RQ-11 Raven Drone CFD Simulation, ANSYS Fluent

$100.00 Student Discount

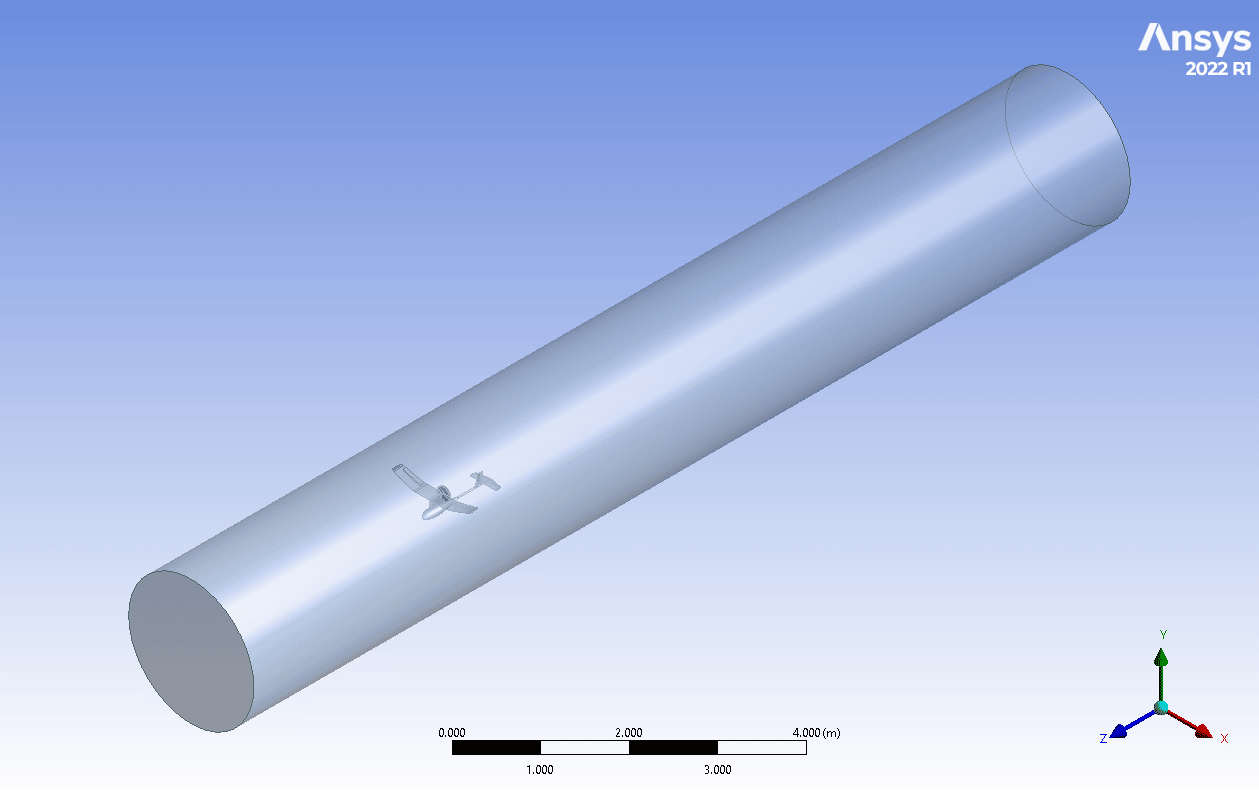

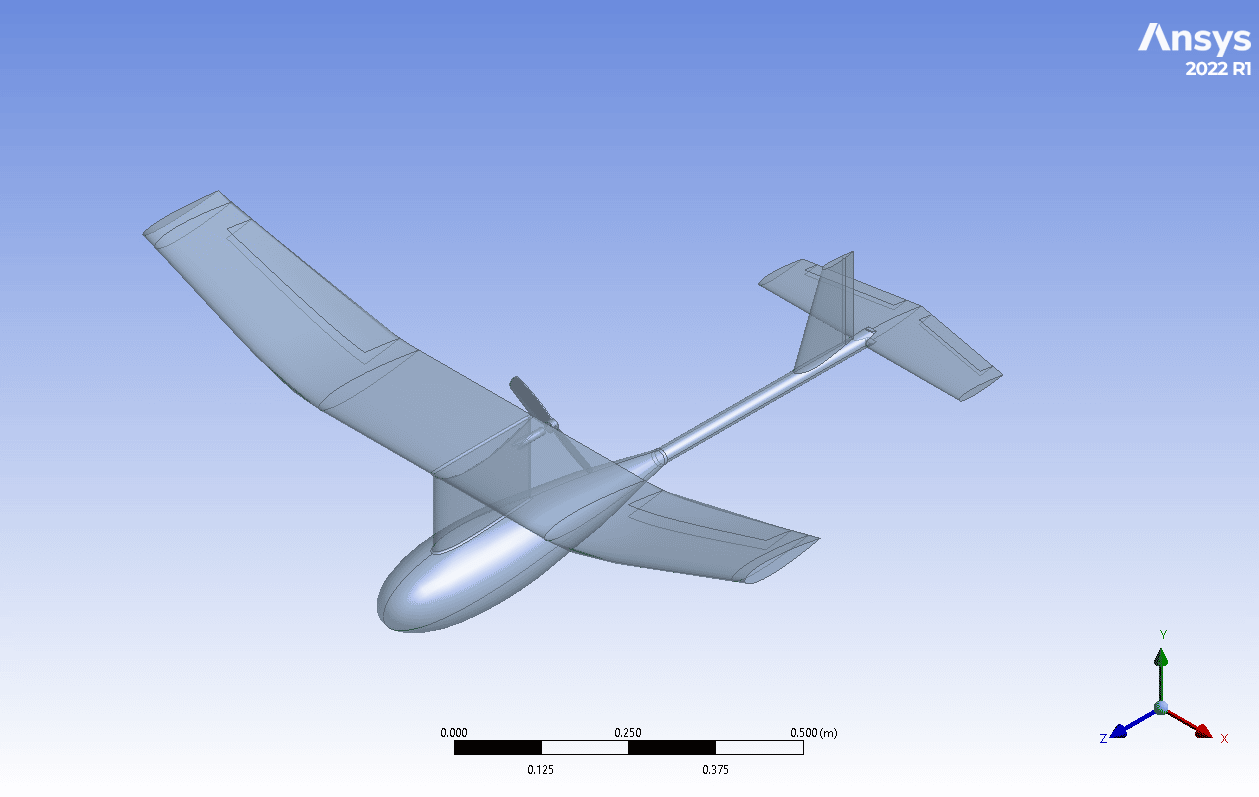

- The problem numerically simulates an RQ-11 Raven UAV using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

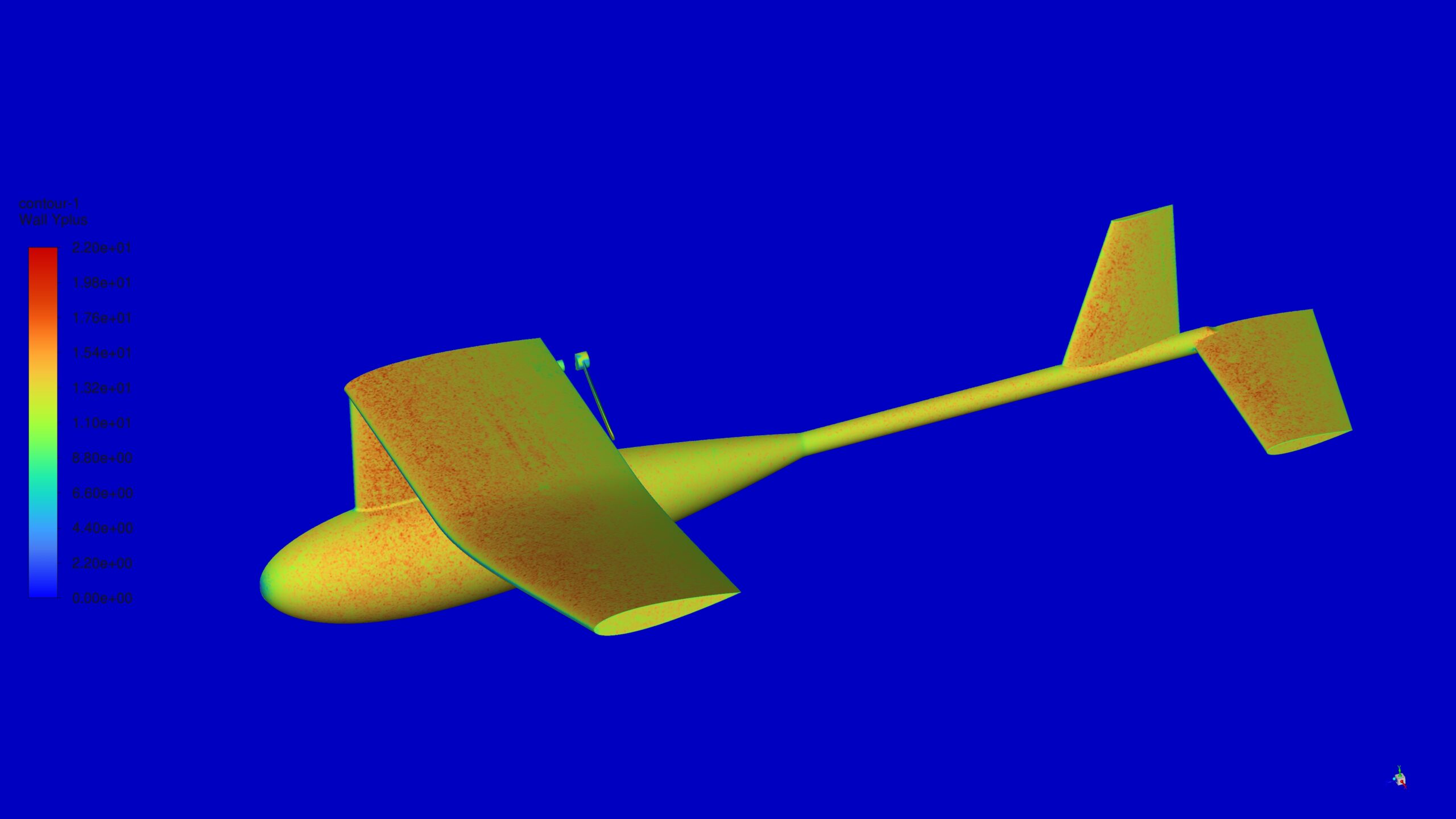

- We mesh the model with Fluent Meshing software. The element number equals 5,300,212 and their type is polyhedra.

- Multiple Reference Frames (MRF) are used to model the rotational motion of propellers.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

RQ-11 Raven UAV Aerodynamic CFD Simulation, ANSYS Fluent Training

Introduction

A lightweight unmanned aircraft system (UAS) with excellent mobility, the RQ-11 Raven, is designed for quick deployment.

The Raven is hand-launched into the air like a model airplane in mere minutes, and it lands itself by auto-piloting to a hovering position. It doesn’t need landing strips that have been adequately prepared. The Raven is best suited for forward-deployed units because it doesn’t require complex support facilities.

Thanks to its automated features and GPS technology, it is easy to use and doesn’t require any specialized knowledge or extensive flight training.

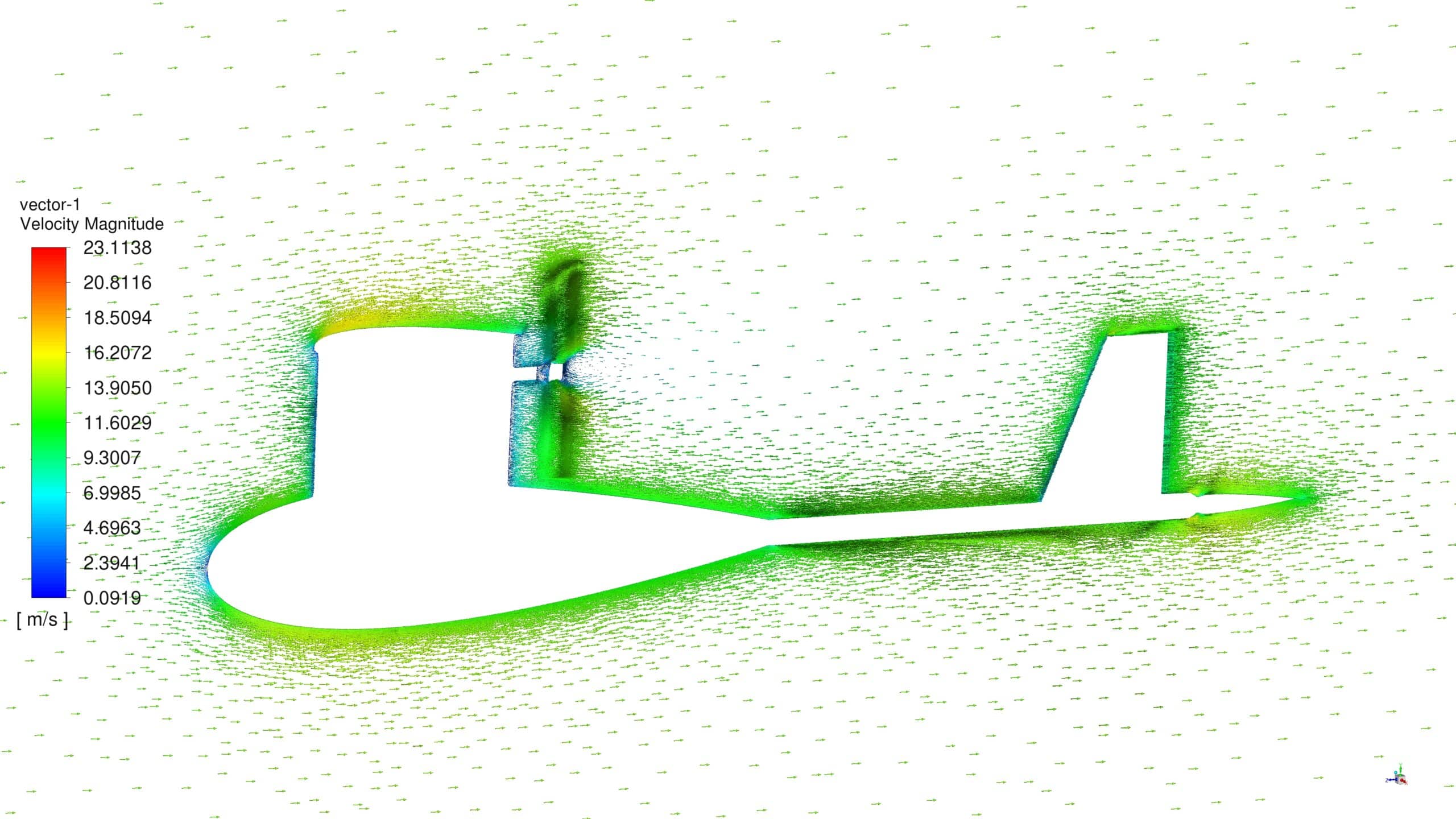

An RQ-11 Raven UAV is modeled in this simulation using ANSYS Fluent software. The device moves at a speed of 13.9 m/s while the propeller rotates at an angular velocity of 1200 rev/min.

The geometry of the present model is three-dimensional and has been designed using Design Modeler software. We do the meshing of the present model with Fluent Meshing software. The mesh type is Polyhedra, and the element number is 5,300,212.

Methodology: RQ-11 RavenUAV CFD Simulation

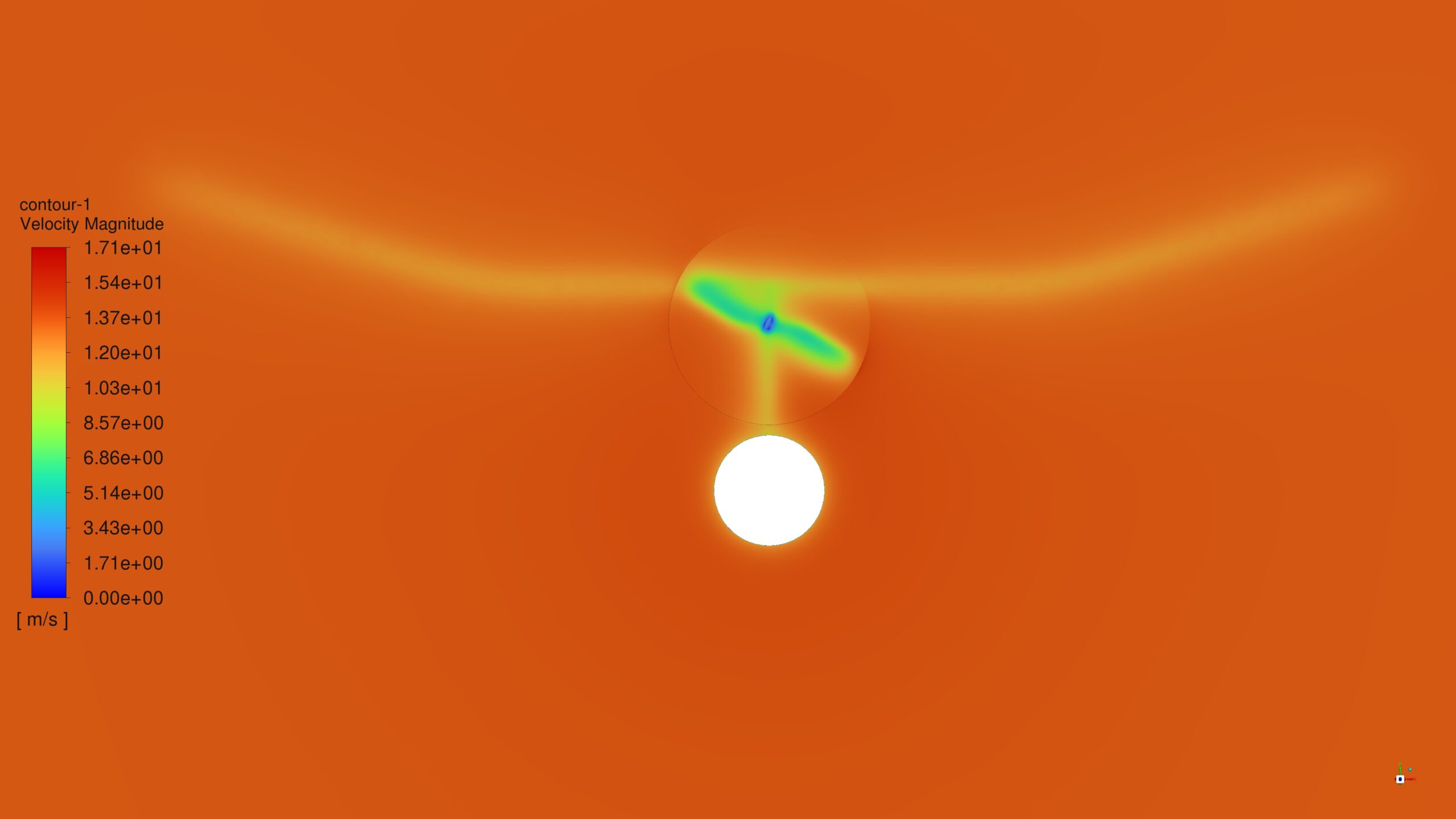

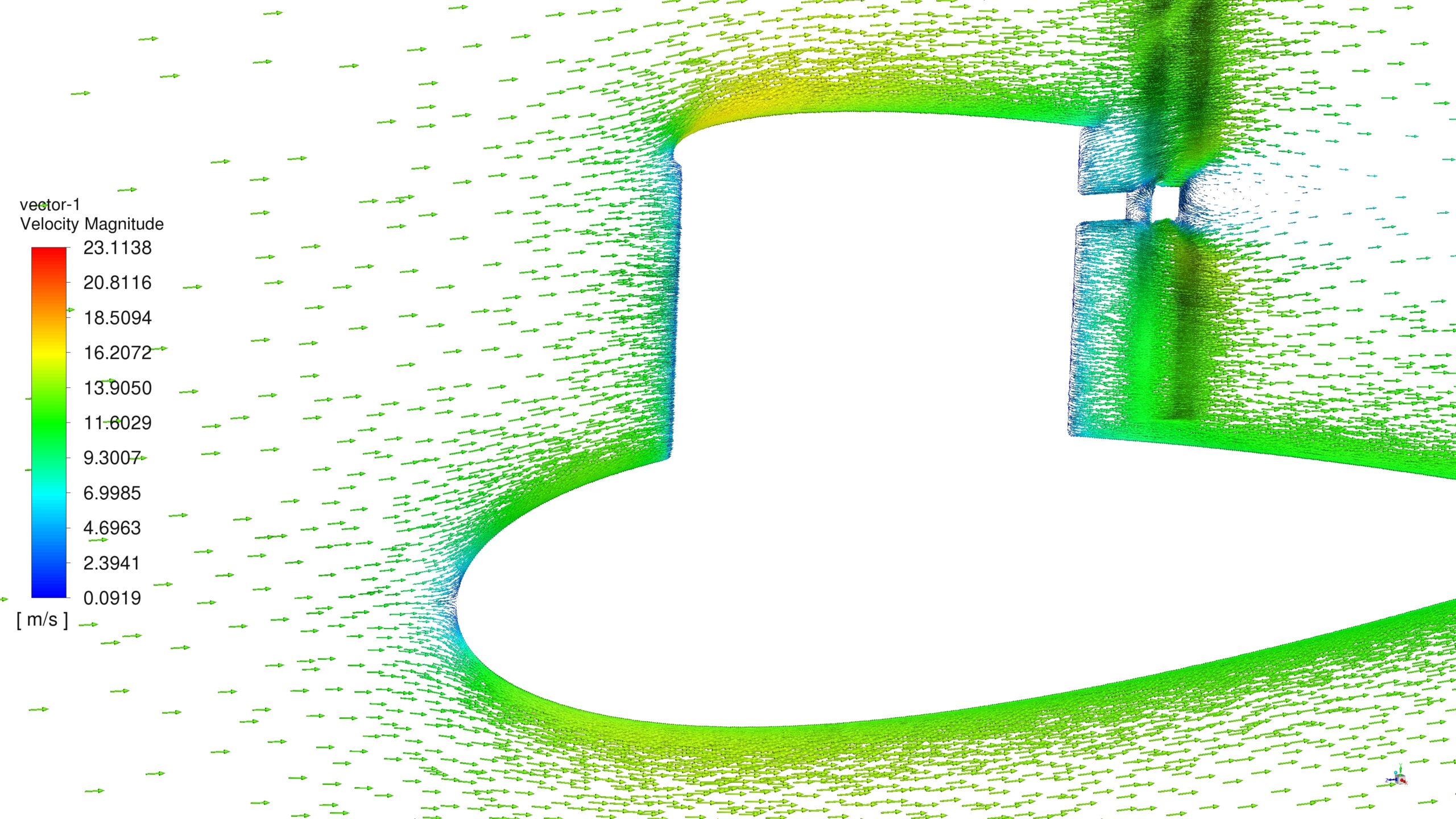

The Multiple Reference Frames (MRF) method is used to model the rotational motion of the propellers.

Conclusion

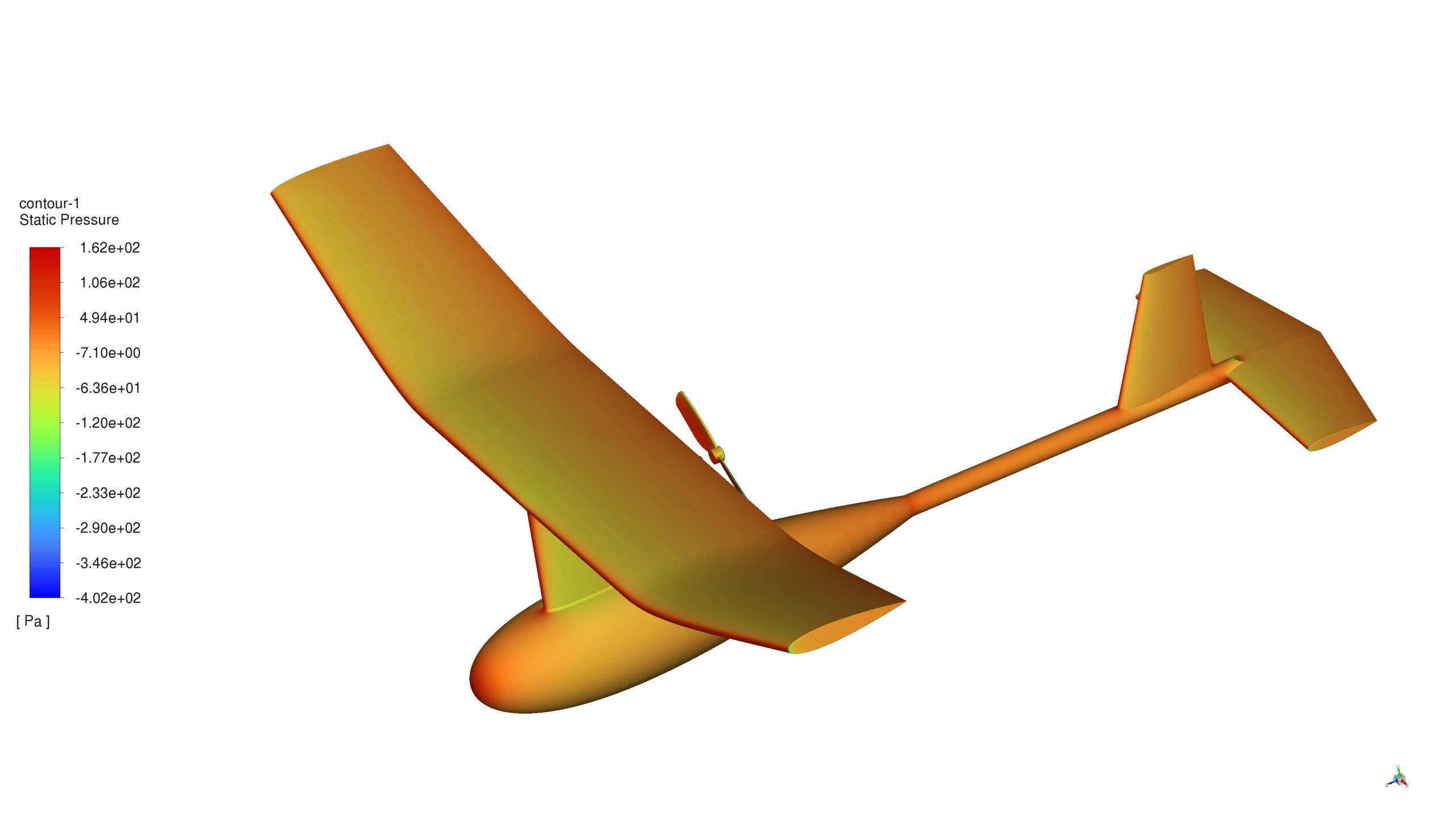

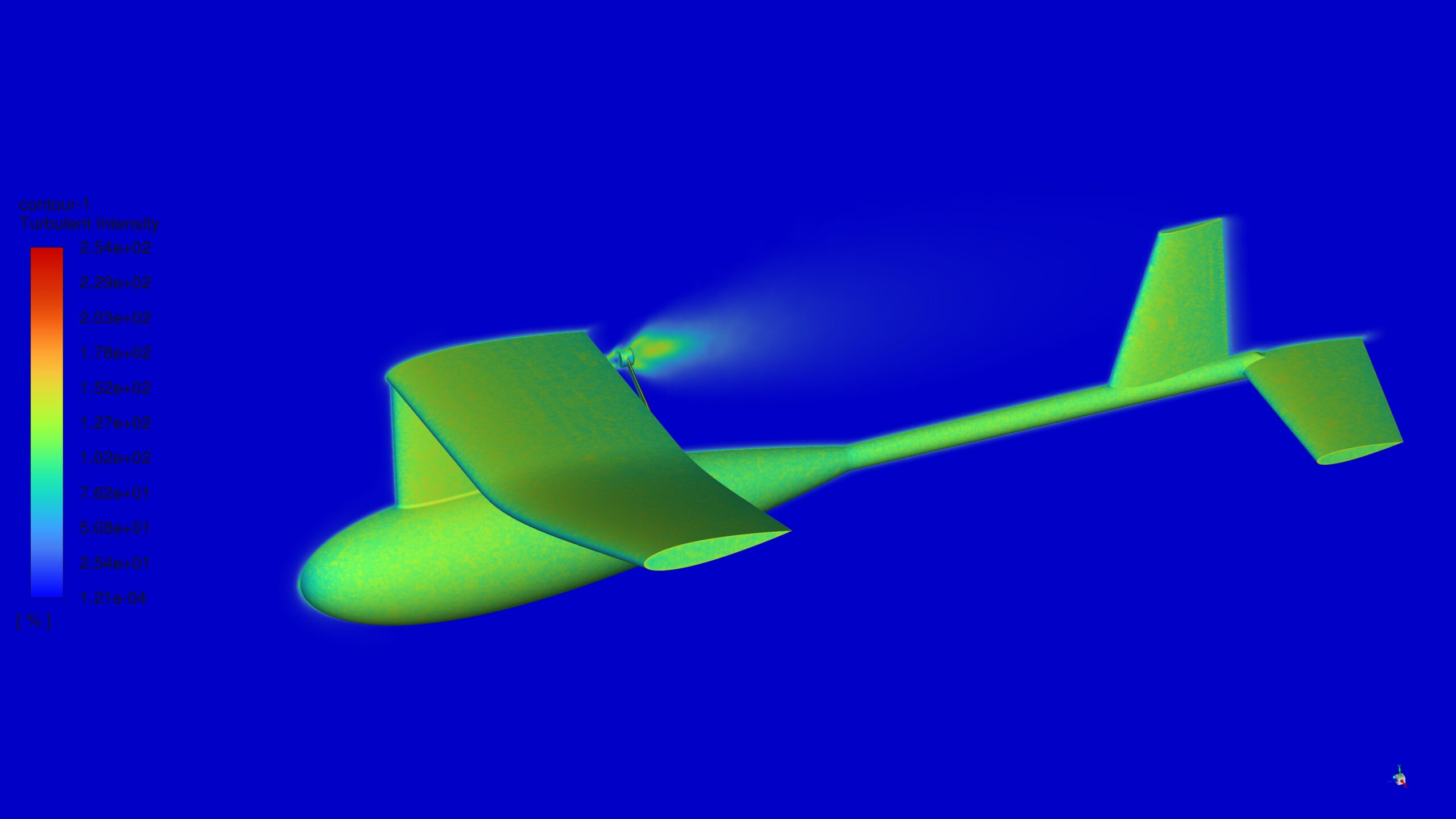

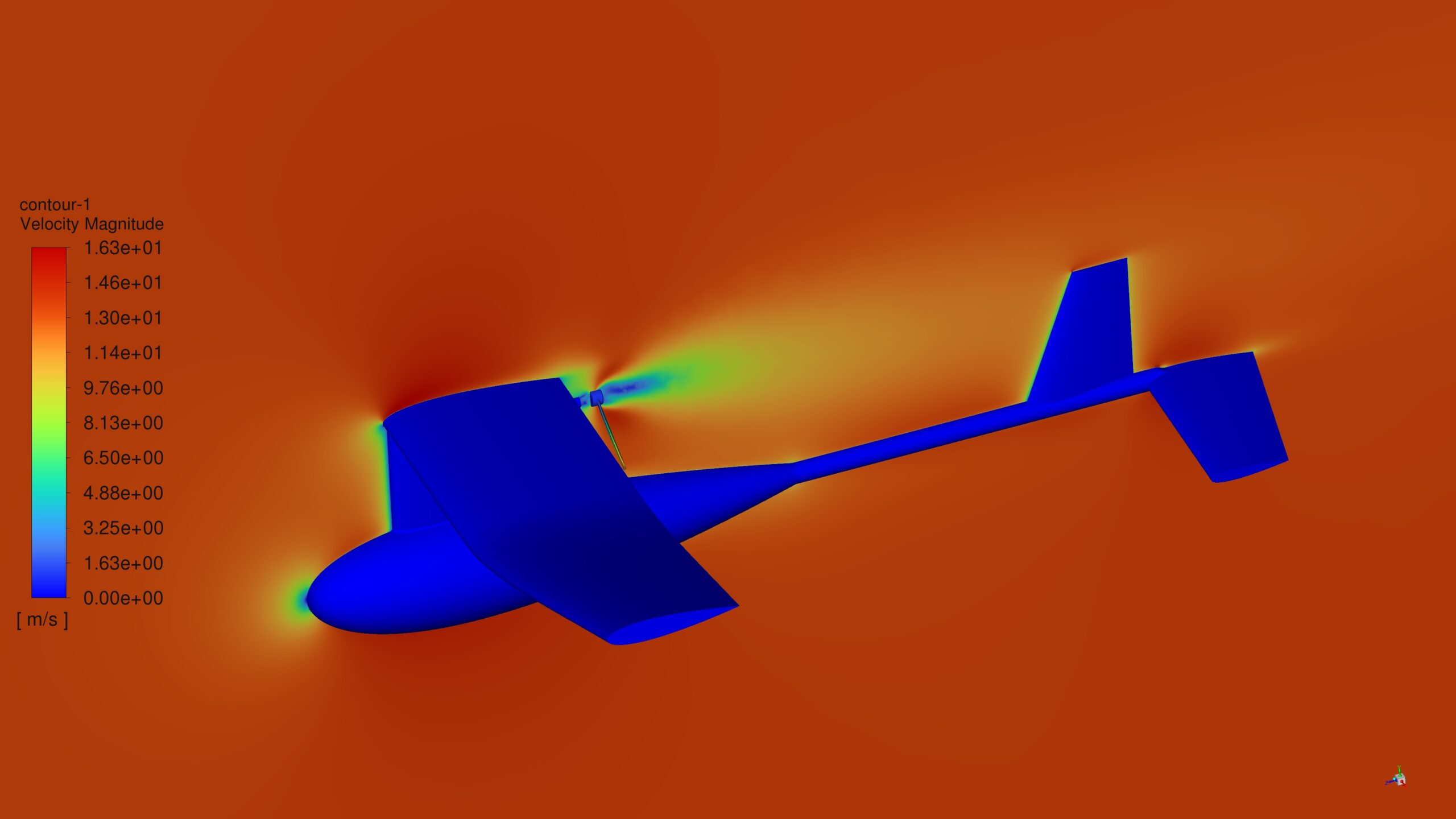

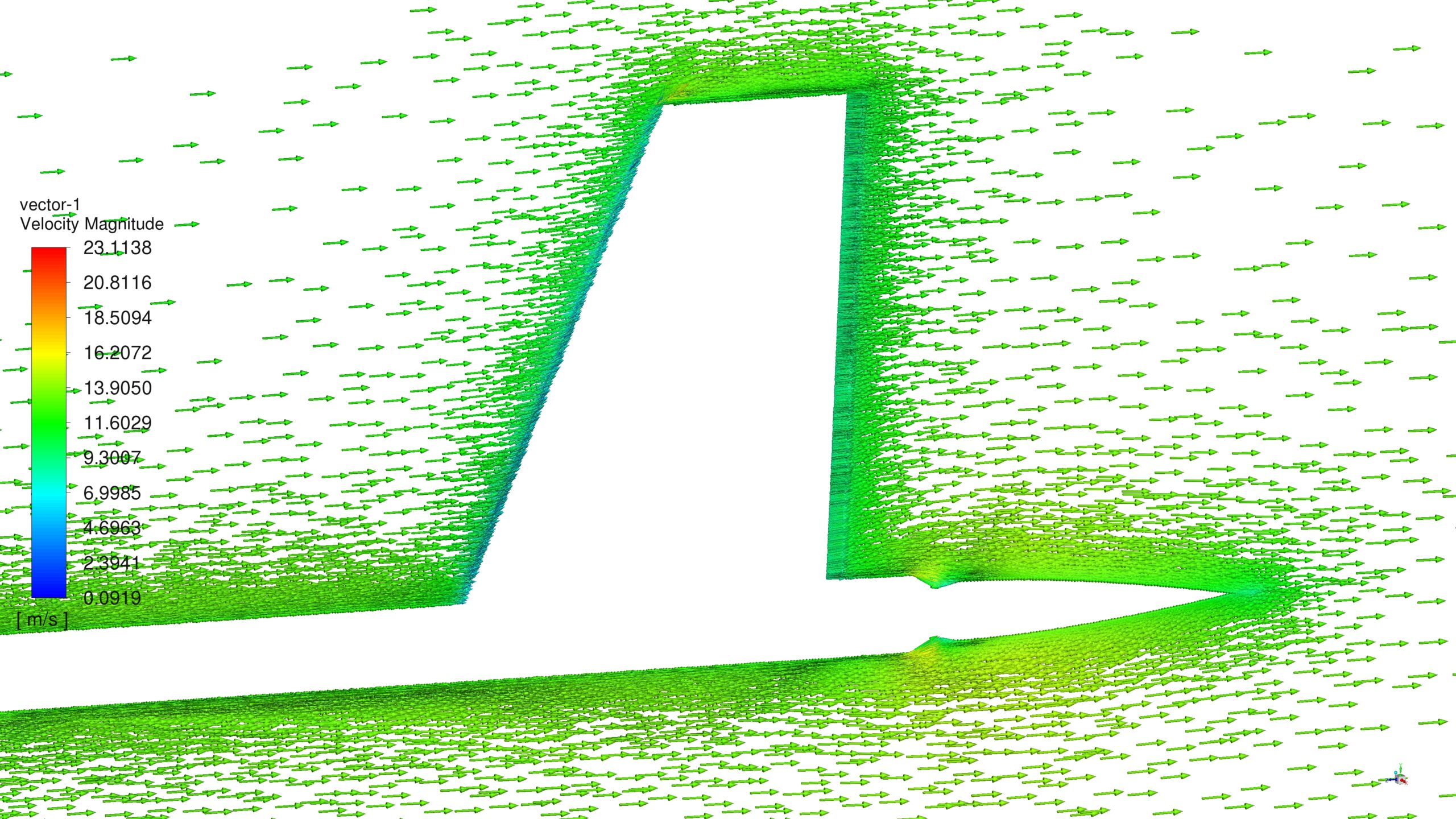

After the simulation process was finished, contours and vectors for parameters such as velocity, pressure and turbulent intensity were obtained. As shown in the velocity contours, the vortexes behind the propeller and the air movement around the UAV are visible.

The maximum amount for the turbulent intensity parameter is exactly behind the propeller due to its rotation.

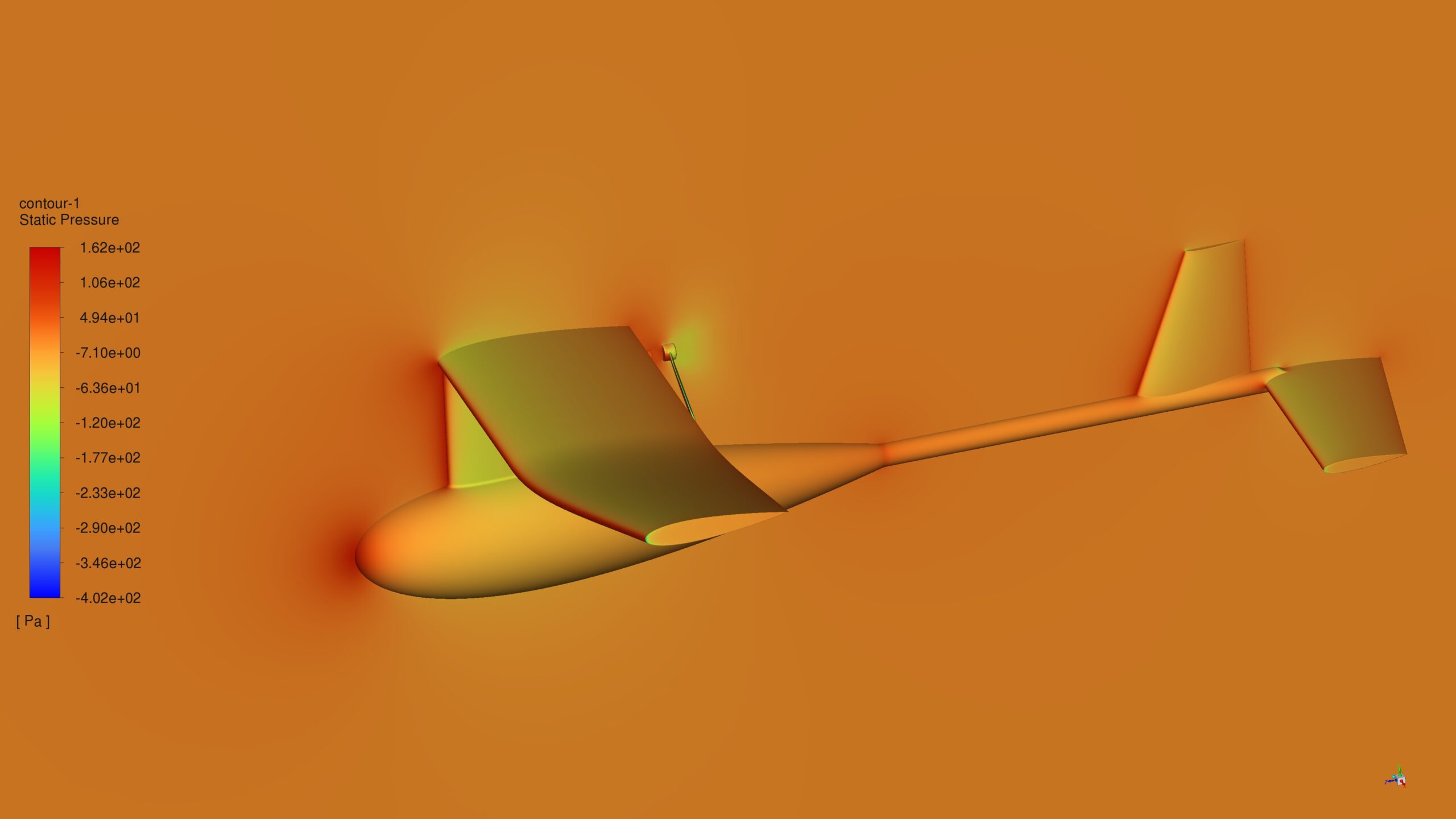

In the static pressure parameter case, as it was predictable, the UAV’s front surfaces endure the highest pressure. The maximum static pressure is exerted on the nose of the UAV, the front surfaces of wings and propellers, which tells us about the necessity of the manufacturing focus on these components.

Dock Nienow –

The RQ-11 Raven simulation is impressive! The detail on aerodynamic behaviors – especially vortexes and turbulence around the propeller – explained exactly why this UAV is so efficient. And knowing the high-pressure points, like the nose and wings, gives great insights into design considerations.

MR CFD Support –

Thank you for your kind words. We’re glad to hear that our simulation of the RQ-11 Raven provided valuable insights into its aerodynamic efficiencies and design considerations. It’s rewarding to know our attention to detail is appreciated.

Dr. Magnus Daugherty MD –

The RQ-11 Raven simulation is truly fascinating! The attention to detail in replicating the drone’s aerodynamics using ANSYS Fluent showcases the depth such simulations can offer. The ability to visualize flow patterns and turbulences around the UAV adds great value, providing insights into potential design optimizations. Great work on simulating the tricky vortexes post-propulsion — definitely a strong stride in understanding UAV aerodynamics!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the RQ-11 Raven drone CFD simulation so insightful. It’s our goal to provide detailed and accurate simulations that can help in understanding and optimizing designs. We’re glad you appreciate the effort that went into visualizing the aerodynamic properties and understanding the crucial load points on the UAV. Your recognition of the intricate flow patterns, especially the vortex simulation, means a great deal to us. Thank you once again for your kind words!

Margie Dicki –

The training was comprehensive and insightful. The details on how the RQ-11 Raven’s aerodynamics were simulated using the model’s flight parameters make me appreciate the complexities of UAS design and operation. Understanding the turbulence and pressure zones will undoubtedly help when considering UAV designs and the quality of the data here ensures a great learning experience.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation training for the RQ-11 Raven drone has provided you with a comprehensive understanding of UAV aerodynamics. At MR CFD, we strive to deliver detailed and quality data to enrich our clients’ learning experiences. Your appreciation motivates us to continue providing top-notch training materials. If you have any further questions or need more assistance with drone aerodynamics or CFD, please feel free to reach out to us.

Lawson Robel IV –

This course sounds excellent. The details of the aerodynamics of the Raven UAV are something I am particularly interested in!

MR CFD Support –

Thank you for your kind words! We’re glad to hear you found the RQ-11 Raven Drone CFD Simulation insightful. Aerodynamics is indeed a key aspect when it comes to UAV design and operation, and we’re happy our course could provide the valuable information you were searching for. If you have any more questions or need further assistance with your aerodynamics studies, feel free to reach out!

Orpha Predovic –

The simulation for RQ-11 Raven Drone’s aerodynamics looks in-depth. Great work on modeling the rotational motion of propellers. Were there any challenges in capturing the vortexes behind the propeller accurately?

MR CFD Support –

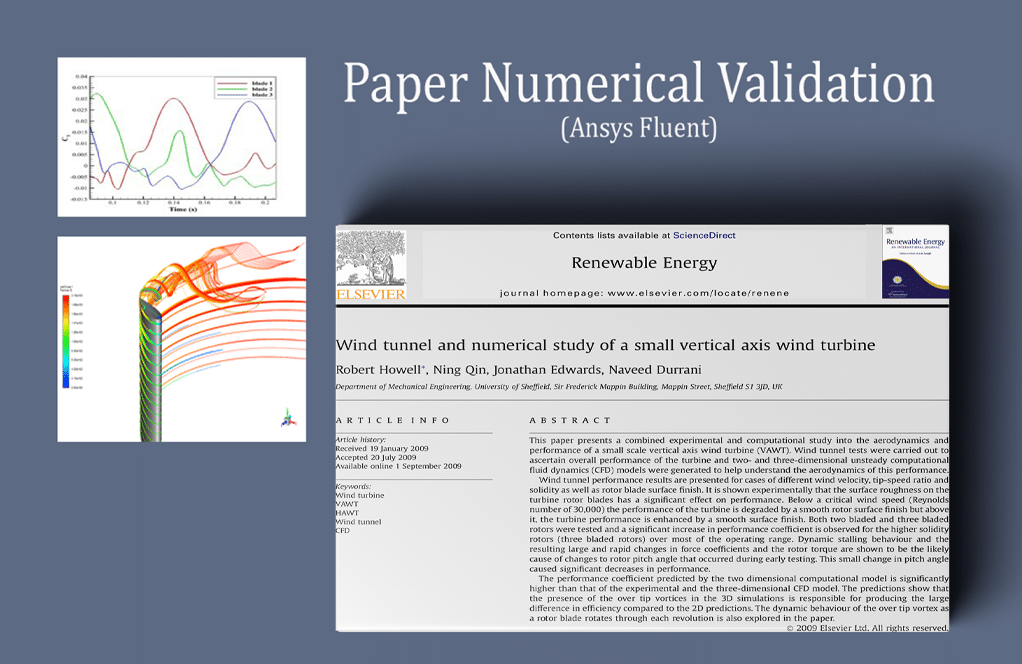

We appreciate your positive feedback on our RQ-11 Raven Drone CFD simulation. In simulations like these, accurately capturing the vortexes behind the propeller is challenging. We carefully set up our computational domain and mesh resolution, and employed advanced turbulence models available in ANSYS Fluent, to accurately predict complex flow phenomena such as vortex shedding. Our validation process, including a grid independence test and comparing against known benchmark cases, ensures that our results are reliable and physically accurate.

Sylvia Ward –

Loved the content! The RQ-11 Raven UAV simulation felt so realistic. Particularly impressed with the detailed analysis on the pressure and turbulence. It encapsulated the complexities of real-world UAV operations superbly.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our simulation of the RQ-11 Raven UAV met your expectations and provided insightful analysis. Your feedback is greatly appreciated, and we look forward to continuing to deliver high-quality CFD simulations. If you have any more questions or need further clarification, feel free to reach out!

Mr. Nicolas Hintz I –

I used the RQ-11 Raven UAV simulation for my project and was impressed with how detailed the models are. The results matched closely with my expectations and the reality of the real UAV. It helped me understand the aerodynamics involved in designs like the Raven. Well done on creating such a helpful training product!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the RQ-11 Raven UAV aerodynamic simulation was beneficial for your project and that the models and results met your expectations. If you require further assistance or have any more projects in the future, please know that we’re here to help. We appreciate you taking the time to provide feedback!

Julian Olson IV –

The way the MRF method is applied in simulating the propeller’s motion sounds intricate; could you expand on that concept?

MR CFD Support –

Certainly! The Multiple Reference Frames (MRF) method allows us to simulate rolling movements by segregating physical sections within our computational area. For the propellers, we allocate a rotational reference frame separate from the static portions. This perforation captures the angular velocity and assures a harmonious link with the stationary domains, resulting in realistic fluid dynamics effects around the rotating propeller without necessitating the re-calculation of the mesh at each timestep.

Prof. Jason Bechtelar –

I’m impressed with the detail presented for the RQ-11 Raven Drone simulation carried out in ANSYS Fluent. It’s fascinating to learn how realistic flight conditions are mimicked and how the aerodynamic behaviors are meticulously analyzed.

MR CFD Support –

Thank you for your positive feedback! We are glad to hear that the RQ-11 Raven Drone CFD simulation details were illuminating for you. We strive to provide meticulous and realistic conditions to ensure that our simulations are as accurate and informative as possible.

Glenda Cremin –

This CFD simulation study was incredibly detailed and informative. The utilization of the MRF method to model the rotating propellers and the capture of turbulent intensity around the UAV really illustrated the complexity of airflow patterns. Data points like the maximum pressure exerted on the UAV’s nose and wing fronts provide critical insights that can enhance design considerations for durability and efficiency. An excellent piece of work that helps bridge the gap between theory and practical application in aerodynamics.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our simulation study of the RQ-11 Raven UAV was able to enrich your knowledge on the subject. Our goal is always to provide detailed and useful insights that can be applied practically. Your comment motivates us to continue delivering high-quality simulations and analyses. We appreciate your time in reviewing our product!

Alena Bailey –

The simulation of the RQ-11 Raven was so intriguing! I was especially impressed with how the propeller’s rotation influenced the airflow and turbulence. It beautifully demonstrated the complex aerodynamic properties and really helped to visualize the UAV’s real-world performance. The Polyhedra mesh with over 5 million elements must have captured the details quite well. Excellent CFD model!

MR CFD Support –

Thank you for your positive feedback on our RQ-11 Raven CFD Simulation using ANSYS Fluent. We are thrilled to know that the simulation provided clear insights into the UAV’s aerodynamics and that you found the visualization of the airflow and the effects of the propeller’s rotation well-executed. We strive to deliver detailed and accurate modeling, and your comments affirm our commitment to quality. Thanks again for choosing our training material!

Mossie Will –

This course was immensely informative and enjoyable. The practical approach to simulate the Raven UAV provided clarity on the aerodynamics of unmanned aircraft. After leveraging this resource, it feels much simpler to visualize the effect of propeller motion on airflow. The data on turbulent intensity and pressure distributions were especially valuable for understanding complex airflow patterns. Excellent resource for both educational and professional development purposes!

MR CFD Support –

Thank you for your thoughtful feedback! We’re thrilled to hear you found the RQ-11 Raven UAV CFD Simulation training so beneficial. Understanding the aerodynamics of UAVs can indeed be a complex task, and we’re glad our course could make it more approachable for you. Your appreciation really motivates us to continue providing high-quality educational material. If you have any other insights or need further assistance in your learning journey, feel free to reach out!

Aron Padberg –

I’m extremely impressed by the detailed analysis of the RQ-11 Raven’s aerodynamics provided here. It’s evident a significant amount of work went into accurately simulating the UAV’s behaviour during flight – particularly the flow visualisation put the amount of ingenuity into perspective!

MR CFD Support –

We appreciate your feedback and are glad to hear that our CFD simulation products meet your expectations. The team works diligently to ensure the simulation’s accuracy and it’s rewarding to know when it adds value for our customers. Thank you for your kind words!

Saul Keebler –

I’m amazed at how detailed the simulation was for the RQ-11 Raven Drone! The insights into the turbulent intensity and where the maximum pressure occurs are particularly invaluable for understanding aerodynamics. Great work!

MR CFD Support –

Thank you for your kind words! We’re thrilled that you found the details of the RQ-11 Raven Drone simulation insightful. Understanding aerodynamics is crucial for UAV design, and we’re glad our training materials helped you gain clarity. If you need further information or assistance with other simulations, feel free to reach out!

Kevin Littel DVM –

The RQ-11 Raven simulation sounds impressive. The use of MRF for the propeller’s rotation and Polyhedra elements for meshing seems quite detailed. These features must give an accurate representation of the aerodynamic performance. Great job!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you appreciate the complexity and accuracy of the RQ-11 Raven CFD simulation using ANSYS Fluent and our meshing approach. Our goal is always to deliver high quality and precise simulations. If you have any more questions or need further assistance, feel free to ask.

Monte Weissnat –

I’m thoroughly impressed with the level of detail in the RQ-11 Raven Drone CFD Simulation learning content! The modeling aspects, such as the use of the MRF method for propeller motion and the clear representation of the pressure distribution on the UAV’s nose and wings, provide an in-depth understanding of real-world aerodynamics applied to UAVs. The skills gained from this training are directly applicable to the field of aerodynamic design and analysis. Fantastic job, team!

MR CFD Support –

Thank you so much for your positive feedback! We’re really glad to hear that you found the RQ-11 Raven Drone CFD Simulation valuable and applicable to real-world scenarios. It’s encouraging to know that our detailed explanations and training content could help enhance understanding in aerodynamic design and analysis. Your appreciation means a lot to our team!

Noah Nienow –

The RQ-11 Raven Drone simulation by MR CFD seems increasingly insightful for understanding airborne device behavior. The detailed simulation captures critical aerodynamics which can aid in drone design considerations, particularly respecting propeller impact on turbulence and pressure distribution upon the UAV body. The high-fidelity nature of this CFD analysis is no small feat, demonstrating MR CFD’s capability to virtually test and inform UAV design prior to physical prototyping.

MR CFD Support –

Thank you for your positive review and recognition of the aerodynamic simulation’s quality for the RQ-11 Raven Drone. MR CFD takes pride in producing detailed and insightful analyses to help with the design and performance improvement of UAVs like the Raven model. We’re grateful for customers like you who appreciate the value these simulations provide to the design process.

Mr. Dangelo Lynch PhD –

Great training material! I finally understood how to use the Fluent software for UAV aerodynamics simulation! Love the coverage on MRF methodology.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training material helped you comprehend the application of Fluent software for UAV aerodynamics simulation. We strive to provide comprehensive and user-friendly resources. If there’s anything else you wish to learn or need assistance with, please don’t hesitate to reach out.