Intake of Jet Engine CFD Simulation by ANSYS Fluent Tutorial

$60.00 Student Discount

- The problem numerically simulates airflow in Jet Intake using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 389136.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates the airflow in a three-dimensional Jet Intake using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The present model is designed in three dimensions using Design Modeler software. The model’s geometry includes a cylindrical computational domain where the jet intake is placed.

The meshing of this present model has been generated by Ansys Meshing software. The total cell number is 389136.

Intake Methodology

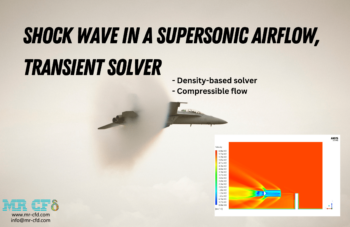

In this project, ANSYS Fluent software investigates steady airflow in a three-dimensional jet intake. Jet engines are one of the aerodynamic primaries and most commonly used thrusters. Jet engines, including the intake section similar to the present work, are used for subsonic and supersonic flows.

In subsonic flows, the flow velocity is higher than free stream velocity inside the intake domain, while in supersonic flows, the flow Mach number increases inside the intake domain. Intake is the first section through which incoming air flows to the engine.

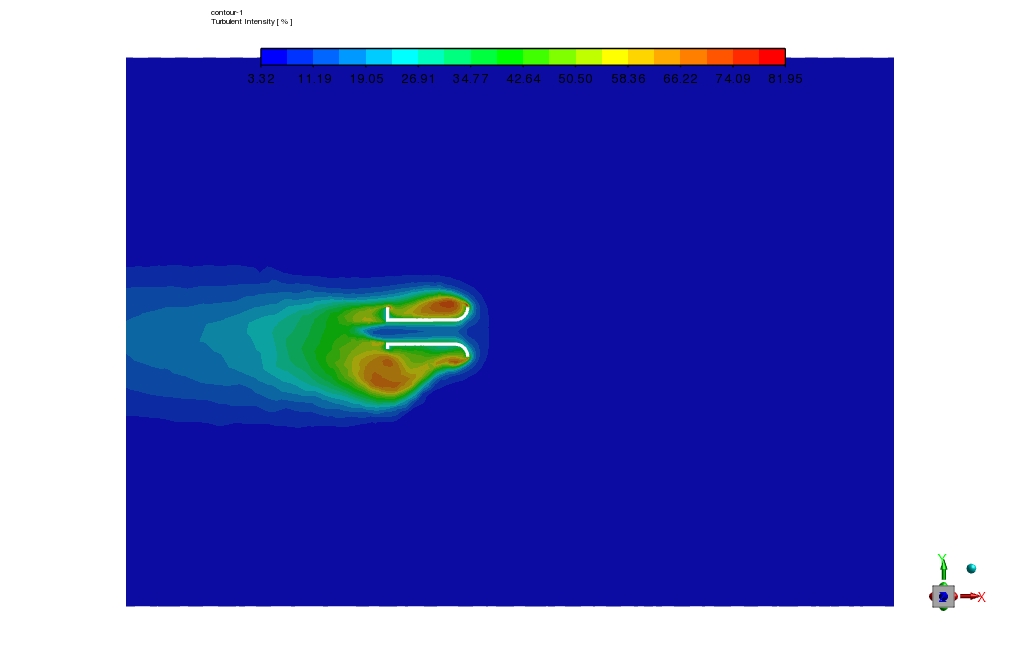

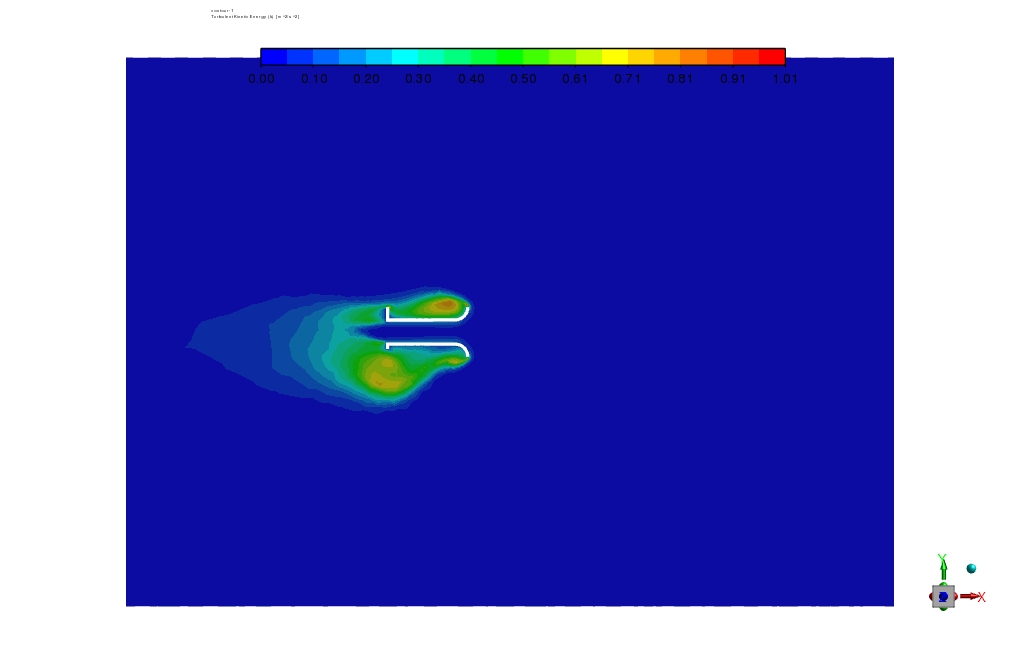

Intake geometry decreases and increases the cross-section to make the airflow uniform. In this project, air flows into the domain with a velocity of 3.55 m/s. Moreover, the standard k-epsilon model is used to solve turbulent fluid equations.

Intake Conclusion

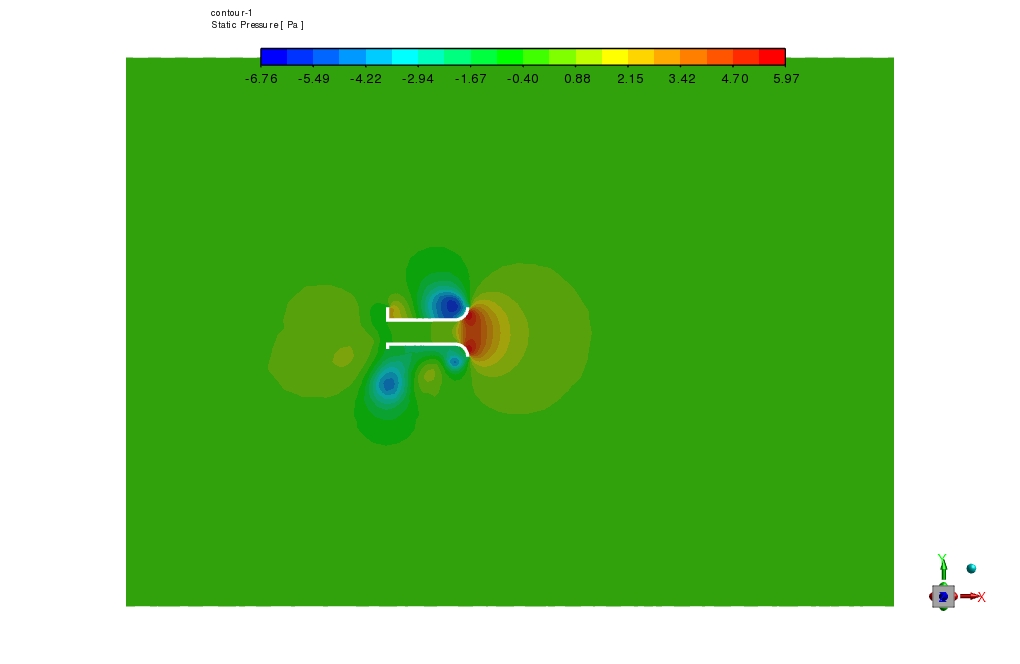

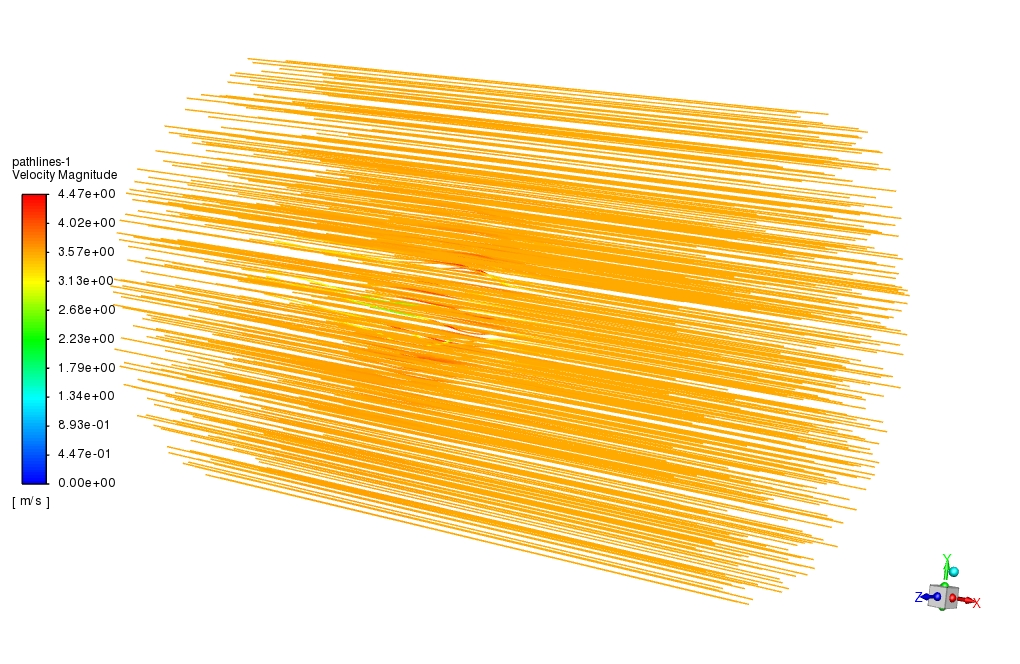

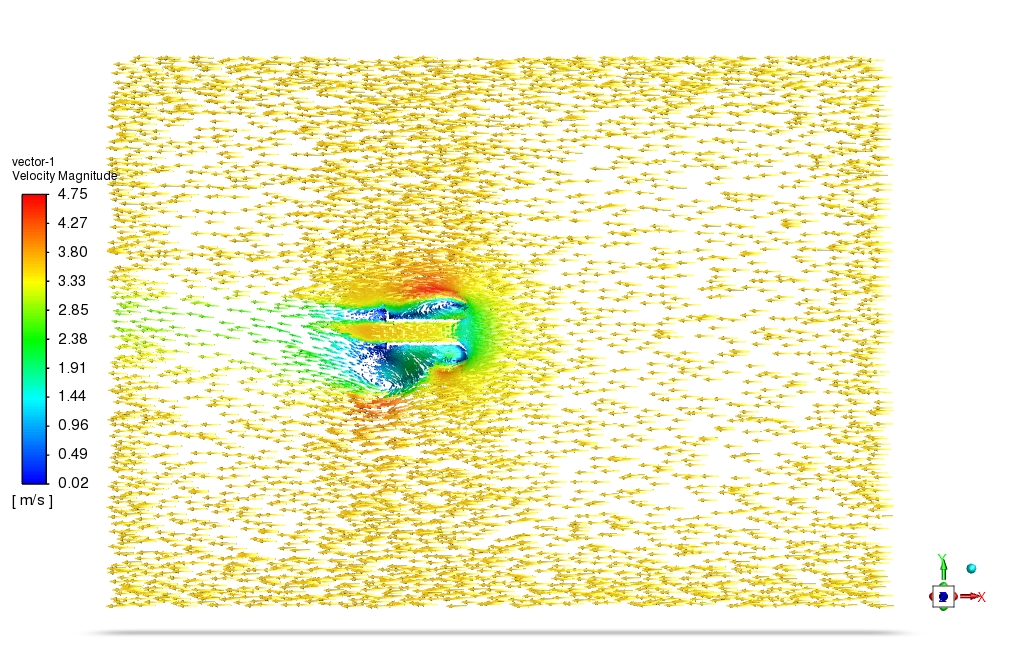

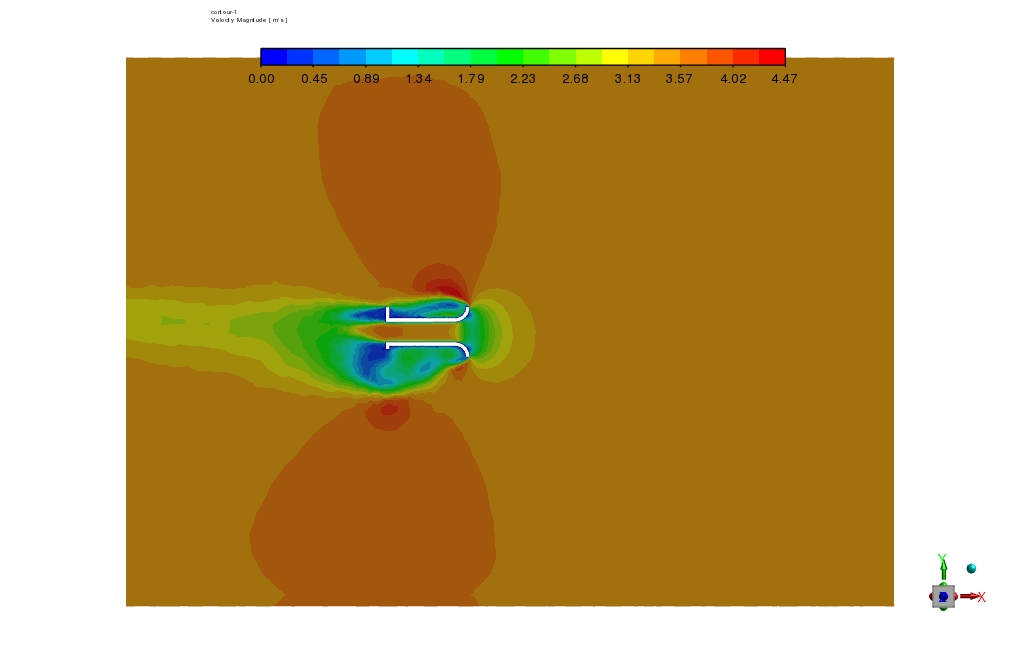

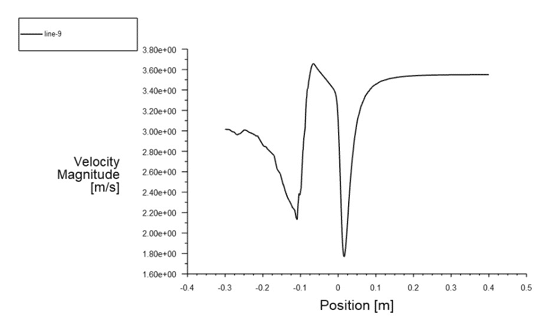

At the end of the solution process, two- and three-dimensional contours related to pressure, velocity, streamlines, and velocity vectors are obtained. Furthermore, based on the data calculated using the Fluent software, the air mass flow rate in the intake domain is equal to 0.02525548 kg/s.

Due to a sudden decrease in the cross-section of fluid flow, velocity inside the intake reaches higher magnitudes equal to 3.6 m/s. Before entering the intake domain, airflow pressure reaches higher values equal to 5.96 Pa due to the sudden decrease in flow cross-section.

Emery Lubowitz –

How can I get started with using this simulation?

MR CFD Support –

ou can purchase this simulation directly from our website. After purchase, you’ll receive a download link along with detailed instructions on how to set up and run the simulation.

Rosemarie Monahan –

Can this simulation be extended to model the entire jet engine?

MR CFD Support –

While the current simulation focuses on the intake, it can be extended to model other components of the jet engine. We are open to contributions and can accommodate your desired simulations.

Mr. Art Keeling DDS –

The tutorial for the jet engine intake simulation was terrific! The visuals made it much easier to understand the airflow dynamics.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our tutorial on jet engine intake simulation was helpful and that the visual aids provided better clarity on airflow dynamics. If you have any further questions or need more assistance, feel free to reach out.

Mr. Alvis Gaylord IV –

I just want to say that the provided material for the ‘Intake of Jet Engine CFD Simulation by ANSYS Fluent’ was incredibly helpful. The step-by-step instructions and the explanations made complex concepts much easier to understand. Thank you for such a comprehensive tutorial!

MR CFD Support –

We are delighted to hear that you found the ‘Intake of Jet Engine CFD Simulation by ANSYS Fluent’ tutorial helpful and that it made CFD concepts clearer for you. We strive to create content that is engaging and educational for our users. Thank you for your positive feedback, and we appreciate your support!

Colten O’Hara –

Fantastic tutorial on the jet engine intake simulation. The step-by-step guidelines made it super easy to follow and it was enlightening to see the impact of geometry on airflow. The level of detail provided in the discussion of the velocity and pressure changes was much appreciated. Can’t wait to apply these principles in my own simulations.

MR CFD Support –

Thank you for your positive feedback on the jet engine intake CFD tutorial! We’re really glad that you found the step-by-step instructions clear and helpful. It’s great to hear that the detail provided on velocity and pressure changes was enlightening for you. We appreciate your eagerness to apply what you’ve learned to your own work and we’re happy to know our tutorial has been beneficial. If you ever have questions while conducting your own simulations or need further assistance, feel free to reach out to us.

Jamar Nitzsche –

This tutorial made the Jet Engine Intake CFD Simulation process so transparent and understandable. It wonderfully covered all the steps and the use of different Fluent features to achieve the results was really well-explained.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found our tutorial clear and informative. Existing customers who apply what they’ve learned from our tutorials make all the effort worthwhile. We appreciate your feedback!

Max Gleason –

This tutorial was a comprehensive view into jet engine intake simulation. Great for beginner and intermediate levels. The step-by-step approach really made complex concepts understandable. Thank you!

MR CFD Support –

We’re glad to hear that you’ve found the tutorial comprehensive and helpful! Thanks for taking the time to provide your positive feedback. If you need further assistance or have more questions in the future, feel free to reach out.

Lorna Leffler –

Awesome simulation tutorial for the jet engine intake! The step-by-step approach really made understanding the computational flow dynamics much easier. Thank you, MR CFD, for such a well-prepared guide.

MR CFD Support –

We’re thrilled to hear that you found the jet engine intake simulation tutorial to be helpful and easy to follow. Thank you for your kind words! At MR CFD, we strive to create foundational resources that inspire and educate our users. If you have further questions or need additional help, please don’t hesitate to reach out.

Darrell Daugherty –

The tutorial for the Jet Engine CFD simulation was a hit! It was easy to follow and understand, particularly knowing how the geometry influences the flow behaviour within the intake. Nicely done!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our tutorial was not only informative but also user-friendly. It’s great to see you appreciating the details on intake geometry and flow dynamics. If there’s anything more you’d like to learn about or any other feedback you have, don’t hesitate to reach out.

Paolo Hills –

I found the detailed explanation on the airflow simulation in a jet engine intake very informative; the simulation approach gives a clear idea of what to expect in real-life jet engine operation. The results obtained also read like they provide critical insights into understanding the importance of intake design.

MR CFD Support –

Thank you very much for your kind words and recognition of our CFD simulation tutorial for a Jet Engine Intake. We’re glad you found the information and our approach informative and insightful. We strive to provide thorough and realistic insights to aid in the understanding of aerodynamics and intake design. Your feedback is greatly appreciated!

Edd Labadie –

I’m truly fascinated by the level of detail in the simulation of the jet engine intake. The use of the standard k-epsilon model for turbulence and the specific attention to the change in flow velocity and pressure across the intake section must provide invaluable insights for engineering applications. Great work!

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the detailed simulation and analysis of the jet engine intake both fascinating and informative. We take great pride in providing in-depth CFD analysis to assist our customers in better understanding complex aerodynamic systems. Your positive feedback is greatly appreciated!

Torrance Effertz –

How computationally intensive is this simulation?

MR CFD Support –

The computational intensity of the simulation depends on several factors, including the complexity of the geometry, the number of cells in the mesh, and the turbulence model used. However, ANSYS Fluent is highly optimized for CFD simulations and can efficiently handle large, complex simulations.

Ellis Kunde –

Absolutely loved the ‘Intake of Jet Engine’ CFD simulation tutorial by MR CFD Company! The step-by-step guide was clear and concise, making the learning process smooth even for complex topics like jet engines and intake flows. The insights on how changes in the intake’s cross-section influence air velocity and pressure were particularly fascinating. Kudos to MR CFD for creating such a high-quality tutorial!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that our ‘Intake of Jet Engine’ CFD simulation tutorial was helpful and insightful. At MR CFD, we strive to provide clear and in-depth learning materials to help our customers understand and apply CFD analysis in practical scenarios. We appreciate your compliment and are glad we could contribute to your learning journey!

Jettie Metz –

This tutorial was incredibly detailed and useful! It greatly helped me understand the airflow in jet engine intakes for both subsonic and supersonic conditions.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the tutorial provided you with a comprehensive understanding of jet intake airflow and that you found it helpful for learning about the aerodynamic concepts in engine intakes.

Mr. Kurt Mayer Sr. –

I bought this tutorial recently. All instructions were clear, and the end results were very satisfying! Watching the flow inside the intake was fascinating, and analyzing the velocity magnitudes gave me a deeper understanding of jet engines.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear you were satisfied with the tutorial and that it provided you with valuable insights into jet engine intake flows. If you need any further assistance or have more questions in the future, feel free to reach out to us!