Condensation inside a Shell and Tube Condenser

$160.00 Student Discount

- The problem numerically simulates the Condensation inside a Shell and Tube Condenser using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 342486.

- We use the Mixture Multiphase model to define water and vapor.

- We define a mass transfer by the evaporation-condensation method.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Condensation inside a Shell and Tube Condenser CFD Simulation, ANSYS Fluent Training

The present problem simulates the condensation process inside a shell and tube condenser using ANSYS Fluent software.

The process of condensation means the conversion of a fluid from a gaseous phase to a liquid phase; This means that when the liquid vapor reaches a saturation temperature, it turns into a liquid. The heat that causes a phase change between a liquid and a gas is called latent heat.

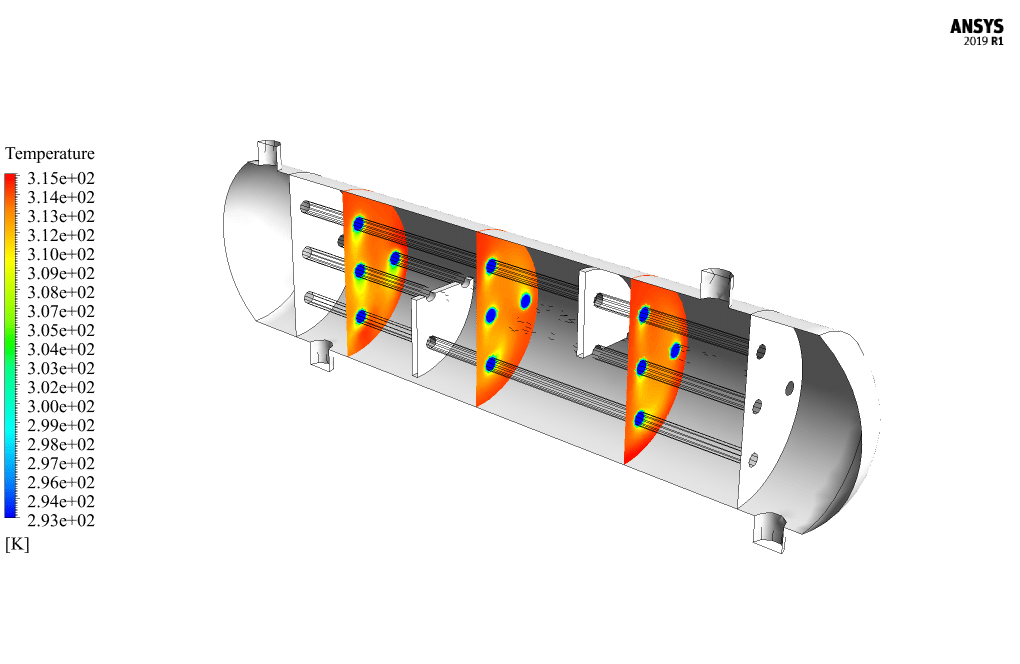

The saturation temperature for the condensation process occurrence is 46 ºC, and the time-frequency coefficient of this mass transfer is defined as 0.1.

In this modeling, the condensation occurs inside a shell and tube condenser. Thus, the flow of cooling water flows through the condenser pipes (tube) with a flow rate of 5 kg/s and a temperature of 20 ºC.

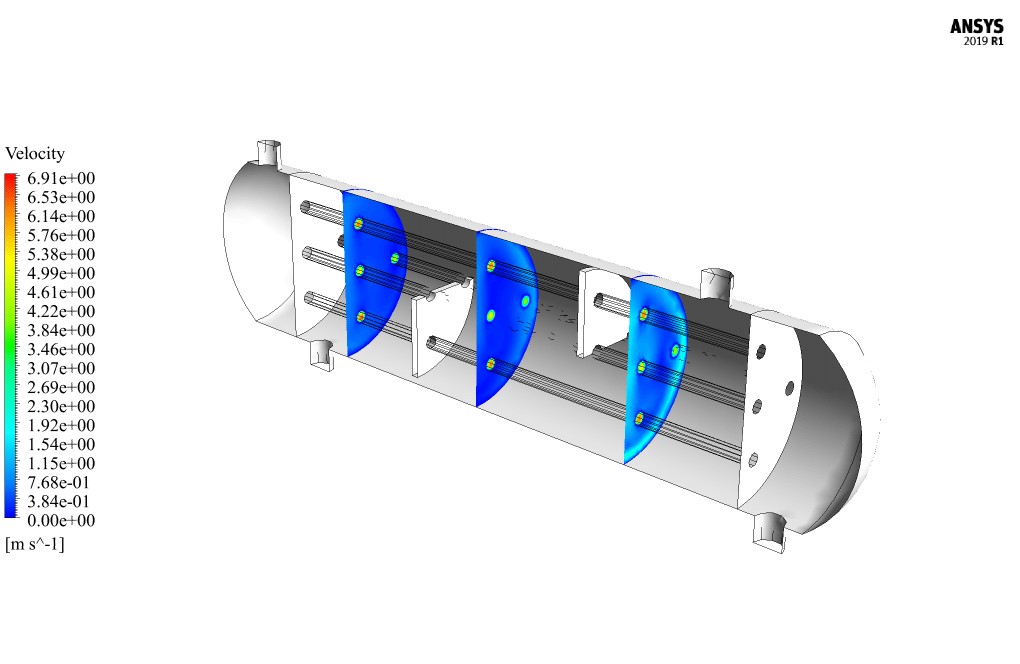

The flow of water vapor inside the shell’s interior with a speed of 10 m/s and in the saturation temperature is equivalent to 46 ºC.

Therefore, saturated steam undergoes a condensation process due to contact with the outer surface of the inner cold pipes, and its temperature drops to a temperature below the saturation temperature. As a result, liquid water is produced.

The present model is designed in three dimensions using Design Modeler software. The model is a shell & tube type condenser heat exchanger designed horizontally. A shell with two baffles is designed to carry hot water, and four rows of pipes are placed inside the shell to carry cold water.

Due to the symmetrical structure of the heat exchanger, the model is semi-drawn. We carry out the model’s meshing using ANSYS Meshing software. The mesh type is unstructured. The element number is 342486.

Condensation Methodology

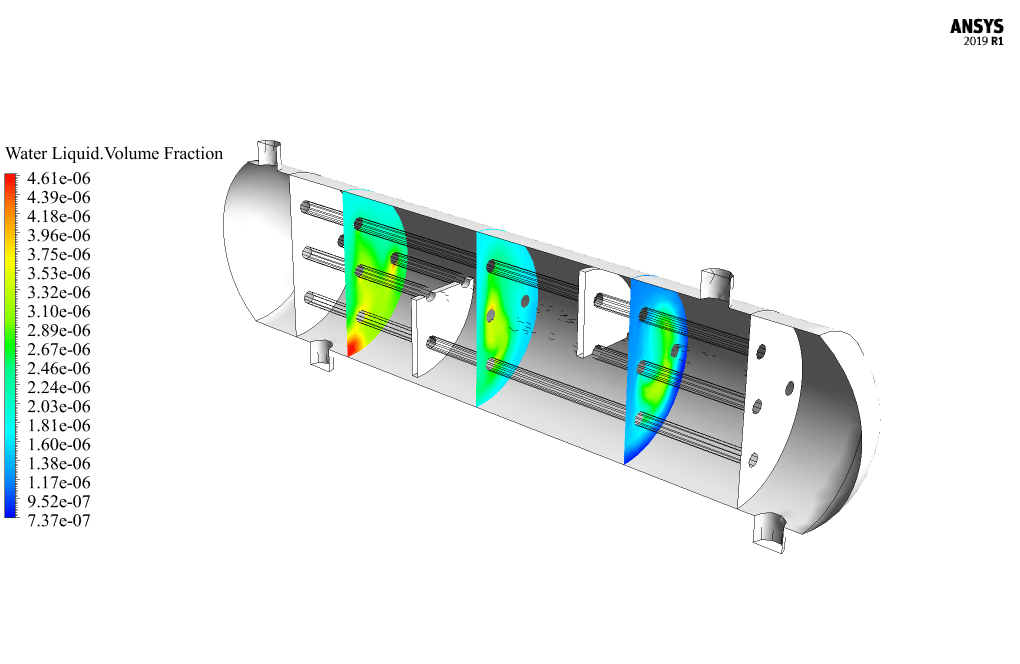

In this simulation, the vapor stream of saturated water is converted to liquid water at saturation temperature. Since two different phases occur in the solution process, it is necessary to define a multiphase flow.

For this simulation, a multiphase mixture model is used; Because the two phases of liquid water and water vapor are thoroughly mixed together. Also, to define condensation, a Mass Transfer in the form of evaporation-condensation must be defined.

Condensation Conclusion

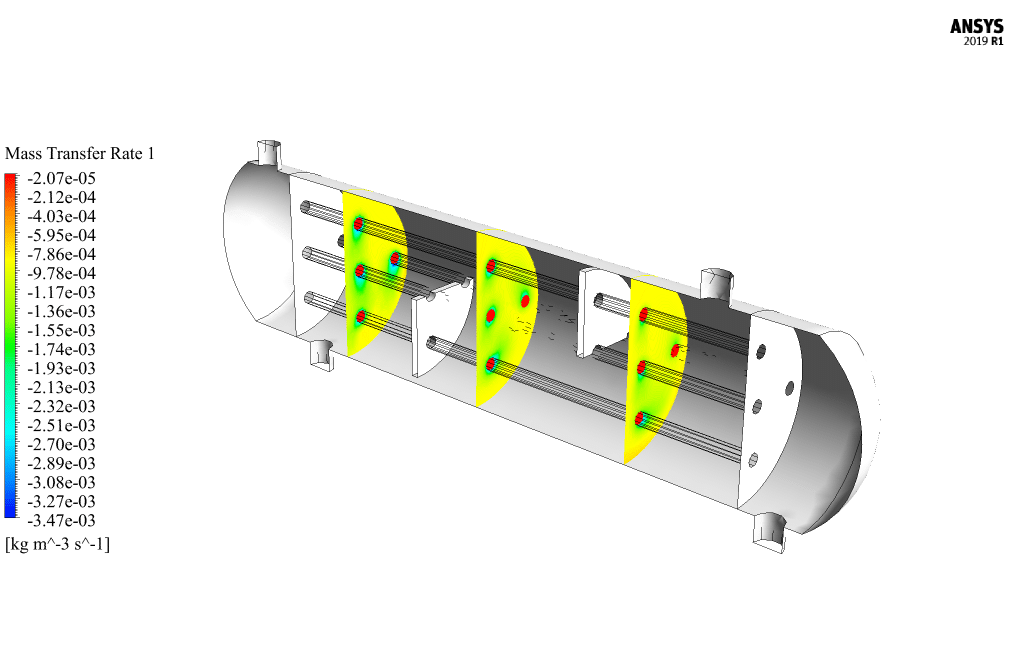

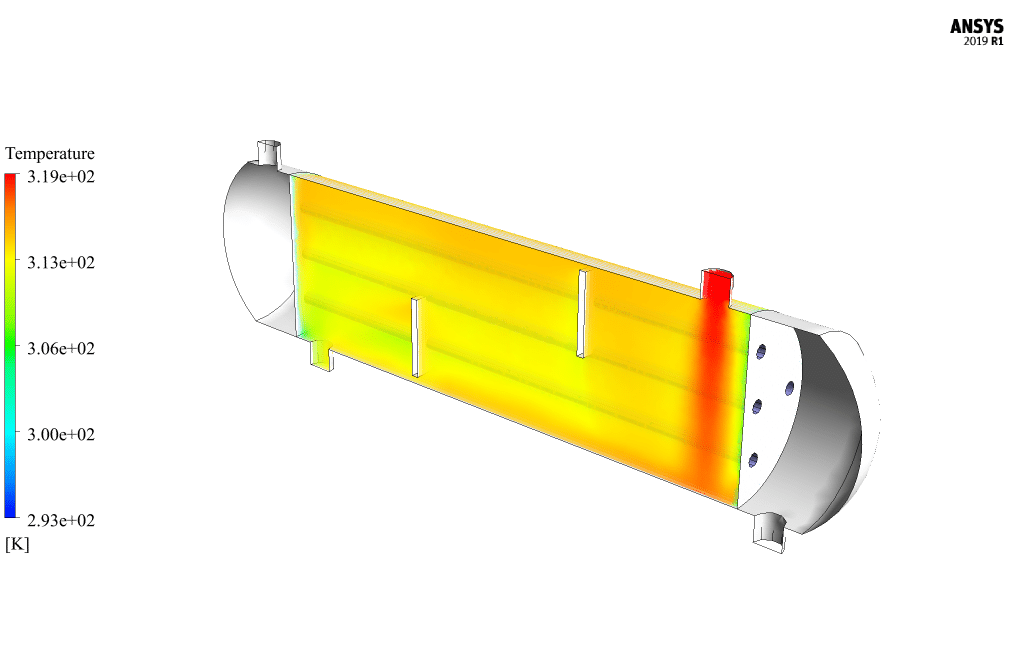

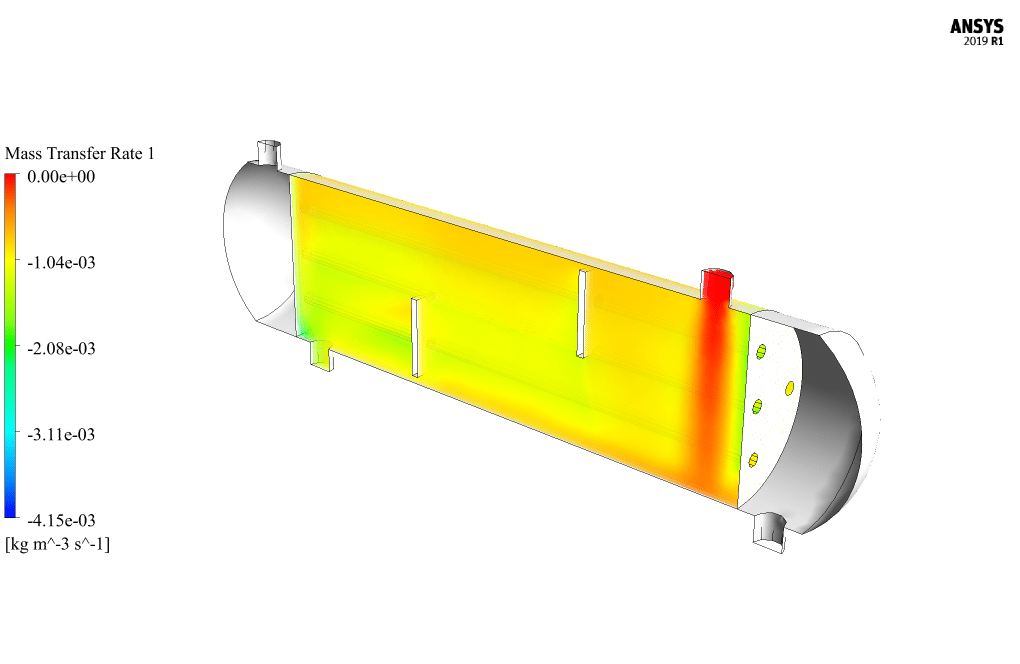

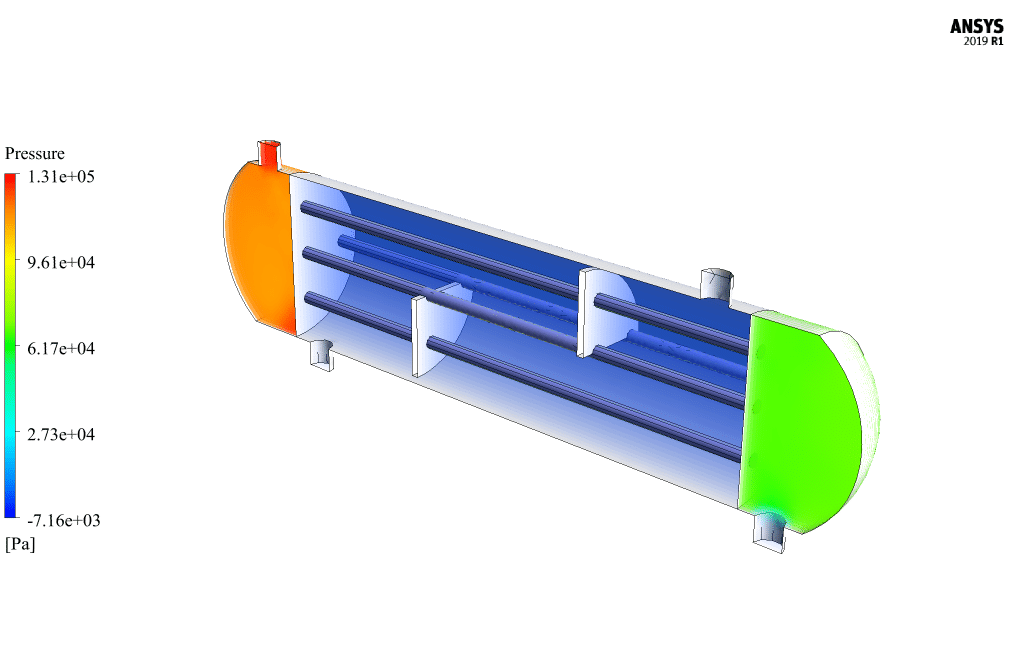

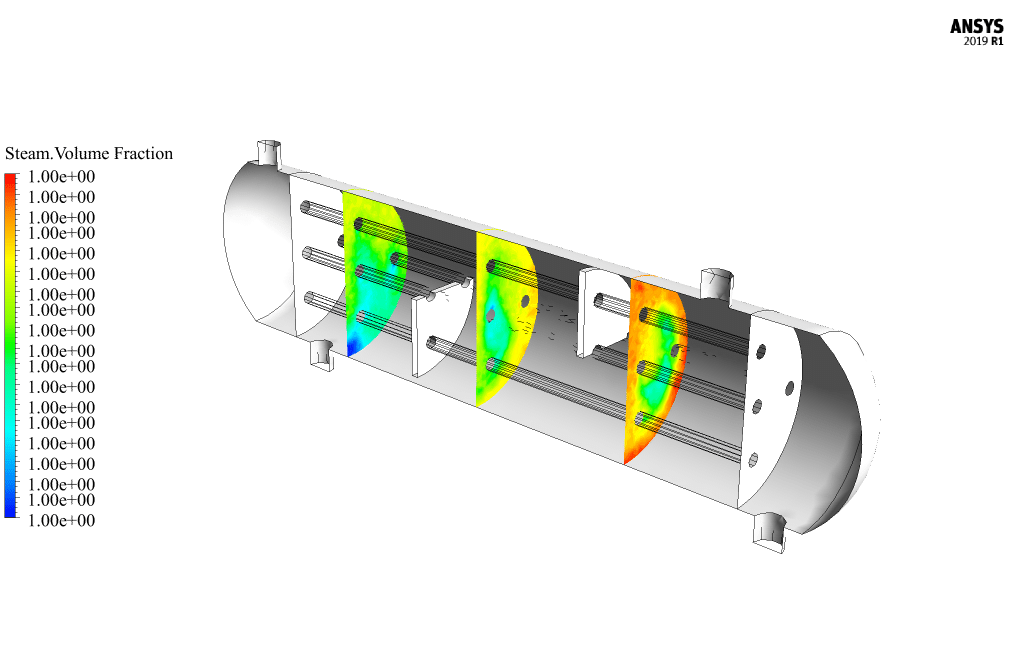

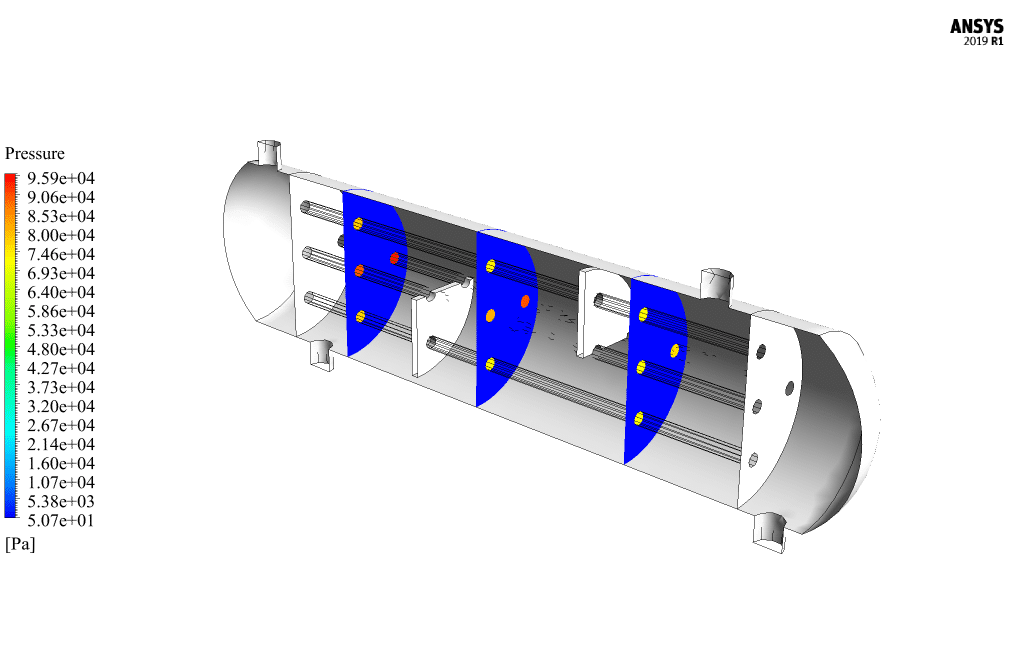

At the end of the solution process, two-dimensional and three-dimensional contours related to pressure, velocity, temperature, water vapor volume fraction, liquid water volume fraction, and mass transfer rate between water and steam or condensation are obtained.

After contact with the cold water pipes and heat transfer between the shell and the cold pipes, the contours show that the hot steam stream undergoes a temperature drop, and its temperature drops below the saturation temperature.

As a result, this process causes the phase change process, water vapor condensation, and water production in the condenser.

Devante Pacocha –

After using this training material, I have an improved understanding of the condensation process and how multiphase flow works within a shell and tube condenser. This has been a crucial learning stepping stone for my thermal engineering studies. Great content!

MR CFD Support –

Thank you for sharing your positive experience with our training material on the ‘Condensation inside a Shell and Tube Condenser’ CFD Simulation. We are thrilled to hear that it contributed to your understanding of thermal processes and multiphase flow. Your feedback is much appreciated, and we hope our products continue to support your educational journey in thermal engineering!

Angeline Schroeder –

I’m astounded by how detailed the simulation covers the condensation process within the shell and tube condenser. The explanation of the methodology and the concise conclusion show a depth that provides a real sense of confidence in the data provided. Great job!

MR CFD Support –

Thank you for the kind words and positive feedback on our simulation! We’re thrilled to hear that the detail and depth of the analysis met your expectations. It is our goal to provide accurate and comprehensive data that instills confidence in the results. If you have any more feedback or need further assistance, please don’t hesitate to reach out!

Ashtyn Christiansen –

I’m really impressed by the level of detail in the condensation process simulation within a shell and tube condenser. The explanation of how the saturation temperature and mass transfer are set makes it clear how the simulation predicts the performance of the condenser. It truly illustrates the power of CFD in optimizing cooling systems.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our detailed explanation on condensation process within a shell and tube condenser was clear and informative. We strive to deliver simulations that not only provide accurate predictions but also help in comprehending the complex physical phenomena involved in systems like condensers. If you have any more thoughts or need further insights, we’re here to help.

Arlene Nicolas V –

I am thrilled with how precisely the simulation captured the condensation process, and I can visibly understand the phase change dynamics through the contours shown. A job well done by the MR CFD team!

MR CFD Support –

Thank you for taking the time to leave such a positive review. We’re pleased to know that our simulation on the condensation process in a shell and tube condenser was able to clearly demonstrate the phase change dynamics and was helpful for your understanding. If you have any more feedback or need further assistance, we’re always here to help!

Prof. Jonatan Nader –

The training helped me master the condensation simulation, but I’m curious about the mass transfer coefficient applied—is 0.1 a common value for such simulations?

MR CFD Support –

The mass transfer coefficient is a procession-specific value that can vary depending on the scenario being simulated. In this case, the selection of 0.1 as the time-frequency coefficient for the condensation mass transfer process was likely determined on the basis of empirical data specific to the conditions of the shell and tube condenser in question, which is meant to recreate realistic scenarios. It is often necessary to refer general values from literature or run sensitivity analyses to determine the most accurate coefficient for the specific problem at hand.

Ms. Joannie Padberg –

This training module seems really comprehensive! It helped me get a solid grasp on the principles of condensation within a condenser system. Good job on offering such detailed explanations, making it easier to understand complex concepts.

MR CFD Support –

We’re thrilled to hear that our training module met your expectations and provided you with a clear understanding of the condensation process within a shell and tube condenser. Thank you for the positive feedback!

Madie Braun –

I’ve recently completed the ‘Condensation inside a Shell and Tube Condenser’ simulation using the ANSYS Fluent and I’m thoroughly impressed by the depth of the material. Your training made it possible for me to understand the complexities of dealing with multiphase flow and the condensation process. The structuring of the condenser model was challenging but rewarding, and seeing the temperature drop and condensation in my results was highly satisfying.

MR CFD Support –

We are delighted to hear that you are impressed with the simulation course and found our material in-depth and informative. It’s gratifying to know that the training helped you understand the intricacies of multiphase flow and condensation. Your realization of the temperature drop and condensation in your results is a testament to the intensive learning and simulation skills you’ve gained. Thank you for your positive feedback, and we wish you continuous success in your CFD endeavors!

Miss Pearlie Mills –

This product sounds comprehensive. The condensation demonstration within the shell and tube condenser shows an intricate process explained seamlessly through the simulation. Well done with the combination of theory and practical analysis!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that the simulation was explained seamlessly and that you recognized the effort to integrate theory with practical analysis. Your feedback is valuable to us, and we look forward to providing more quality CFD learning content.

Malinda Schmidt –

This training for simulating a shell and tube condenser in ANSYS Fluent has exceeded my expectations. The detailed explanations provided made it very clear how the condensation process and the mass transfer were set up and simulated. The temperature drop below saturation and the visualization of water production were especially helpful in understanding the effectiveness of such a heat exchanger.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our training on the shell and tube condenser simulation using ANSYS Fluent met your expectations and provided clear insight into the condensation process. It’s gratifying to know the detailed visualizations enhanced your understanding of the heat exchanger’s effectiveness. We appreciate you taking the time to share your experience.

Rickey Pagac –

I’m impressed with the level-of-detail in this study! Fantastic explanation of the condensation process in the shell and tube condenser. The methodology behind using a multiphase mixture model for accurately capturing the phase change is commendable. It’s clear that a lot of expertise went into this simulation.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you appreciated the in-depth analysis and methodology used in the Condensation inside a Shell and Tube Condenser simulation. Your feedback motivates us to continue delivering high-quality CFD simulation training. If you have any further questions or need more information, feel free to reach out.

Derick Orn –

The content and the methodology of this courseware seems incredibly detailed and competent. The step-by-step guide through the process of condensation inside a shell and tube condenser is laid out with clarity. Excited to apply this knowledge practically!

MR CFD Support –

Thank you for your kind words and enthusiasm! We are pleased to hear that you found the guide detailed and clear. It’s fantastic to know that our training materials are helping our customers to understand complex processes and encouraging practical application. If you have any further feedback or need more information, feel free to reach out. We’re here to help!

Luis Monahan –

What an engaging tutorial! The detailed explanation of the condensation process and methodology helped me understand the physical principles and ANSYS Fluent settings. The practical results like temperature and phase change contours are precisely what I needed to grasp for my project on industrial refrigeration systems. Thank you for an outstanding educational experience.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our training material was helpful and that it contributed positively to your project on industrial refrigeration systems. It’s always our goal to provide clear and useful content that aids in understanding complex simulations. If you have any further questions or need additional guidance in the future, please feel free to reach out.