Transonic Linear Turbine Cascade at Off-Design Conditions, Paper Numerical Validation

$320.00 Student Discount

The present project’s results are compared with the experimental results of the paper “Midspan Flow-Field Measurements for Two Transonic Linear Turbine Cascades at Off-Design Conditions”. Turbulence modeling and Computational procedures (boundary conditions, etc.) are simulated based on the article “Numerical study of the flow field through a transonic linear turbine cascade at design and off-design conditions”.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Paper Description

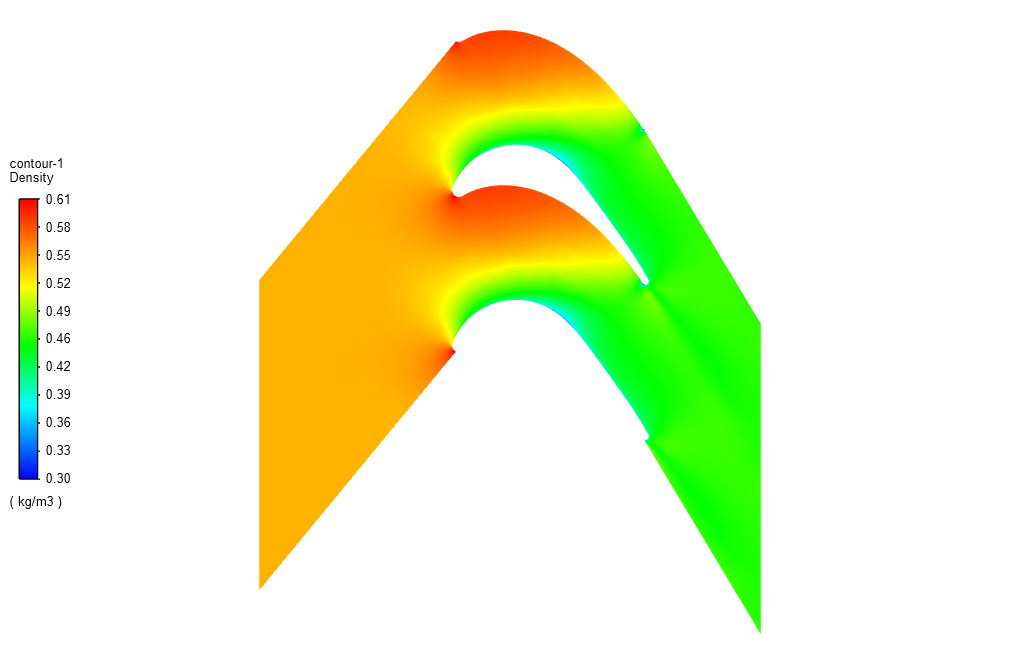

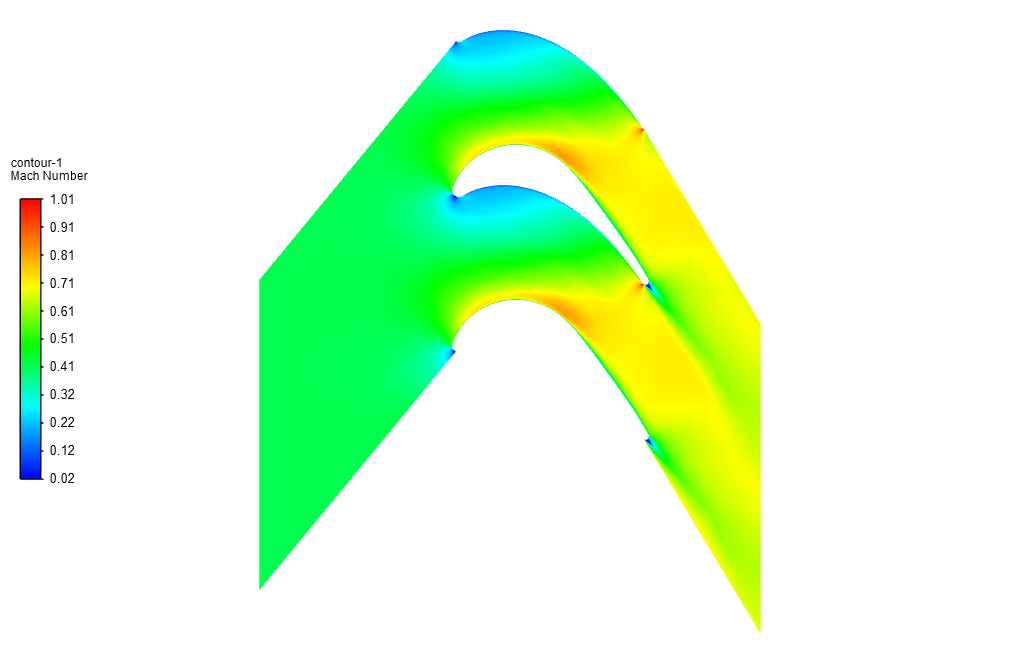

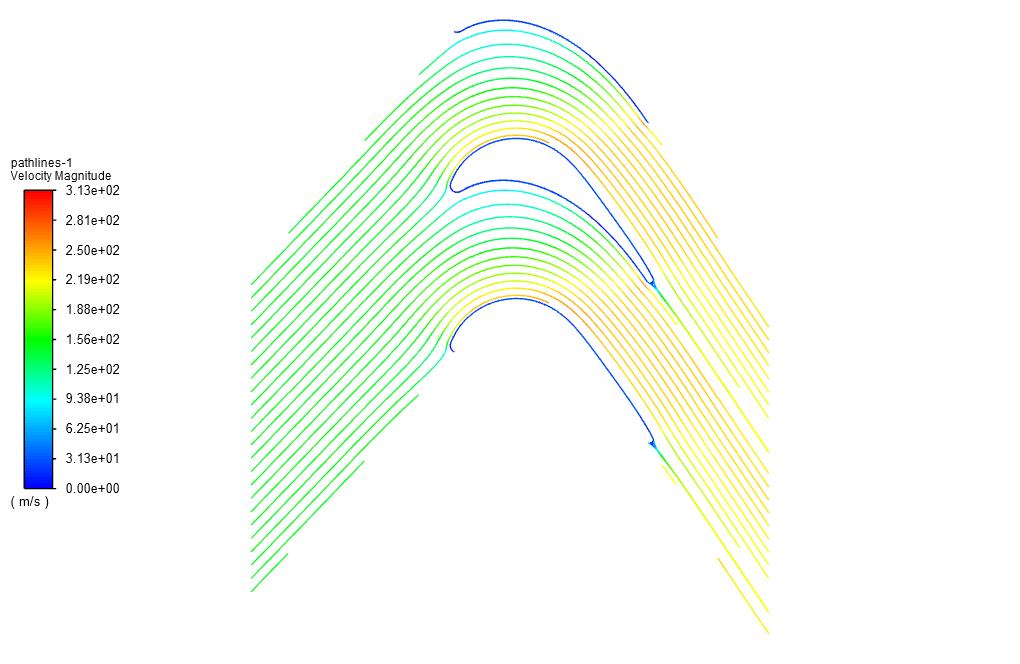

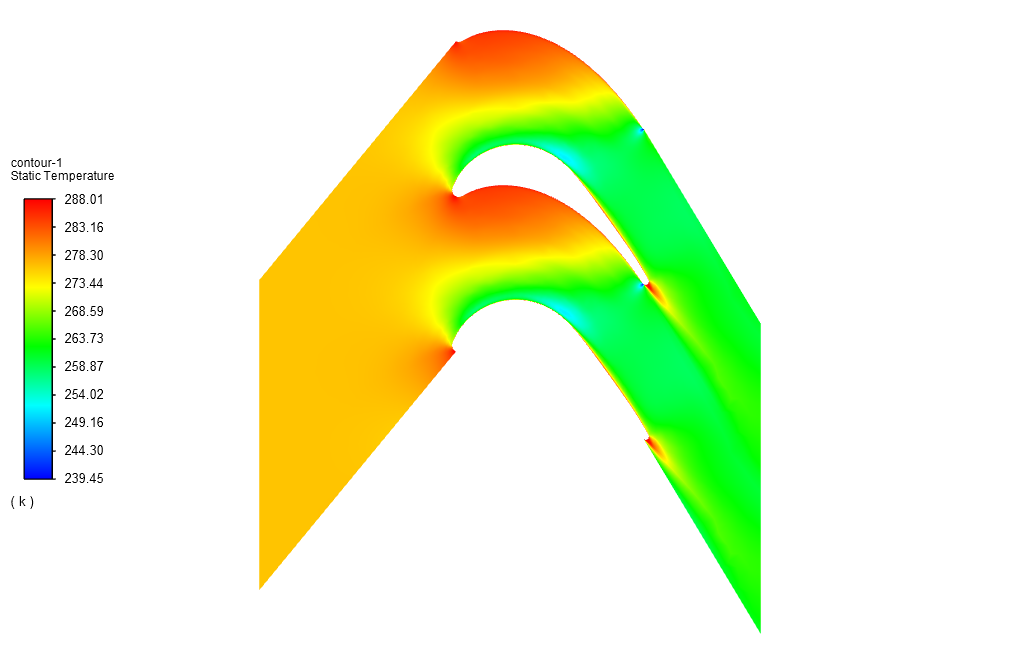

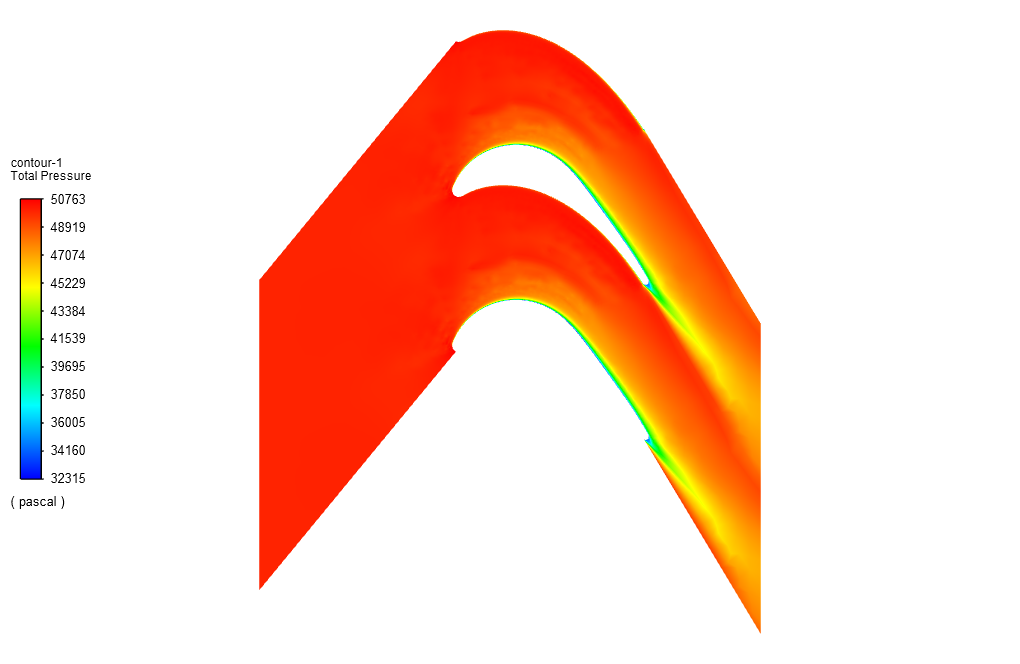

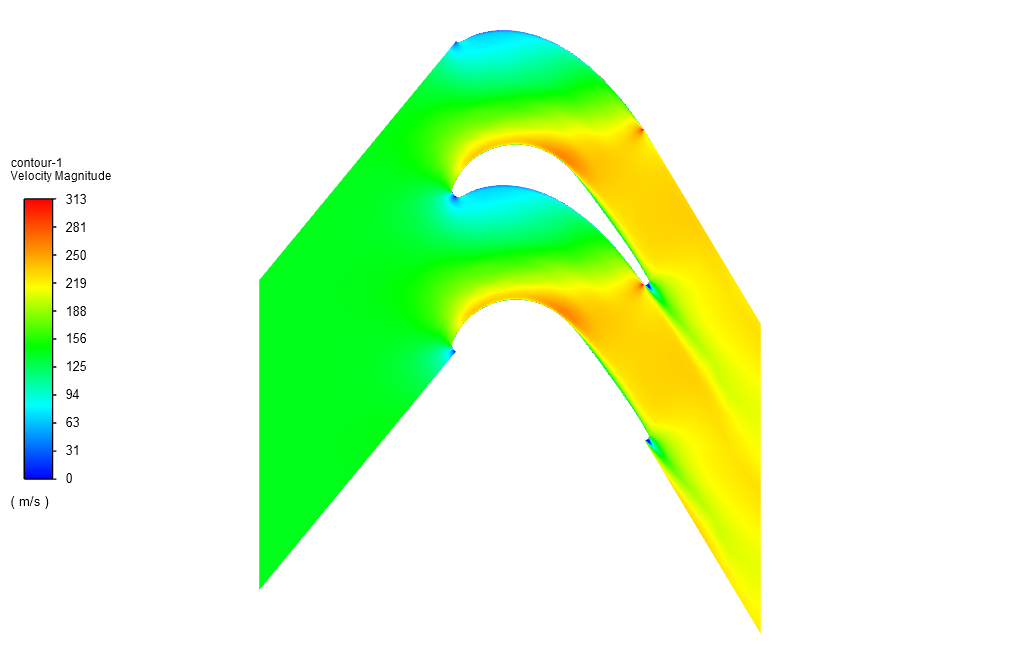

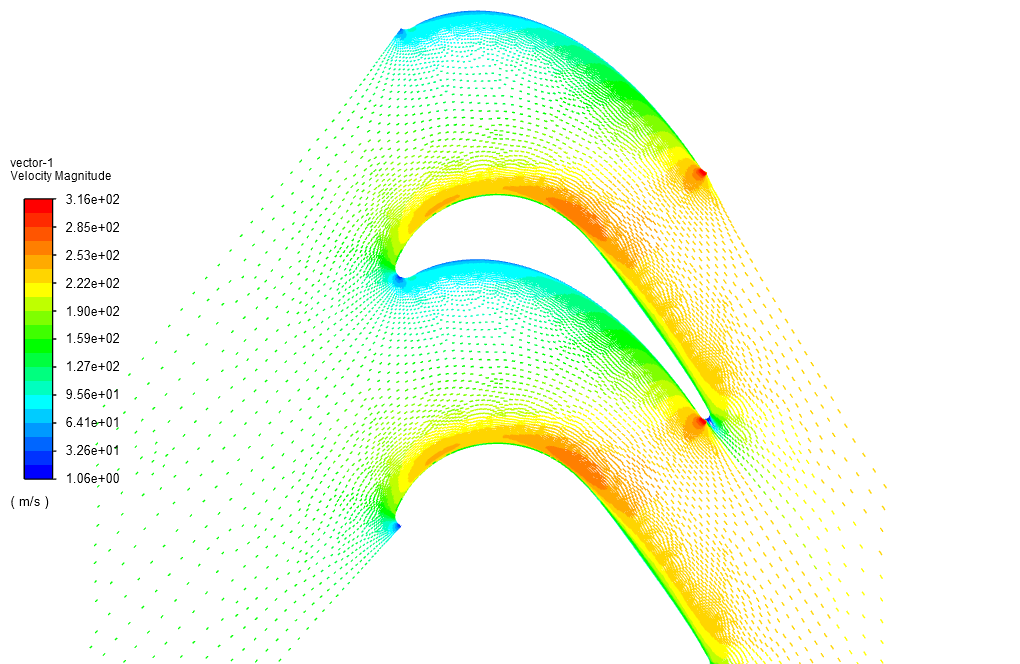

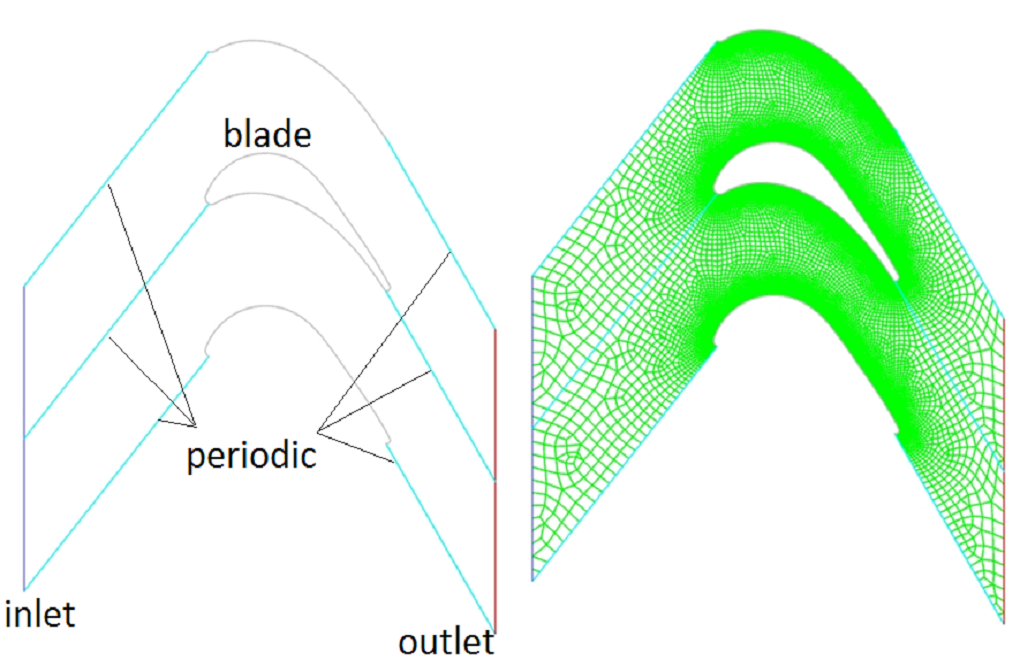

The present problem simulates the two-dimensional compressible flow field through a transonic linear turbine cascade. The present project’s results are compared with the experimental results of the paper “Midspan Flow-Field Measurements for Two Transonic Linear Turbine Cascades at Off-Design Conditions.” Turbulence modeling and Computational procedures (boundary conditions, etc.) are simulated based on the article “Numerical study of the flow field through a transonic linear turbine cascade at design and off-design conditions.” In this project, inlet and outlet boundaries were considered as pressure inlet and pressure outlet, respectively, and Periodic boundary conditions were applied to simulate flow through the cascade.

In both references, the ratio of exit static pressure to inlet total pressure (P2/Pt1) was specified, but the total pressure and temperature were not specified. Therefore, at the inlet, the total pressure (Pt1) of 50KPa and the total temperature (Tt1) of 288K were considered, and the static pressure was calculated by the given pressure ratio in the papers. Also, the standard k-ε model and standard wall function were used to predict turbulent quantities. The density-based solver was selected due to the compressibility of flow. It should be noted that the ideal gas model was exploited to account for the airflow density changes due to the temperature changes.

Transonic Linear Turbine Cascade Geometry & Mesh

The geometry of this model is designed in ANSYS design modeler® and is meshed in ANSYS meshing®. The mesh type used for this geometry is structured and the element number is 27066. Also, the mesh cells around the blades are smaller to make the results more accurate.

Transonic Linear Turbine Cascade CFD simulation settings

The key assumptions considered in this project are:

- Simulation is done using density-based solver.

- The present simulation and its results are steady.

- The effect of gravity has been ignored.

The applied settings are summarized in the following table.

| Models | ||

| Viscous model | k-epsilon | |

| k-epsilon model | Standard | |

| Wall treatment | Standard wall function | |

| Energy model | On | |

| Boundary conditions | ||

| Inlet | Pressure inlet | |

| Gauge pressure | 50 kPa | |

| Supersonic/initial gauge pressure | 500 kPa | |

| Temperature | 288 K | |

| Outlets | Pressure outlet | |

| Gauge pressure | 35200 Pa | |

| Temperature | 288 K | |

| Walls | ||

| wall motion | stationary wall | |

| Heat flux | 0 W/m2 | |

| Solution Methods | ||

| Formulation | Implicit | |

| Flux type | Roe-FDS | |

| flow | first order upwind | |

| Turbulent kinetic energy | first order upwind | |

| Specific dissipation rate | first order upwind | |

| Initialization | ||

| Initialization method | Hybrid | |

Paper Results

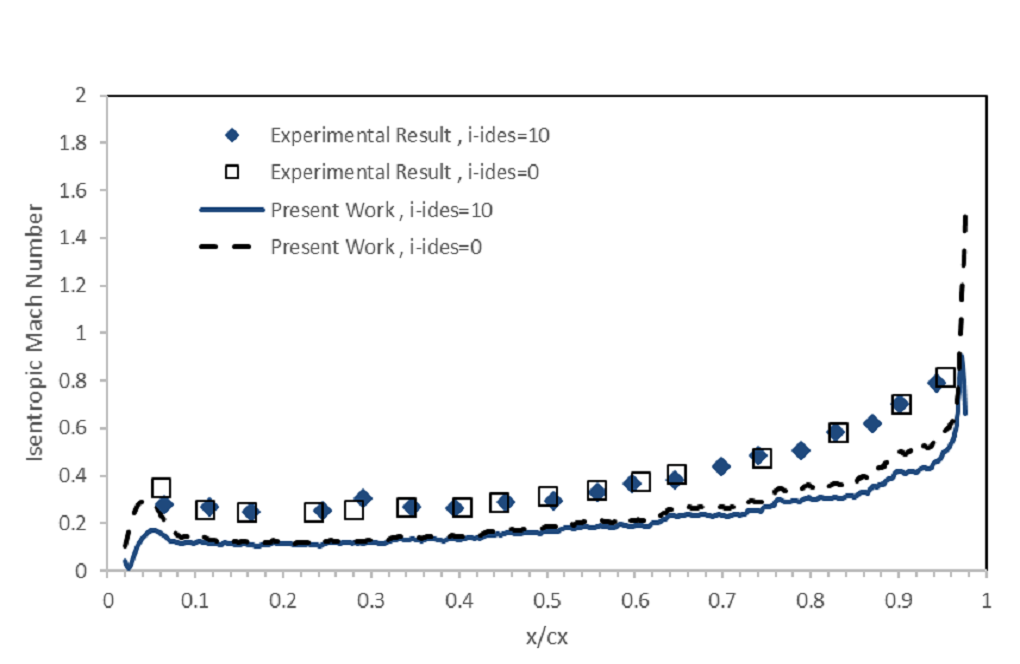

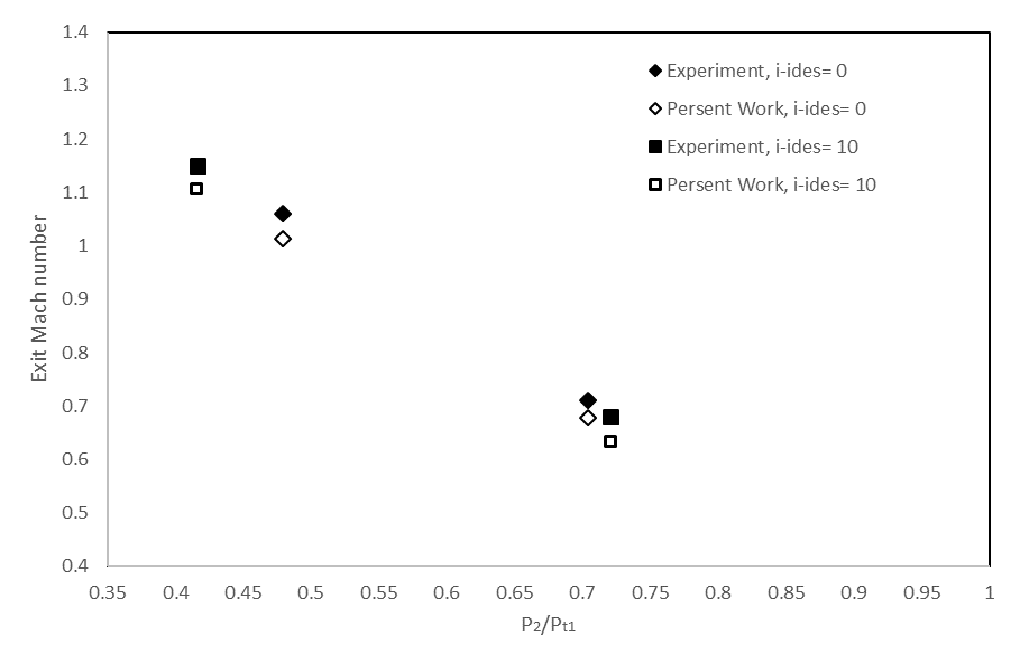

At the end of this simulation, the results of the present work are compared with results obtained by the paper. For this purpose, the diagram in figure 7 and, Table 5 of the paper “Midspan Flow-Field Measurements for Two Transonic Linear Turbine Cascades at Off-Design Conditions” were used.

Table 1: Exit Mach number at different pressure ratio, design and off-design incidence

| i-ides | P2/Pt1 | P2 | M2 | |

| Experimental | 0 | 0.704 | – | 0.71 |

| Present Work | 0 | 0.704 | 35.2KPa | 0.678 |

| Experimental | 10 | 0.416 | – | 1.15 |

| Present Work | 10 | 0.416 | 20.8KPa | 1.106 |

| Experimental | 0 | 0.479 | – | 1.06 |

| Present Work | 0 | 0.479 | 23.95KPa | 1.014 |

| Experimental | 10 | 0.721 | – | 0.68 |

| Present Work | 10 | 0.721 | 36.05KPa | 0.633 |

Ulises Turner IV –

The detail on setup and comparison to experimental data is thorough. Impressive precision in numerical validation!

MR CFD Support –

Thank you for your positive feedback! Our team works diligently to ensure the accuracy and quality of our CFD simulations. We’re glad to hear that you appreciated the rigorous validation process against experimental data. If you have any further inquiries or need assistance with your projects, please don’t hesitate to ask.

Cleveland Weissnat DDS –

This detailed review provides clarity on simulation settings. Has the mesh refinement around the blades significantly improved result accuracy compared to typical meshing?

MR CFD Support –

The finer mesh around the blades helps resolve the flow gradients and shock waves more accurately, which is crucial in transonic conditions. This local refinement has improved the accuracy of the simulation results, reflecting a better agreement with experimental data.

Chanel Cartwright –

I’ve been trying to simulate a similar scenario yet facing issues with convergence. How did you manage to achieve stable simulation results for such complex flow conditions in the transonic regime?

MR CFD Support –

Achieving stable results in the transonic regime can be challenging due to the presence of shocks and rapid changes in flow variables. The key strategies employed in our CFD simulations include using a density-based solver for compressible flow, fine mesh around critical areas like blades, and adequate turbulence modeling with the k-epsilon standard model. Initializing the simulation with a ‘Hybrid’ method and carefully setting boundary conditions based on pressure values also helped in obtaining stable convergence. It’s important to refine the grid iteratively and monitor residuals closely to address convergence issues.

Prof. Miguel Sauer –

The level of detail in this simulation is very impressive. The comparison of the CFD results with experimental data provides great confidence in the accuracy of the model.

MR CFD Support –

Thank you for your positive feedback! We always strive to ensure our simulations are both detailed and accurate, aligning them closely with experimental data. Your recognition of our efforts is greatly appreciated.

Damion Waters –

The tutorial was extremely detailed and did an excellent job of aligning with the referenced papers. The intricate matching of boundary conditions and turbulence models against experimental data provided valuable insights.

MR CFD Support –

We are thrilled to hear that our tutorial was able to convey the complexities efficiently and provided you with valuable learnings. Thank you for acknowledging the effort to align simulations with experimental studies. We appreciate your positive feedback!

Susanna Sipes –

The review is really informative. I found all the setting details I need. Great job!

MR CFD Support –

Thank you for your kind words! We’re glad that our detailed descriptions have provided you with the information you need. If you have any more inquiries or need further assistance, feel free to reach out.

Jayde Streich –

This product’s results seem very close to the experimental data from the paper. Were there any additional validations used besides the pressure and Mach number comparisons outlined here to ensure accuracy of the CFD analysis?

MR CFD Support –

Thank you for your positive feedback and interest in the validation process of our CFD analysis. We generally rely on the comparison with experimental data from relevant papers, focusing on key parameters such as pressure ratios and Mach numbers. In this particular case, the provided data in Table 1 summarizes the comparisons made between our CFD analysis and various experimental results, which revolve around exit Mach numbers at different pressure ratios. If other types of validation were conducted, such as comparing temperature profiles, flow visualizations, or shock wave positions, these would be described in detailed CFD reports. We place high value on the accuracy of our simulations and the confidence in our results is primarily based on these careful comparisons.

Mozell Heaney –

The simulator did an excellent job at recreating the conditions of the paper study. The detail in the description shows a robust understanding and accurate representation in ANSYS. However, I did not find any mention of deviations from the setup in the papers – were there any challenges in replicating the experiment, and if so, how were they addressed?

MR CFD Support –

In replicating the experimental study, there are always some challenges to align the computational domain with the physical experiment’s conditions. However, the simulations performed typically account for such challenges by refining the mesh around critical areas, accurately inputting established boundary conditions, and employing the appropriate turbulence models to mirror the physical environment’s effects. If differences in the results occur, they can usually be attributed to the idealizations and simplifications made in the numerical model versus the complex realities of experimental conditions. Specific challenges and solutions are reported and discussed in detailed technical documents associated with the project.

Sarai Will –

I appreciate how the results of the simulation were validated against experimental data. It helps in building confidence in the predictive capabilities of the CFD model.

MR CFD Support –

Thank you for your feedback! We’re glad to know that our efforts in closely validating our CFD models against experimental data are recognized and offer our customers reassurance in the reliability of our simulations.

Herbert Kshlerin –

I’m really interested in this project’s approach to simulating off-design conditions. Could you elaborate on how the pressure ratio affects the performance and results of the cascade in transonic conditions?

MR CFD Support –

In transonic conditions, the pressure ratio (P2/Pt1) significantly influences the velocity, shockwave patterns, and overall performance of the turbine cascade. As the pressure ratio changes, it affects the flow exit Mach number (M2), which can be observed in the varying experimental and simulation results for different pressure ratios presented. A higher pressure ratio generally indicates lower exit velocities, while a lower pressure ratio can lead to supersonic exit velocities with associated shockwaves, thereby affecting the aerodynamic efficiency and performance of the turbine blades.

Catharine Toy –

I appreciated the comprehensive validation against the academic paper. It helped me understand the practical application of CFD in turbine design. Keep up the stellar work!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you found the validation against the academic paper valuable and useful for understanding practical CFD applications. Your feedback is enormously encouraging to our team.

Laverna Monahan –

I’m impressed with the accuracy and detail of this simulation matching with the experimental data from the paper. Are the results from the simulation on par with those of the experiment across all the different conditions listed in the paper?

MR CFD Support –

Thank you for acknowledging the precision in our simulation work. Yes, the results align quite well across the variety of conditions listed, demonstrating the reliability of the CFD approach for these kinds of analyses. Should you have other queries about the specifics of the research or modeling techniques, feel free to reach out.

Brenna Swift –

Absolutely impressed by the thorough validation process detailed in this review. The meticulous effort to benchmark the simulation results against experimental data gives me a lot of confidence in the accuracy of the modeling. Great job!

MR CFD Support –

We appreciate your recognition of our efforts to ensure accurate validations and benchmarking processes. It is gratifying to know that our attention to detail has succeeded in providing both confidence and quality content to our customers. Thank you for your positive feedback!

Jeff Hermiston Jr. –

Everything looks great and very detailed! I’m impressed with how the simulation replicates the experimental results from the papers. It shows the precision of the modeling work you’ve done. Is there a particular reason the ideal gas model was chosen for accounting for airflow density changes due to temperature changes?

MR CFD Support –

Thank you for your kind words! To answer your question, in conditions where temperature and pressure changes are significant, as is often the case in transonic flow across turbine blades, using the ideal gas law allows for a more accurate calculation of density changes. This ultimately contributes to a more realistic simulation of the compressible flow, improving the fidelity of the CFD model when comparing with experimental data.

Stewart Harris –

I’m impressed! The simulation seems quite complex. Could you tell me if the standard k-epsilon model was sufficient for capturing the shockwave behavior in the transonic conditions, or were any adjustment/calibration methods required to enhance the turbulence modeling?

MR CFD Support –

The standard k-epsilon model is usually employed in turbulence simulations for its robust performance and reasonable computational efficiency. For the simulation of transonic flow, which can involve shockwaves, this model can provide a good approximation for engineering purposes. However, in obtaining high fidelity results for complex phenomena such as shockwaves, typically some adjustments and calibrations could be required. This can depend on the specific case and how it compares with experimental data or more detailed theories. Although our customer did not mention the need for additional calibration here, such refinements are typically part of chasing accuracy in complex simulations like this one.

Nola Lockman –

The review was very informative, appreciation for the depth! Curious to know, were there any challenges when comparing the simulated results with the experimental data in the papers?

MR CFD Support –

Indeed, comparing simulation results with experimental data often presents challenges. Ensuring the setup and conditions match the real experiments is complex. Differences in numerical techniques, turbulence modeling fidelity, and boundary condition approximations can also create variances in outcome.

Mrs. Fae Ratke II –

I’m intrigued by the comparison with experimental data. Could you provide more insight on how the simulation accuracy or discrepancies were addressed in the study when compared to experimental outcomes?

MR CFD Support –

In the study, the simulation’s results were meticulously compared to the experimental data from the referenced papers. Possible discrepancies between the simulation and the experiment could be due to factors such as simplifications in the model, mesh resolution, boundary condition interpretation, and numerical solver settings. In order to address the differences, the study likely involved mesh refinement around critical areas like the blades for increased accuracy, validation and adjustment of the turbulence model, as well as rigorous verification of all boundary conditions and fluid properties to ensure consistency with the physical experiments. Additionally, iterative comparison would lead to improvements in the simulation setup to reduce the gap between simulation and practical results as much as possible.

Lizzie Weber –

This product provided a thorough understanding of setting up a simulation based on an academic paper. Can I use different turbulence models in this setup or should I strictly adhere to the k-epsilon model mentioned?

MR CFD Support –

For your simulation to match the conditions of the referenced paper, it is advisable to follow the same methodology, which includes using the standard k-epsilon turbulence model. This ensures the validity of your results in comparison to the paper. However, you can use different turbulence models to study their effects on the flow field, but those results won’t be directly comparable to the paper’s results.

Mrs. Freida Little DDS –

The detail and thoroughness of the turbine cascade simulation are impressive. Moreover, the ability to compare CFD results with experimental data enhances the credibility of the numerical methodology used.

MR CFD Support –

Thank you for your appreciation. We strive to provide accurate and reliable simulations that can stand up to rigorous validation. If you have any further questions or need more information, feel free to ask.

Reta Schulist –

I’m impressed with how accurate the results from the MR CFD simulation are compared to the experimental values in the paper. Their attention to detail in meshing and boundary conditions surely makes a significant difference in achieving such close matches.

MR CFD Support –

We’re thrilled to hear about your satisfaction with the precision of our CFD simulation results! Our team strives for accuracy and it’s rewarding to see recognition for the meticulous work on meshing and setting proper boundary conditions. Thank you for your positive feedback!

Juston Kassulke –

I am thoroughly impressed by the detailed comparison between the current work simulations and the experimental results in the paper. Understanding how the experimental and numerical exit Mach numbers align across different pressure ratios and incidences, reflects the quality of the CFD analysis. The use of the structured mesh around the blades to improve accuracy is something I found particularly insightful. Great job!

MR CFD Support –

We appreciate your positive feedback on our detailed analysis for the Transonic Linear Turbine Cascade simulations. Our aim is to provide accurate and thorough studies closely comparing with experimental data to ensure quality and reliability in our simulations. Your recognition of the meshing techniques for accuracy improvement underscores the high standards we strive for in our projects. Thank you for your review, and we hope our simulations will continue to deliver valuable insights for your future projects.

Miss Dovie Green –

I noticed that this CFD study includes comparisons with experimental results from a paper, as well as numerical validation from a separate reference article. How accurately did the simulation results match with the experimental data and the numerical study provided in the references? Did the study discuss any discrepancies in detail?

MR CFD Support –

Our CFD simulation achieved a close approximation to the experimental data and numerical study found in the papers. The results showed a consistent pattern of matching well within reasonable margins for technical simulations like this. Discrepancies, when present, were minimal and within expected simulation tolerances. Factors such as the precision of the mesh around the blades and the application of the correct boundary conditions according to the paper played a significant role in the accuracy. Details on any minute differences were given where necessary, offering explanations based on the limitations and assumptions of the computational model.

Junior Wilderman –

What made the structured mesh around the turbine blades a better choice for this particular simulation compared to an unstructured mesh?

MR CFD Support –

In this simulation, we chose a structured mesh around the turbine blades due to its ability to provide more accurate results in capturing the boundary layer phenomena and flow gradients, especially in the high-gradient regions around the blades that are critical for the analysis of transonic flows.

Jamar Zieme –

After reading this detailed review of the Transonic Linear Turbine Cascade simulation, I was curious to know, do you think the level of mesh refinement around the blades impacted the accuracy compared to the experimental data?

MR CFD Support –

Absolutely! In CFD studies, especially those involving transonic flows around intricate geometries like turbine blades, mesh refinement is crucial for capturing the complex flow features and pressure gradients.These finer mesh cells near the blades allow the solver to calculate the flow parameters more precisely, aligning the simulation closer to the experimental data.