Dehumidifier With DPM Model, CFD Simulation ANSYS Fluent Training

$120.00 Student Discount

The present simulation is about a Dehumidifier With DPM Model via ANSYS Fluent, and the results of this simulation have been analyzed.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Dehumidifier With DPM Model Description

The present simulation is about a dehumidifier via ANSYS Fluent. A dehumidifier is an air conditioning device that reduces and maintains the level of humidity in the air. This device is used to increase the health and thermal comfort of the people in the environment, eliminate the musty odor, and prevent mildew growth by removing water from humid air.

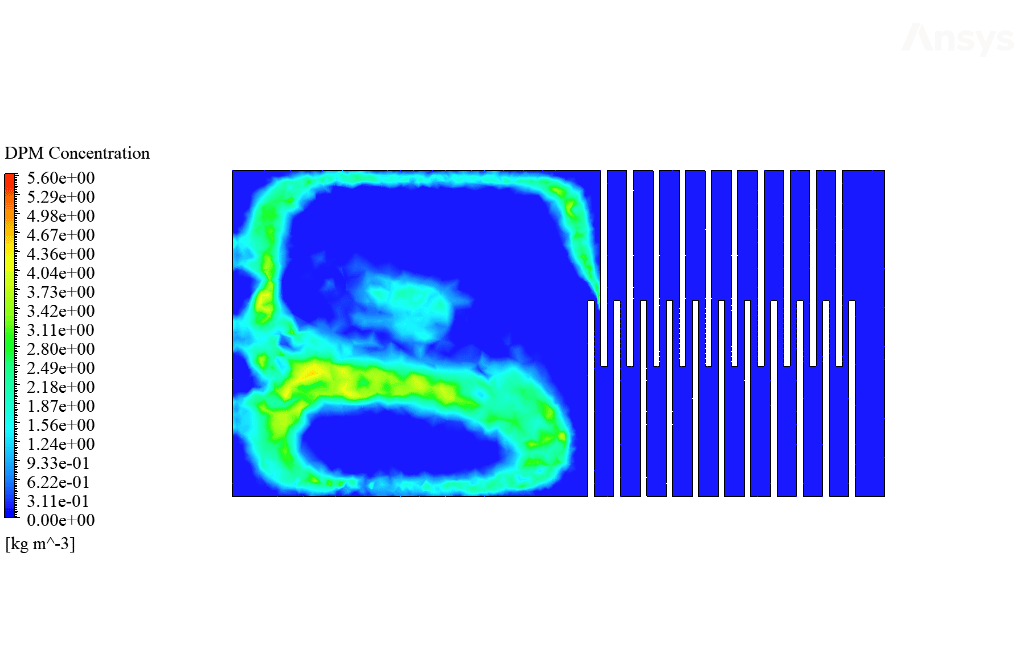

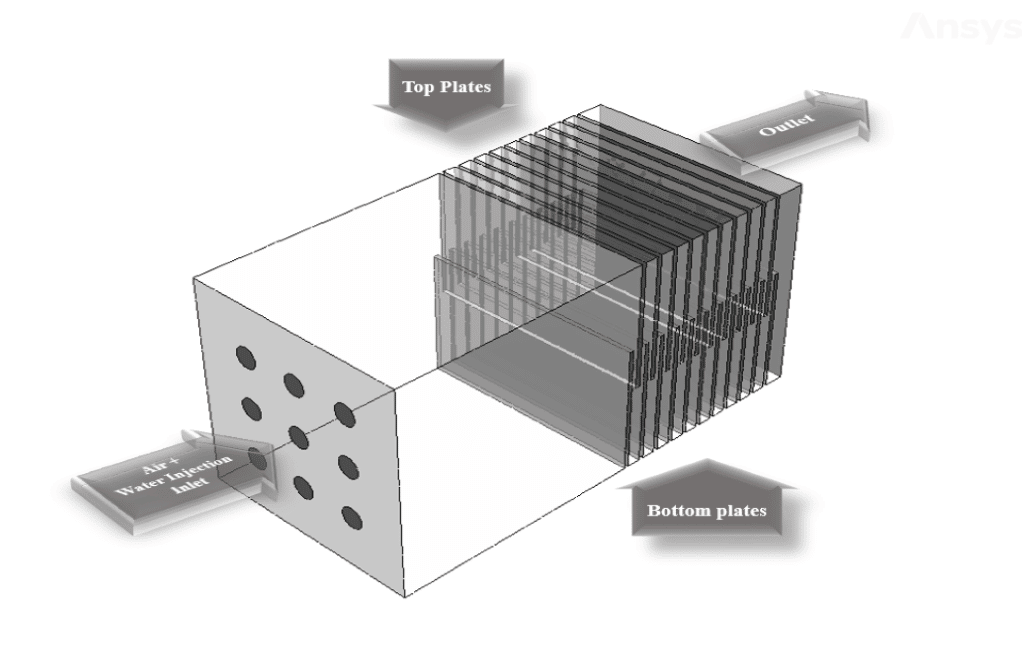

This project uses moisture absorption by surfaces to dehumidify the air. A chamber is designed where several rows of plates are placed inside the barrier as flow barriers. The presence of these barriers causes the humid airflow to pass through a winding path and constantly contact different plates, thus trapping the moisture in the air by these plates.

In this study, humid airflow is assumed to be a combination of airflow as a continuous medium and injection of many water particles as a discrete medium. Therefore, the discrete phase model (DPM) is used, and an injection is defined.

The use of the discrete phase model causes the solution approach to change from Eulerian-Eulerian to Eulerian-Lagrangian. In this modeling, a continuous airflow with a velocity of 0.05 m/s and a temperature of 373.15 K enters the chamber and collides with 21 plates perpendicular to the flow path. Simultaneously, the water flow is sprayed in a discrete environment from the nine holes of the chamber inlet to the continuous airflow.

Water injection is defined as inert particles with a diameter of 0.0001 m and a mass flow rate of 1e-5 kg/s, and a velocity of 0.05 m/s. Also, the behavior of discrete particles in contact with the surface of the plates is defined as a trap so that the discrete particles are separated from the continuous airflow and dehumidification results.

Geometry & Mesh

The present geometry is designed in a 3D model via Design Modeler. The computational zone is the interior of a dehumidifier. Inside the chamber, 21 rows of plates are designed as obstacles perpendicular to the fluid flow path.

Ten plates are connected to the upper level of the chamber, and eleven plates are connected to the lower level of the chamber and are placed in the middle with one arrangement. The air inlet is from the chamber’s left side, and nine separate vents are defined as the center for spraying water with discrete particles.

The mesh of the present model has been done via ANSYS Meshing. Mesh is done unstructured, and the number of production cells equals 2863327.

Set-up & Solution

Assumptions used in this simulation:

- pressure-based solver is used.

- The present simulation is steady.

- The effect of gravity on the model is ignored.

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | realizable | |

| near-wall treatment | standard wall function | |

| Discrete Phase | On | |

| interaction | interaction with continuous phase | |

| Injection | On | |

| injection type | surface | |

| particle type | inert | |

| diameter | 0.0001 m | |

| velocity | 0.05 m.s-1 | |

| total flow rate | 1e-5 kg.s-1 | |

| Energy | On | |

| Boundary conditions | ||

| Inlet | Velocity Inlet | |

| velocity magnitude | 0.05 m.s-1 | |

| temperature | 373.15 K | |

| discrete phase BC type | escape | |

| Outlet | Pressure Outlet | |

| gauge pressure | 0 Pascal | |

| discrete phase BC type | escape | |

| Plates | Wall | |

| wall motion | stationary wall | |

| heat flux | 0 W.m-2 | |

| discrete phase BC type | trap | |

| Methods | ||

| Pressure-Velocity Coupling | SIMPLE | |

| pressure | second-order | |

| momentum | first-order upwind | |

| turbulent kinetic energy | first-order upwind | |

| turbulent dissipation rate | first-order upwind | |

| energy | first-order upwind | |

| Initialization | ||

| Initialization methods | Standard | |

| gauge pressure | 0 Pascal | |

| temperature in chamber | 373.15 K | |

| temperature | 373.15 K | |

Dehumidifier With DPM Model Results

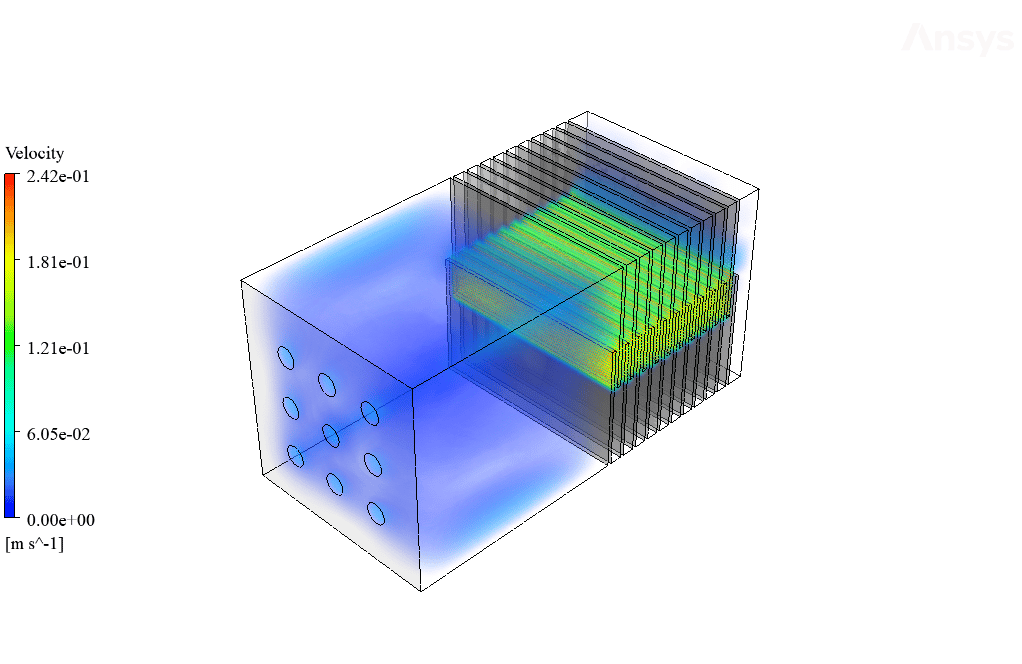

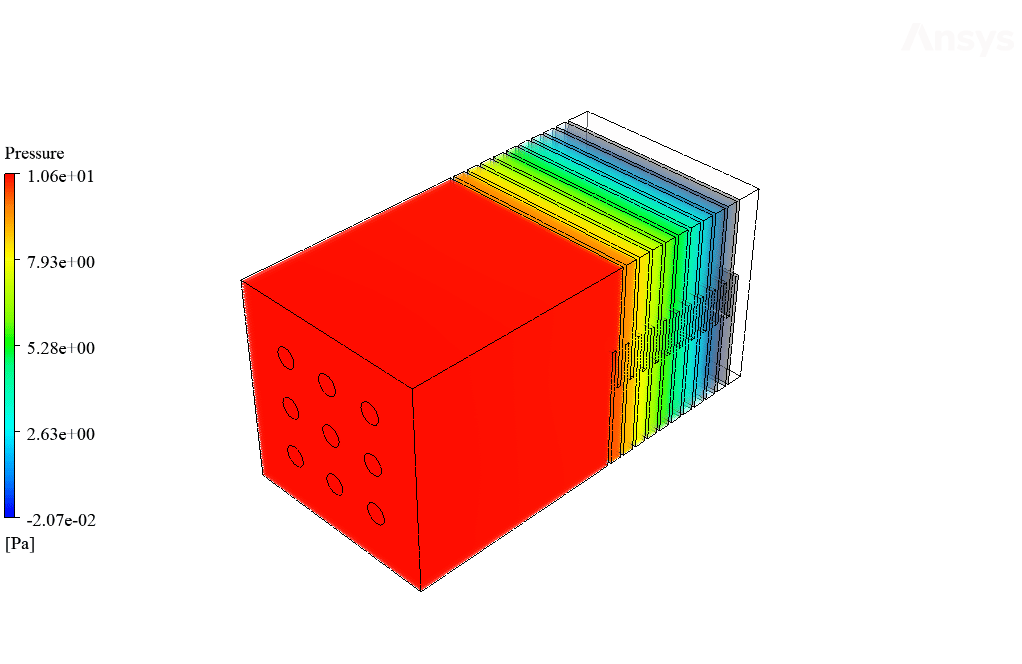

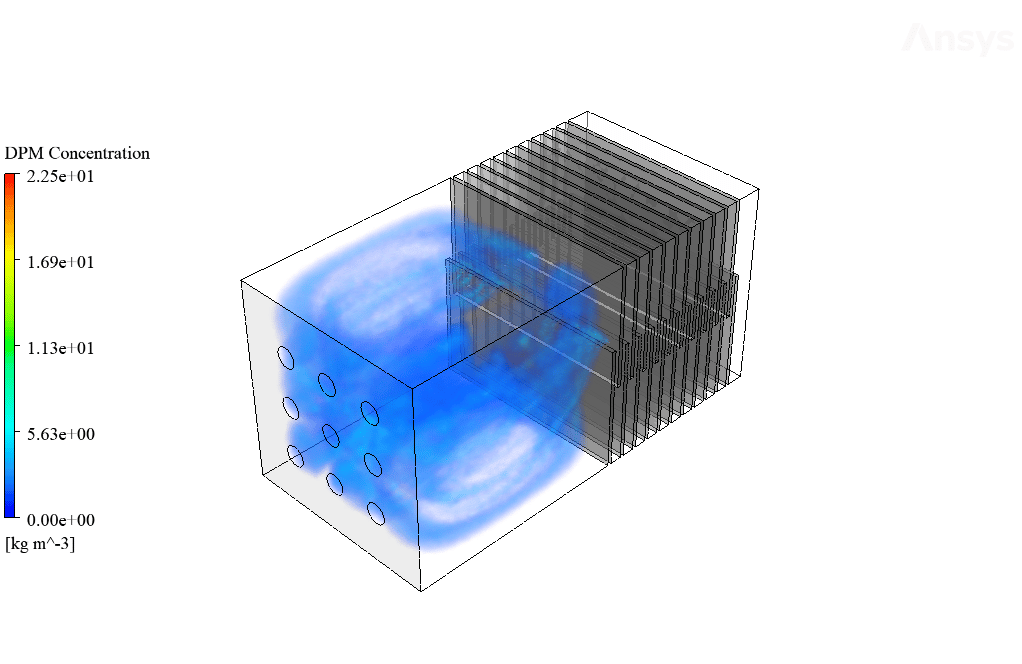

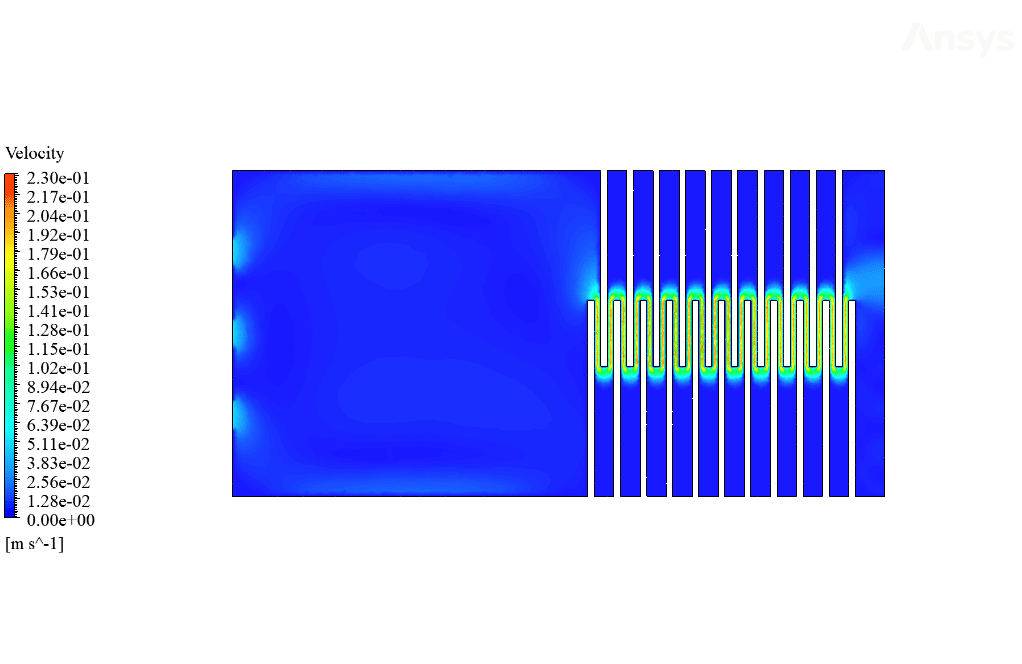

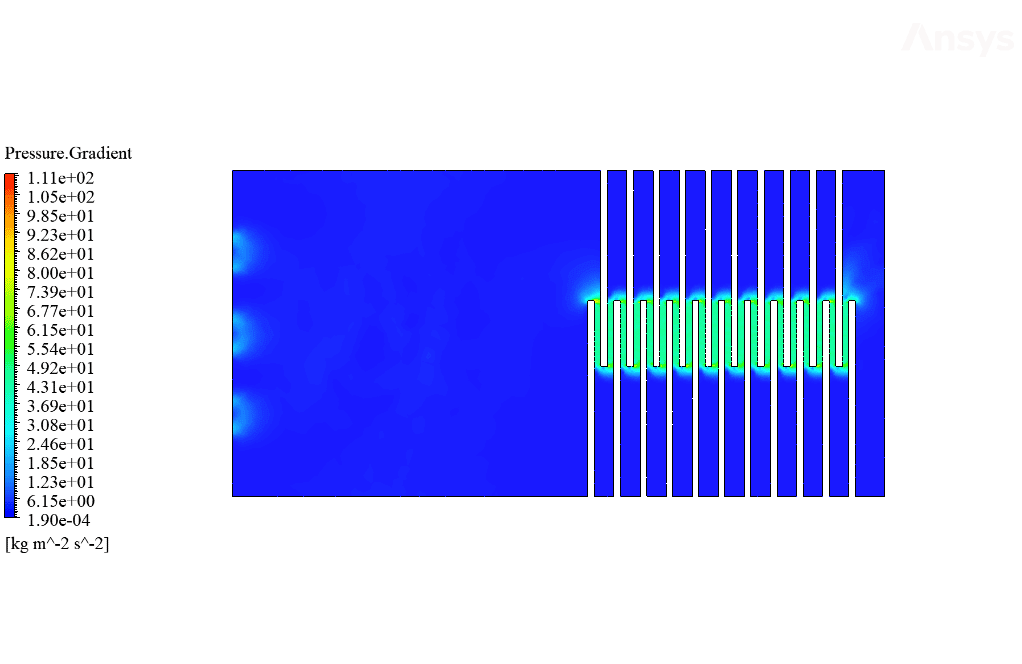

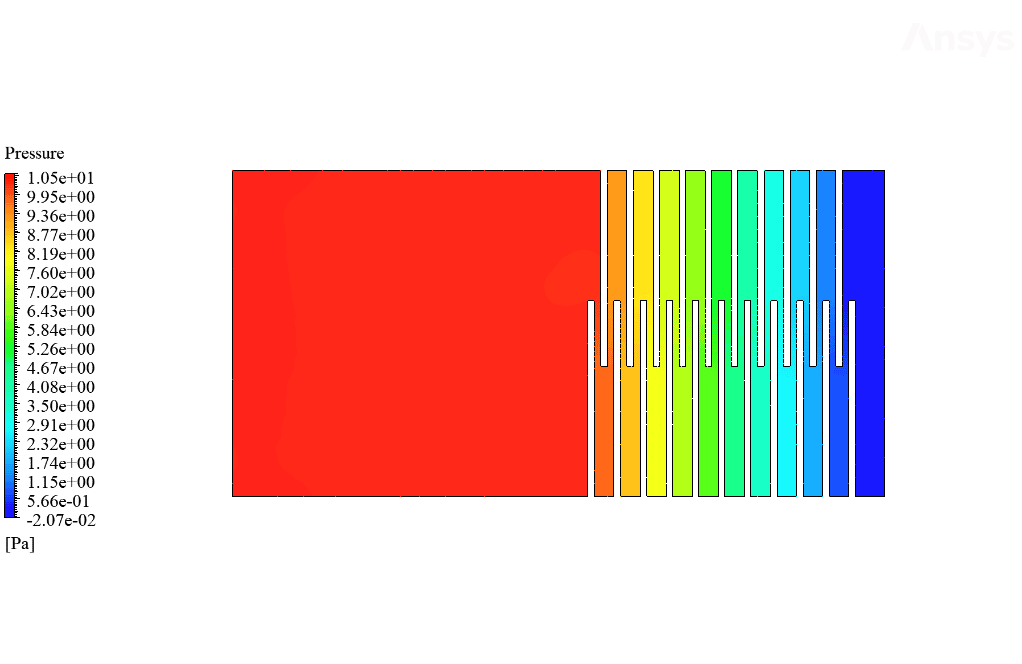

After calculation, 2D and 3D contours related to velocity, pressure, pressure gradient, and DPM concentration are obtained. The particle tracks based on residence time are also shown. The results show that the fluid flow passes through a tortuous path through the space between the plates and is in constant contact with the surface of the plates.

These contacts cause discrete water particles in the air to be trapped by these plates in the space between the plates. Thus, the dehumidification process of moist air is done correctly by trapping water droplets. The results show that the 175 tracked water particles are all trapped by the plates.

Friedrich Ortiz –

I must say the balance between theoretical foundations and practical exercises is fantastic! Having a hands-on illustration of dehumidification coupled with clear explanations has deepened my understanding significantly.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our product was effective in enhancing your understanding of the dehumidification process. We strive to maintain a comprehensive learning experience, blending theory with practical simulations. It’s great to know we’ve succeeded with our Dehumidifier with DPM Model training. We appreciate your support!

Adolfo Purdy –

The results demonstration clearly showcased the dehumidification process, illustrating the air’s journey and how effectively it’s dehumidified by the system. Fantastic detail in showing particle residence times and interaction with the plates!

MR CFD Support –

Thank you for your positive feedback on the Dehumidifier With DPM Model simulation results. We are pleased to know that the intricate details provided demonstrated the process clearly and effectively. Your appreciation is a testament to our commitment to delivering comprehensive learning experiences at MR CFD. If you have any more questions or need further information, feel free to reach out.

Tad Shanahan –

In the simulation description, what happens to the water particles when they contact the plates and why is ‘trap’ chosen as the boundary condition for this interaction?

MR CFD Support –

The ‘trap’ boundary condition is chosen for the interaction between the water particles and the plates to simulate the removal of moisture from the air stream. When the water particles come into contact with the plates, they are trapped and removed from the air, effectively lowering the humidity level within the chamber. This mimics the operational principle of a real dehumidifier, where collected moisture is separated from the circulating air.

Dr. Raquel Zemlak III –

The use of discrete phase model in this DE humidifier module is fascinating. Can this model handle multiphase flows with different particle types simultaneously?

MR CFD Support –

In the context of the dehumidifier simulation using DPM, the model handles the interaction between the continuous air phase and the discrete water particles. However, should you wish to simulate multiple types of discrete particles simultaneously, the setup would be more complex, requiring additional definitions for each type of particle, such as size, mass, and material properties. ANSYS Fluent does offer the capability to simulate multiphase flows with different particle types using the DPM.

Ellis Davis –

The level of detail in this product description is impressive. It seems like MR CFD offers a comprehensive guide through the entire process of simulating a dehumidifier using ANSYS Fluent. The inclusion of detailed boundary conditions and initialization methods must make it easier to understand the simulation’s setup. Excellently addressed real-world application regarding humidity control within indoor spaces. Kudos to MR CFD Company for providing such an instructive learning tool!

MR CFD Support –

We are incredibly grateful for your kind words and satisfied to hear that you found the Dehumidifier with DPM Model simulation using ANSYS Fluent beneficial. Our goal is to provide detailed and accessible learning materials to help our customers tackle real-world engineering challenges. Thank you for choosing our training products; we look forward to continuing to support your learning journey!

Prof. Claude Jakubowski –

A truly comprehensive guide for the simulation of a dehumidifier with the DPM model. The track capture of water particles, an essential aspect for dehumidification, was very well-explained. The detail in setting up boundary conditions and using the trap option for discrete phase BC was particularly enhancing.

MR CFD Support –

Thank you for your positive review. We’re thrilled to hear that the explanation of the dehumidification process with particle tracking was clear and helpful. It’s our goal to provide detailed and practical insights into CFD simulations, and we appreciate your recognition of the work put into setting up the boundary conditions accurately.