Spoiler Modes Comparison for F1 Car Aerodynamics

$100.00 Student Discount

- The problem numerically simulates Spoiler Modes Comparison for F1 Car Aerodynamics using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the polyhedral element number equals 450000.

- We aim to compare the open and close modes of the spoiler and observe the difference between the lift and drag forces.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Spoiler Modes Comparison for F1 Car Aerodynamics, ANSYS Fluent Tutorial

In this project, two different Spoilers in open and closed modes are compared using CFD simulation in ANSYS Fluent software to observe the lift and drag force difference between these two modes. We perform this CFD project and investigate it by CFD analysis.

As a moving device, the car has always been involved with air flow, so the science of aerodynamics has helped engineers bring the best performance to the car.

In recent years, the science of aerodynamics has experienced tremendous progress because, in the past, only a wing or spoiler was installed on a car to study its impact.

However, the process has become so complex today that engineers spend many hours researching and developing wind tunnels and computer simulators.

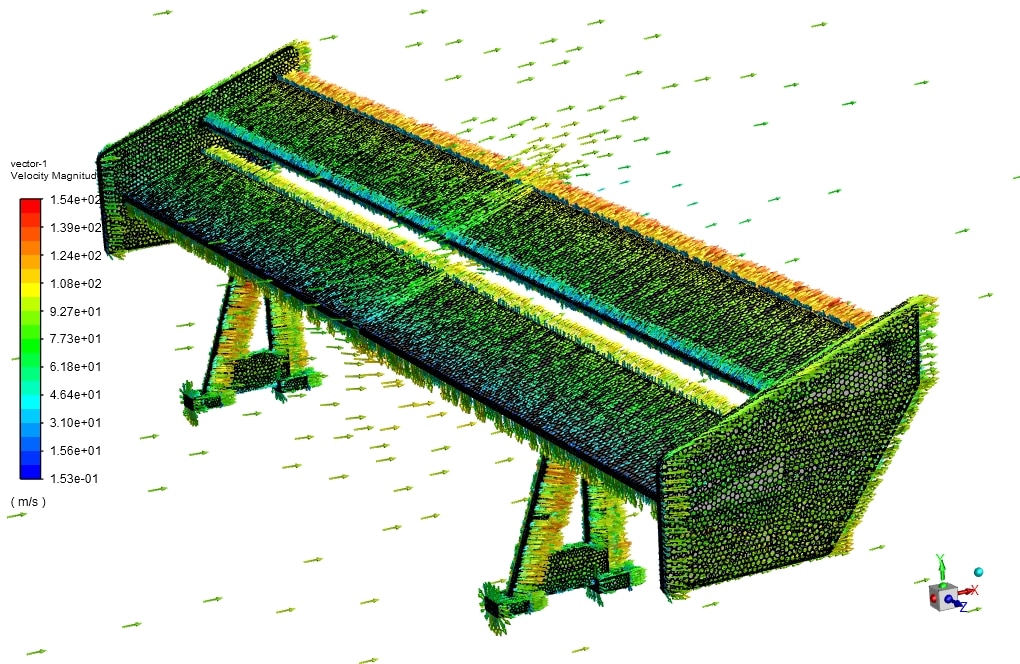

The present model is designed in three dimensions using SOLIDWORKS and then imported into the Design Modeler software.

We generate the mesh in Ansys meshing software. The elements are first used as tetrahedral. Then Fluent meshing converts them into the polyhedral mesh, which has fewer cells and better quality.

This mesh includes 1832373 Tetra elements for open mode and 1988126 for closed mode. Also, the number of polyhedral elements is about 450000 elements.

Spoiler Methodology

One of the problems with cars at high speeds is that the lift force increases, and then the vehicle loses control. Spoilers are designed to control the passage of air through vehicles. However, the precise design of this device has always been a challenge for researchers.

When a car reaches speeds above 145 km / h, the spoiler can show the difference between life and death, so simulating spoilers in computing software is essential.

Aerodynamics comes in two parts: increasing the downforce for traction and stability of the car and reducing drag or air resistance with the help of the chassis at high speeds and secondary accelerations.

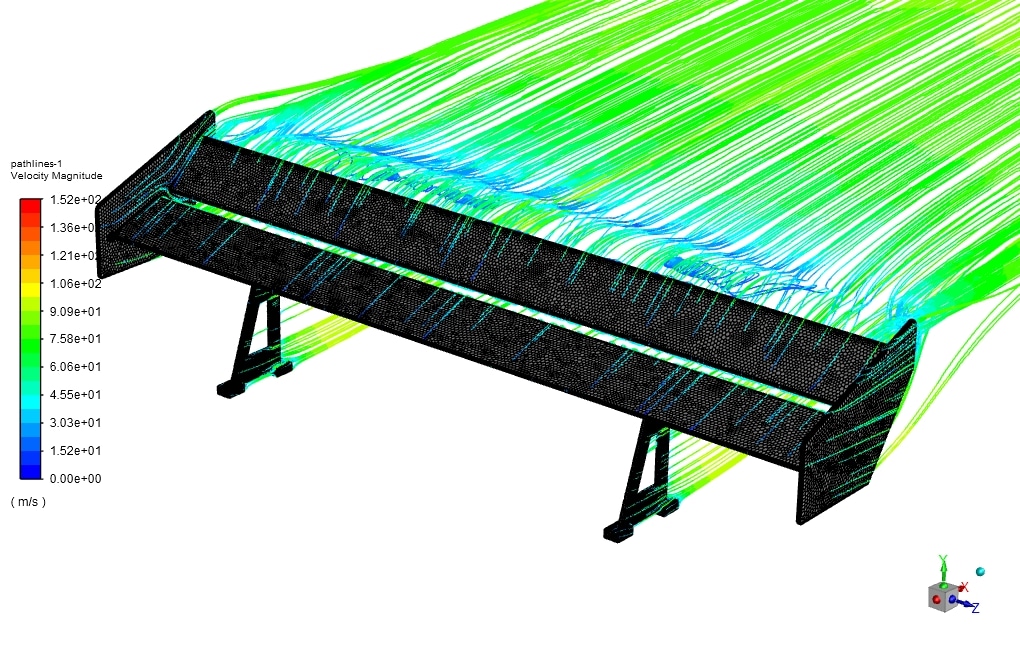

Aerodynamic engineers have always sought to strike the right balance between these parameters. For example, in Formula One races, cars are allowed to use a dual-mode spoiler to reduce the lift force by opening the spoiler on straight routes, which significantly reduces drag and makes the car accelerate about 340 km/h.

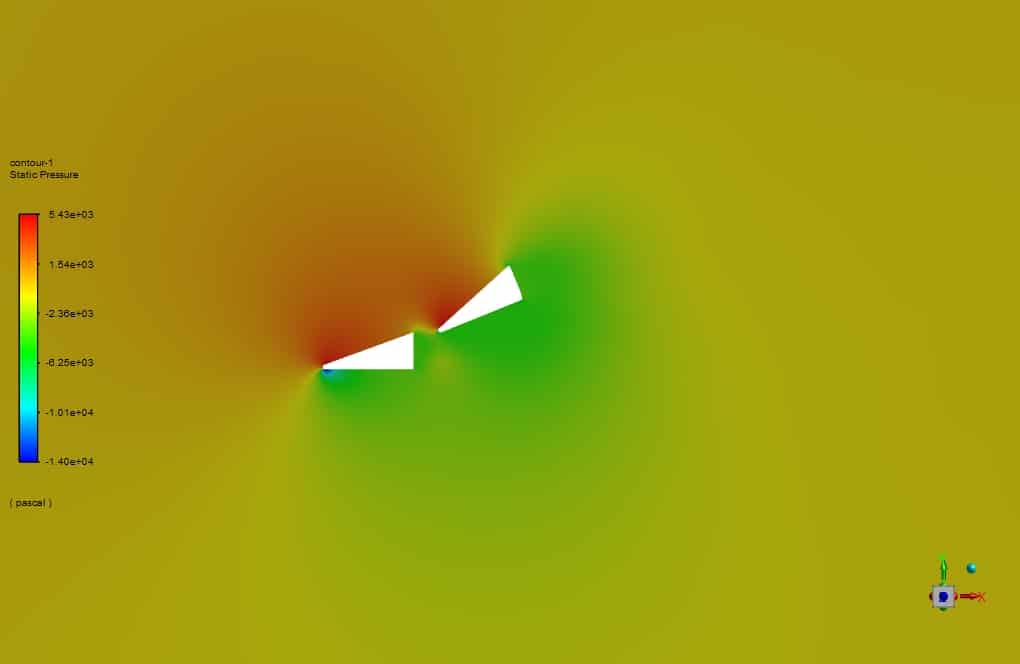

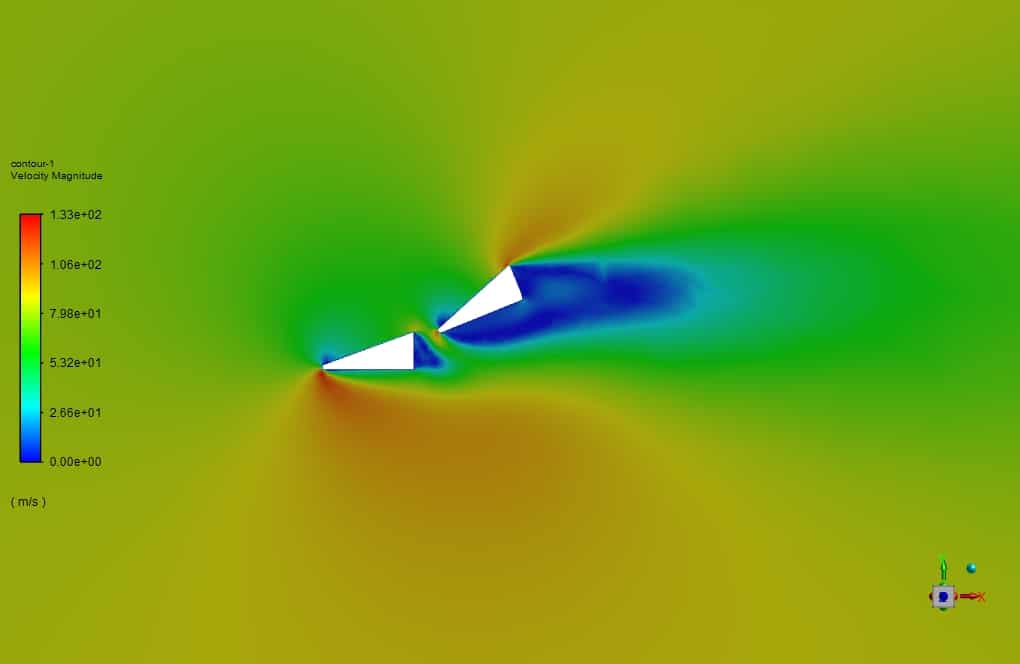

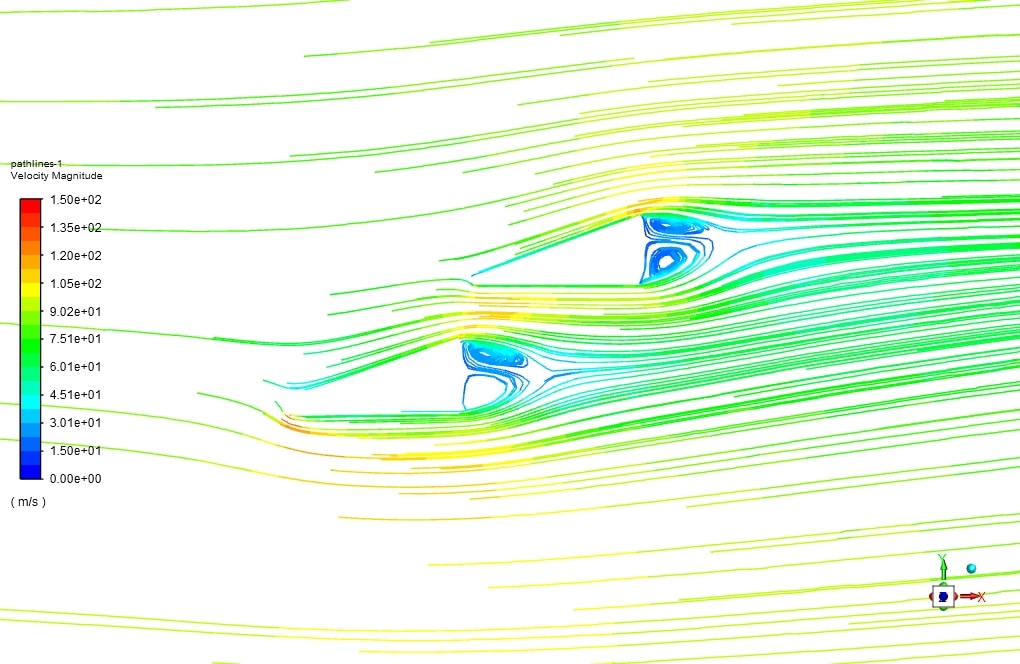

This simulation aims to compare the open and close modes of the spoiler and observe the difference between the lift and drag force between these two modes. This simulation is performed using the k-w SST turbulence model.

Spoiler Conclusion

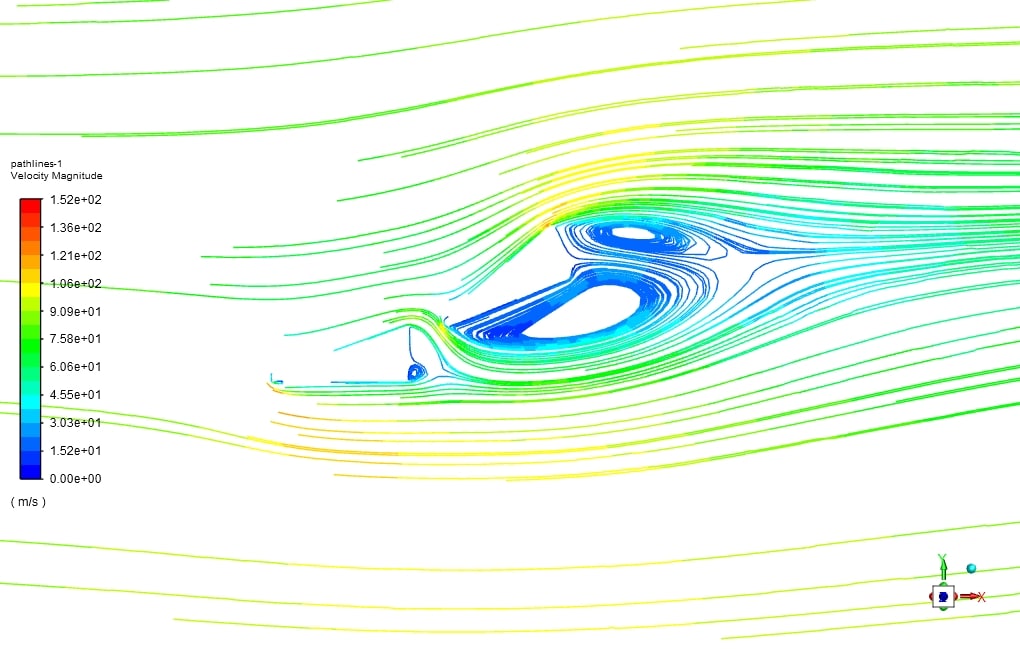

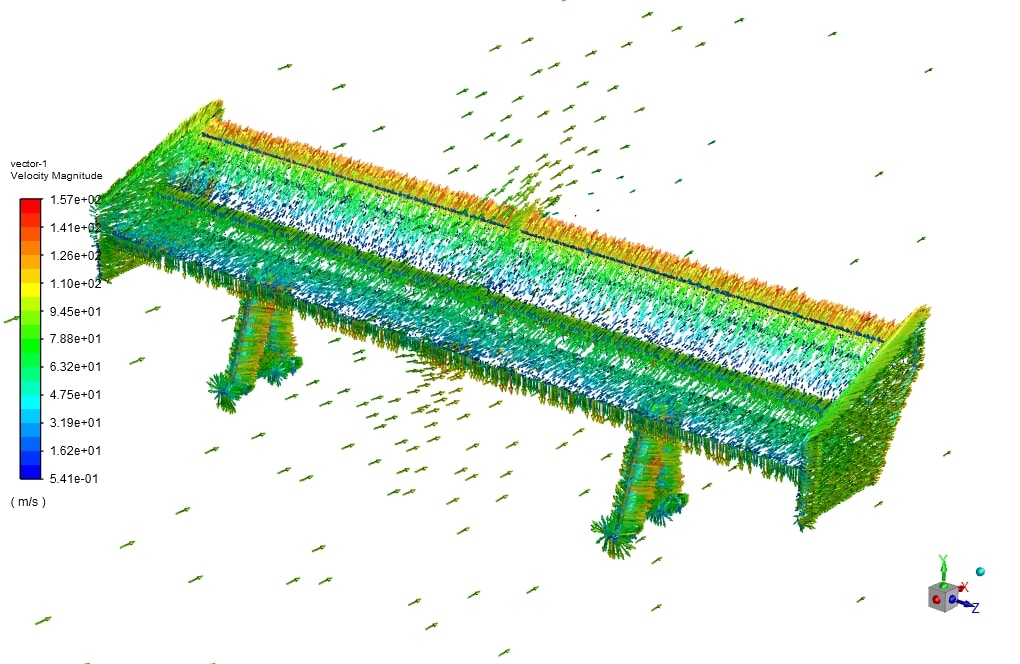

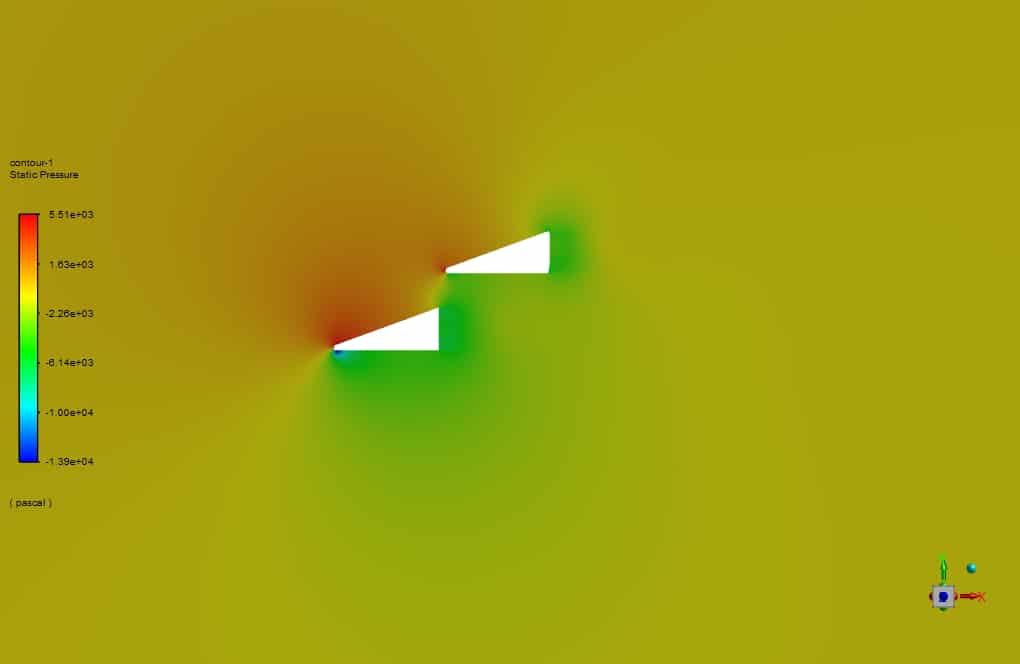

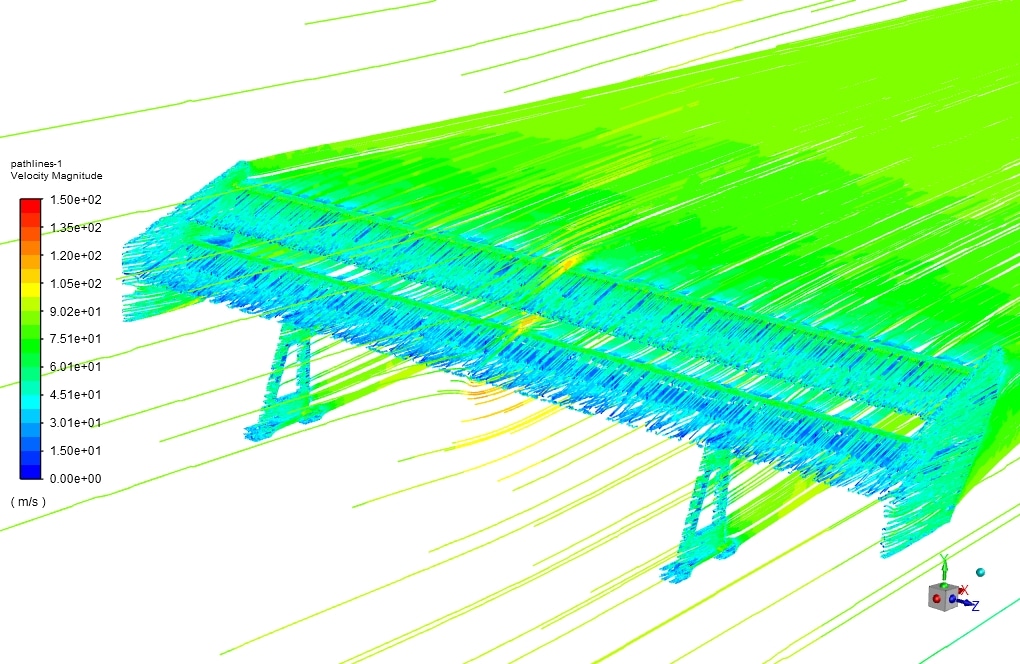

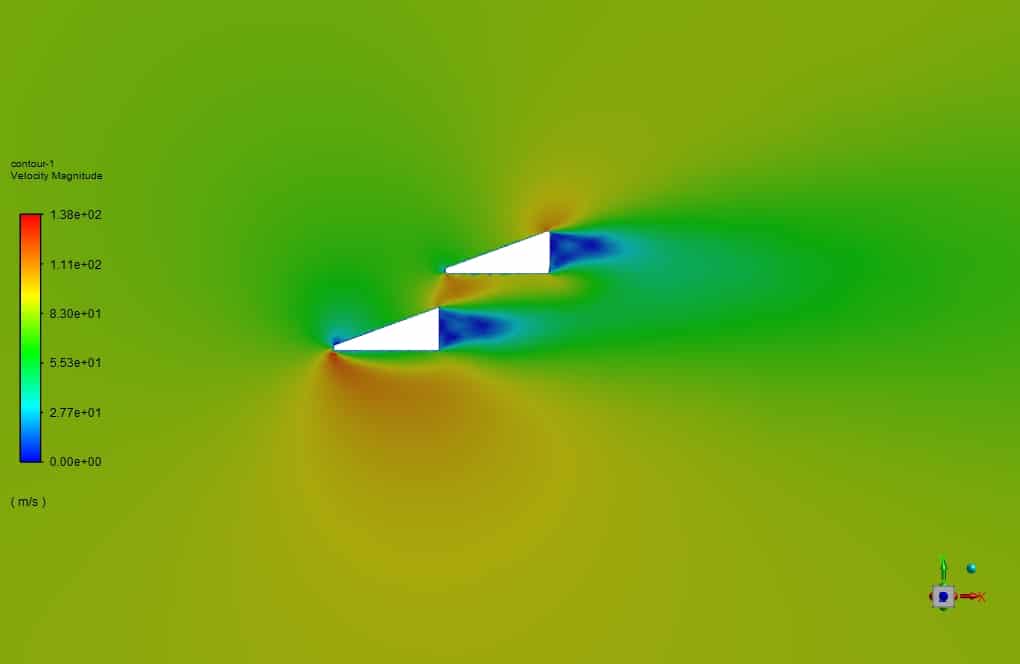

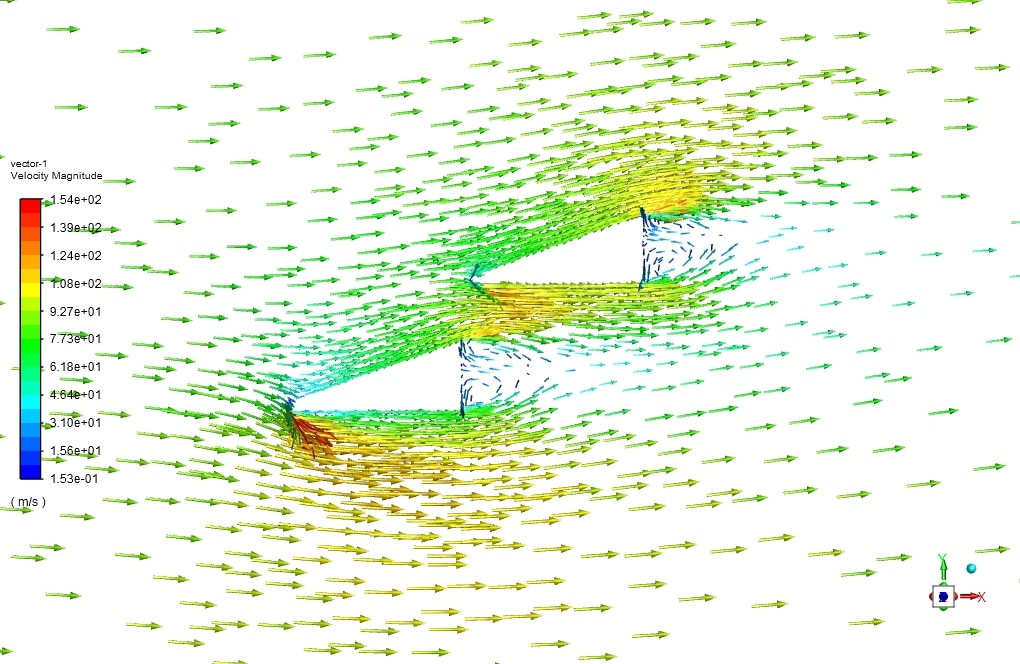

At the end of the solution process, we obtain two- and three-dimensional contours related to pressure, velocity, streamlines, and velocity vectors.

Furthermore, The comparison between the two modes shows that the lift force in the closed mode is about 700 Nm higher, which is the main reason for using the spoiler to make the car more stable on winding routes and momentary accelerations.

On the other hand, the drag force in the open state is less than 450 Newtons, which also indicates that in cases where it is not necessary to use the downforce force, and the speed is more desirable, opening the spoiler and using the drag reduction system, the drag force can be significantly reduced.

The results also showed that the wider angle profile performs better than the closed spoiler (zero degrees angle).

| Drag (N) | Lift(N) | Title | ||||

| Total | viscous | Pressure force | Total | viscous | Pressure force | |

| 998 | 19 | 979 | -1864 | 2 | -1866 | DRS- on (Open Mode) |

| 1445 | 11 | 1434 | -2557 | 2 | -2559 | DRS -off (Close Mode) |

Mr. Russell Lang –

This tutorial was incredibly detailed and enlightening! The comparative analysis of the spoiler modes and their effect on drag and lift forces was precisely what I needed for my research. Seeing the numerical difference in forces really puts into perspective the importance of aerodynamic design in F1 cars. Great job on presenting clear and concise findings!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our tutorial was able to provide you with the detailed information you needed for your research. Aerodynamics plays a crucial role in Formula 1, and we’re glad our findings on spoiler modes could offer valuable insights. If you need further information or assistance with your research, please don’t hesitate to reach out!

Brown Toy –

I was amazed to see the detailed comparison between the two spoiler modes. Fantastic tutorial for understanding F1 car aerodynamics! The well-illustrated concepts and computational results truly highlight the significance of using spoilers for balancing speed and vehicle stability.

MR CFD Support –

Thank you for your positive feedback on our F1 car aerodynamics tutorial. We’re delighted to hear that you found the comparison enlightening and useful. It’s great to know our efforts in illustrating the complex mechanisms of spoiler modes are appreciated!

Monroe Schuppe –

I found the distinction between lift and drag forces in the two spoiler modes quite intriguing. The data is clear but it does make me wonder, do these simulated forces closely reflect real-world racing conditions? How accurate is this CFD model in predicting the performance of a real F1 car?

MR CFD Support –

In the MR CFD simulation of spoiler modes for F1 car aerodynamics, we strive to accurately represent real-world racing conditions. The accuracy of our CFD model is ensured by employing advanced turbulence models like the k-w SST and proper boundary conditions. These simulations are validated with experimental data and benchmarking against real-world tests when possible. While some discrepancies can occur due to simplified models or computational limitations, the results present a close approximation of real-life spoiler performance for F1 cars.

Mortimer O’Hara –

The tutorial on F1 car spoiler aerodynamics was incredibly detailed and insightful. Observing the impact on lift and drag forces between the open and closed modes of the spoiler was fascinating. This simulation surely contributes significantly to understanding vehicle dynamics in high-speed situations. Great job on conducting a thorough CFD analysis!

MR CFD Support –

We appreciate your enthusiasm and positive feedback on the F1 car spoiler aerodynamics tutorial! It’s wonderful to hear that you found it to be detailed and insightful. Understanding the balance between lift and drag forces is essential in high-speed vehicle dynamics, and we’re glad to contribute to this knowledge. Thank you for taking the time to review our product.

Hillard Orn –

The project on the F1 car spoiler modes was very insightful. The attention to detail in aerodynamic analysis especially impressed me, understanding the importance of spoiler positioning and its impact on drag and lift forces. Well-executed and thorough CFD work!

MR CFD Support –

Thank you for your kind words! We’re glad to hear that our tutorial on the comparison of spoiler modes for F1 car aerodynamics met your expectations and provided valuable insights. It’s always great to receive positive feedback from customers, and we look forward to providing you with more quality CFD educational content.

Derek Little PhD –

I was fascinated by the clarity of the simulation results showing how the changes in spoiler modes affect the car’s aerodynamics. The detailed comparison of lift and drag forces is particularly informative for understanding the trade-offs between stability and speed.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you found the simulation results insightful and that the details provided a clear understanding of the aerodynamic trade-offs. It’s always a priority for us to deliver useful analysis for applications like improving F1 car performance. If you have any further interest in our CFD projects or need assistance, please don’t hesitate to ask.