Mixer CFD Simulation Training Package: 5 Projects by ANSYS Fluent

$299.00 $119.60 HPC

- Powder Distribution in Mixer – Master transient Eulerian multiphase simulation with mesh motion to model powder behavior in a rotating propeller mixer at 30 rpm.

- Six Blade Stirring Mixer – Learn to simulate complex geometries using Multiple Reference Frames (MRF) with the Mixture model and k-ε turbulence for steady-state analysis.

- Nanofluid Porous Mixer – Enhance heat transfer simulation skills by modeling nanofluids with modified properties through porous media in a 3D SpaceClaim design.

- Mixer Tank Simulation – Develop expertise in VOF multiphase modeling with three distinct phases (air, water, salt) using Frame Motion for impeller rotation.

- Side Entry Mixing Tank – Conduct comparative analysis of mixing performance at different rotational speeds to optimize industrial mixing applications.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Mixer CFD Simulation Training Package: 5 Projects by ANSYS Fluent

Master Advanced Mixing Simulation Techniques with ANSYS Fluent

Elevate your CFD skills with our comprehensive Mixer CFD Simulation Training Package featuring five detailed projects using ANSYS Fluent. Whether you’re an engineer, researcher, or industry professional, this hands-on training will equip you with the expertise to simulate complex mixing processes across various applications.

What You’ll Learn in This Training Package

This specialized training package guides you through increasingly complex mixer simulations, covering essential aspects of computational fluid dynamics in mixing applications:

- Multiphase modeling techniques for powder-liquid interactions

- Rotating machinery simulation using MRF and mesh motion approaches

- Heat transfer enhancement strategies in mixing applications

- Turbulence modeling for accurate flow prediction

- Parametric analysis to optimize mixer performance

Detailed Project Descriptions

Project 1: Powder Distribution in Mixer, Transient CFD Simulation

This comprehensive project focuses on simulating powder distribution in a stationary fluid after mixing using ANSYS Fluent’s advanced multiphase capabilities:

- Geometry and Mesh Development: Create a mixer tank with rotating propeller in ANSYS SpaceClaim and generate a high-quality mesh of 657,330 cells using ANSYS Meshing

- Transient Analysis Setup: Configure time-dependent simulation parameters for accurate temporal evolution

- Eulerian Multiphase Modeling: Implement the Eulerian approach with granular options for realistic powder behavior

- Dynamic Mesh Motion: Model propeller rotation at 30 rpm to capture realistic mixing dynamics

Project 2: Six Blade Stirring Mixer CFD Simulation

Master the simulation of complex stirring mechanisms with this six-blade mixer project:

- Advanced Geometry Handling: Design and work with complex six-blade configurations in DesignModeler

- High-Resolution Meshing: Generate and manage unstructured meshes with over 5.4 million cells for accurate results

- Mixture Multiphase Modeling: Implement the Mixture model for efficient multiphase simulation

- Multiple Reference Frames: Apply MRF techniques for steady-state analysis of rotating impeller systems

- Turbulence Modeling: Utilize the k-ε model for accurate turbulent flow prediction

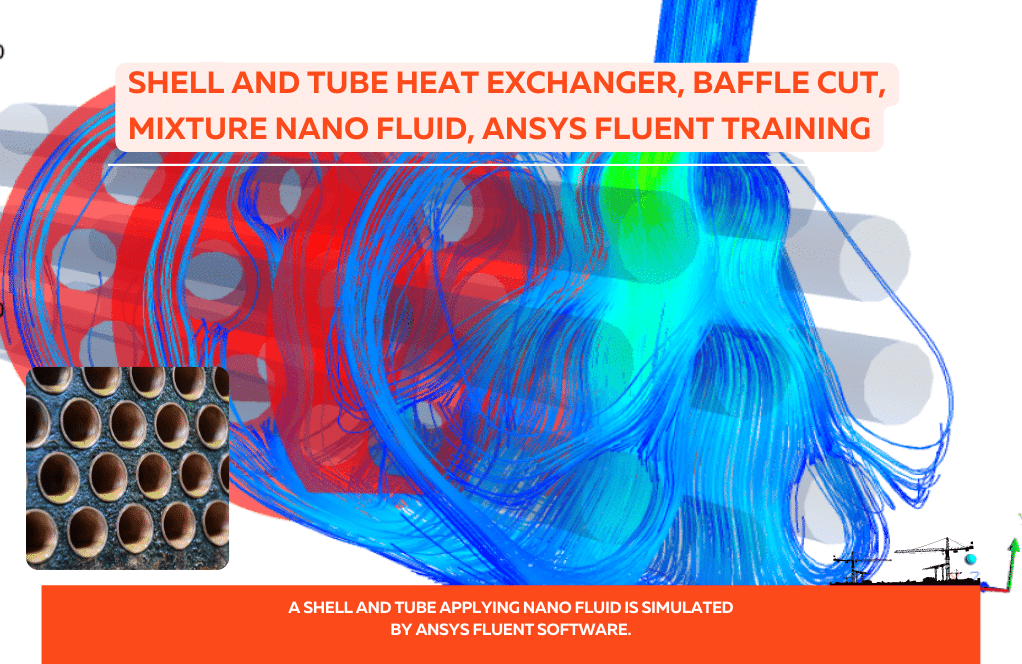

Project 3: Nanofluid Porous Mixer for Heat Transfer Enhancement

Explore cutting-edge applications combining nanofluids and porous media for improved heat transfer:

- 3D Modeling in SpaceClaim: Create geometries specifically designed for heat transfer applications

- Nanofluid Property Modeling: Implement modified thermophysical properties to accurately represent nanofluids

- Porous Media Configuration: Configure cell zone conditions for porous regions to simulate flow resistance

- Thermal Performance Analysis: Evaluate heat transfer enhancement strategies and optimization techniques

Project 4: Mixer Tank CFD Simulation with Multiple Phases

Develop expertise in complex multiphase mixing simulations:

- Design Modeler Workflow: Create mixer tank geometries using ANSYS Design Modeler

- Efficient Meshing Strategies: Generate optimal meshes with 152,641 elements for accurate yet efficient computation

- VOF Multiphase Implementation: Configure the Volume of Fluid model for three distinct phases (air, water, and salt)

- Frame Motion Technique: Apply frame motion methodology to simulate impeller rotation

Project 5: Side Entry Mixing Tank at Different Rotational Speeds

Complete your training with this comparative analysis project:

- Parametric Study Setup: Configure and execute simulations at multiple rotational speeds

- Performance Comparison: Analyze and compare mixing efficiency across different RPM settings

- Flow Pattern Visualization: Develop advanced post-processing techniques to visualize complex flow structures

- Industrial Application Analysis: Draw practical conclusions for real-world implementation

Who Should Enroll in This Training Package

- Process Engineers seeking to optimize mixing operations

- R&D Professionals developing new mixer designs

- CFD Specialists expanding their simulation capabilities

- Graduate Students focusing on fluid dynamics and mixing technology

- Industry Consultants working on mixing-related challenges

Technical Requirements and Prerequisites

- Basic understanding of fluid dynamics principles

- Familiarity with ANSYS Workbench environment

- Access to ANSYS Fluent (2019 R2 or later recommended)

- Computer with suitable specifications for CFD simulation (16GB RAM minimum)

Transform your approach to mixer design and optimization with this comprehensive CFD training package. Gain hands-on experience with industry-standard software and develop the skills to tackle complex mixing challenges with confidence!

You must be logged in to post a review.

Reviews

There are no reviews yet.