Non-Return Valve (Dynamic Mesh), CFD Simulation ANSYS Fluent Training

$120.00 Student Discount

In this project, which has been done by the CFD simulation method with the help of Ansys Fluent software, a non-return valve is simulated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Non-Return Valve Project Description

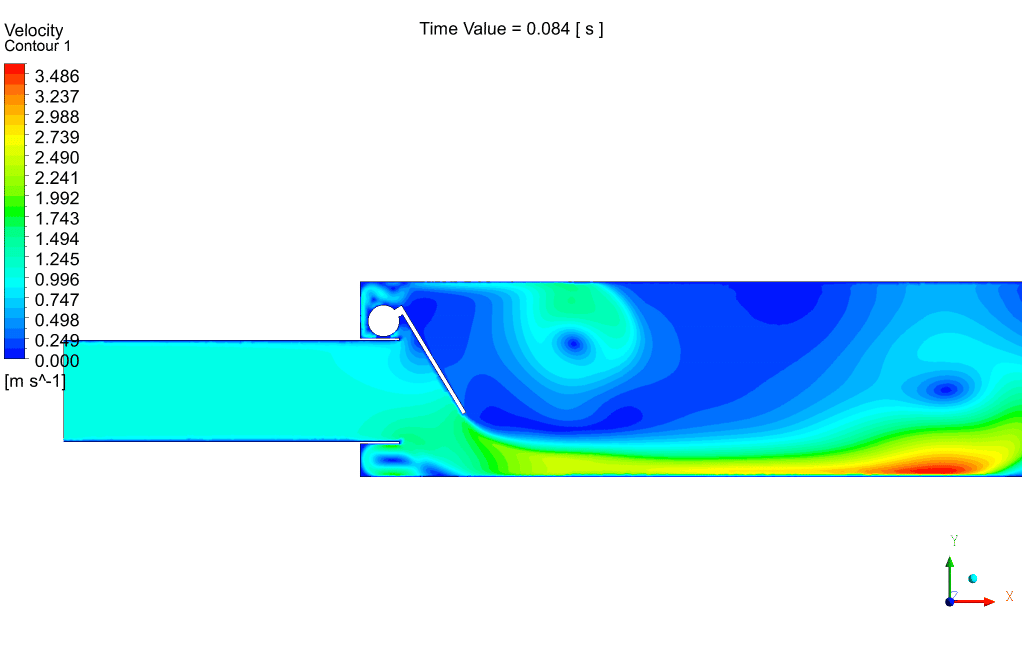

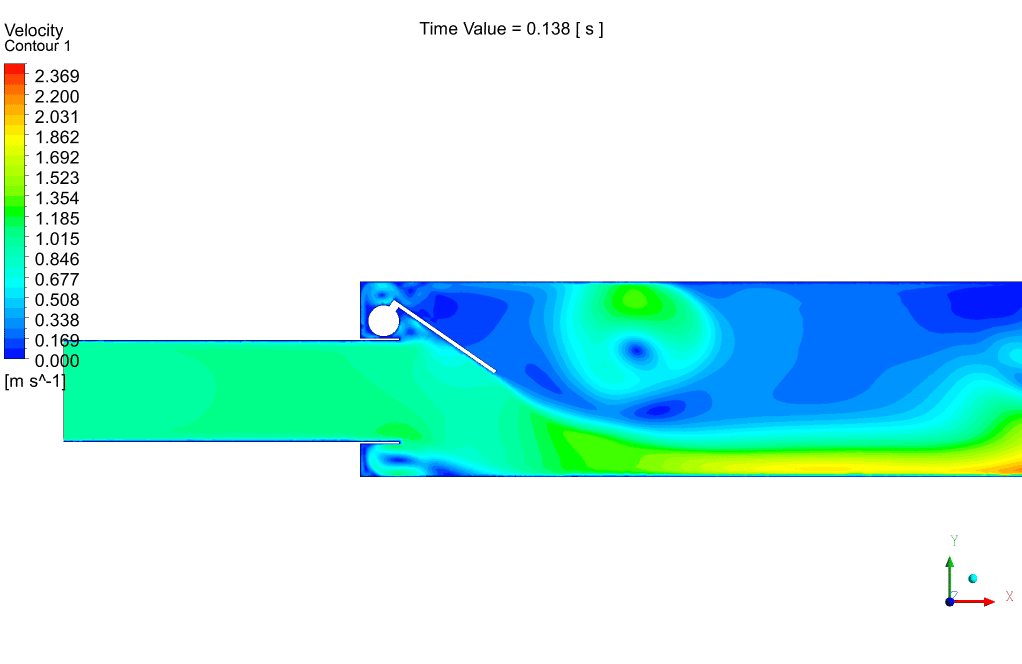

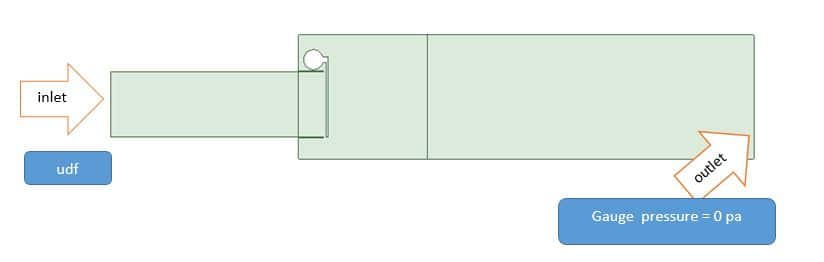

A non-return valve is simulated in this project, which has been done by the CFD simulation method with the help of Ansys Fluent software. These valves move the fluid flow in only one direction and prevent it from moving in the opposite direction. In some industrial applications, the pressure at the outlet may increase relative to the inlet and cause the flow to return, and this factor can be harmful to us, so in these cases, we use this type of valve. In this simulation, dynamic mesh and one DOF rotation capability are used. Input speed up to 0.4 seconds 1 m/s and then almost zero (0.000001m/s) is defined using UDF.

Geometry & Mesh

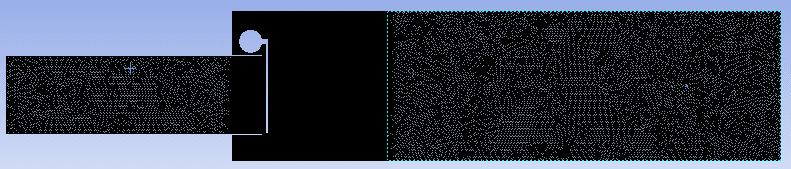

The two-dimensional geometry of this project has been produced with SpaceClaim software.

The length of the calculation area is 26 cm, and the width is 5 cm.

The meshing of this project has been done with Ansys Meshing software, and the type of elements is unstructured. Also, the total number of elements is 61580.

CFD Simulation

- the pressure-based solver method has been selected.

- The simulation is transient.

- The gravity effect is ignored.

The following tables represent a summary of the defining steps of the problem in this project and its solution:

| Models | ||

| Viscous model | k-omega | |

| Model | SST | |

| Dynamic mesh | On | |

| Six DOF | On | one DOF rotation |

| Spring | 1 n-m/rad | |

| Boundary conditions | ||

| Inlet | velocity inlet | |

| Velocity magnitude | UDF | |

| Outlet | Pressure outlet | |

| Gauge pressure | 0 pa | |

| Walls | Stationary wall | |

| Solution Methods | ||

| Pressure-velocity coupling | Simple | |

| Spatial discretization | Pressure | Second-order |

| Momentum | second-order upwind | |

| Turbulent kinetic energy | first-order upwind | |

| Turbulent dissipation rate | first-order upwind | |

| Initialization | ||

| Initialization method | Standard |

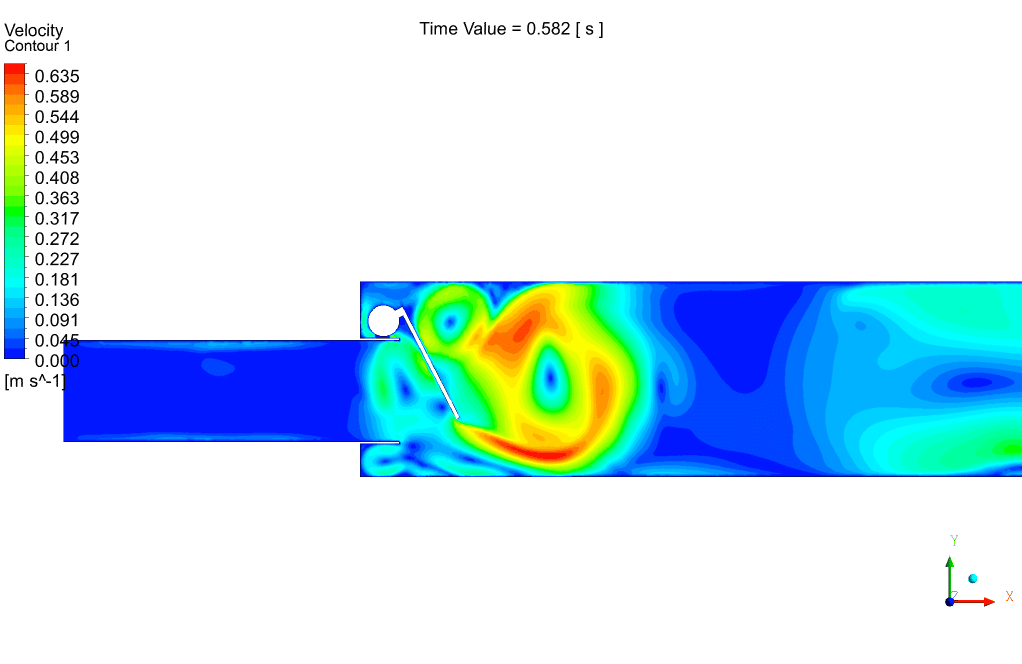

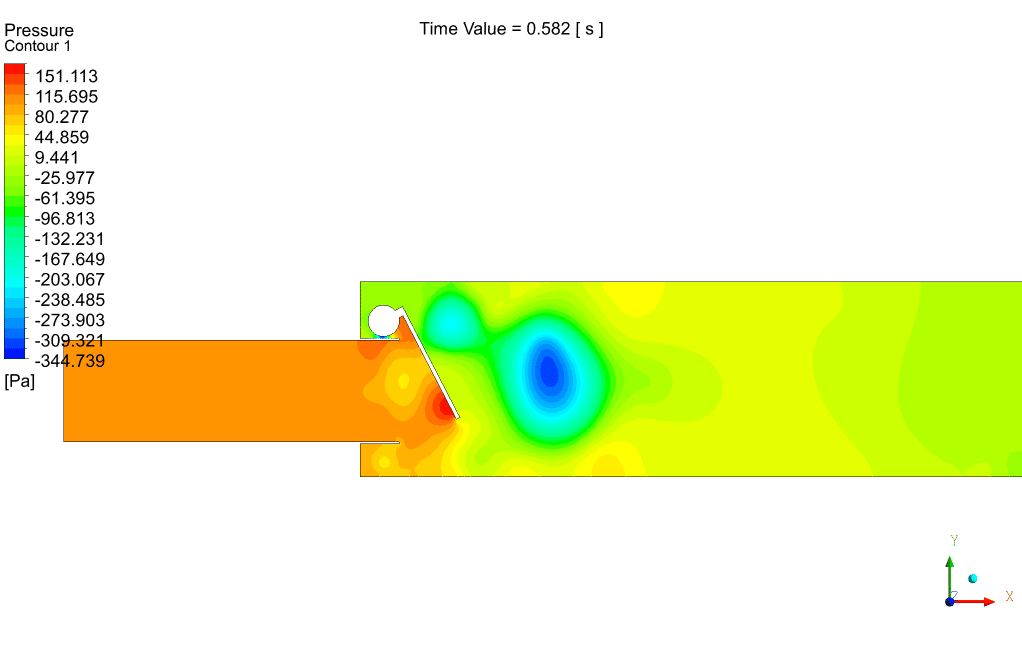

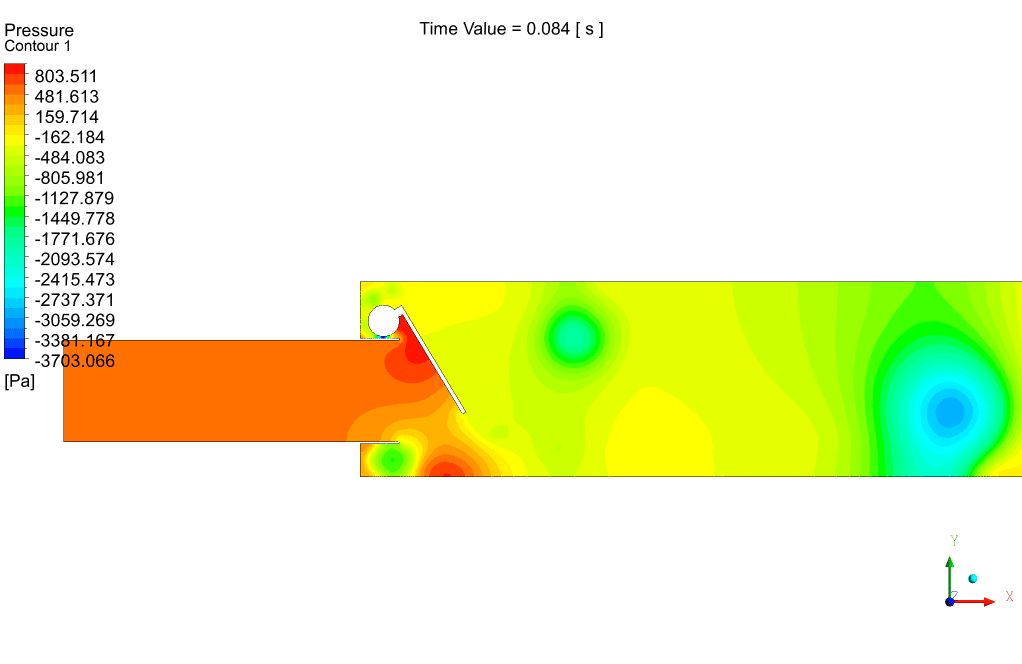

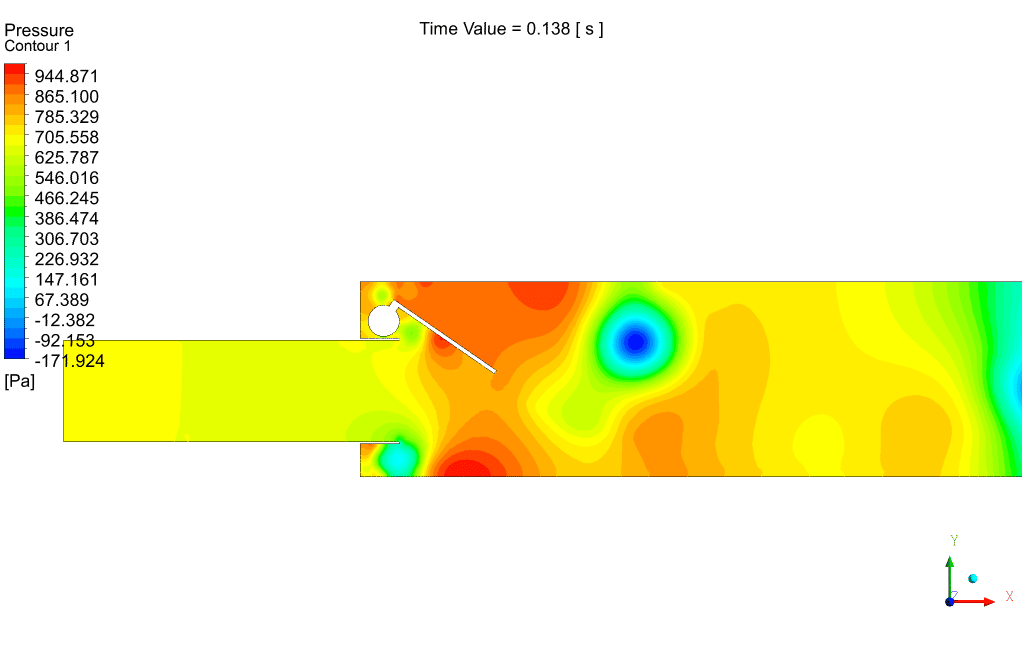

Non-Return Valve Results

At the end of the simulation, we see that the valve opens up for 0.4 seconds due to the high speed and kinetic energy of the water. From this moment on, when the flow velocity is also zero, the valve starts to close. The spring force defined for the valve also accelerates the closing of the valve and does not allow the flow to return to the inlet. We can also see the input speed diagram in terms of time defined by UDF. The graph of the force applied to the valve is also drawn over time.

Prof. Cooper Upton II –

Just blown away by the depth of coverage on the Non-Return Valve CFD simulation course! The use of dynamic meshing and the detail on setting up boundary conditions and spring force exemplify your top-notch training content. Kudos!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found the Non-Return Valve CFD simulation course to be detailed and informative. Our goal is always to provide comprehensive and practical learning experiences. We appreciate you taking the time to share your feedback!

Prof. Kelley Mertz –

I’m impressed with the dynamic mesh application! Can you explain how the one DOF (Degree Of Freedom) rotation affects the simulation?

MR CFD Support –

In the simulation of the non-return valve, the one Degree Of Freedom (DOF) rotation allows the valve disc to rotate around a single axis, which is crucial for accurately representing the valve’s operational behavior. When the fluid flow pushes against the valve, the DOF setting ensures that the valve can only move in the intended manner, hence preventing fluid backflow. This also enables the simulation to capture the dynamic interaction between the flow and the moving part of the valve—such as the opening and closing movements—under varying flow conditions.

Deion Casper PhD –

The training was fantastic, very clear simulation steps, and well-explained physics. Especially loved the dynamic mesh and DOF features integration.

MR CFD Support –

Thank you for your kind review. We’re thrilled to hear you found the training comprehensive and helpful. Your appreciation of the simulation’s dynamic mesh and degree of freedom integration means a lot to us. Stay tuned for more advanced CFD training!

Skye Stark –

This sounds like a comprehensive training module! It would be great to know what kind of support material, like tutorials or user guides, is provided to help understand the usage of dynamic mesh and the setting of UDF for velocity profiles.

MR CFD Support –

Thank you for your positive feedback! The training module comes with detailed step-by-step tutorials that illustrate how to set up and use the dynamic mesh feature in ANSYS Fluent. Additionally, examples of UDF (User-Defined Functions) scripts for defining velocity profiles are provided along with guides on how to implement and compile them within the simulation environment. If there are still any uncertainties or specific questions while going through the material, our customer support is also available to assist further.

Joey Kilback –

I’m impressed with the detail in this simulation! The use of a dynamic mesh for a non-return valve seems thorough. What factors were taken into account for the strength of the spring, to ensure it responded accurately once flow velocity was reduced to zero?

MR CFD Support –

In defining spring strength for the one DOF rotation in the simulation, we considered both the kinetic energy of the flowing water and the desired response time of the valve closure. Accurate spring parameters ensure that when the flow velocity drops, the valve quickly responds and shuts without allowing any backward flow, effectively replicating the mechanical behavior of a real non-return valve.

Daniela Koelpin –

I’m impressed by the detailed explanation in the Non-Return Valve CFD simulation training. The use of dynamic mesh and UDF for controlling flow velocity sounds very adept for studying valve behavior under varying flow conditions.

MR CFD Support –

Thank you for your positive feedback! We’re glad you found the details of the Non-Return Valve CFD simulation training impressive, specifically the application of dynamic mesh and user-defined functions (UDF). It’s always rewarding to know that our learning products are helping users understand and study complex fluid behaviors effectively. If you have any further questions or need additional guidance, we’re here to help!