Helical Blade Wind Turbine, 5 different RPMs

$140.00 Student Discount

- The problem numerically simulates Helical Blade Vertical Axis Wind Turbine using ANSYS Fluent software.

- This project investigates TSR (tip speed ratio) using different rotational speeds for blade turbines.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the polyhedral element number equals 507457.

- We perform this simulation as unsteady (Transient).

- We use the Mesh Motion method to define rotational motion in the distinct zone around blades.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Helical Blade Vertical Axis Wind Turbine (Small Scale), 5 different RPMs, ANSYS Fluent Training

Description

The present problem simulates the airflow passing over a small-scale VAWT with helical blades using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

Wind energy is one of these energies that has presented various choices to researchers. This energy currently has the fastest growth rate among other renewable sources. The devices used to generate wind energy are called wind turbines.

A wind turbine is a device that converts the kinetic energy of the wind current into the rotational energy of the rotor shaft.

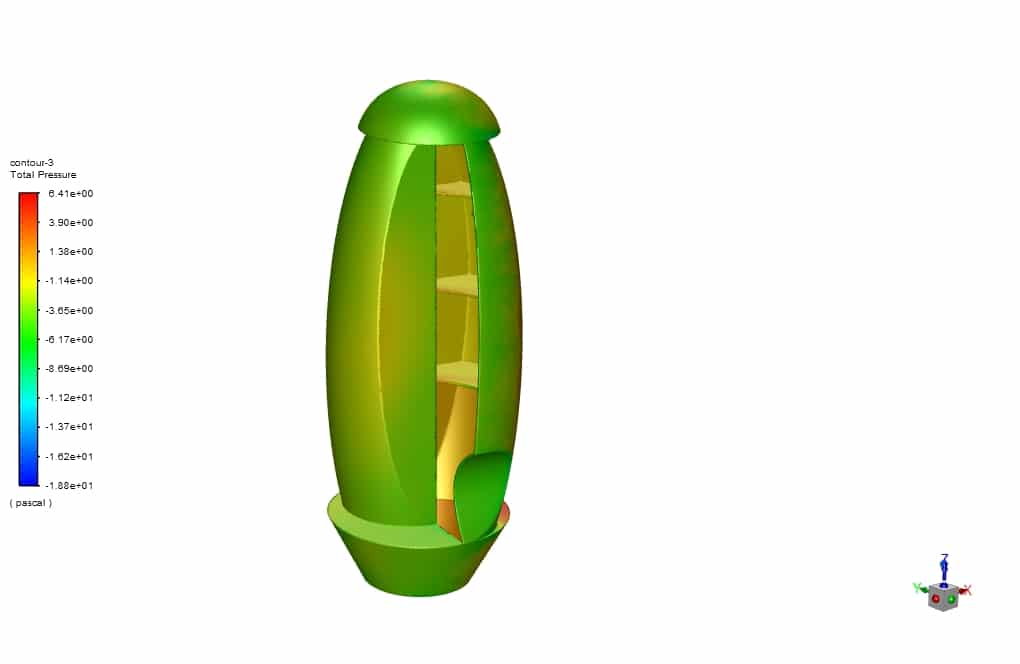

The present model is designed in three dimensions using SOLIDWORKS and imported into the Design Modeler software and consists of a helical blade VAWT placed inside a rectangular domain.

The meshing of the model was done using ANSYS Meshing software first to generate a tetrahedral mesh, and then using the Fluent meshing software, the tetrahedral mesh generated for the wind turbine was converted to polyhedral mesh with fewer cells and better quality.

The element number is equal to 2457591 tetrahedral or 507457 polyhedral. Also, due to the nature of the present problem, the transient solver has been enabled.

VAWT Methodology

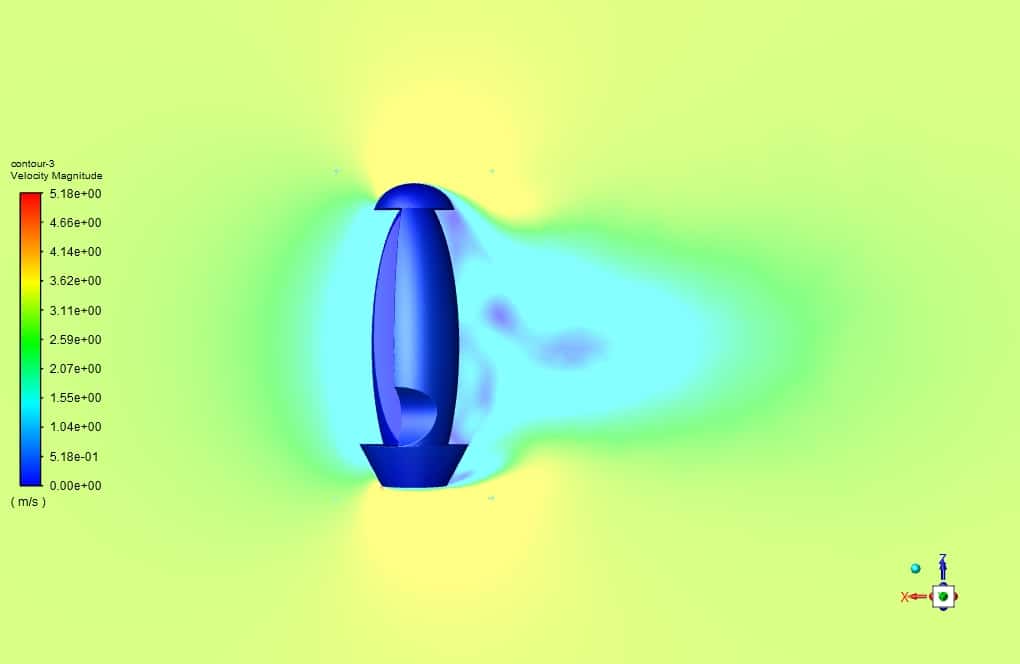

This project aims to simulate a wind turbine with dimensions of 10 x 20 cm and an average diameter of 7 cm in the present problem using ANSYS Fluent software. This simulation was performed at a wind velocity of 2 m/s and rotating speeds of 60-40-80-100-120 rpm, and torque was reported as output.

Small-scale wind turbines can be used in such subways and tunnels and spaces where there is a lot of wind production, but the dimensions of the environment are limited. They should be tested at different speeds to determine the generator for wind turbines. This process is related to different TSRs (Tip Speed Ratio).

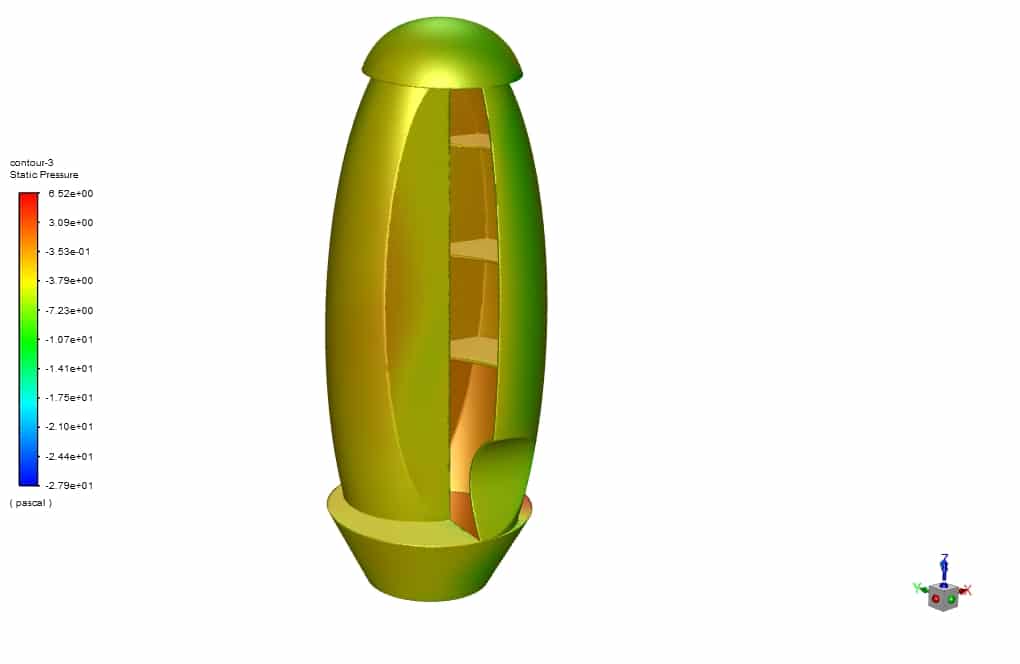

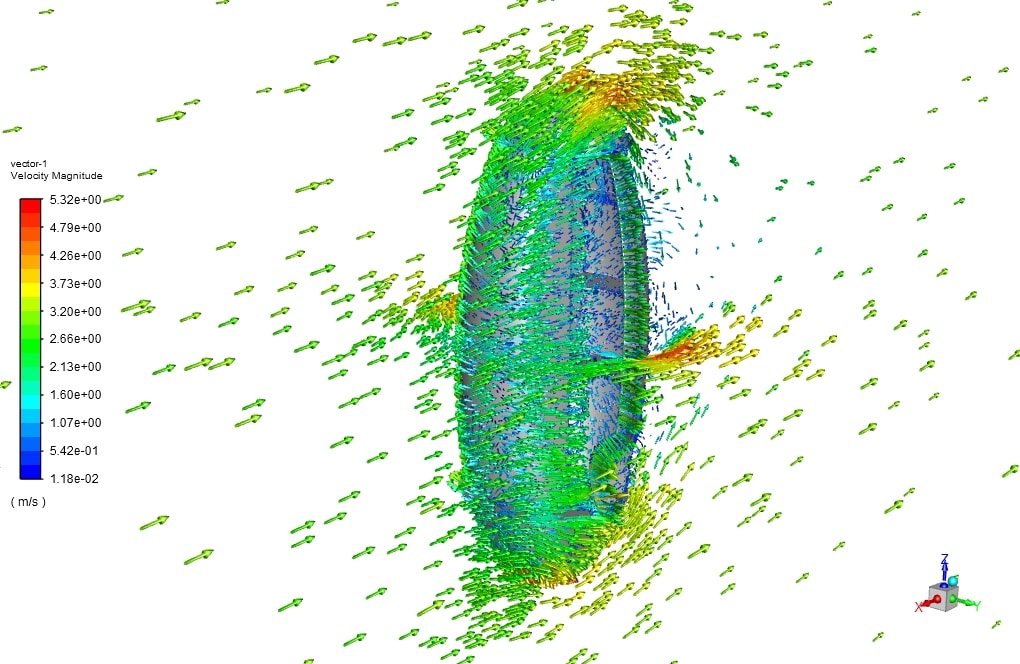

The rotational computational domain must rotate around the blade axis using the Mesh Motion method to model the helical blade. Due to the greater importance of the turbine in the problem results, it is preferable to mesh the rotational zone around the blades with finer elements.

The cylindrical rotational computational domain around the turbine helical blade with a diameter of 1.12 is considered. The meshing is done more accurately in this domain.

The rotational domain is separated using interface surfaces that transfer values between the two domains. Moreover, the standard k-epsilon model is used to solve turbulent fluid equations.

VAWT Conclusion

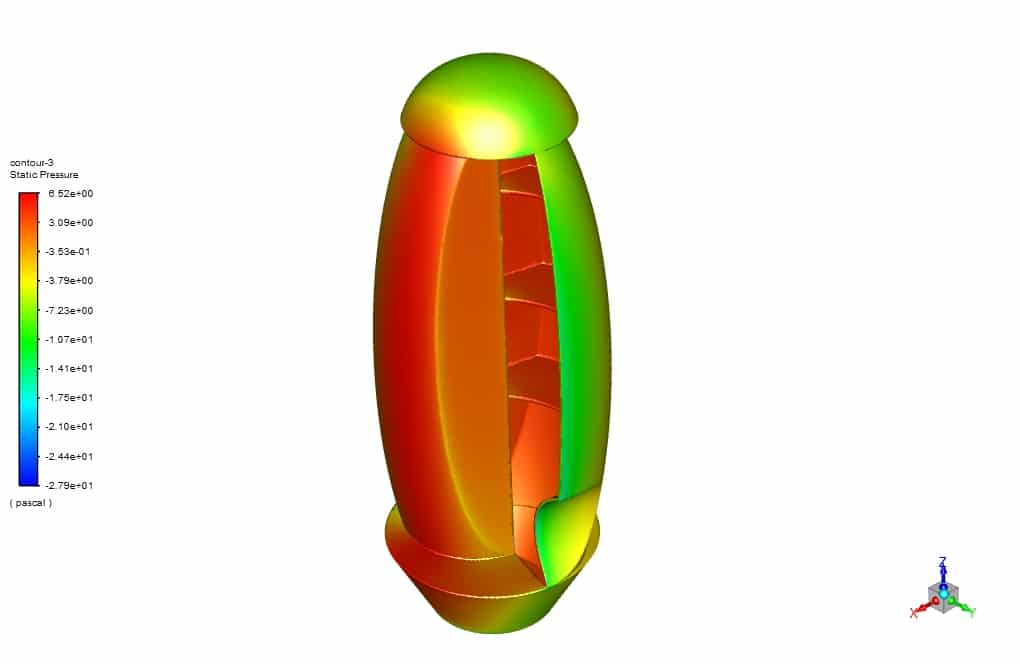

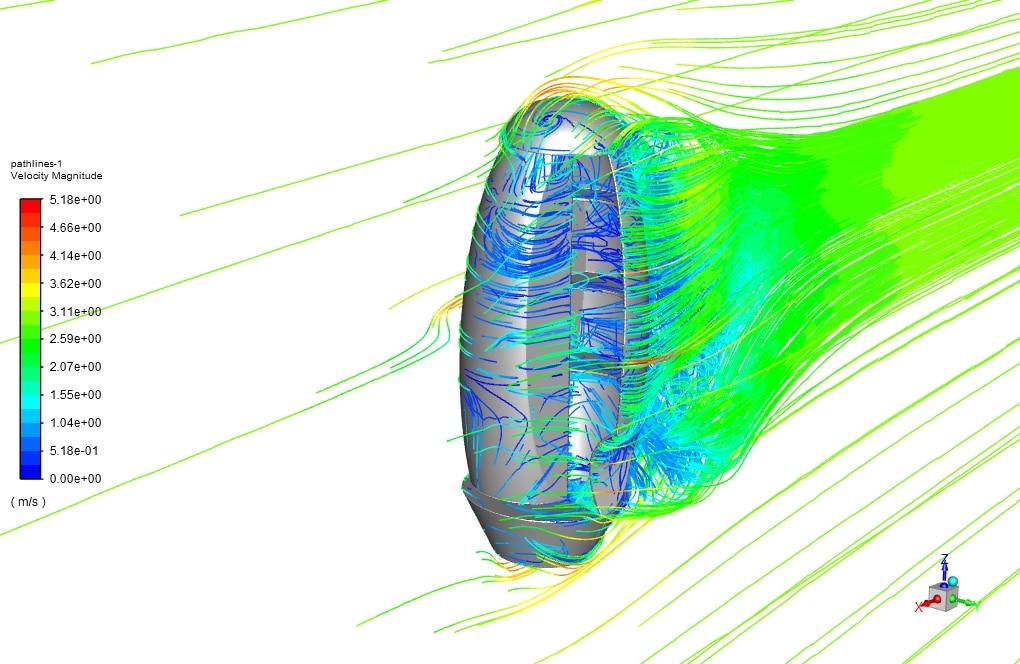

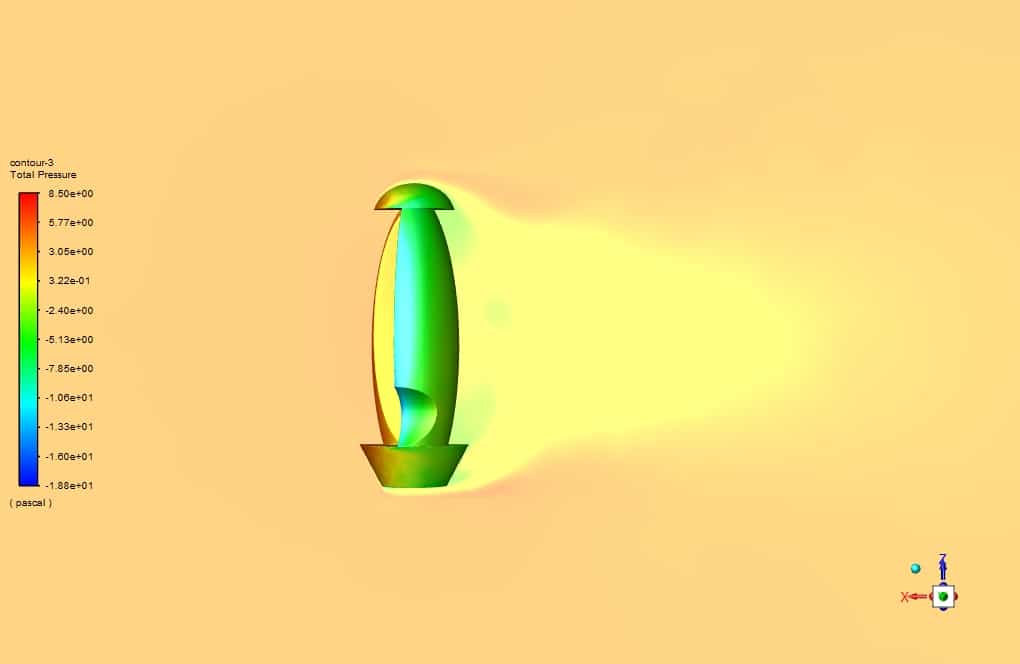

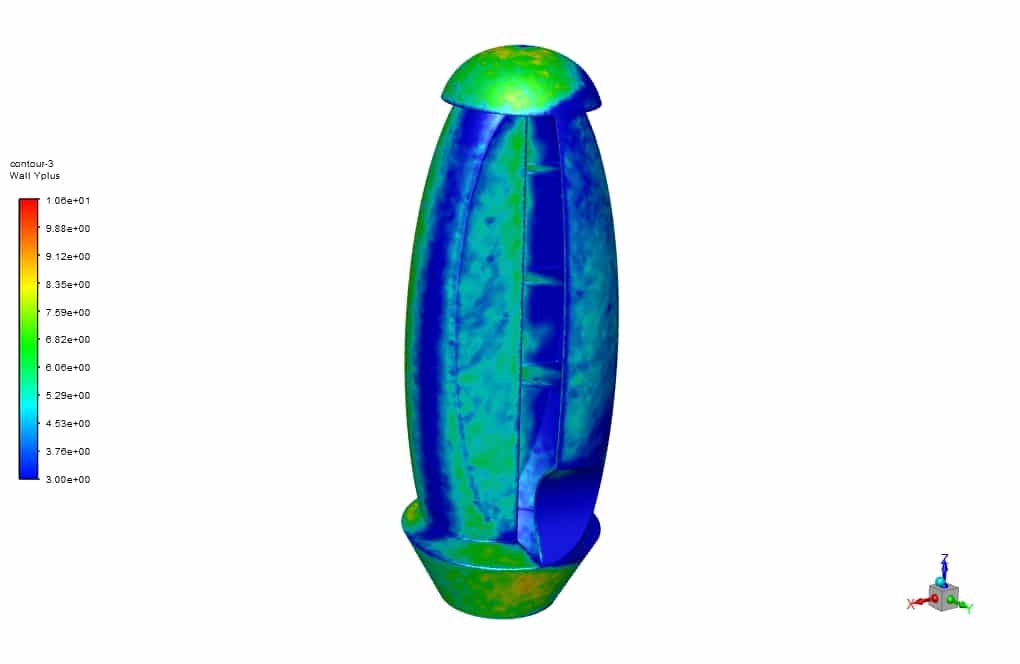

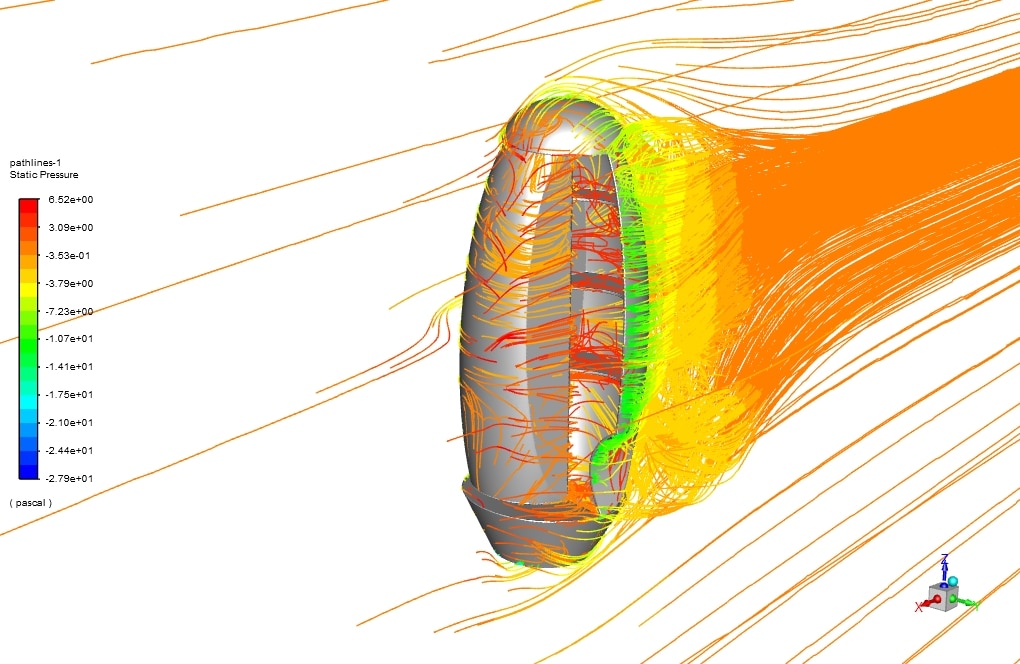

At the end of the solution process, two-dimensional and three-dimensional contours related to pressure, velocity, and streamlines are obtained. As seen in the pressure contour, the stagnation point is obvious in the frontal area of the helical blade turbine.

Furthermore, a wake region occurs at the back region of the turbine due to the flow separation. Also, using the Fluent itself, it has been calculated how much torque power the turbine can transfer to the generator as output.

These results show that at 80 rpm, this turbine can transmit the most torque. However, if we do this test with the TSR criterion, this turbine has the highest torque at TSR = 0.46. Therefore, to design this turbine, the angles of attack and profiles must be designed so that the wind turbine can be close to the distance at TSR = 0.46.

In the next step, the performance of this turbine can be examined at different operating points according to TSR, for example, at a constant rotational speed of different flow velocities. In this way, it is possible to identify the working points with the maximum performance for the turbine, which is the maximum torque.

Reviews

There are no reviews yet.