S2S Radiation Heat Transfer, CFD Simulation ANSYS Fluent Training

$120.00 Student Discount

The present simulation is about S2S radiation heat transfer via ANSYS Fluent.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

S2S Radiation Heat Transfer Description

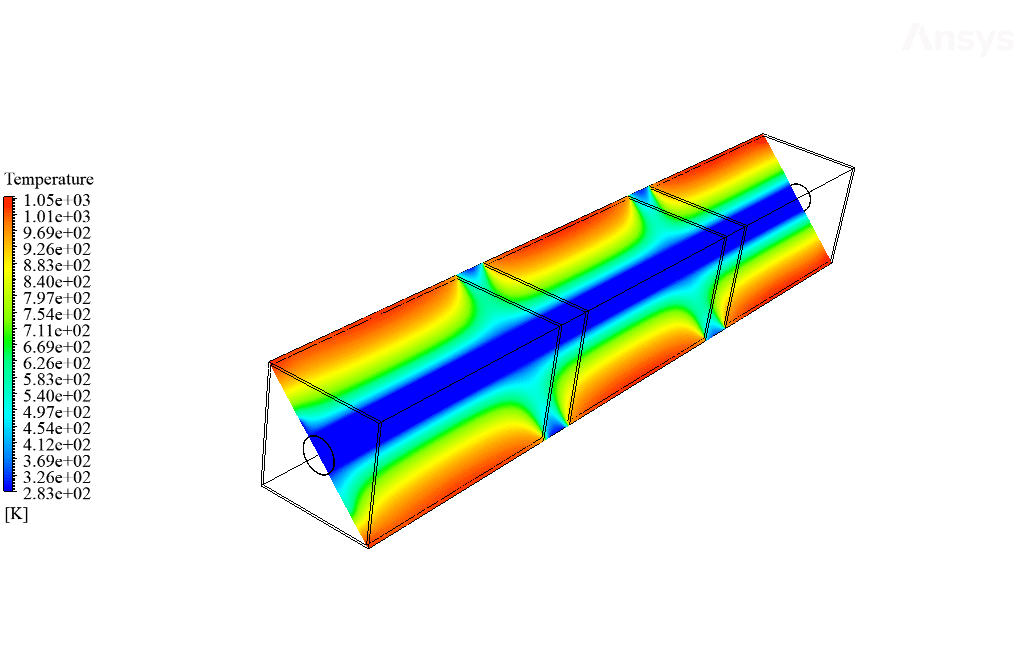

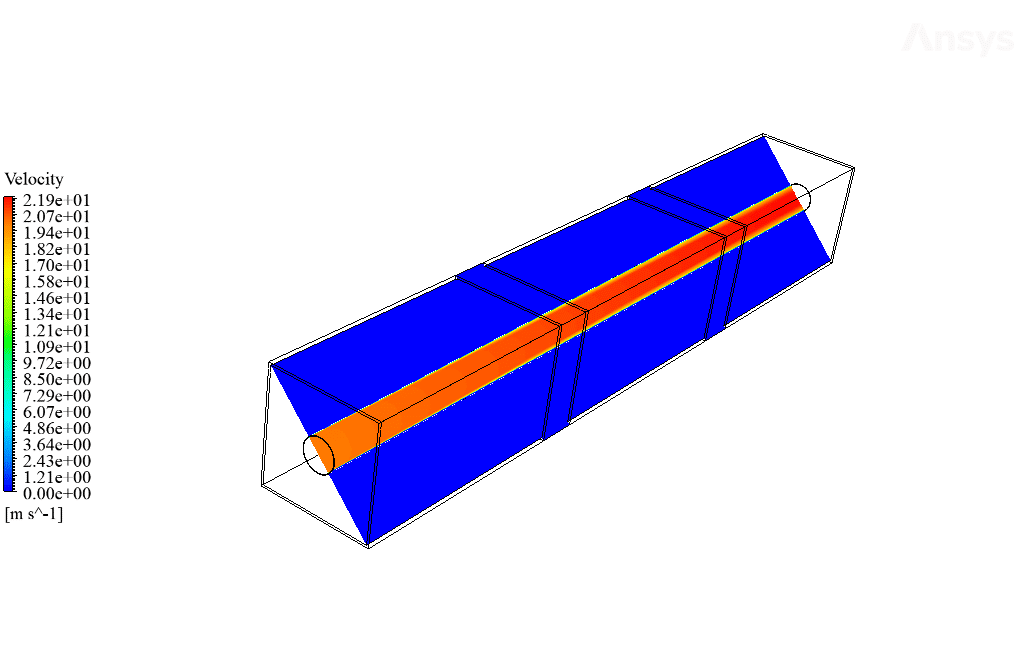

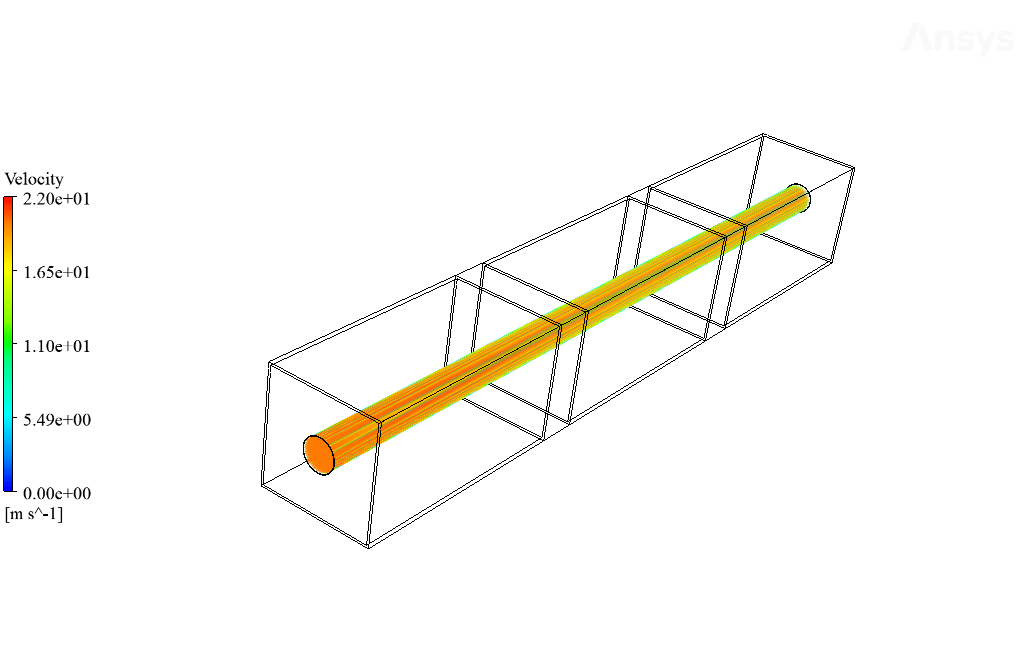

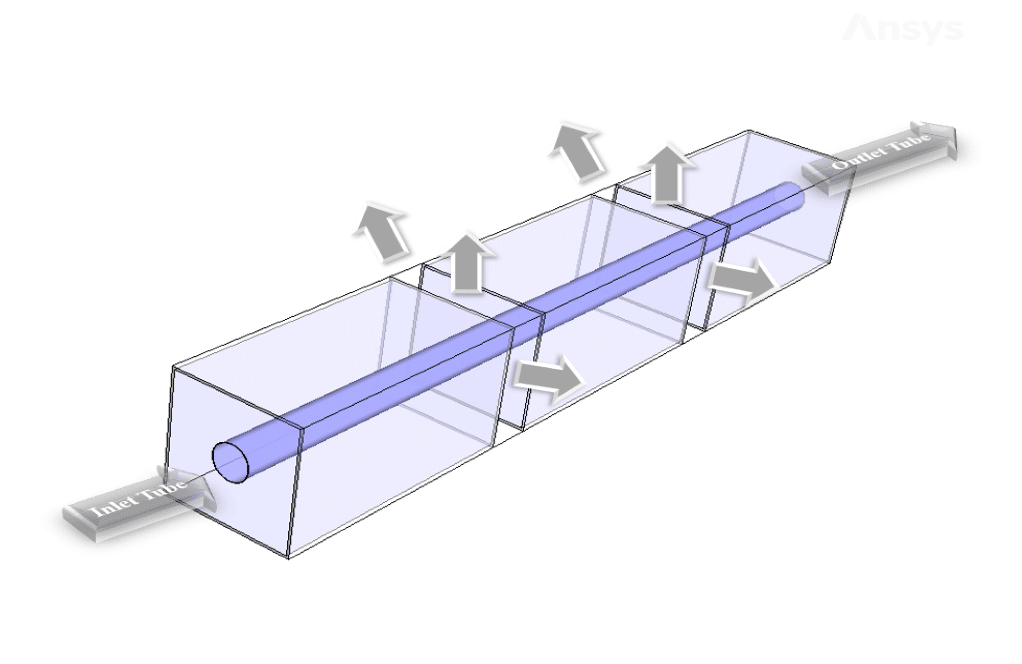

The present simulation is about S2S radiation heat transfer via ANSYS Fluent. In this project, plates model the three boxes, and inside these boxes, a tube is designed. The fluid flow inside the tube moves at a temperature of 283 K and a velocity of 20 m/s, and there is airflow inside the boxes around the tube.

It is assumed that these metal plates have a heat source of 1133333.33 W/m3. It is also assumed that radiation heat transfer occurs between the box plates and the surface of the tube. Therefore, the software has used the surface-to-surface (S2S) radiation model.

The surface-to-surface radiation model calculates the radiation exchange in an enclosure of gray-diffuse surfaces. The exchange between the two surfaces depends partly on their size, separation distance, and orientation. These parameters are calculated by a geometric function called a “view factor”. The main assumption of the S2S model is that any absorption, emission, or scattering of radiation can be ignored; Hence, only surface-to-surface radiation is considered for analysis.

The S2S model assumes that the pages should be gray and diffuse. The emissivity and absorptivity of a gray surface are independent of the wavelength, and according to Kirchhoff’s law, the emissivity is equal to the absorptivity (ε = α). Also, the reflectivity is independent of the outgoing (or incoming) directions for a diffuse surface.

Geometry & Mesh

The present geometry is designed in a 3D model via Design Modeler The computational zone is related to the interior of three boxes created by several plates. An output boundary is considered between each of the boxes. A pipe is also passed through the interior of these boxes.

The mesh of the present model has been done via ANSYS Meshing. Mesh is structured, and the number of production cells is equal to 2101788.

Set-up & Solution

Assumptions used in this simulation:

- Pressure-based solver is used.

- The present simulation is steady.

- The effect of gravity on the model is ignored.

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | standard | |

| near wall treatment | standard wall function | |

| Radiation | Surface to Surface (S2S) | |

| Boundary conditions | ||

| Inlet-tube | Velocity Inlet | |

| velocity magnitude | 20 m.s-1 | |

| temperature | 283 K | |

| internal emissivity | 1 | |

| Outlet-tube & Outlet-plates | Pressure Outlet | |

| gauge pressure | 0 Pascal | |

| internal emissivity | 1 | |

| Inner & Outer Plates’ Wall | Wall | |

| thermal condition | coupled | |

| Tube’s Wall | Wall | |

| heat flux | 0 W.m-2 | |

| Methods | ||

| Pressure-Velocity Coupling | Coupled | |

| pressure | Second-order | |

| momentum | Second-order upwind | |

| turbulent kinetic energy | First-order upwind | |

| turbulent dissipation rate | First-order upwind | |

| energy | Second-order upwind | |

| Initialization | ||

| Initialization methods | Hybrid | |

S2S Radiation Heat Transfer Results

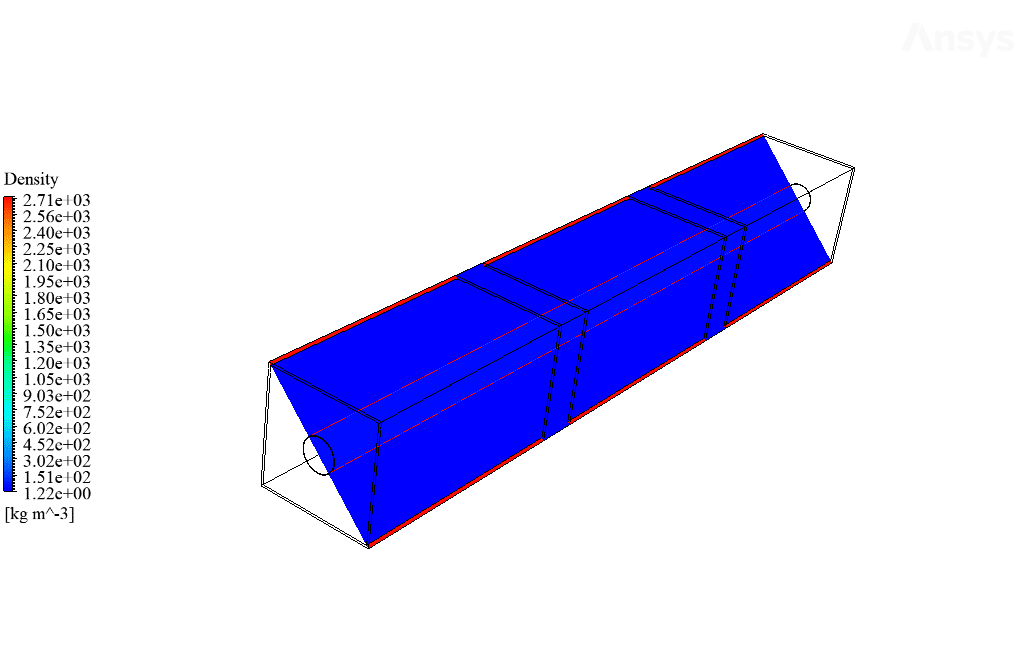

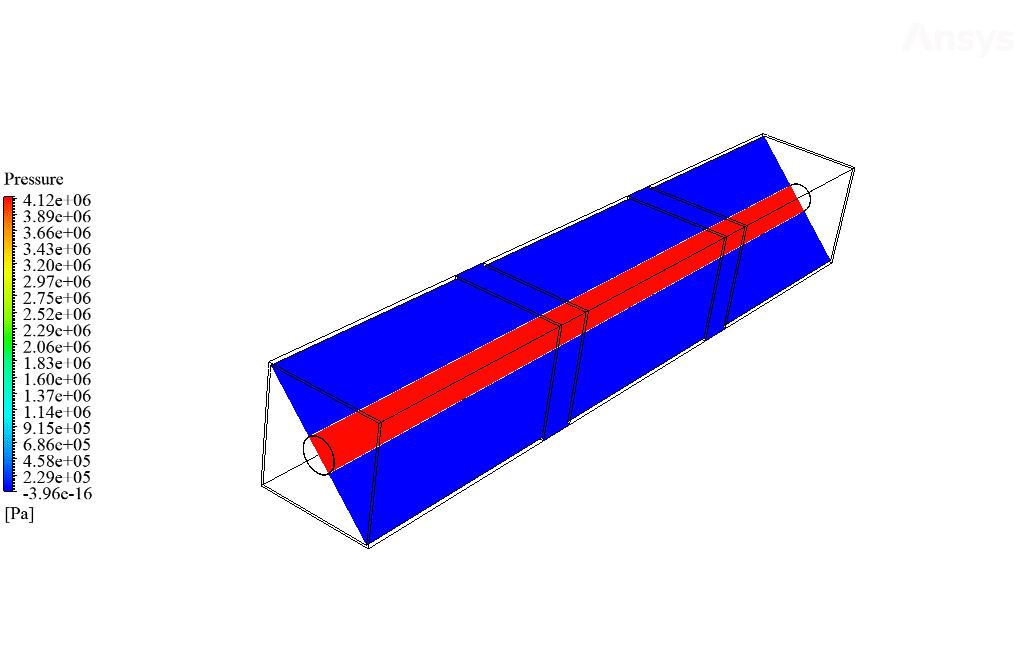

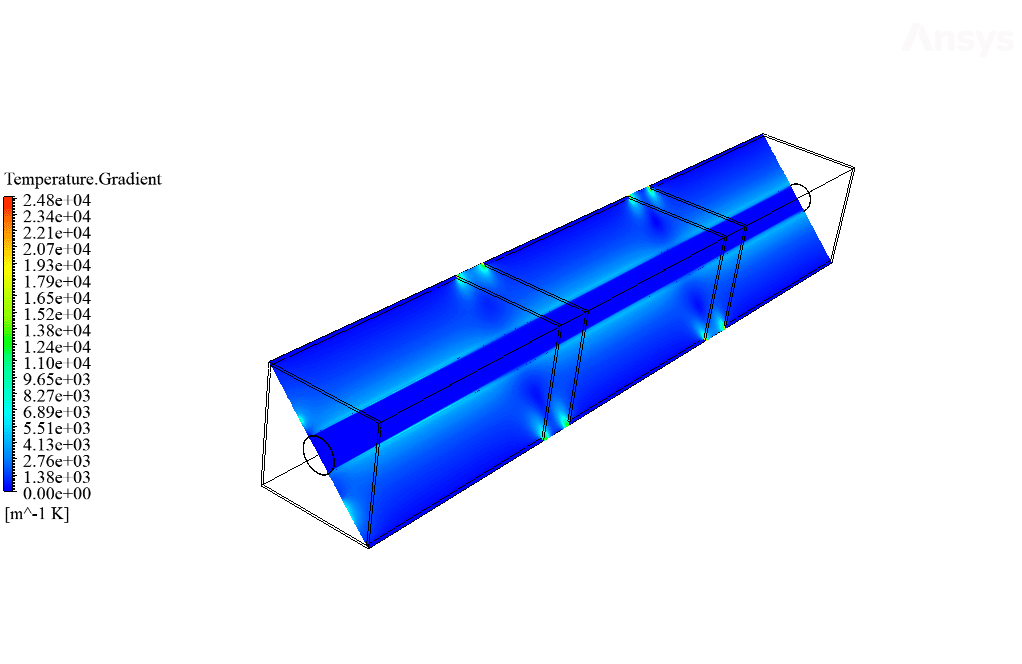

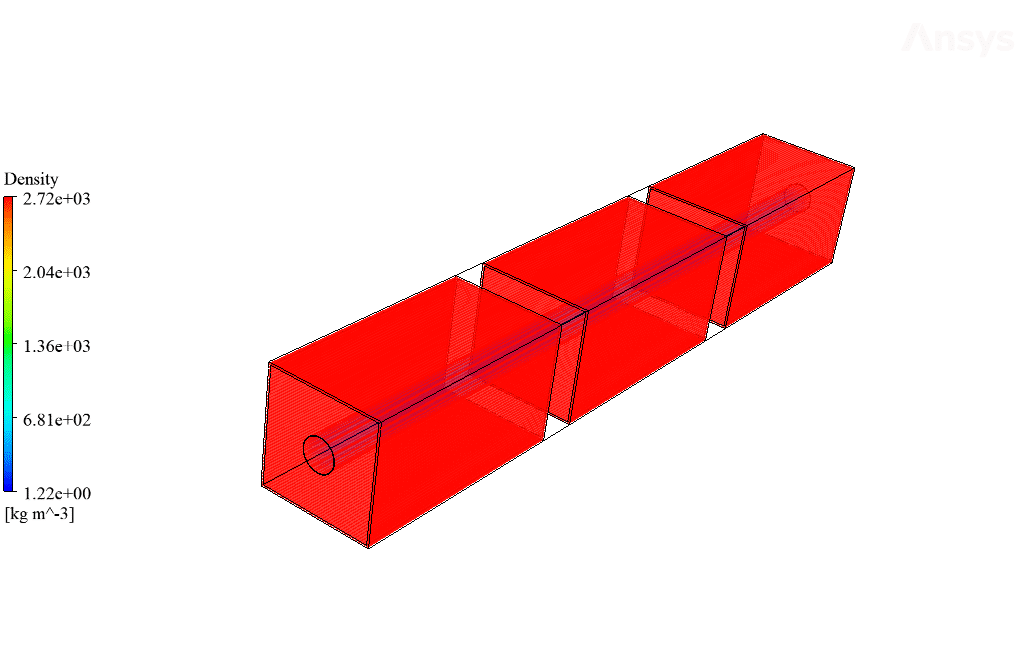

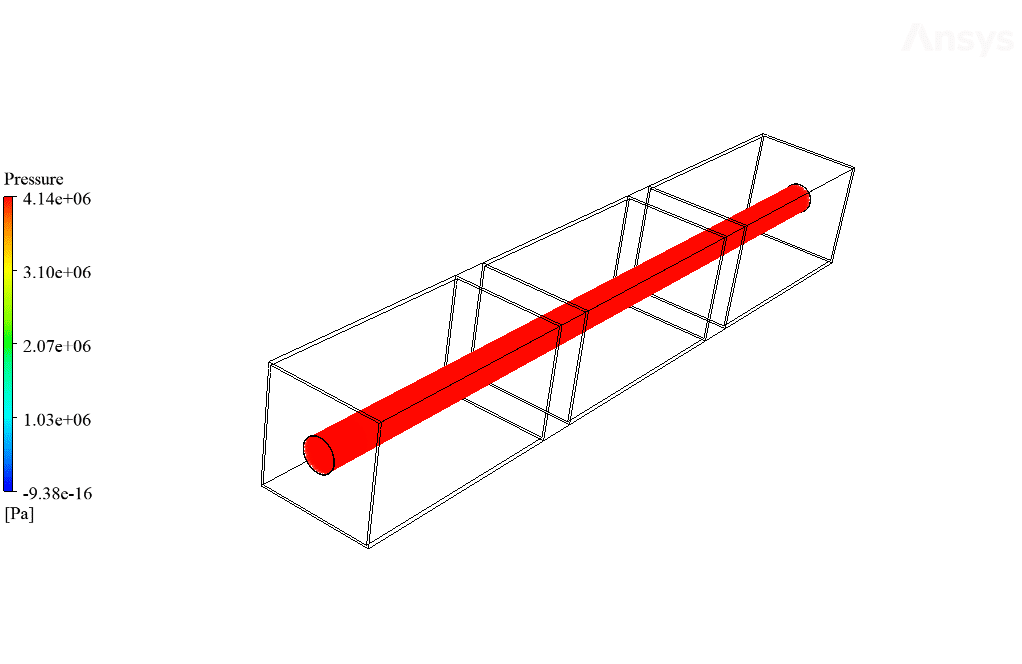

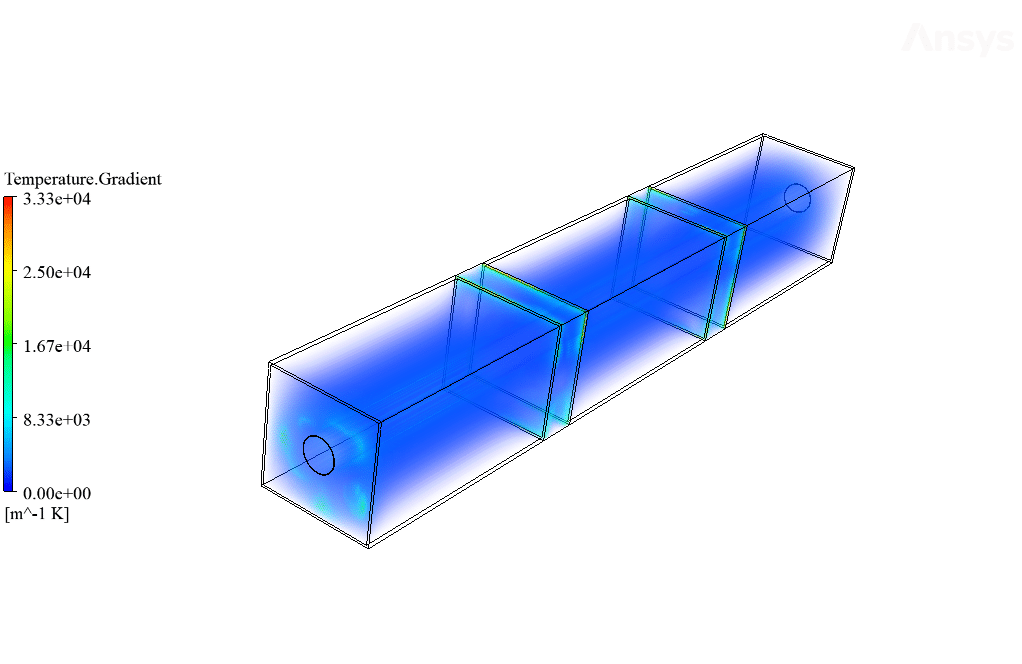

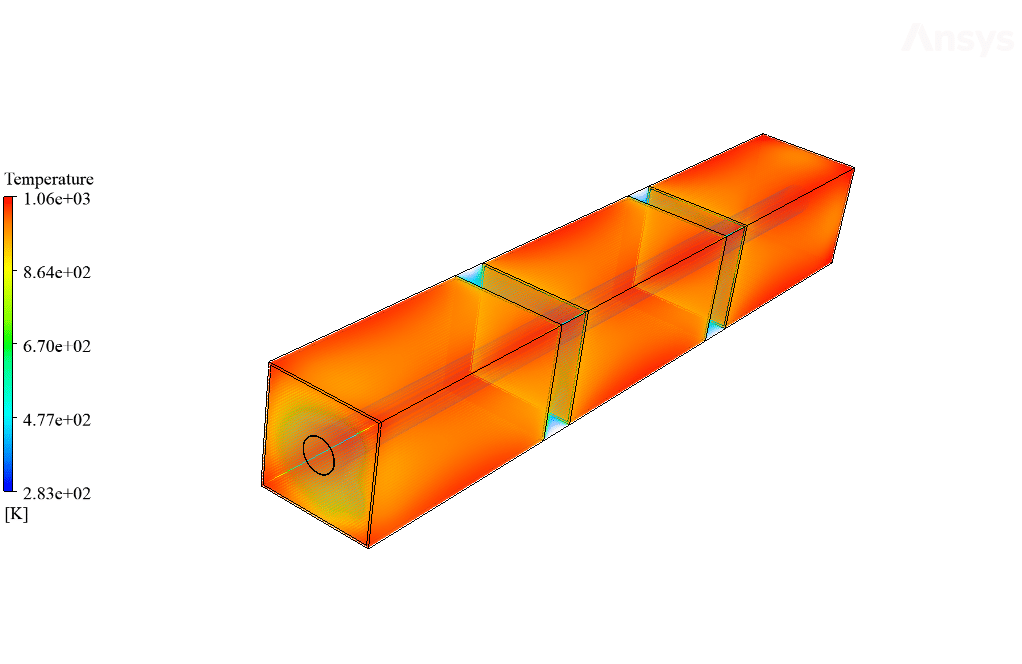

After calculation, 2D and 3D contours related to temperature, temperature gradient, velocity, pressure, and density are obtained. The contours show that the heat generated by the plates is transferred through radiation between the surfaces in the space around the pipe. This radiation heat transfer between the surfaces leads to an increase in the air temperature of the tube.

Natasha McClure III –

I’ve always been curious about how radiation heat transfer complexities are managed in simulations. Your detailed explanation cleared it up for me and the results are fascinating. Thanks for demonstrating the S2S model effectively in a dynamic setup.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our S2S radiation heat transfer simulation was able to elucidate the complexities of radiation heat transfer for you, and that you found the demonstration and results engaging. If you have any more questions about the simulations or any further interests, feel free to reach out to us.

Kamille Kerluke –

The S2S Radiation Heat Transfer simulation project you shared actually sparked my interest in the interplay between radiation transfer and airflow around the structures. Your explanation of the view factor and the assumption of the pages being gray and diffuse is particularly helpful in understanding the underlying theory. It seems like an ideal setup for learning about radiation heat transfer in enclosed structures.

MR CFD Support –

Thank you! We’re delighted to hear that the project on S2S radiation heat transfer met your educational needs and piqued your interest. Understanding the concept of the view factor and the assumptions used in the S2S model is crucial for grasping the simulation’s intricacies fully. We appreciate your recognition of the project’s helpfulness and if you have any further questions or require additional learning materials, please feel free to reach out to us.

Julius Parisian –

Was it mentioned in the simulation if natural convection was considered in addition to the S2S radiation for heat transfer calculations?

MR CFD Support –

Yes, the description of the setup mentions air inside the boxes around the tube, suggesting that natural convection could contribute to the heat transfer. However, no explicit mention of considering natural convection in the calculations is made, so the simulation mainly focuses on S2S radiation heat transfer.

Sidney Schmitt –

I’ve noticed an incredible uniformity in the temperature distribution in the provided simulation results. Could you explain how the S2S model ensures this level of consistency despite the complex interactions between radiating surfaces?

MR CFD Support –

The S2S (Surface-to-Surface) radiation model is designed to calculate radiation exchange between gray-diffuse surfaces within an enclosure very effectively. The accuracy of the simulation is due to the careful calculation of view factors—geometric functions that account for surface size, separation distance, and orientation, which influence how heat is radiated between surfaces. In addition, by assuming that the surfaces are gray and diffuse (consistent emissivity and reflectivity), the S2S model simplifies the complex interactions to a more predictable and stable state, promoting uniform heat transfer and hence, a more uniform temperature distribution.

Tiara Becker –

I’m impressed with the level of detail of this S2S radiation heat transfer simulation and the comprehensive training provided!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you’re satisfied with the quality of the simulation and the training. It’s our pleasure to provide detailed and useful educational materials to help our customers understand complex phenomena. Don’t hesitate to reach out to us if you need any further assistance or information.

Guido Farrell –

The clear explanation of the S2S model helped me understand the surface radiation heat transfer used in my own projects. The detailed results enabled me to improve the heat management in designs. Excellent training material.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our detailed S2S radiation heat transfer simulation was helpful in enhancing the heat management in your designs. Your success inspires us to continue providing high-quality training materials.

Everardo Stark –

I was impressed by how detailed the simulation is when handling radiation heat transfer! It’s quite clear how the S2S model is applied and it seems like a comprehensive approach to handling such a scenario.

MR CFD Support –

Thank you for your feedback! We are glad to hear that the details and application of the S2S radiation model in the simulation met your expectations. Our goal is to provide comprehensive and accurate simulations to help users understand complex physical phenomena. We appreciate your recognition of our efforts!

Emanuel Keebler –

This course has helped me grasp the complexities of S2S radiation heat transfer in Ansys Fluent. The clear description and detailed setup instructions made this complex concept easy to understand.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our training has demystified S2S radiation heat transfer for you in ANSYS Fluent. Should you have any further learning needs, please don’t hesitate to reach out.

Ms. Shayna Grant IV –

Everything about the way the heat transfer is simulated with S2S method was clear, but I’m curious if with the provided settings, the distribution of temperature around the corners of the boxes seemed realistic?

MR CFD Support –

Thank you for your positive feedback. To address your question, yes, with the settings provided in this simulation, the temperature distribution around the corners should be evaluated realistically. The S2S radiation model considers the geometric factors such as size, separation distance, and orientation to calculate the radiation exchange accurately, including the effects at the corners. The results, which include temperature contours, help to visualize these distributions. If further detailed inspection is needed, adjustments to the mesh or simulation parameters could be made for enhanced precision.

Dr. Gregoria Huel IV –

The S2S Radiation Heat Transfer course was meticulous and very helpful. The view factor explanations were particularly insightful; breaking it down made understanding the S2S model much easier. Thank you for this excellent CFD training!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our S2S Radiation Heat Transfer simulation training was helpful and that the explanations on the view factor were clear and insightful. Your satisfaction is our top priority! If you have any more questions or need further assistance in the future, don’t hesitate to reach out.

Dr. Idella Bechtelar –

The simulation handles the heat source and S2S radiation very well. The insights from the temperature contours demonstrate the importance of considering radiation heat transfer in the thermal analysis.

MR CFD Support –

Thank you for the positive feedback! We are thrilled to hear that the simulation met your expectations and provided valuable insights into S2S radiation heat transfer. Should you need more information or assistance with your thermal analysis projects, feel free to reach out to us.

Miss Stacy Jerde PhD –

Are the plates and the tube considered of the same material, or do they have different thermal properties in the S2S radiation heat transfer simulation?

MR CFD Support –

In the S2S radiation heat transfer simulation conducted via ANSYS Fluent, the plates and the tube could have distinct thermal properties. This typically includes differences in emissivity, material density, specific heat capacity, and thermal conductivity, key factors that impact the rate and efficiency of heat transfer. However, to precisely answer this, further information regarding the materials used for the plates and the tube in the specific simulation is required.