Radiant Floor Heating System, Paper CFD Validation

$280.00 Student Discount

- The problem numerically simulates Radiant Floor Heating System using ANSYS Fluent software.

- This project is validated with a reference article.

- We design the 3-D model by the Design Modeler software.

- We mesh the model with ICEM software, and the element number equals 640618.

- We use the Discrete Ordinates (DO) model to consider radiation heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Radiant Floor Heating System, Paper Numerical Validation, ANSYS Fluent CFD Simulation Training

The present problem simulates heat transfer in a room through a radiant underfloor heating system using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

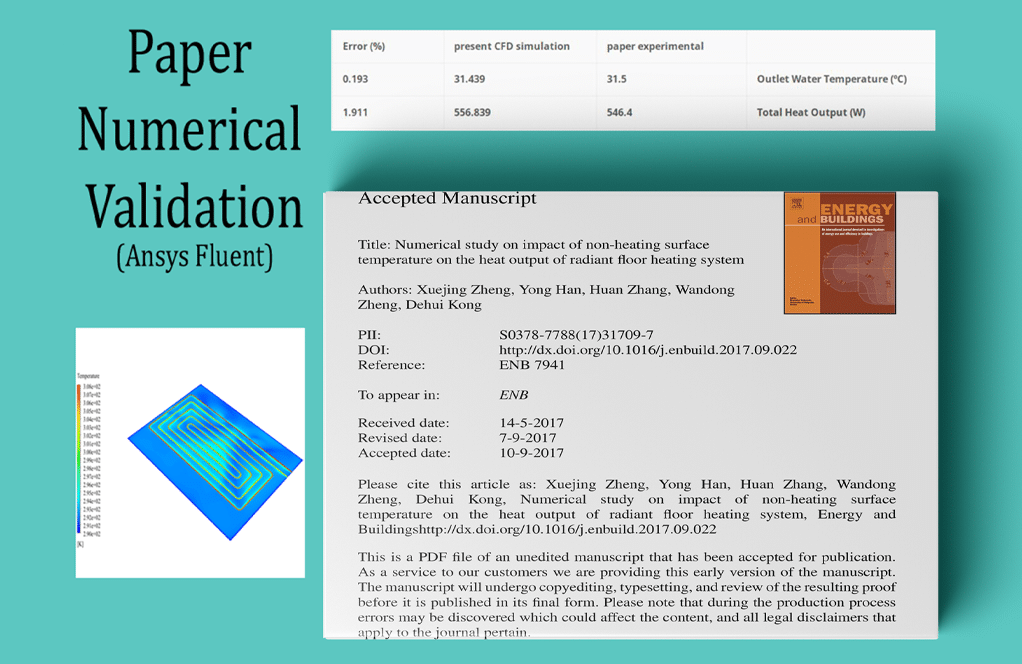

This simulation is based on an article [Numerical study on the impact of non-heating surface temperature on the heat output of radiant floor heating system]. CFD simulation results are compared with the paper results and validated.

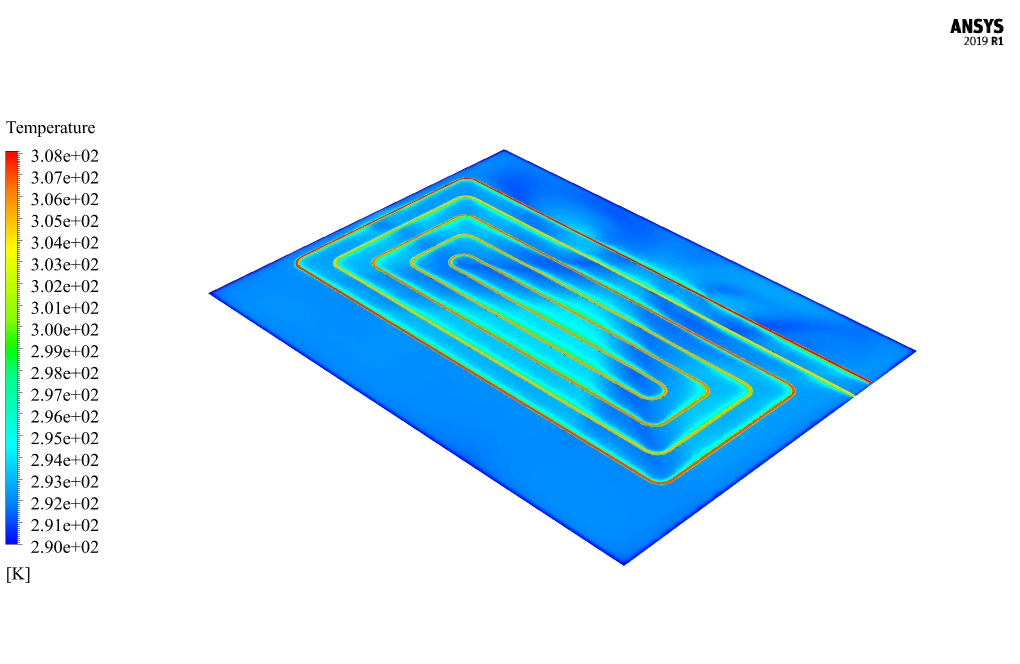

The present model is designed in three dimensions using SOLIDWORKS software and Design Modeler. The geometry of this model consists of a room on the floor, of which there is a spiral tube. The room has a length and width of 4 m and 3 m, and its height equals 2.8 m.

The pipe has a diameter of 2 cm. The meshing of the present model has been done using ICEM software. The mesh type is hybrid; meshing combines structured and unstructured mesh.

Structured mesh is used inside the pipe’s interior and the outer layer of the pipe, and most of the room’s interior, while in a limited part of the outer space of the pipe. The element number is 640618.

Underfloor Heating Methodology

This underfloor heating system consists of a pipe that twists in horizontal directions and covers the floor’s entire surface. The flow of water inside the pipe has significant heat, and the occurrence of heat transfer from the outer surface of this pipe to the air inside the room causes the heating of the ambient air.

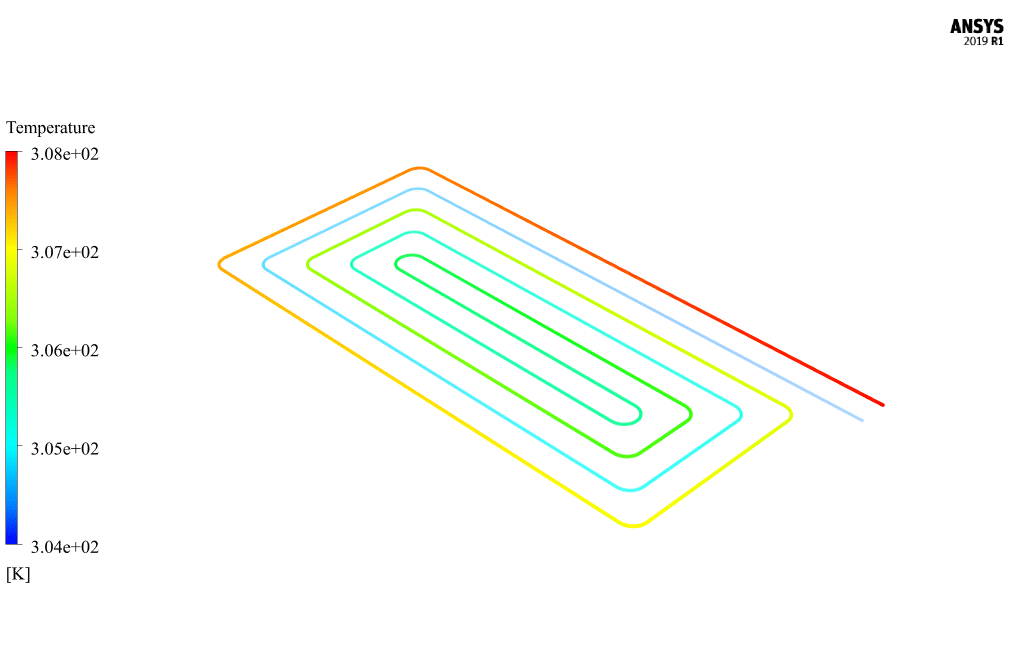

Hot water flows with a mass flow rate of 0.0374 kg/s and a temperature of 35 ºC enter the pipe and pass through a path full of screws inside the pipe to have an excellent opportunity to transfer heat to the room environment.

Also, the radiation model has been used to apply heat radiation from the room’s walls and the heating system’s pipes, etc. The DO (discrete ordinates) model has been used to define radiation.

According to Table 2 of the paper, the water inlet temperature is defined as 35 ºC, the mass flow rate of water at the inlet boundary is equal to 37.4 g/s, and the room’s ceiling and other walls’ temperatures are equal to 16.8 ºC.

In this project, a room has been designed in which a floor heating system has been installed on the floor to create heating inside the room.

This model is the most comprehensive for the definition of radiation and has a high-resolution accuracy. The radiative heat transfer equations for a discrete number of finite solid angles are solved using this model.

Moreover, the RNG k-epsilon model and energy equation are enabled to solve the turbulent fluid equations and calculate temperature distribution inside the domain.

Underfloor Heating Conclusion

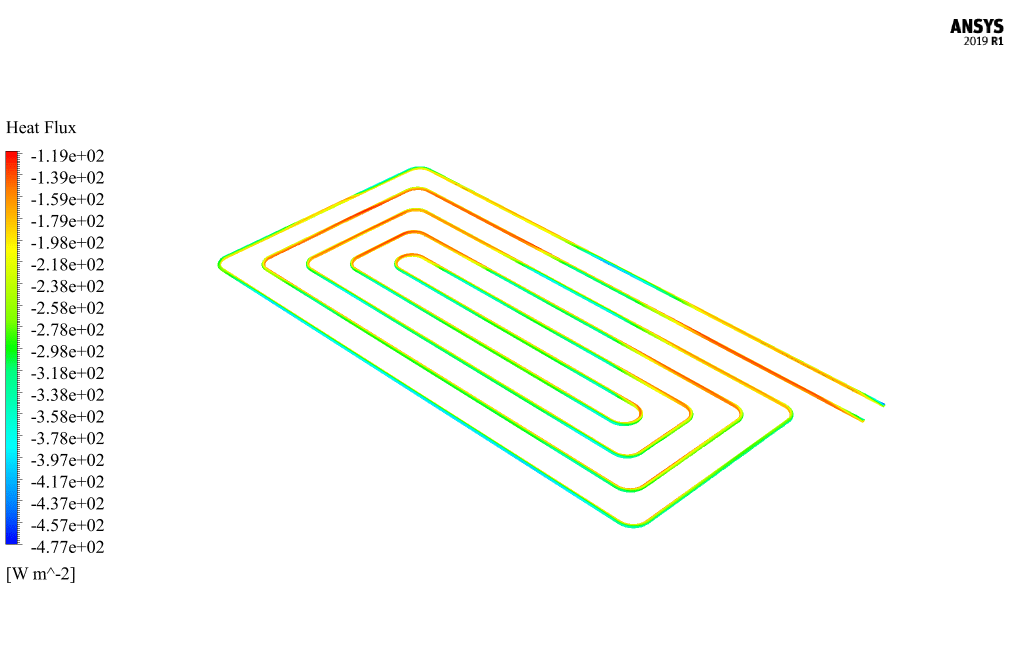

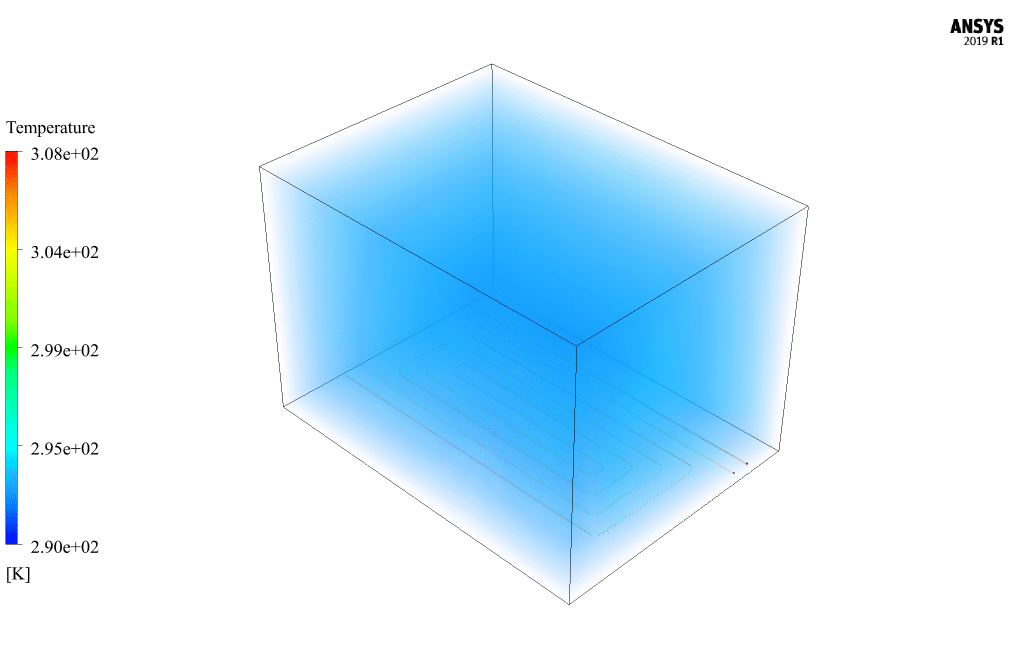

At the end of the solution process, three-dimensional contours related to the temperature inside the room and the tube and the heat flux contour on the outside surface of the tube are obtained. Meanwhile, a two-dimensional plate is drawn to pass through the middle of the heating pipe.

A two-dimensional contour of temperature is obtained on this two-dimensional plate. These contours will indicate the occurrence of heat transfer.

According to the resulting contours, heat is transferred from the outer surface of the pipe to the interior of the room and causes heating of the air inside the room. The validation of the present simulation is based on Tables 5 and 6 of the mentioned article.

The pipe’s outlet temperature value is extracted from case 1 of Table 5 of the paper. It is compared with the temperature value calculated in this simulation through the area-weighted average at the outlet boundary of the pipe.

Also, the amount of heat output power on the surface of the pipe is extracted from case 1 of Table 6 of the article. It is compared with the heat transfer rate calculated in this simulation through the total heat transfer rate on the outer surface of the pipe.

The following table shows the comparison between the results in the paper and the present numerical simulation results

| Error (%) | present CFD simulation | paper experimental | |

| 0.193 | 31.439 | 31.5 | Outlet Water Temperature (ºC) |

| 1.911 | 556.839 | 546.4 | Total Heat Output (W) |

Chase Jones –

Fantastic CFD simulation training! The comparison with the referenced paper’s results was particularly impressive – great to see such academic rigor applied. The use of discrete ordinates model for radiation provided clarity on heat dispersion beautifully. Well done, MR CFD Company!

MR CFD Support –

We are thrilled to receive such positive feedback! It’s exhilarating to know our commitment to academic rigor and detail is appreciated by our customers. Thank you for taking the time to recognize the efforts of the MR CFD team. Your support fuels our passion for delivering high-caliber learning experiences!

Abdul Rempel –

The comparison between simulation results and the experimental values seems very promising. The minimal error percentage showcases the accuracy of the CFD model. Great job on conducting such a thorough and precise validation study.

MR CFD Support –

Thank you for recognizing the efforts of our team in carefully validating the simulation results against experimental data. It’s important to us to provide high-quality, accurate models, and we’re glad to see that appreciated by our customers. Your positive feedback is very encouraging!

Lucious Miller Sr. –

The tutorial on Radiant Floor Heating System by MR CFD was great! This CFD tutorial was well laid out, practical, and it’s incredible how closely the simulation results matched with the paper validation. The step-by-step approach enhanced my understanding of underfloor heating using a spiral tube, giving me better insights into thermal comfort studies.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the tutorial on the Radiant Floor Heating System met your expectations and provided you with a comprehensive understanding of the process. Thy close match with the paper validation confidence in our simulations’ accuracy and utility. If you need further assistance or have any more queries, please feel free to reach out.

Prof. Ova Hayes PhD –

I love how detailed the comparison of simulation results with the paper data is! It provides such a clear understanding of the validation process.

MR CFD Support –

Thank you for your positive feedback. We’re delighted to hear that you appreciate the efforts made to ensure our simulations are accurately validated, ensuring clients can trust the quality of our CFD analysis.

Albertha Schmitt –

This simulation is astounding! I could really see how the temperature contours show effective heat distribution. The comparison with experimental data brings a lot of confidence to the accuracy of the simulation. How close was the simulation’s outlet temperature to the one in the paper?

MR CFD Support –

I am glad you enjoyed it! The simulation’s results validated against the paper demonstrate a high degree of accuracy. Specifically, the outlet water temperature from the CFD simulation had an error percentage of only 0.193% compared to the paper’s experimental value, showing a very close agreement between the simulated data and experimental findings.

Lazaro Brekke –

I was able to deepen my understanding of radiant heating systems thanks to this CFD simulation training. The detailed comparison with validation from academic papers provides a solid trust in the simulation’s accuracy. Could you elaborate on whether similar comparison and validation methods can be applied to other heating systems, such as forced air or conventional radiators?

MR CFD Support –

Absolutely, the methods of comparison and validation applied in this simulation training can also be adopted for assessing other heating systems. By matching simulation data with experimental or previously published results, we can quantify the accuracy and reliability of our simulations across different designs, including forced air systems and conventional radiators.