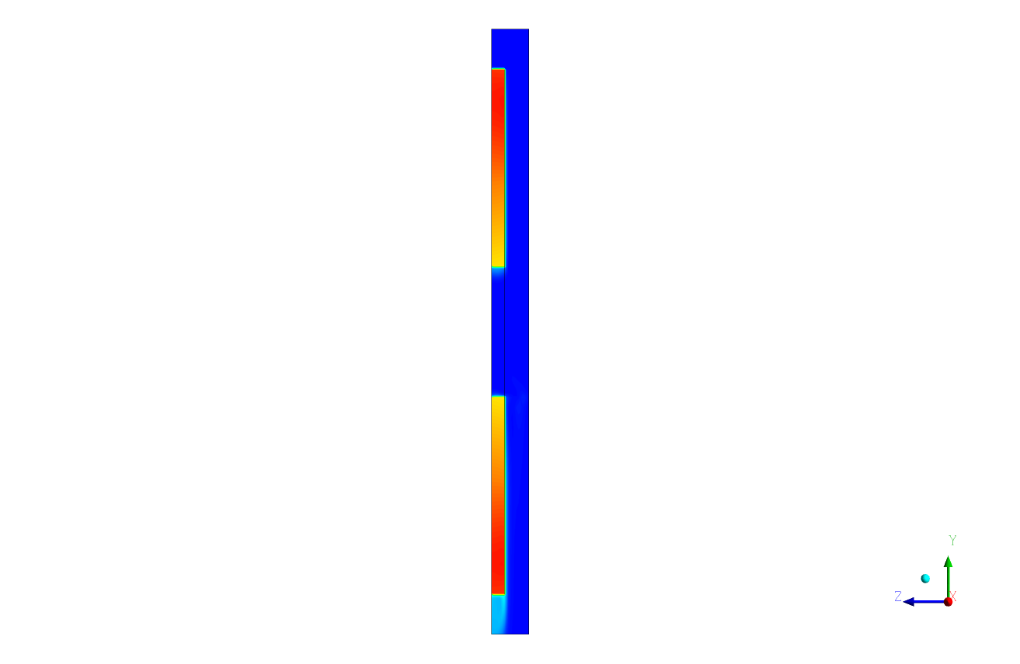

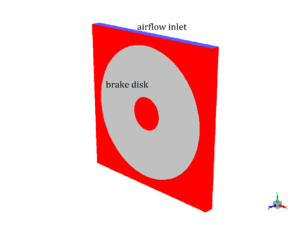

In this project, the heat conduction of a brake disk system is modeled and simulated by ANSYS Fluent. The disk revolves with the speed of 20rad/s and a braking pad is set to make contact with the disk. This frictional contact will result in heat generation inside the disk and the pad. The heat produced in the contact region will be dissipated based on heat conduction formula. Energy and laminar model is activated. Also, MRF model (frame motion) is activated to model the rotational motion of the disk. A UDF is implemented to account for the radial heat flux.

Brake Geometry and mesh

The modeled geometry for this simulation consists of a brake disk and a pad and a fluid flow domain. We design and mesh it inside Gambit®. The mesh type used for this geometry consists of both types of structured and unstructured (hybrid) and the element number is 198594.

Brake CFD Simulation Settings

The key assumptions considered in this project are:

- Simulation is done using pressure-based solver.

- The present simulation and its results are considered to be steady and do not change as a function time.

- The effect of gravity has not been taken into account.

The applied settings are summarized in the following table.

| (brake) | Models | |

| Viscous model | Laminar | |

| Energy model | Activated | |

| Cell zone conditions | ||

| Solid | ||

| MRF | Rotational velocity | 20 rad/s |

| Boundary conditions | ||

| Inlets | velocity inlet | |

| airflow | 10 m/s | |

| Temperature | 300 K | |

| Outlets | outflow | |

| Walls | ||

| wall motion | stationary wall | |

| (brake) | Solution Methods | |

| Pressure-velocity coupling | Simple | |

| Spatial discretization | pressure | standard |

| energy | first order upwind | |

| momentum | first order upwind | |

| Initialization | ||

| Initialization method | Standard | |

| gauge pressure | 0 Pa | |

| velocity (x,y,z) | (0,0, 0) m/s | |

| Temperature | 300 K | |

Results

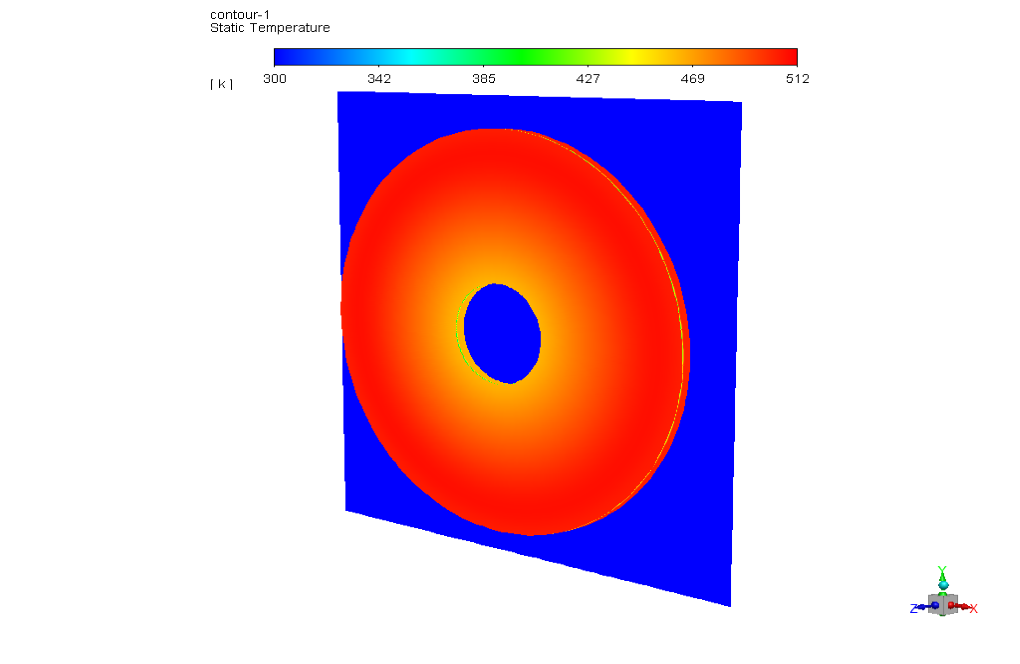

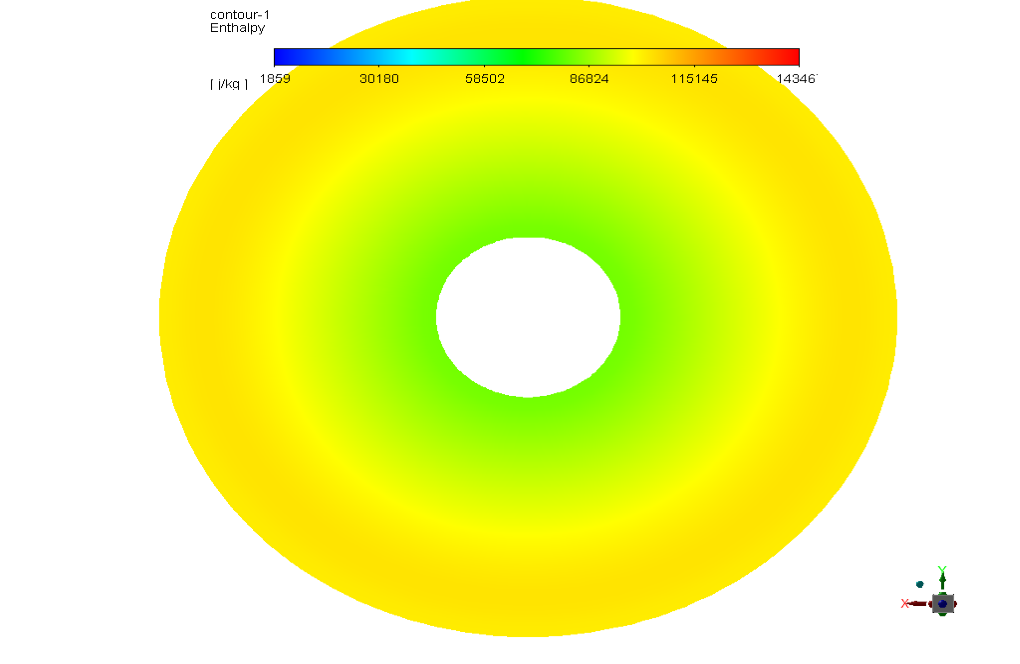

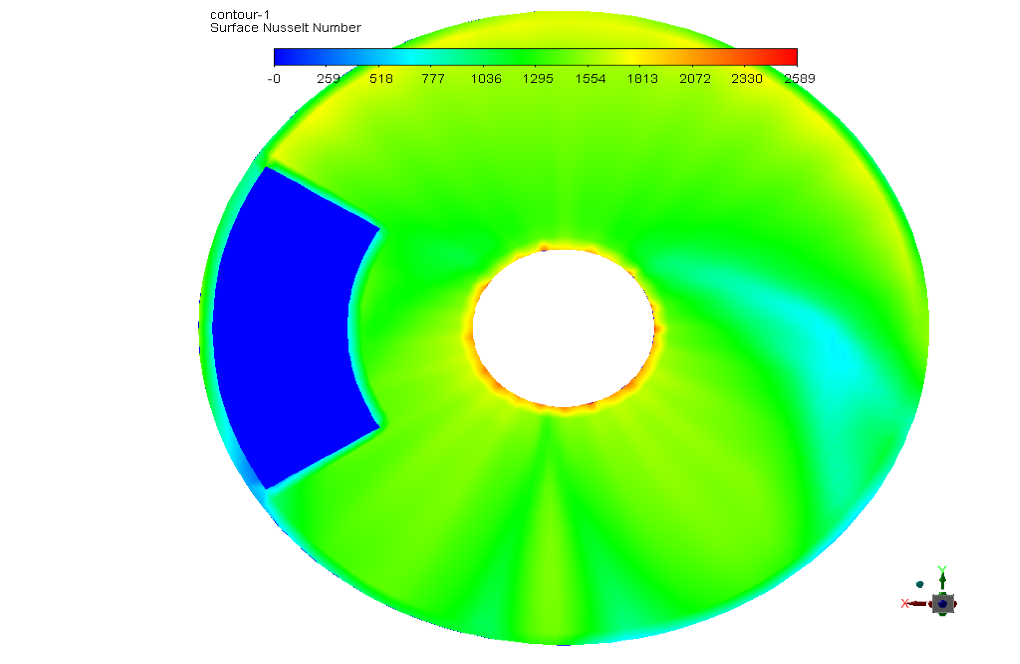

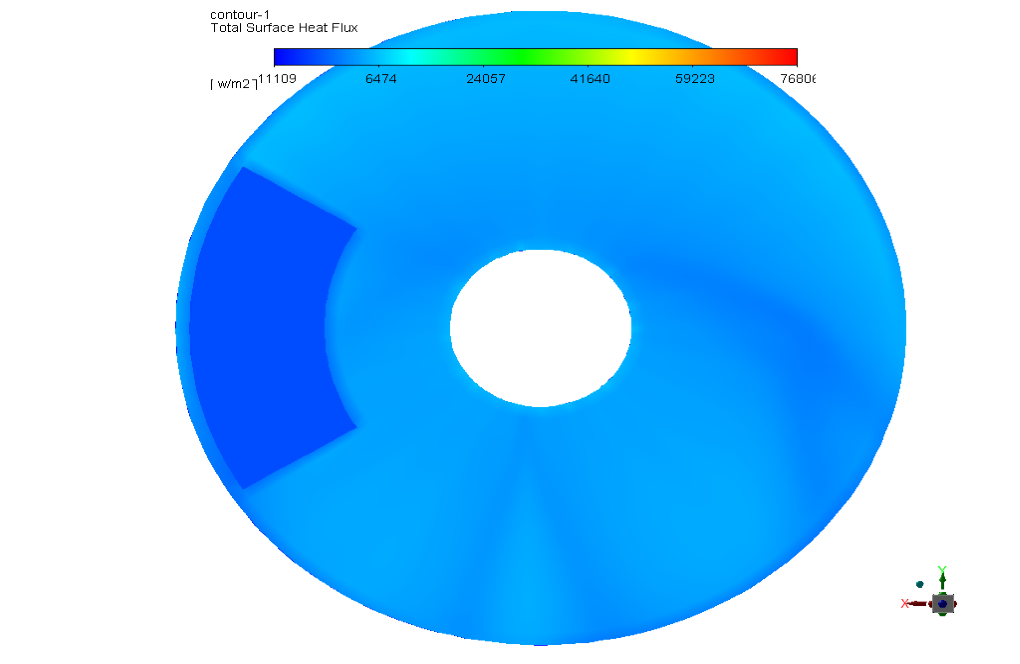

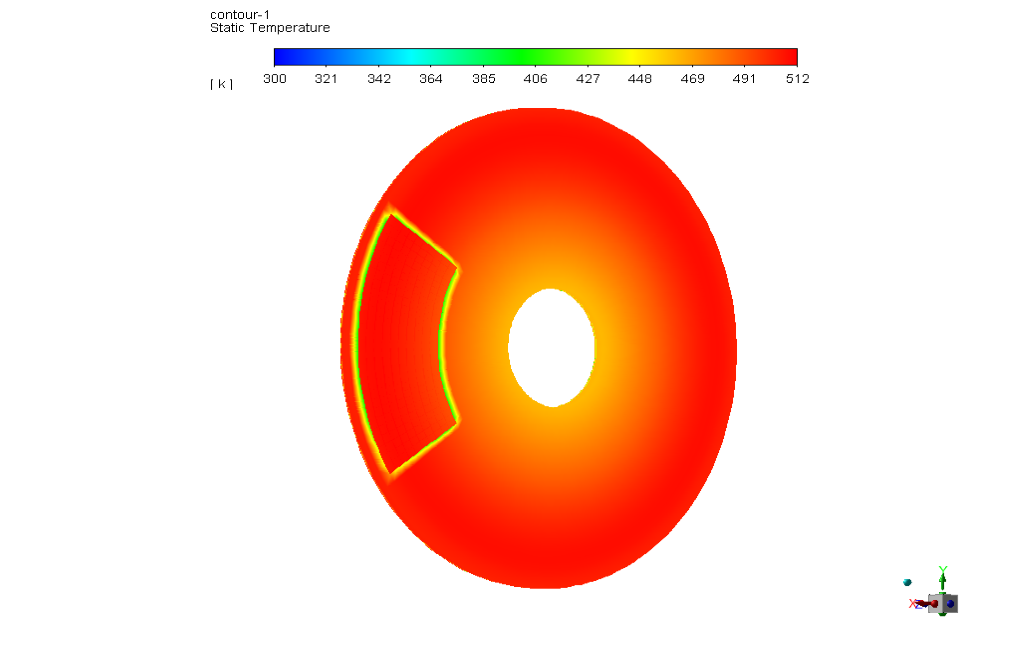

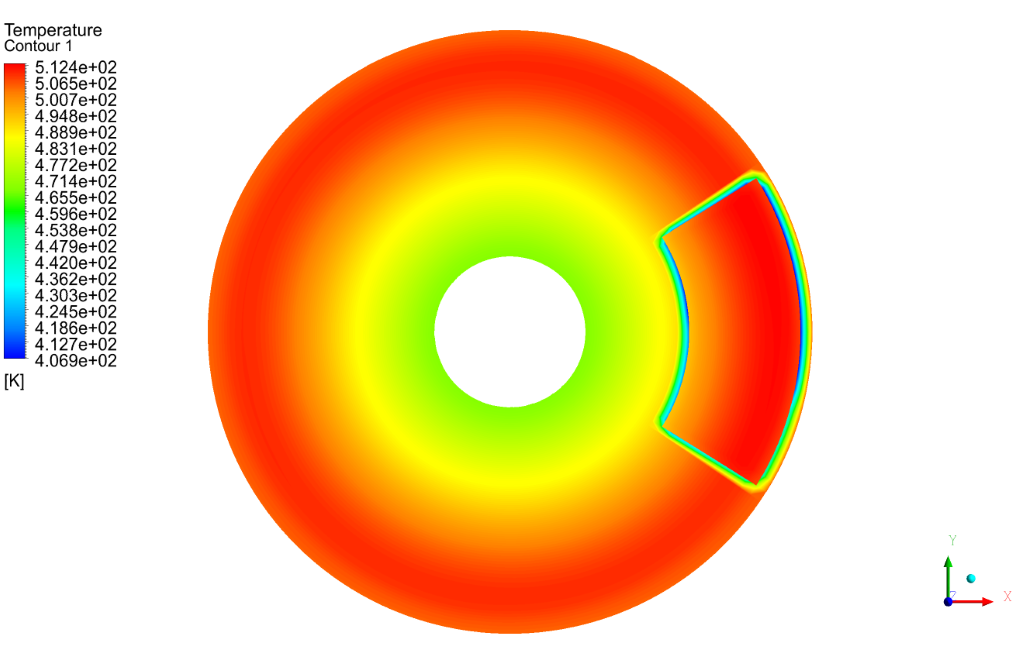

At the end of the solution, we present the contours of temperature, surface heat flux, surface Nusselt number, surface enthalpy and flow streamlines around the brake disk.

Bria Hartmann –

What computational software is utilized for this simulation?

MR CFD Support –

This simulation is conducted using ANSYS Fluent, a leading computational fluid dynamics (CFD) software.

Enid Stamm –

This simulation is a groundbreaking development in the field of automotive engineering and design!

Amiya Willms –

This simulation is a valuable tool for professionals in automotive engineering and design.

Concepcion Swaniawski –

This simulation is an effective tool for optimizing the design of brake disk systems.

Justine Mohr MD –

Is there a way for me to contribute to this simulation?

MR CFD Support –

We welcome contributions! Feel free to share your ideas or suggestions.

Lavon Feil –

I was impressed with the details of the CFD simulation settings, especially the inclusion of the MRF model for the rotational motion of the disk. Can I find more educational materials about setting up the simulation—particularly the use of UDF for radial heat flux and managing boundary conditions for a non-stationary but steady-state problem as presented here?

MR CFD Support –

We’re thrilled to hear that you appreciate the details provided in our Brake Disk System Conduction Heat Transfer simulation training. If you are looking for more educational materials, our product comes with comprehensive step-by-step tutorials and user guides that cover how to set up the simulation including aspects such as using UDFs for radial heat flux, managing boundary conditions, and the intricacies of non-stationary but steady-state problems. Feel free to explore our documentation and training materials provided with the course for in-depth learning.

Dr. Luz Boyer DDS –

The review given seems very thorough! I was curious whether the heat distribution on the brake disk surface is uniform, or if there are hotspots due to the friction. Can the simulation capture this level of detail?

MR CFD Support –

The heat distribution on the brake disk surface is not uniform due to friction between the brake pad and disk during contact. The simulation accurately captures the variations in temperature, and you can observe hotspots where the contact pressure and friction are highest. These details are visible in the temperature contours resulting from the simulation.

Candida Ruecker –

The training material sounds comprehensive, but could you clarify what specific applications learning this simulation could be?

MR CFD Support –

The knowledge acquired from this simulation can be applied in the automotive industry for designing more efficient brake systems, in material science for developing better heat-resistant materials, and generally within mechanical engineering to understand heat transfer in non-stationary friction systems. Additionally, it’s valuable for CFD analysts who are interested in thermomechanical analysis and anyone working on optimizing friction and heat dissipation in mechanical designs.

Celia Douglas –

The training sounds comprehensive, but is the UDF used in this project provided as part of the course materials, and is it customizable for different radial heat flux conditions?

MR CFD Support –

Yes, the User-Defined Function (UDF) is provided as part of the course materials to enhance learning and application of the concepts taught. Additionally, the UDF is designed to be customizable, allowing learners to adjust parameters for different radial heat flux scenarios they might encounter in their own simulations.

Gloria Swaniawski –

This course seems very comprehensive. Has any comparison with experimental or real-world data been done to validate the simulation results?

MR CFD Support –

We always strive for the greatest accuracy in our simulations. While the training material provided offers an extensive understanding of simulation setup, obtaining validation through direct comparisons with experimental or real-world data would depend on external data availability, which is often conducted by users or independent researchers to validate their individual project results.

Mr. Drake Murphy Sr. –

I am delighted with the detailed simulation provided by MR CFD on Brake Disk Conduction Heat Transfer, which has enhanced my understanding of brake system thermodynamics. Your training module expertly combines theoretical concepts with practical simulation elements, making it easier for me to grasp the complex heat transfer processes in braking systems. The inclusion of a UDF for radial heat flux is particularly beneficial. Thank you for a comprehensive and informative course.

MR CFD Support –

We are thrilled to hear that our Brake Disk System Conduction Heat Transfer simulation training has been beneficial for your understanding of brake system thermodynamics. Your acknowledgment of the UDF implementation for radial heat flux underlines the quality and depth of our training content. We greatly appreciate your positive feedback and are pleased that the course met your expectations. Thank you for choosing MR CFD for your learning journey!

Bartholome Pacocha –

What grade of mesh is used for the geometry in the simulation? And does using a hybrid mesh affect the results in contrast to exclusively structured or unstructured meshes?

MR CFD Support –

In this simulation, a hybrid mesh was utilized for the geometry, comprising both structured and unstructured elements, with a total element number of 198594. The grade or quality of the mesh isn’t specified within the dataset. However, the use of a hybrid mesh typically aims to combine the advantages of structured meshes (i.e., computational efficiency and ease of construction in regular domains) with the flexibility of unstructured meshes (better conformity to complex geometries). The impact on the results depends on the distribution and alignment of the mesh with respect to the flow features and gradients of interest, such as thermal and velocity fields; an appropriately refined and well-constructed hybrid mesh can deliver accurate results while optimizing computational resources.

Jennyfer Bergstrom –

I would love to know more about how the radial heat flux UDF correlates with the temperature distribution in the simulation. Can you give a deeper insight into it?

MR CFD Support –

The UDF (User-Defined Function) implemented in the simulation is designed to capture the non-uniform distribution of heat due to friction in the radial direction across the brake disk. Since the friction and the consequent heat generation would be higher where the brake pad contacts the disk, the UDF accounts for this by governing the radial heat flux as per the actual physical process. The temperature distribution in the simulation is closely linked with the heat flux defined by the UDF; areas with higher heat flux due to friction will show higher temperatures, contributing to a more accurate depiction of thermal gradients and heat dissipation across the brake disk system.

Mr. Jaydon Spinka Jr. –

What is the significance of using a UDF for the radial heat flux in this simulation?

MR CFD Support –

The UDF, or User Defined Function, is used to more accurately account for the distribution and magnitude of radial heat flux due to the friction between the brake disk and pad. This helps in creating a more realistic simulation of how heat is generated and dissipated within the components during braking. It is a crucial aspect for accurately predicting the thermal performance and safety of the brake system.

Brannon Hayes –

The project description mentions the use of a UDF for radial heat flux. Could you provide some insight into how this UDF is implemented and its role in the accuracy of the simulation results?

MR CFD Support –

The user-defined function (UDF) for radial heat flux in this simulation is programmed to capture the detailed heat transfer phenomena due to friction at the contact surface between the braking pad and the disk. It calculates the radial distribution of heat flux that directly affects the temperature profile within the brake disk and pad. This enhances the accuracy of the simulation by providing a more realistic heat source term that mimics the real behavior during braking, improving the predictability of thermal stresses and material deformation within the system.

Elyssa Williamson –

I was really impressed by how well the brake disk system conduction heat transfer simulation mimicked real-world conditions. The use of a UDF to account for radial heat flux seemed particularly useful.

MR CFD Support –

Thank you for your positive feedback! We always strive to provide realistic simulations, and we’re glad to hear that you appreciated the level of detail, including the implementation of user-defined functions to accurately model the heat flux in the brake system.

Ms. Ciara Sanford I –

This training looks like it covers a complex simulation. Could you tell me if the UDF is provided in the course, or do I need to write it myself?

MR CFD Support –

In the training for the ‘Brake Disk System Conduction Heat Transfer’ simulation using ANSYS Fluent, a User-Defined Function (UDF) is necessary to account for the radial heat flux. The UDF is indeed provided as part of the course material, so you don’t need to write it yourself. It has been programmed and tested to work with the simulation parameters mentioned in the project description.

Valerie Wisozk –

I’m interested in how the radial heat flux is applied using a UDF. Could you please elaborate on that process?

MR CFD Support –

Certainly! In this simulation, a User-Defined Function (UDF) is implemented to accurately simulate the radial heat flux resulting from friction between the brake pad and the disk. The UDF is written in C programming language and complied within the ANSYS Fluent environment. It programmatically defines the heat flux distribution along the radius of the disk to create a more faithful representation of the heat transferred through conduction during braking.

Ross Windler –

I am amazed by the precision and complexity of the Brake Disk System Conduction Heat Transfer simulation in ANSYS Fluent. It’s impressive how various factors such as velocity, energy dissipation, mesh design, and UDF implementation for the heat flux are taken into account to provide such detailed analysis and accurate results.

MR CFD Support –

Thank you for your positive feedback on our Brake Disk System simulation training! Your appreciation inspires us to continue delivering high-quality products that provide detailed insights and realistic simulations. Should you have any further inquiries or require more advanced tutorials, please let us know, and we’d be happy to assist.

Javier Ward –

The description mentions applying a UDF for radial heat flux. Could you detail the need for this UDF in the brake disk simulation and how it contributes to the accuracy of the results?

MR CFD Support –

The User-Defined Function (UDF) is utilized to accurately simulate the radial heat flux that occurs due to the frictional heating at the interface between the brake disk and the pad. Solid bodies like brake disks usually have varied and non-uniform heating, especially due to friction. A UDF allows for the definition of custom heat flux profiles that match empirical data or theoretical predictions closer than standard boundary conditions within ANSYS Fluent. By accounting for heat generation and its distribution across the brake disk, the UDF enhances the simulation’s precision in predicting temperature profiles, heat distribution, and associated thermal stresses.

Natalia Durgan –

I’m extremely satisfied with the Brake Disk System Conduction Heat Transfer training. The course creatively demonstrated the heat generation due to friction and its conduction through the brake parts.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear you enjoyed the Brake Disk System Conduction Heat Transfer training and found it educational. We strive to provide in-depth and practical simulations to enhance learning experiences. Looking forward to serving you with more quality training products!

Freddy Cormier –

The innovative use of CFD in this simulation is commendable!

Gage Treutel –

I’m impressed by the level of detail in this project description regarding the Brake Disk System CFD Simulation. I especially appreciate the inclusion of real-world operating conditions such as the rotation speed and the consideration of temperature extremes. It provides a comprehensive view that adds a lot of value to this training material.

MR CFD Support –

Thank you for your kind words! We are glad to hear that our detailed approach in the Brake Disk System CFD Simulation Training has been helpful for you. Understanding real-world operating conditions is crucial for effective learning, and we always strive to provide comprehensive training materials.

Arvel Anderson –

Very impressed with how the simulation accounts for the dynamic conditions of braking. Can you share which parameters we can adjust to simulate different braking intensities?

MR CFD Support –

Thank you for your positive feedback! To simulate different braking intensities, you can adjust parameters such as the rotational speed of the brake disk, the initial contact pressure between the brake pad and the disk, the friction coefficient between the contact surfaces, and the cooling conditions or airflow around the braking system. These changes can help model a range of braking scenarios from gentle to severe braking.

Helmer Kshlerin –

Is it possible to adapt this simulation setup for evaluating different braking materials and their thermal properties?

MR CFD Support –

In the answered simulation structure, different braking materials and their thermal properties can be evaluated by updating the ‘cell zone conditions’ and ‘material properties’ in ANSYS Fluent to reflect the new materials’ characteristics such as thermal conductivity, density and specific heat capacity.

Fae Altenwerth –

I’d like to know if the temperature effects of the brake pad material properties were considered in the simulation?

MR CFD Support –

In this simulation, they use a steady-state approximation, which does not account for the variation of material properties with temperature change. A constant property model is used for simplicity, and the main focus is on heat conduction and dissipation in the brake disc system.

Matilda Hahn –

The training seems quite comprehensive, but I’m curious about whether any wear or structural deformation of the brake pad or disk due to the friction and high temperatures was considered in the CFD simulation?

MR CFD Support –

In the simulation described, the primary focus has been on the conduction heat transfer analysis within the brake disk system. It does not consider the wear or structural deformation explicitly. The models utilized, including the energy and laminar flow, are aimed at analyzing temperature distribution and heat flux. Structural deformations and material wear would typically require a coupled simulation with structural analysis software as well to capture the full extent of the physical phenomena involved.

Dr. Scarlett Konopelski III –

What is the value of the radial heat flux specified in the UDF?

MR CFD Support –

For the provided specifics of the simulation, the actual value of the radial heat flux defined within the user-defined function (UDF) is not mentioned. If you wish to know the precise value used in this simulation for the radial heat flux, please direct your question to MR CFD’s technical support team for additional details.

Cleve Stiedemann –

This was a thorough simulation of a brake disk system! I particularly appreciated the use of the UDF for radial heat flux. Can you comment on the level of experience required to set up and implement such UDF files in ANSYS Fluent?

MR CFD Support –

Certainly, the use of a User-Defined Function (UDF) to simulate radial heat flux in ANSYS Fluent suggests an intermediate level of experience. Writing and implementing UDFs requires knowledge of C programming and a good understanding of the physical phenomena being modeled. With this expertise, users can extend Fluent’s capabilities and tailor simulations to specific needs.

Justen Sanford –

The product description for the Brake Disk System Conduction Heat Transfer training was very thorough. I learned a lot about brake systems and their simulation in ANSYS Fluent. The heat generation and dissipation aspects were particularly interesting.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Brake Disk System Conduction Heat Transfer training insightful and that it enhanced your understanding of heat conduction in braking systems. If you have any more questions or need further assistance with your simulations, feel free to reach out to us.

Maxime Hartmann –

I was really impressed by the detail in modeling the heat conduction in the brake disk system! Could you tell me more about how the UDF is used to account for radial heat flux?

MR CFD Support –

The UDF (User-Defined Function) is utilized to precisely calculate and apply the radial heat flux that is a result of frictional heating between the brake pad and the brake disk. It enables the software to adjust the heat flux according to the changing conditions at the contact interface during the simulation. Essentially, it customizes the heat transfer calculations beyond the standard settings available within ANSYS Fluent, providing a more accurate and localized result for heat generation and distribution.

Dr. Ethyl Jenkins PhD –

This training module seems very comprehensive. Is this suitable for beginners, or do I need previous experience with ANSYS Fluent to understand the concepts?

MR CFD Support –

This training module is designed with detailed explanations and step-by-step procedures, making it accessible even for beginners. You should be able to follow along without previous experience, but having a basic understanding of ANSYS Fluent’s interface and fundamental CFD concepts would enhance your learning experience.

Brooklyn Lang –

The content and results seem very comprehensive, but I’m wondering how exactly is the UDF (User-Defined Function) utilized for modeling radial heat flux? It would be great to have a bit more insight on that aspect.

MR CFD Support –

The UDF is used to define the radial distribution of heat flux due to friction in the contact area between the brake disk and the pad. This heat flux corresponds directly to the rate at which energy is being transferred from the region of contact into the brake components. Specifically, it calculates the generated heat based on the frictional force and the relative sliding velocity at each point along the disk’s surface, which varies with the radius due to the brake disk’s rotation.

Lon Nikolaus III –

The training was really comprehensive and offered practical insights. I was able to learn how to set up and solve a complex thermal-structural interaction problem efficiently.

MR CFD Support –

Thank you so much for your positive feedback! We’re glad to hear that our training on the brake disk system heat transfer was helpful and comprehensive. We always strive to provide high-quality, practical simulations that can enhance the learning experience. If you have any further questions or need support in your CFD journey, feel free to reach out to us!

Bill Kovacek –

The level of detail in the report is amazing! Understanding how heat is distributed and dissipated in a brake system is crucial for safety and performance, and this simulation training seems to handle it adeptly.

MR CFD Support –

We’re thrilled to hear that you appreciate the depth and detail of our Brake Disk System CFD Simulation Training. Ensuring a clear understanding of heat distribution within braking systems is indeed vital for both performance optimization and safety assurance. Your positive feedback motivates us to continue delivering high-quality training programs. Thank you!

Melyna Gusikowski –

Is the brake simulation accurate for predicting the performance in real-life emergency braking situations?

MR CFD Support –

The brake simulation is designed to model heat transfer within a braking system under specific conditions. While it can provide detailed insights into temperature distribution, heat flux, and other aspects during the braking process, it should be noted that real-life emergency braking involves complexities such as varying speeds, material properties under extreme stress, and ambient conditions which may not be fully encompassed in the simulation. Therefore, while helpful for preliminary analysis and understanding system behavior, further testing and validation against real-life data would be necessary for accurate prediction of performance in emergency situations.

Clyde Nader Sr. –

The training description mentions using a UDF for radial heat flux. Could you provide an example of when using a UDF becomes essential in simulations like this one?

MR CFD Support –

UDFs, or User-Defined Functions, become essential when you have specific functions or customized formulas governing your physical model, which are not available within the standard ANSYS Fluent functions. In this particular simulation of the brake disk system’s heat transfer, the UDF is critical for accurately simulating the radial heat flux resulting from the frictional contact between the brake pad and the disk, a phenomenon that the standard Fluent models may not precisely capture. This functionality enables a more accurate representation of heat generation and dissipation behavior during the braking process.

Dr. Darrell Bergnaum DDS –

This training has given me solid knowledge about the simulation of heat transfer in a brake system. Could you please clarify if any specific initial conditions for pressure and temperature are assumed for this type of analysis?

MR CFD Support –

For this type of heat conduction analysis in a brake disk system, the standard initial conditions typically set the gauge pressure to 0 Pa and the temperature to a reference value of 300 K. These conditions provide a baseline for the analysis to observe how the heat generated from friction during braking affects the entire system.

Laila Ruecker IV –

The simulation training really helped me understand the heat conduction in brake systems! I appreciate the clear explanations and the use of visuals to show the various thermal properties. The structured mesh cover also seemed to have a big impact on the accuracy of results. Great job!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our simulation training was helpful to you. Understanding heat conduction is crucial for brake system efficiency, and we aim to provide detailed analyses with clear visual aids. Your appreciation for the meshing quality and the accuracy it provides to our simulations is greatly valued. If you ever have questions or need further assistance with such topics, feel free to reach out!

Carol Bernhard –

I’ve been thoroughly impressed by how much I learned from the Brake Disk System Conduction Heat Transfer training. The complexity of heat generation and dissipation was presented in an easy-to-understand manner. Particularly helpful was the use of the UDF for radial heat flux, which clearly illustrated the key concepts of heat transfer within the brake system. A well-executed simulation!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you found the Brake Disk System Conduction Heat Transfer simulation training valuable and that the UDF implementation was clearly understandable. We always strive to provide comprehensive learning experiences, and it’s great to know we’ve succeeded. If you have any more questions or need further assistance in your learning journey, feel free to reach out. We’re here to help!

Vincenza Sipes –

Did the simulation provide any insights regarding the distribution of temperature on the brake pads?

MR CFD Support –

Yes, the simulation provided detailed information about the temperature distribution on the brake pads. As the pads make contact with the spinning disk, friction generates heat, which can be observed in the temperature contours presented in the results. These contours enable an understanding of the heat conduction and dissipation characteristics of the system.

Buck Herzog –

I appreciate your training on conduction heat transfer in a brake disk system. The combination of practical geometry, detailed simulation setup, and comprehensive results presentation, like temperature contours and heat flux, has boosted my understanding of heat dissipation in braking systems.

MR CFD Support –

We are thrilled you found the training on heat transfer in brake disk systems to be helpful! Understanding the dynamics of heat dissipation is pivotal, and we’re glad that our simulation was able to enhance your knowledge. Thank you for your positive feedback!