Dehumidifier With VOF Model, CFD Simulation ANSYS Fluent Training

$140.00 Student Discount

The present simulation is about a Dehumidifier with VOF Model via ANSYS Fluent, and the results of this simulation have been analyzed.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Dehumidifier With VOF Model Description

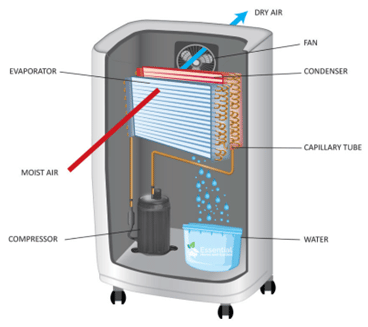

The present simulation is about a dehumidifier via ANSYS Fluent. A dehumidifier is an air conditioning device that reduces and maintains the level of humidity in the air. This device is used to increase the health and thermal comfort of the people in the environment, eliminate the musty odor, and prevent mildew growth by removing water from humid air.

This project investigates a humidification-dehumidification system with a phase change process. These systems consist of two sections the evaporator and the condenser.

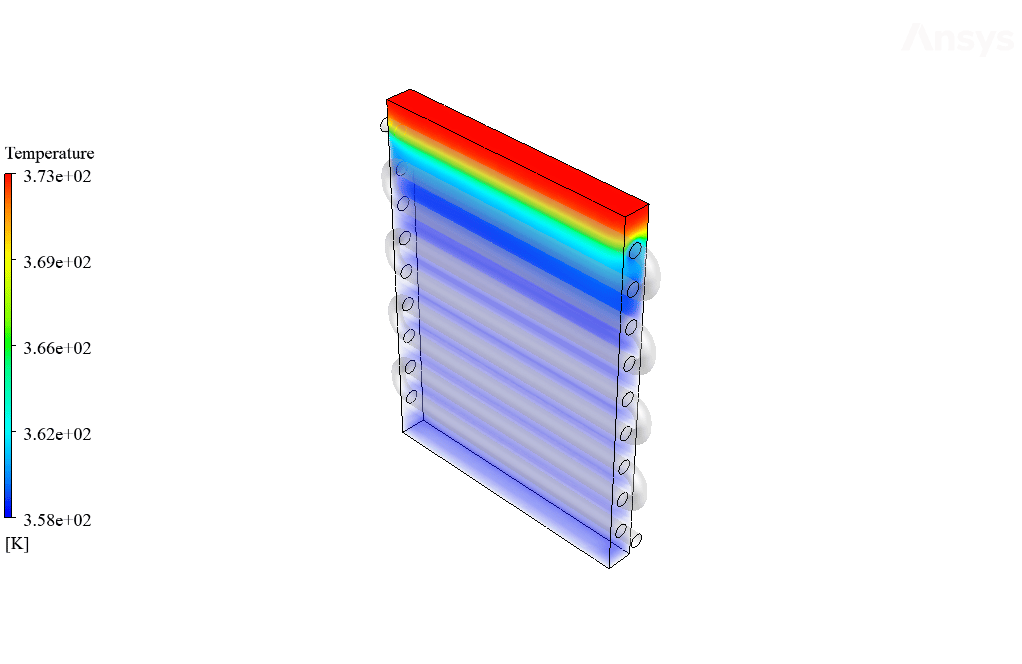

First, the airflow inside the copper pipes is heated and compressed by the compressor and goes to the condenser section. In this section, the air inside the pipes is reduced by temperature due to blowing the fan, and condensation occurs.

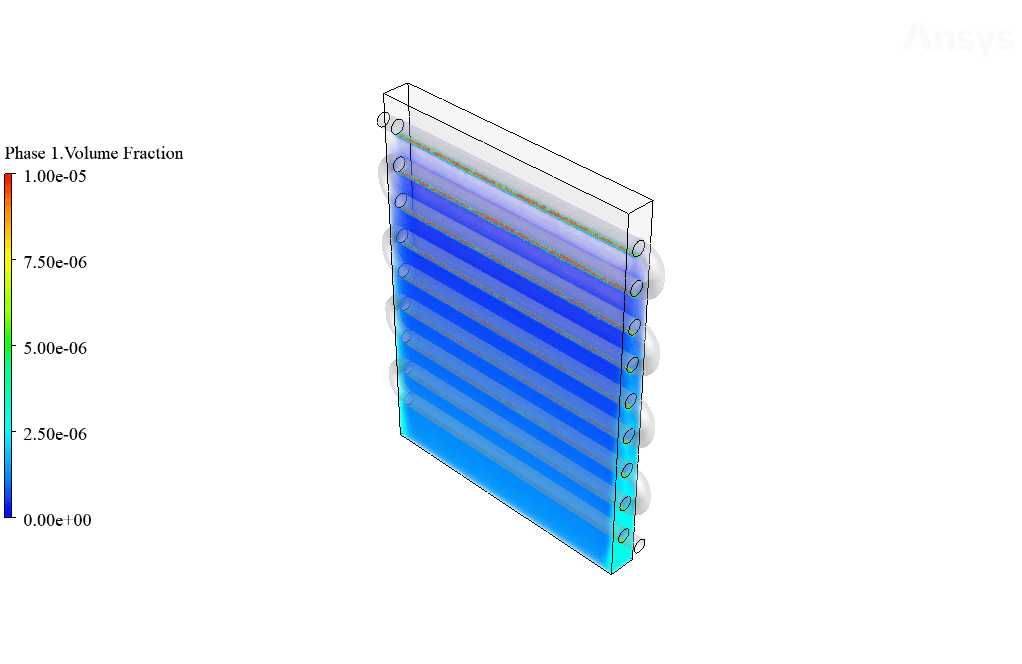

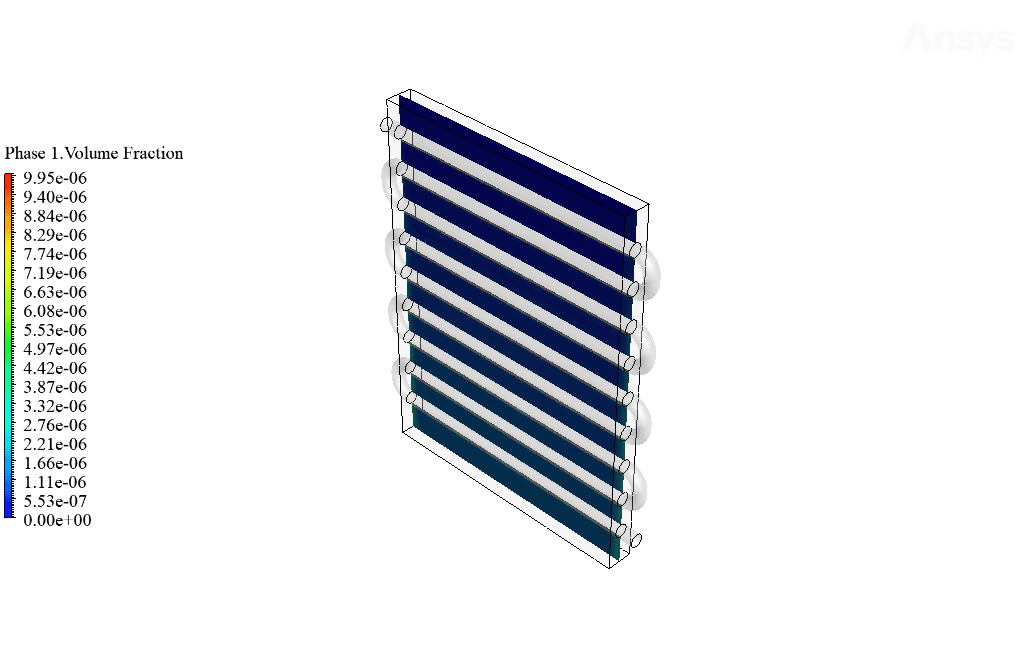

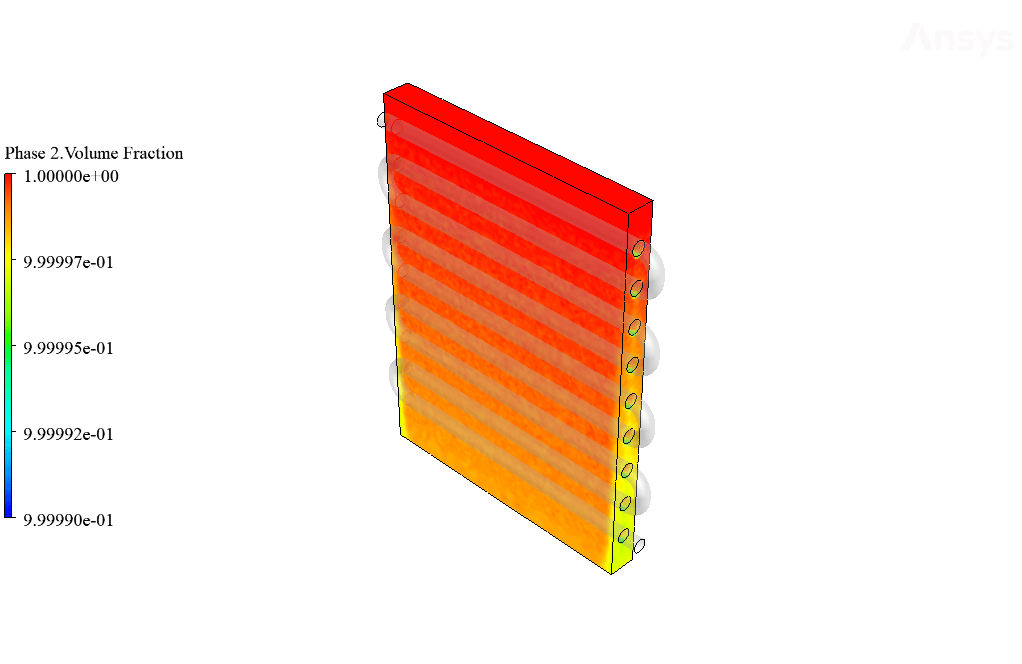

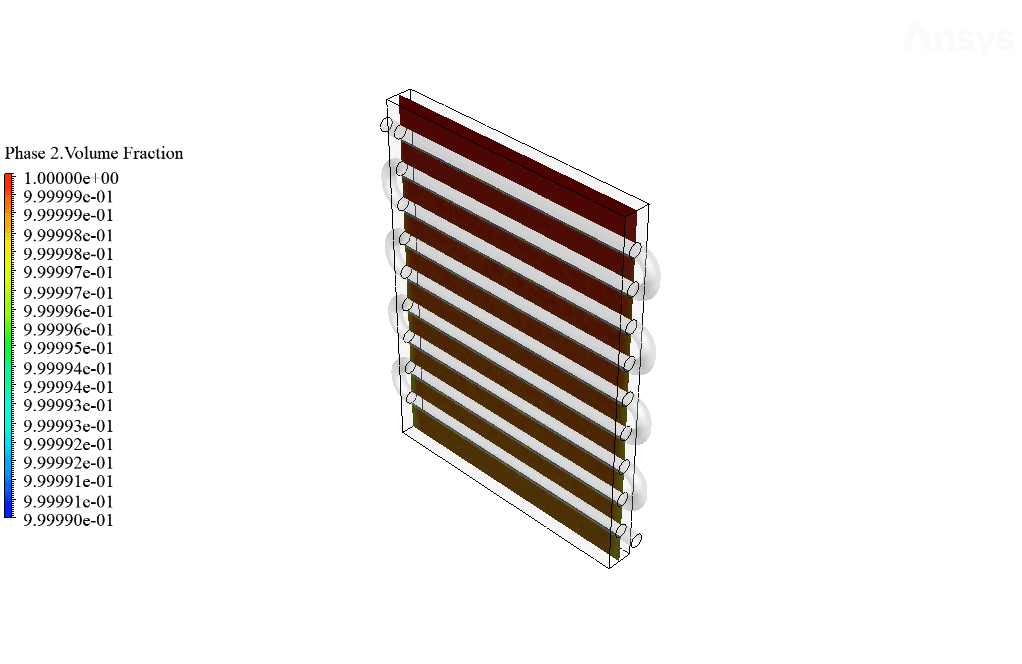

The resulting liquid then goes to the evaporator section to evaporate again when it receives heat and turns into a gas phase. This heat is taken from the humid air blown into the pipes. Receiving heat from humid air causes dry air to be obtained. In this study, water vapor is considered humid air. Therefore, a multi-phase model must be defined, consisting of water and vapor.

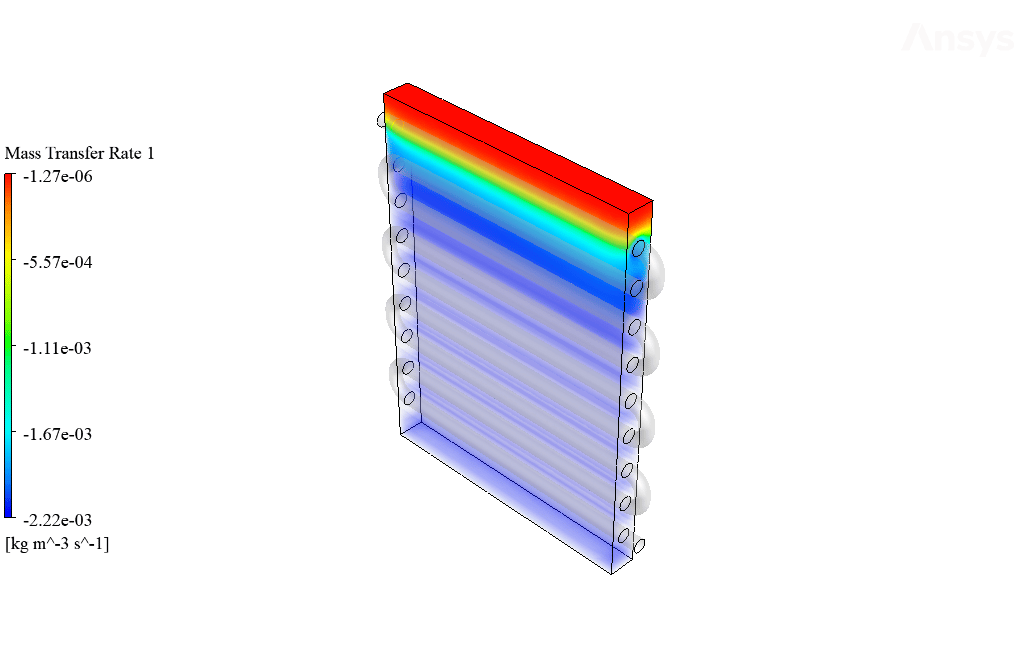

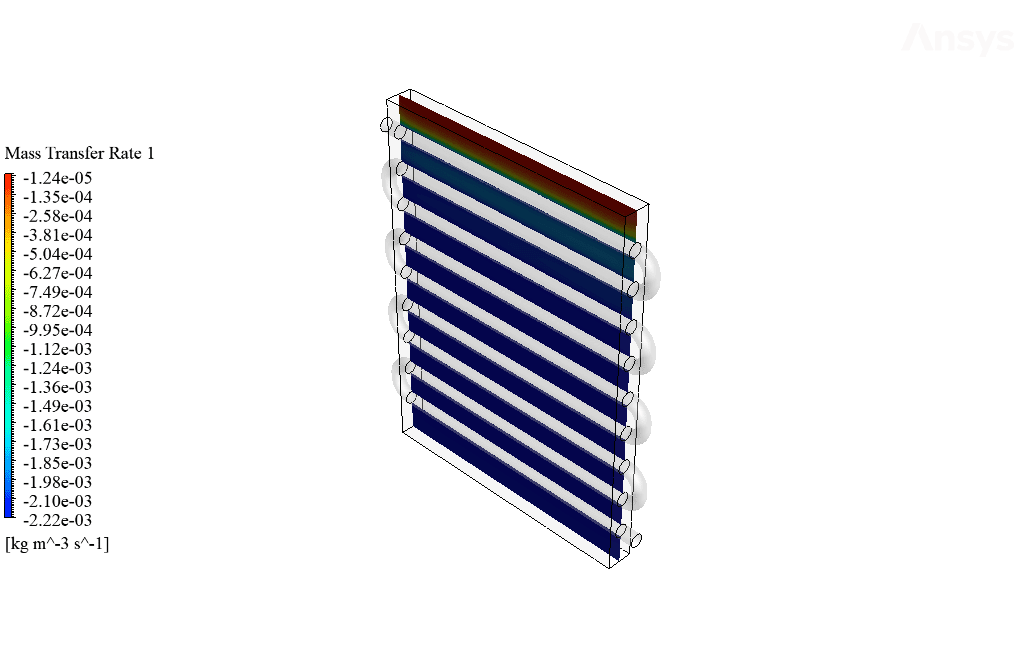

Then the mass transfer between vapor and water is defined in evaporation-condensation type so that steam becomes liquid water by decreasing the temperature to below saturation temperature.

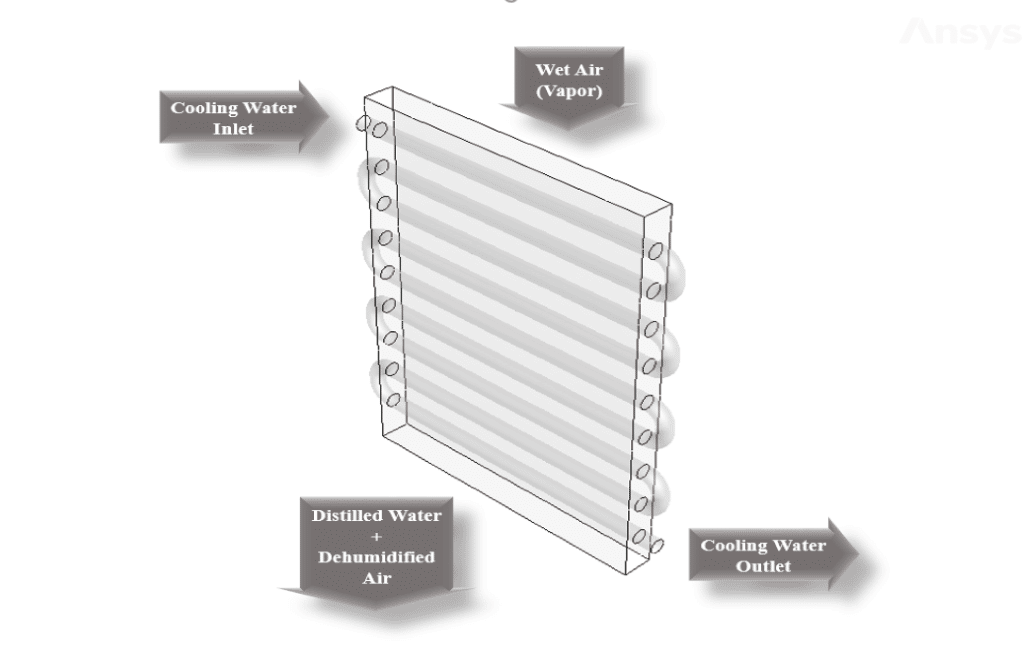

The amount of water resulting from the phase change between vapor and water indicates the amount of dehumidification. Since the two phases of water and vapor are entirely separate from each other, the volume of fluid (VOF) model is used. So, a chamber is designed with spiral tubes, So that the pipes have a flow of cold water and the chamber contains water vapor.

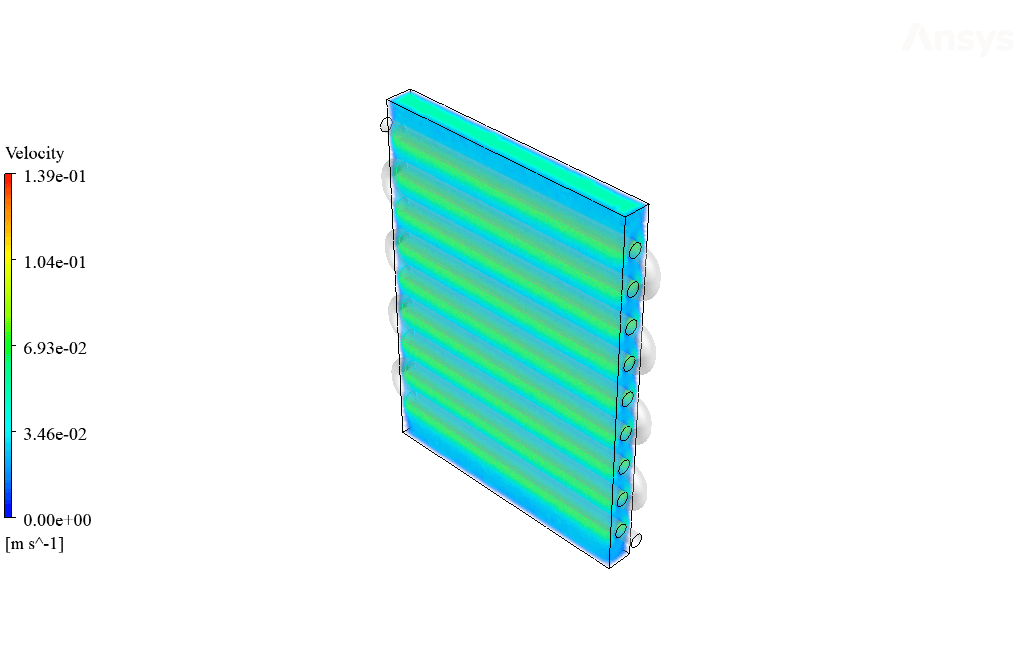

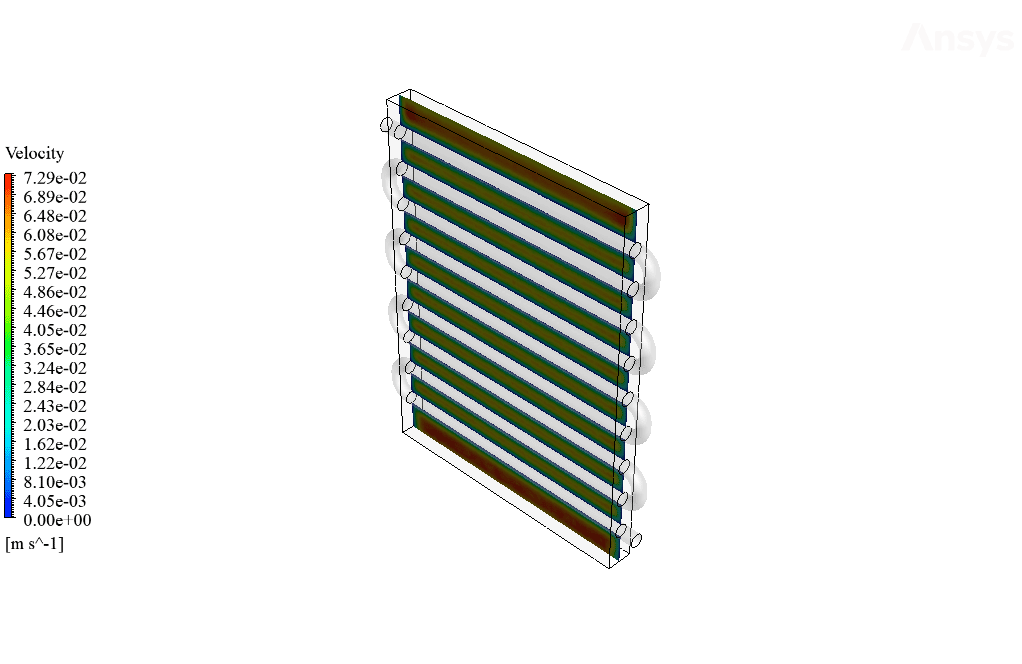

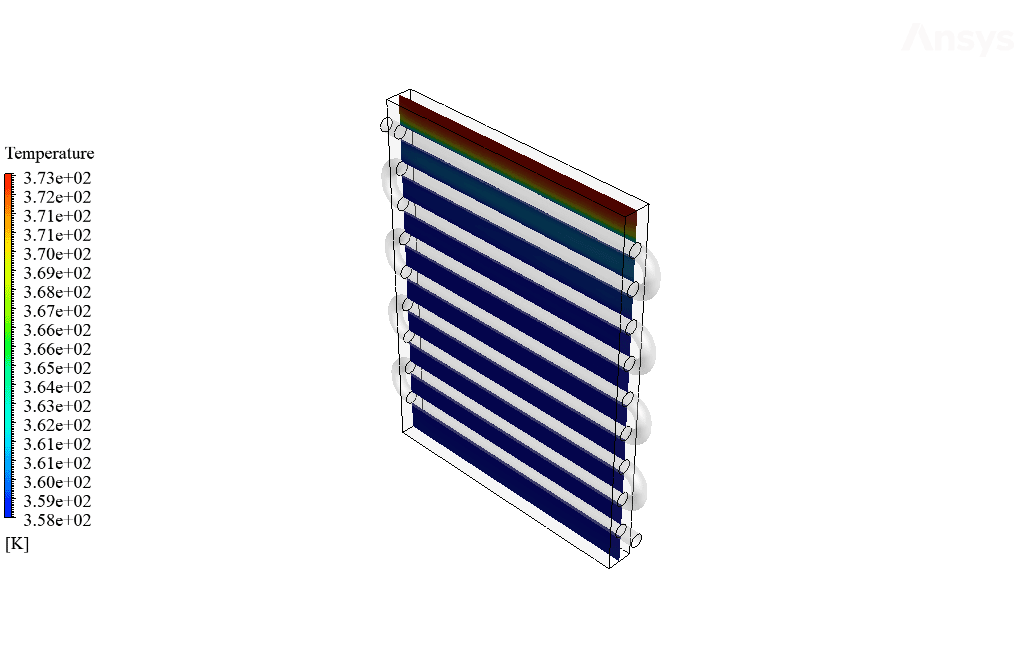

The vapor enters the chamber with a saturation temperature of 373.15 K and velocity of 0.05 m/s and contacts the surface of a pipe with water flow at a temperature of 358.15 K and a velocity of 0.01 m/s.

Geometry & Mesh

The present geometry is designed in a 3D model via Design Modeler. The computational zone is the interior of a dehumidifier. This dehumidifier consists of a chamber with spiral tubes. Steam flows inside the chamber, and cold-water flows inside the spiral pipes.

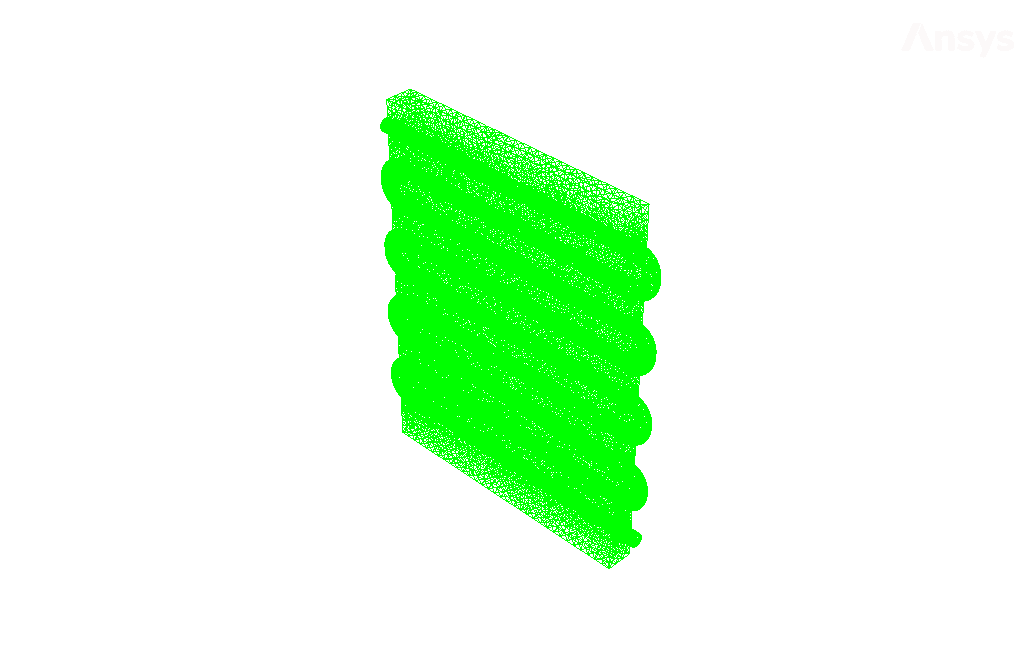

The mesh of the present model has been done via ANSYS Meshing. Mesh is done unstructured, and the number of production cells is equal to 1522772.

Set-up & Solution

Assumptions used in this simulation :

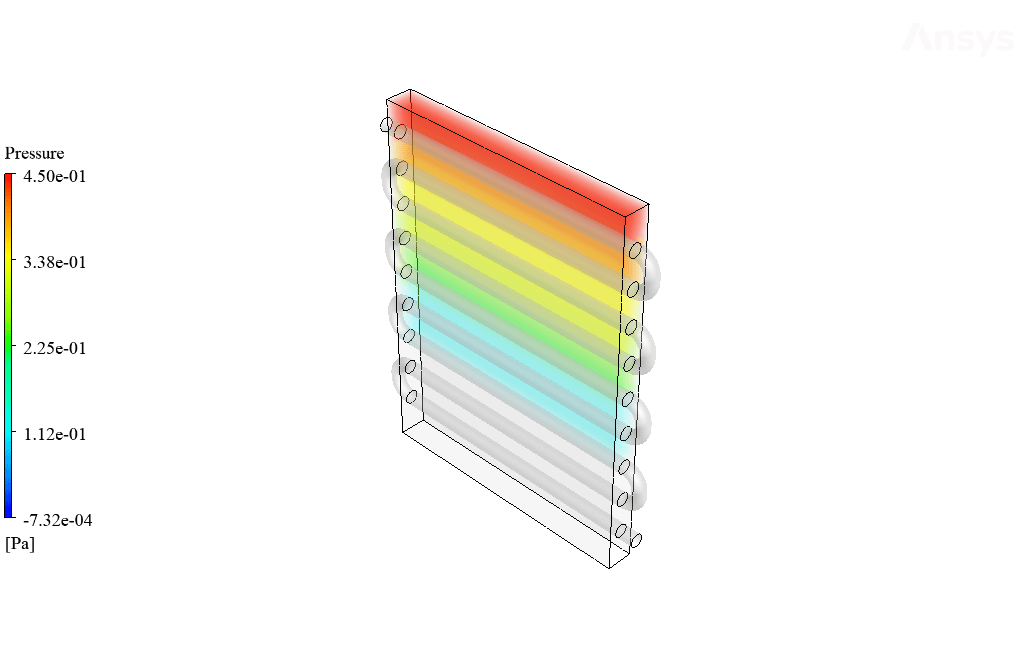

- Pressure-based solver is used.

- The present simulation is steady.

- The effect of gravity on the model is considered, and the gravitational acceleration is defined as 9.81 m/s2.

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | realizable | |

| Near-wall treatment | standard wall function | |

| Multiphase | VOF | |

| number of eulerian phases | 2 (water & vapor) | |

| interface modeling | sharp | |

| mass transfer mechanism | evaporation-condensation | |

| Energy | On | |

| Boundary conditions | ||

| Inlet-Wet Air | Velocity Inlet | |

| velocity magnitude | 0.05 m.s-1 | |

| temperature | 373.15 K | |

| volume fraction of water | 0 | |

| volume fraction of vapor | 1 | |

| Inlet-Cool Water | Velocity Inlet | |

| velocity magnitude | 0.01 m.s-1 | |

| temperature | 358.15 K | |

| volume fraction of water | 1 | |

| volume fraction of vapor | 0 | |

| Outlet-Dry Air | Pressure Outlet | |

| gauge pressure | 0 Pascal | |

| Outlet-Cool Water | ||

| gauge pressure | 0 Pascal | |

| Inner Wall | Wall | |

| wall motion | stationary wall | |

| thermal condition | coupled | |

| Outer Wall | Wall | |

| wall motion | stationary wall | |

| heat flux | 0 W.m-2 | |

| Methods | ||

| Pressure-Velocity Coupling | Coupled | |

| pressure | PRESTO | |

| momentum | First-order upwind | |

| turbulent kinetic energy | First-order upwind | |

| turbulent dissipation rate | First-order upwind | |

| volume fraction | modified HRIC | |

| energy | First-order upwind | |

| Initialization | ||

| Initialization methods | Standard | |

| gauge pressure | 0 Pascal | |

| volume fraction of vapor in chamber | 1 | |

| volume fraction of vapor in tube (patch) | 0 | |

| velocity | 0 m.s-1 | |

| temperature in chamber | 373.15 K | |

| temperature in tube (patch) | 358.15 K | |

Cristina Torp –

The spiral tubes in this setup—are they positioned horizontally or vertically in the dehumidifier chamber, and does this positioning affect the dehumidification process?

MR CFD Support –

In the described setup for the dehumidifier simulation, although the precise positioning of the spiral tubes is not explicitly mentioned, the gravitational effect is considered in the simulation pointing to the significance of the positioning. While the VOF model is utilized assuming two separate phases of water and vapour interacting with gravity, the orientation (horizontal or vertical) could impact the distribution of phases and the efficiency of heat transfer and condensation. Usually, the positioning is designed for optimal phase separation and heat exchange. Should you need specifics about positioning and its effects on the dehumidification process, please refer to the simulation results or consult the provider for more detailed insights.

Ms. Amelie Kohler PhD –

I am really impressed with the level of detail in the simulation of the dehumidifier. The consideration of temperature variations and the use of VOF for phase change is excellent. This must have really helped in visualizing the process of dehumidification!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the detail of our dehumidifier simulation met your expectations and provided valuable insights. Visualizing the dehumidification process accurately is crucial for understanding and improving these systems. If you have any more feedback or need further information, don’t hesitate to reach out.

Dr. Kendra O’Keefe IV –

Thank you for the clear and detailed breakdown of the dehumidifier CFD simulation using the VOF model. It’s intriguing to see how real-world processes can be replicated and analyzed through simulations like this. The multi-phase approach effectively demonstrates the dehumidification process, especially the transition between vapor and water which indicates the amount of dehumidification. Furthermore, the use of a pressure-based solver and various other first-order upwind methods provides confidence in the numerical accuracy of the results. It’s great to learn how such complex systems are tackled in simulations.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our detailed breakdown of the dehumidifier CFD simulation using the VOF model was helpful and insightful. It’s always encouraging to know that our efforts to accurately replicate and analyze complex physical processes provide valuable learning experiences. If you have any more questions or need further insights, feel free to reach out to us.

Terrance Bergnaum –

I was impressed by how the VOF model facilitated a clear separation of phases in the dehumidifier simulation. It made understanding phase transitions very straightforward!

MR CFD Support –

We are glad to hear that the VOF model in this CFD simulation made it easier for you to understand the phase transitions! At MR CFD, we aim to provide clear and comprehensible learning material. Thank you for your positive feedback!

Crystel Bradtke –

The review was really informative! I’m impressed with the level of detail provided about the vapor and water phases in the dehumidification process.

MR CFD Support –

Thank you for your kind words! We are thrilled that you found the description informative and helpful. Understanding the intricacies of the vapor-water phase interactions is crucial in simulating a dehumidifier, and we strive to provide clear and detailed information in our trainings. If you have any more questions or need further clarification, feel free to ask. We’re here to help!

Dr. Kiarra Krajcik –

Your detailed simulation of a dehumidifier using ANSYS Fluent is fascinating. I’m particularly interested in how the interaction between the cold water in the spiral pipes and the warm, saturated air was modeled to predict condensation and dehumidification effectively. Would this set-up be adequate for industrial scale applications or are there significant scaling challenges?

MR CFD Support –

The simulation set-up described does effectively model the interactions needed to predict condensation and dehumidification, such as the heat exchange between the cold water in the spiral pipes and the saturated air. By adjusting the operating conditions, geometrical scaling, and boundary conditions within ANSYS Fluent to reflect a full-scale industrial application, as well as conducting validation against experimental data, this model can be tailored for industrial scale usage. The primary challenges in scaling up entail ensuring accurate physical representation of phenomena such as heat transfer and phase change, potential changes in flow patterns due to increased system size, and the computational resources needed to handle more extensive and complex simulations.

Dr. Maryse Kuphal I –

The project overview is quite informative! But can you explain how the condensate is collected and removed from the system in the simulation?

MR CFD Support –

In the simulation, the condensate formed during the dehumidification process is collected at the bottom of the chamber due to gravity. An outlet is typically modelled to allow the removal of condensate from the system. The simulation would track the phase change from vapor to liquid and the consequent movement of the liquid water to the outlet, where it is removed from the computation domain, thus ensuring a continuous dehumidification process within the system.

Ozella Bashirian –

The simulation process for the dehumidification system using the VOF model in ANSYS Fluent was quite detailed. It’s admirable how the simulation encompassed the interaction between water and vapor, factoring in the mass transfer between them. The detailed setup reflects a thorough understanding of the system’s physical phenomena. A job well done!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our detailed simulation setup met your expectations and provided you with a clear understanding of the dehumidification process. Our goal is to facilitate a real-world understanding of such systems, and it’s great to know we’ve achieved that for you.

Tate Feest –

Just fantastic! The detail and accuracy of this dehumidifier CFD simulation by MR CFD were outstanding. As someone learning about multiphase flows with ANSYS Fluent, I found the explicit setup instructions and careful explanation of the VOF model and boundary conditions incredibly valuable. The inclusion of mass transfer mechanisms for evaporation-condensation processes offered real insight into how dehumidifiers work. It’s clear how meticulously this simulation has been crafted, from the design all the way through the mesh, setup, and solution. The insights gained here are practical for my ongoing studies.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our product was so helpful in your learning process. Understanding multiphase flows and the dynamics of dehumidifiers can be quite complex, and we strive to create clear, detailed simulations that are both educational and practical. It is rewarding to know our careful planning and meticulous detail have made a positive impact on your studies. If you have any further questions or need more insight as you continue to learn with ANSYS Fluent, don’t hesitate to reach out to us!

Dr. Gerardo Ondricka –

I recently used the Dehumidifier with VOF Model training material, and it was quite informative! I particularly found the geometry and mesh section comprehensive, clarifying the setup’s detailing. The outcome of the simulation was fascinating. Seeing the actual phase change process and understanding the dynamics within the dehumidifier deepened my grasp of the dehumidification concept.

MR CFD Support –

Thank you for your positive feedback on our Dehumidifier with VOF Model training material! We’re glad to hear that it helped strengthen your understanding of the dehumidification process and that the detailed explanation of the geometry, mesh, and simulation results was beneficial for you. We strive to deliver informative and practical information to our users. We are looking forward to providing you with more valuable learning resources in the future!

Keagan Leffler –

I just recently completed the ‘Dehumidifier With VOF Model’ CFD simulation training using ANSYS Fluent and I am thoroughly impressed. The balance between theoretical content and hands-on practice with the software was spot on. The step-by-step instructions were clear and easy to follow. I particularly appreciated the inclusion of utilizing the VOF model to properly represent the phase change, which is a critical aspect in studying dehumidifiers. Plus, the explanation of setting up the mass transfer was enlightening.

MR CFD Support –

We’re so pleased to hear that you found the ‘Dehumidifier With VOF Model’ simulation training to be helpful and informative. It’s great that the aspect of the phase change and the details of setting up mass transfer were particularly useful for you. Your positive feedback is much appreciated, and we hope the skills you’ve gained will serve you well in your future projects. Thank you for taking the time to share your experience.

Maureen Schmidt –

I’m amazed by how well the simulation seems to be handling the VOF model and tracking the phase change! Did the results indicate how effective the dehumidifier is in reducing humidity levels in the environment?

MR CFD Support –

Thank you for your kind words! Our simulation results showed the efficiency of the dehumidifier by illustrating the mass transfer between vapor and water, specifically detailing the condensation rates. We also observed the dry air’s outlet temperature and vapor content to assess the system’s effectiveness. These metrics indeed indicated that the dehumidifier has a significant impact on reducing humidity levels.

Roselyn Willms –

What an insightful product! It’s clear that a significant amount of detail and expertise has been put into creating this Dehumidifier With VOF Model CFD Simulation training. As someone who has delved into it, I find the balance of theory and practical application to be outstanding. The step-by-step approach demystifies the complexities behind the multiphase simulation and I especially appreciate the thorough explanation of mass transfer within the dehumidification process. Well done!

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear that you found the details and step-by-step guidance useful for understanding the complexities of the dehumidification process using CFD simulation. Your satisfaction with the training content is very important to us, and we aim to continue providing high-quality, informative products. If you have any more questions or need further assistance, feel free to reach out!

Ms. Marcelle Grimes I –

I’m struggling to visualize the dehumidifier’s design. Could you explain how the spiral tubes are arranged within the chamber, and how that design enhances dehumidification efficiency?

MR CFD Support –

Each spiral tube within the chamber is meticulously positioned for maximum contact with the humid air. This arrangement ensures efficient heat transfer, facilitating the condensation of water vapor as it passes over the cold surfaces of the spiral tubes. The geometry’s specific design promotes thermal exchange, leading to effective dehumidification as water vapor condenses into liquid due to the temperature differential across the tube surfaces.

Karley Cormier Sr. –

Certainly appreciate the thorough work on the dehumidifier CFD simulation. Wondering if you could clarify, how does the model take into account the heat transfer between the dehumidifier coils and the humid air? Also, is the effect of refrigerant within the coils considered in the simulation process?

MR CFD Support –

In the dehumidifier CFD simulation, the heat transfer between the coils and the humid air is accounted for using thermal boundary conditions. The ‘Inner Wall’ settings within the simulation refer to the condition of the dehumidifier coils, which are set to be coupled, suggesting a direct thermal interaction between the fluid inside the coils (cold water) and the walls of the coils, hence, between the coils and humid air. The energy equation is activated, allowing the calculation of temperature fields and the heat transfer effects. Meanwhile, the actual refrigerant in the coils is simplified to cold water in this simulation, with the main focus being on the phase change from vapor to water in the humid air, not the refrigerant cycle itself. This abstraction is common in simulations for complexity management.

Jewell Eichmann PhD –

I’ve never seen such complex projects being explained in such a digestible format. The detailed step-by-step guide on setting up and conducting the dehumidifier system simulation is fantastic. It really showcased the power of the VOF Model in water vapor interaction with the temperature change, not to mention the thorough setup and boundary conditions. Absolutely great training materials for any CFD enthusiast!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our training material on dehumidifier simulation using the VOF model in ANSYS Fluent was helpful and easy to understand. It is our goal to provide clear, detailed, and practical guides for our users to enhance their CFD knowledge and skills. Your enjoyment and satisfaction with the learning experience validates our efforts, and we greatly appreciate your review!

Flossie Monahan –

Just wanted to say that this training product for simulating a dehumidifier using the VOF model in ANSYS Fluent was absolutely phenomenal! The details about the evaporation-condensation process are explained clearly, and the setup advice is spot-on. Learning about determining the phase change between vapor and water truly helped me grasp the core concepts of dehumidification systems.

MR CFD Support –

Hello! Thank you for taking the time to provide your positive feedback on our dehumidifier CFD simulation training using the VOF model in ANSYS Fluent. We’re thrilled to hear that you found the training materials clear and helpful in understanding the phase change process in dehumidification systems. Your words are very much appreciated, and it’s great to know our product contributed positively to your learning experience. Thank you for choosing MR CFD Company for your learning journey!

Mr. Buck Yost Jr. –

I am fascinated by the simulation’s capability to model phase changes! Can you explain if it’s possible to see and measure the specific regions where the most condensation occurs within the system?

MR CFD Support –

Yes, with the CFD simulation, you can observe the specific regions where condensation occurs. The volume fraction results will show you where the water vapor transforms into liquid water. Additionally, the condensed water’s mass flow rate and temperature fields will let you analyze the regions of highest condensation.

Millie Beer –

I just finished the Dehumidifier With VOF Model CFD Simulation ANSYS Fluent Training course. The level of detail in setting up the multiphase model using VOF was excellent, and it was especially helpful to learn about handling the mass transfer in evaporation-condensation processes. This will be incredibly beneficial for my future projects in HVAC system design!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the course on Dehumidifier With VOF Model CFD Simulation was helpful and provided you with the detailed information you need for HVAC system design. If there’s anything else we can assist you with in your learning journey, please let us know. Keep up the great work!

Prof. Jesus Connelly III –

Thank you for such a detailed explanation of the dehumidifier simulation using the VOF model in ANSYS Fluent. This well-documented case seems to be an excellent resource for understanding the process of dehumidification through phase change. Your description covers all the primary steps, from setting up the geometry and mesh to specifying boundary conditions and solution methods.

MR CFD Support –

Thank you for your positive feedback! We’re glad that you found our ANSYS Fluent simulation training for the dehumidifier informative and comprehensive. It’s our goal to provide detailed explanations to help users understand complex processes like dehumidification and phase change. If you need any further information or assistance with our CFD products or have any other inquiries, feel free to reach out!

Mckayla Rice –

I am impressed with how thorough the simulation setup for the Dehumidifier With VOF Model was. The detailed explanation of the methods used for pressure-velocity coupling, alongside the initial conditions prepared and gravity effects considered, reflects an in-depth understanding of the multiphase flow and heat transfer processes involved. The practical treatment of the mass transfer between vapor and water, catering for evaporation and condensation, provides significant insight into real-world dehumidification systems.

MR CFD Support –

Thank you for your encouraging words! We’re glad to hear that you found the simulation setup to be thorough and reflective of an in-depth understanding. It’s important to us to convey complex CFD concepts in a way that is deeply informative yet intelligible. We take pride in providing quality training materials for our learners and we’re delighted to have your appreciation. If you have any more questions or need further assistance, don’t hesitate to reach out!

Fritz Stiedemann –

I thoroughly enjoyed the learning experience with the Dehumidifier With VOF Model training course. The balance between the theoretical concepts and practical examples was meticulously presented, making it easier to understand CFD’s complex methodologies.

MR CFD Support –

Thank you so much for your positive feedback! We are glad to hear that our training course provided a good balance of theory and practical application to aid your understanding of computational fluid dynamics. Your satisfaction is very important to us. If there’s anything more diverse in CFD training that you’re interested in learning about, feel free to let us know!

Deron Blanda –

The VOF model’s use in this dehumidifier simulation is impressive. How effectively does the simulation capture the phase change process?

MR CFD Support –

The simulation effectively captures the phase change process by using the VOF model to separate the water and vapor phases. The mass transfer between vapor and water is set as evaporation-condensation type, allowing for accurate monitoring of the phase change from steam to liquid water which in turn denotes the dehumidification amount.

Dr. Name Block IV –

This product made understanding the VOF model so much clearer, especially applying it to a dehumidification system. The description of mass transfer between vapor and water in the simulation was particularly helpful.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our dehumidifier simulation with the VOF model provided you with a clear understanding of the complex processes involved in dehumidification systems. If you have any further questions or need additional information on our products, feel free to reach out!

Zion Eichmann –

What is the purpose of using the VOF model in this dehumidifier simulation?

MR CFD Support –

In this simulation, the Volume of Fluid (VOF) model is used to accurately simulate the phase change between vapor and liquid water during the dehumidification process. The VOF model allows tracking of the interface between the two distinct phases, which is essential for modeling the mass transfer due to condensation and evaporation. It provides a clear picture of dehumidification efficiency by indicating the amount of water resulting from the phase change.