F-35 Considering Compressible Flow, ANSYS Fluent CFD Simulation Training

$100.00 Student Discount

- The problem numerically simulates the F-35 Considering Compressible Flow using ANSYS Fluent software.

- We design the 3-D model with the CAD software.

- We mesh the model with ANSYS Meshing software, and the element number equals 1,845,364.

- We use the ideal gas to consider a compressible flow.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The Lockheed Martin F-35 Lightning II is an American family of single-seat, single-engine, all-weather stealth multirole combat aircraft. It is also able to provide electronic warfare and intelligence, surveillance, and reconnaissance capabilities.

Interestingly, the F-35 speed could reach 500 m/s, which results in supersonic airflow. Therefore, actual case wind tunnel experiments are expensive in terms of both costs and time, so CFD solvers are often employed to evaluate for initial tests.

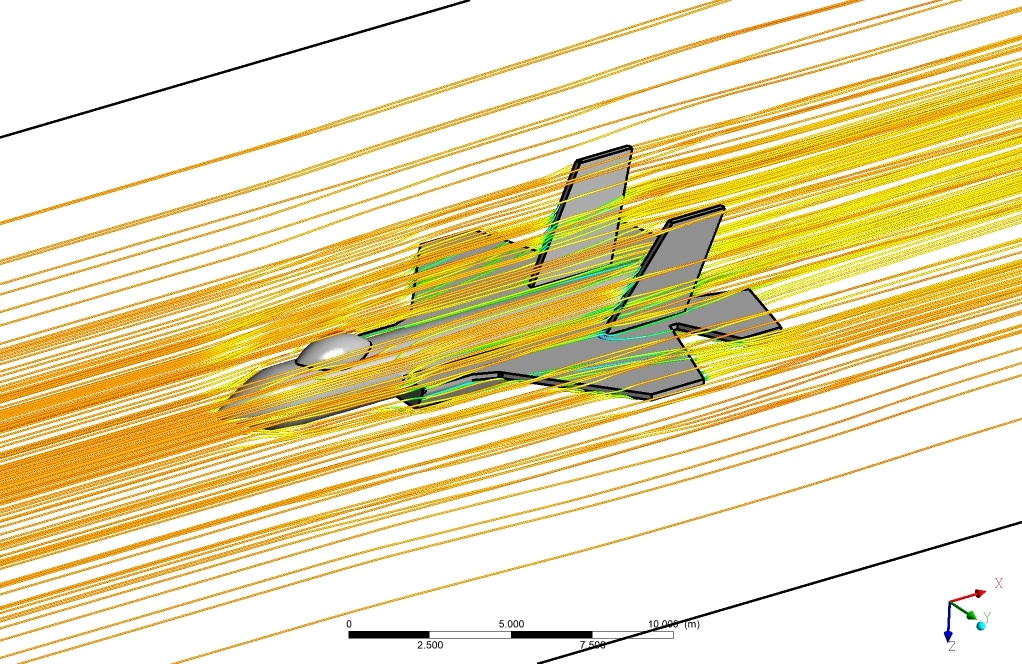

This project is going to study a Supersonic Compressible Flow adjacent to an F-35 plane. The geometry is a 20-meter F-35 plane inside a 150-meter wind tunnel.

For the current problem, the element number is equal to 7,182,542. Regarding the quality of the mesh, the maximum skewness of 0.79 with an average of 0.22 is a satisfactory mesh for the current problem.

Also, 25 prism layers were added adjacent to both water tunnel walls and the turbine’s body to accurately calculate the boundary layer.

Finally, the mesh is generated through ANSYS-Meshing. Finally, the mesh was converted to Polyhedral in the ANSYS FLUENT software, and it was reduced to 1,845,364 elements with the same quality. As a numerical study, the initial step towards the modeling is the production of the CAD geometry.

F-35 Methodology

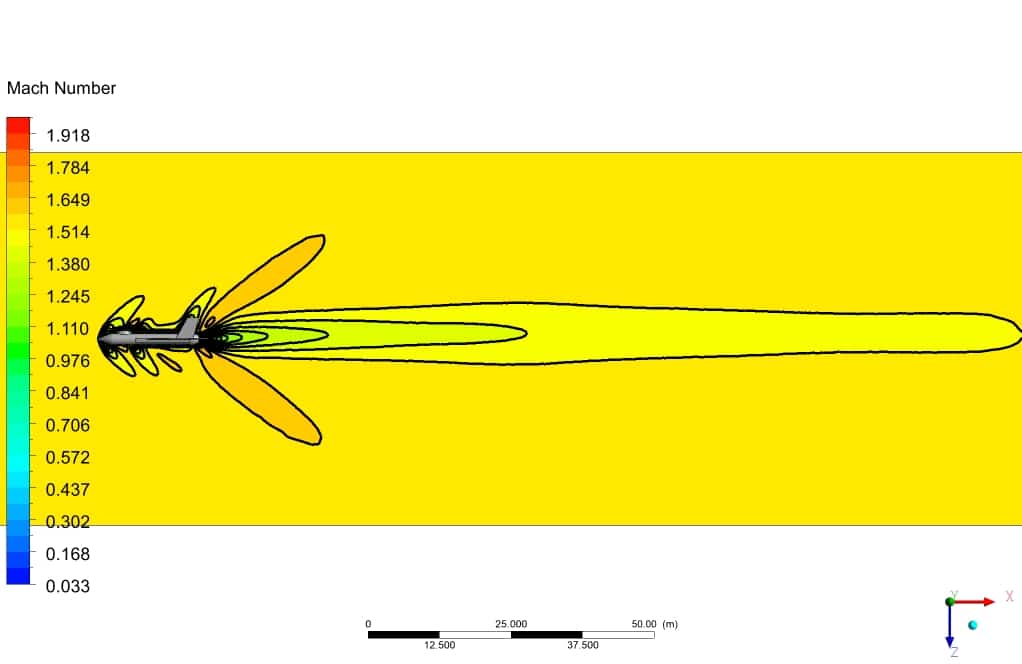

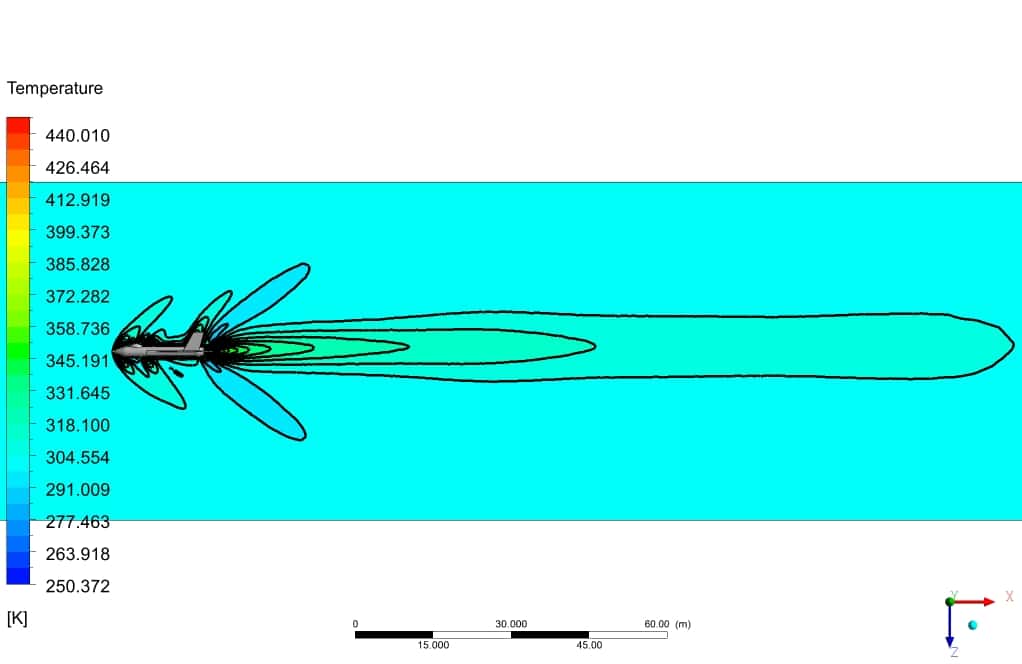

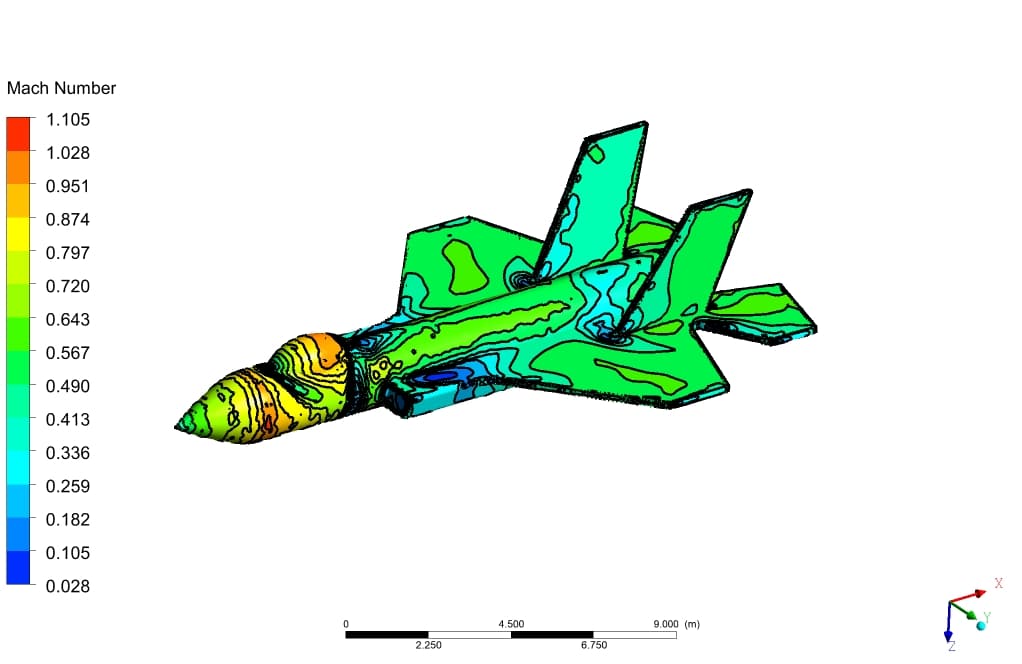

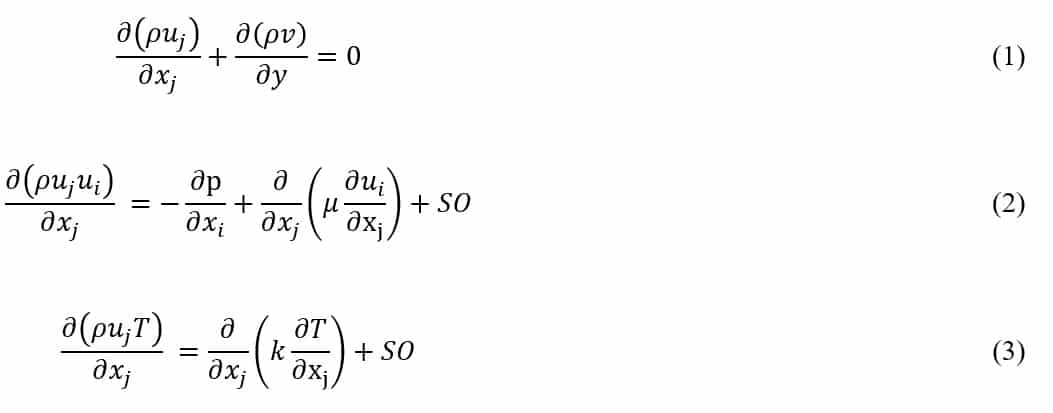

The air is considered a compressible ideal gas, and the Mach number of 2.0 was achieved at the maximum speed of 544 m/s. To study the current problem, one must solve the flow equations in the differential form.

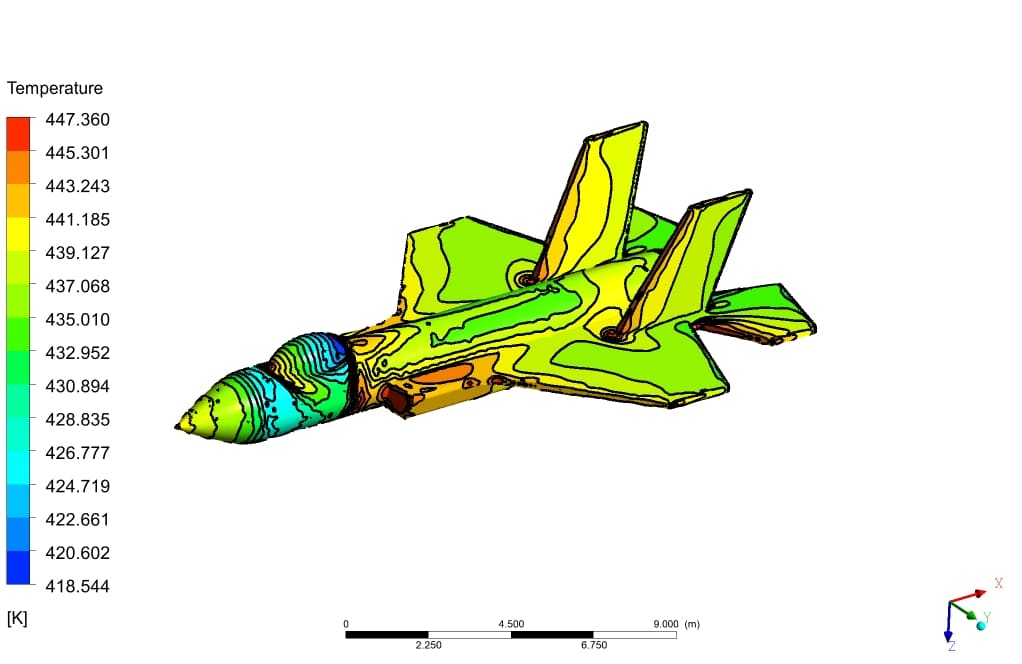

Also, the non-isothermal, compressible ideal gas condition was assumed inside the wind tunnel. Therefore, the energy equation was also solved in addition to the flow and the turbulent equations. Briefly, the governing mass and momentum equations are written as follows:

F-35 Conclusion

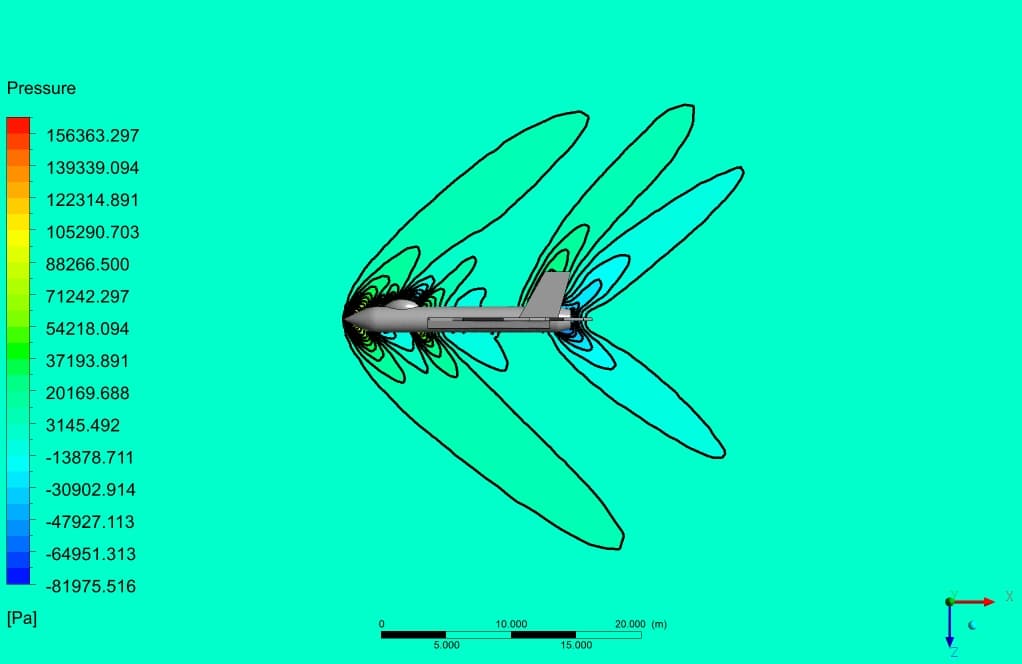

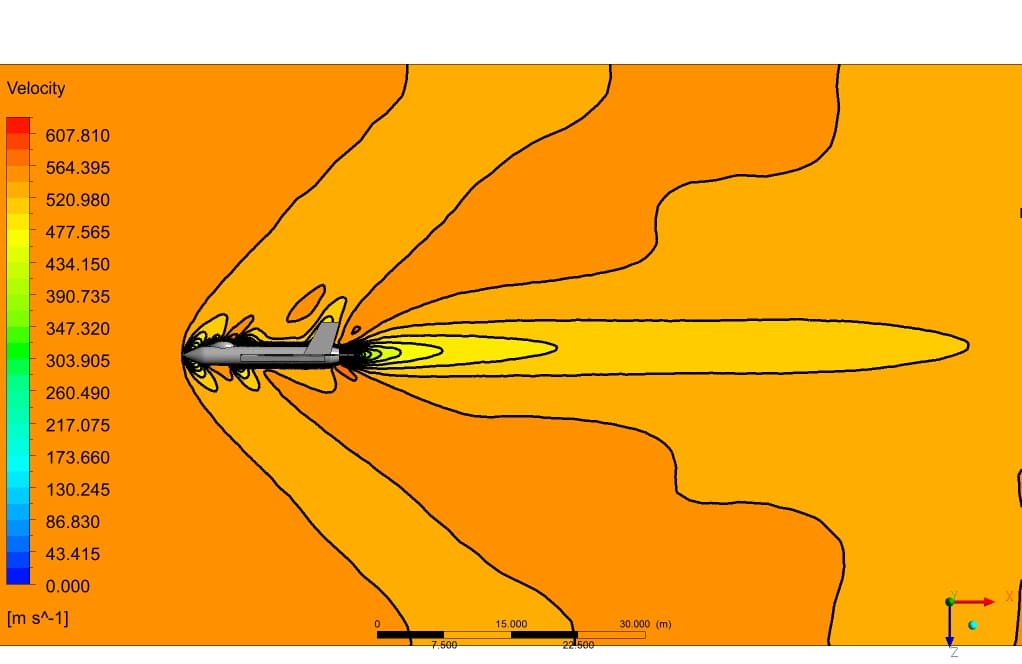

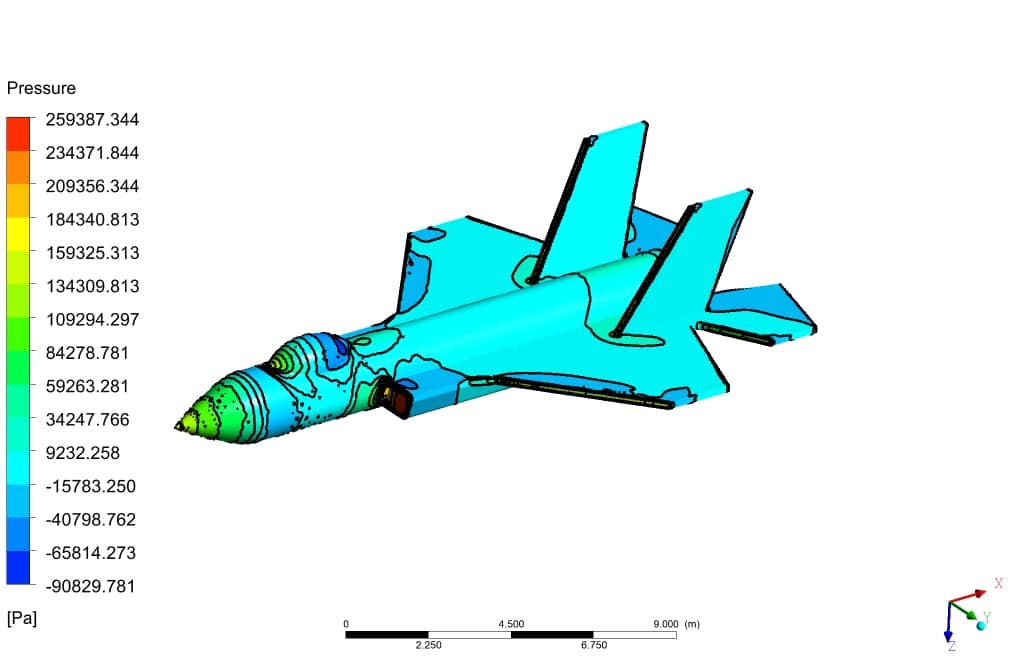

Also, the drag force and the shock profiles were obtained during the study. After the solution convergence, we observe the results through post-processing. Meanwhile, as an assurance of a valid convergence, we monitor the drag value during the solution iterations.

In this study, the solution was a converged one when the drag force reached a constant rate, and the residuals were below 10-6 values. Afterward, we present the results regarding the pressure and the velocity field in the figures.

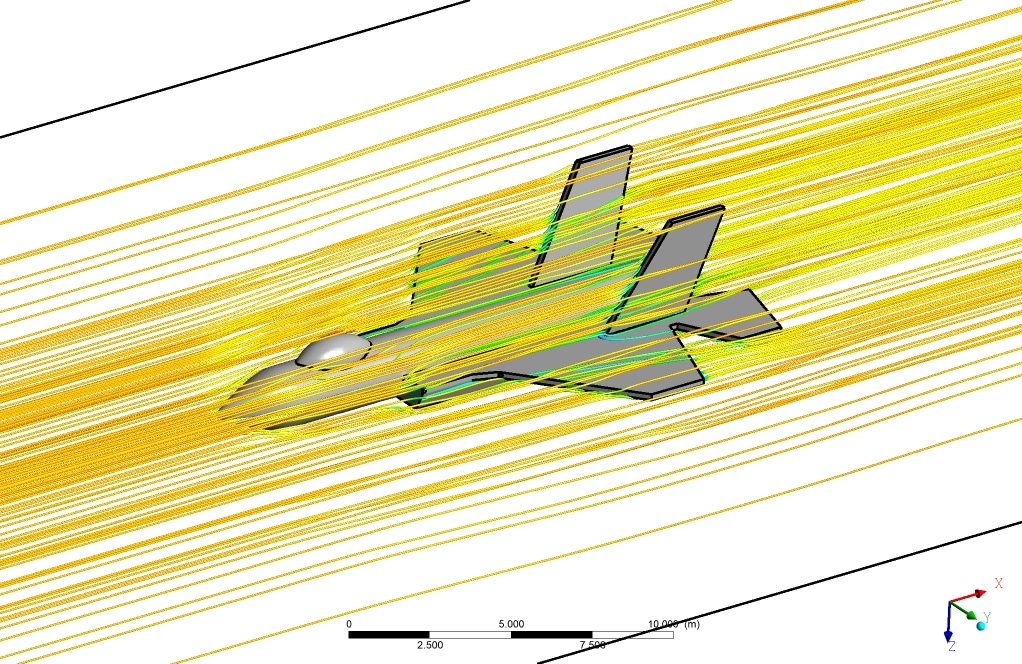

Furthermore, we can observe the shock profile from both the pressure and the Mach number contours. For the velocity field, we represent both contour and streamlines to give much insight into the problem.

Also, we present the temperature gradient and its variations in different locations because the increase in temperature is important in aerodynamic compressible flow calculations. Finally, we calculate the drag force at 181.66 (kN), which is accurate for a 20-meter airplane with the noted specifications.

Mr. Lavern Brown III –

I recently completed the ‘F-35 Considering Compressible Flow’ CFD simulation training, and it’s truly outstanding! The study of shock profiles and observation of drag force behavior were incredibly insightful. Having an accurate way to predict aerodynamic performance is game-changing, and this simulation provided a deeper understanding of compressible flow around the advanced aircraft geometry of an F-35. Also, exhibiting the temperature gradients was invaluable for grasping the thermal effects at high speeds. Kudos to the creators for a well-structured and high-fidelity simulation training package!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found the ‘F-35 Considering Compressible Flow’ CFD simulation training to be useful and educational. Observing the aerodynamic behavior of supersonic flows is crucial for the design and analysis of high-speed aircraft, and we’re happy our product could provide you with a comprehensive understanding. Your feedback is greatly appreciated and motivates us to keep offering high-quality, informative simulations. Thanks for choosing our training.

Prof. Rhiannon Watsica II –

I’m thoroughly impressed by the detail of your study on compressible flow around an F-35 in ANSYS Fluent. Great job on achieving such accurate drag force calculations and providing insight into shock profiles and temperature variations. Keep up the fantastic work!

MR CFD Support –

Thank you so much for your kind words! We’re glad that you noticed the detail and accuracy of the compressible flow simulation around the F-35. Your recognition motivates us to keep providing high-quality CFD training sessions. If you have any more questions or need further assistance, don’t hesitate to reach out to us!

Alexys Zboncak –

The simulations taught me a lot, especially the part about monitoring the drag value for convergence. It really showed how critical it is to ensure accurate results in aerodynamic studies.

MR CFD Support –

Thank you for your feedback! We are thrilled to hear that our training on the F-35 Supersonic Compressible Flow CFD Simulation gave you valuable insights into convergence monitoring and aerodynamics. We strive to provide detailed and accurate simulations to enhance understanding and facilitate learning. If there are any other concepts or studies you’re interested in, don’t hesitate to explore more with us!

Laverna Kuhn IV –

I’m thoroughly impressed with your CFD course on the F-35 and how it captures the complexities of supersonic compressible flow. The detailed meshing process sounds like it set a solid foundation for accurate simulation.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you’re impressed with our F-35 compressible flow CFD course. Accurate simulation is indeed our priority, and a detailed meshing process is critical for capturing the complexities of such flows. Your feedback is highly appreciated!

Leopold Batz –

This course was an incredible resource for understanding supersonic flow around the F-35! The comprehensive approach to using high-fidelity CFD simulation shed light on critical areas like drag, shock profiles, and temperature gradients. I really appreciated the detailed explanation on how you achieved solution convergence and how you set up your meshing strategy with polyhedral conversion for accuracy enhancement.

MR CFD Support –

Thank you for your thoughtful review. It’s great to hear you found the explanations on convergence and meshing strategy valuable and that the course elements helped deepen your understanding of supersonic flows. Your positive feedback is greatly appreciated, and we’re thrilled to have been able to assist you with your learning journey!

Edwina Hamill DDS –

The F-35 simulation training was impressive. I’ve always been fascinated by supersonic aerospace dynamics and seeing how CFD tools like ANSYS Fluent can predict phenomena like shock waves and temperature gradients with such precision is remarkable. Kudos to the MR CFD team for creating such a detailed and practical learning product!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you enjoyed our F-35 supersonic CFD simulation training. It’s fantastic to know that our efforts in accurately simulating complex aerospace dynamics have provided valuable insights. We strive to deliver quality and detailed educational content, and your appreciation truly motivates us to keep producing excellent work. Thanks again for choosing and complimenting our products!

Prof. Patsy Greenfelder –

This training really opened up my understanding of supersonic flow behaviors, especially around such an advanced aircraft as the F-35. The visualization of shock waves and temperature distributions were particularly eye-opening!

MR CFD Support –

Thank you for your positive feedback! We’re glad that the training helped to enhance your understanding of supersonic flow and its complexities. It’s always rewarding to hear that our visualizations and simulations are providing clear and insightful information on such intricate topics.

Florian Macejkovic –

I’m really impressed by how in-depth the study of the F-35 jet’s simulated flight conditions is! The balance between accuracy and computational efficiency seems very well-managed.

MR CFD Support –

Thank you for your positive feedback! We strive to maintain that balance to provide reliable and efficient simulations. We’re glad to hear you found the study thorough and insightful.

Prof. Jerrod Stracke IV –

The drag coefficient is crucial in analyzing aircraft performance. Can I get some insights on how the drag coefficient was determined in this simulation?

MR CFD Support –

In this CFD simulation of the F-35 considering compressible flow, the drag coefficient was calculated based on the drag force obtained from the simulation results. The drag force, reported at 181.66 kN, was used along with the reference area of the aircraft and the dynamic pressure of the freestream flow to compute the drag coefficient. Since the flow is compressible and the aircraft is traveling at supersonic speeds, shock waves also play a significant role in the total drag, which is considered in the final computation of the drag coefficient.

Prof. Dusty Harvey –

Great resource to understand the aerodynamics involved with supersonic flight, specifically with a complex aircraft like the F-35. The level of detail in both the simulation setup and the results analysis was truly impressive. The visuals provided for the shock profile and temperature gradients were particularly helpful in comprehending the intricate behaviors of compressible flow at high speeds. Thank you for such comprehensive training material.

MR CFD Support –

Thank you for your positive review! We’re pleased to hear that our training material on the F-35 supersonic flow simulation has met your expectations and provided valuable insights. If you have further interests or questions regarding CFD simulations or other topics, feel free to explore our product range. We are always here to help you deepen your understanding and skills.

Ms. Hillary Emard II –

I was impressed with the comprehensive analysis of the F-35 considering compressible flow. This simulation captures essential flight characteristics exceptionally well. Great work!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the CFD simulation of the F-35 aircraft valuable and that it met your expectations for capturing flight characteristics. We appreciate your recognition of our efforts to provide a thorough and comprehensive analysis.

Lily Stoltenberg –

I’m very impressed with the detailed analysis that was provided and how the results were meticulously post-processed. The ability to observe the shock profiles and accurately calculate the drag force adds huge value, especially for such a complex aircraft like the F-35. The solvers’ reliability in achieving convergence with residuals below 10^-6 is commendable, and the use of polyhedral mesh for efficiency without compromising quality is a great approach.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that the detailed analysis and the meticulous post-processing of the CFD simulation for the F-35 met your expectations. Our teamwork hard to ensure accuracy and reliable results in our simulations. Your recognition of the efficient use of polyhedral mesh and the solver’s reliability means a lot to everyone here at MR CFD. If you ever have any more questions or need further assistance, feel free to reach out. Thank you for choosing our products, and we look forward to serving you again in the future.