Storage Tank CFD Simulation, ANSYS CFX

$120.00 Student Discount

- Thermal Analysis in a storage tank via ANSYS CFX software.

- The geometry is designed using ANSYS Design modeler software and the mesh is created on this geometry using ANSYS Meshing software.

- The mesh type is Structured with 10,100 cells.

- Thermal Energy is enabled to capture the temperature.

- The Mixing & Convection phenomena are involved in this simulation.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

Storage Tank is a device that contains liquids or compressed gases for different aims such as thermal, time, and velocity purposes.

A container can hold the fluid for short or long terms and in hot or cold thermal conditions.

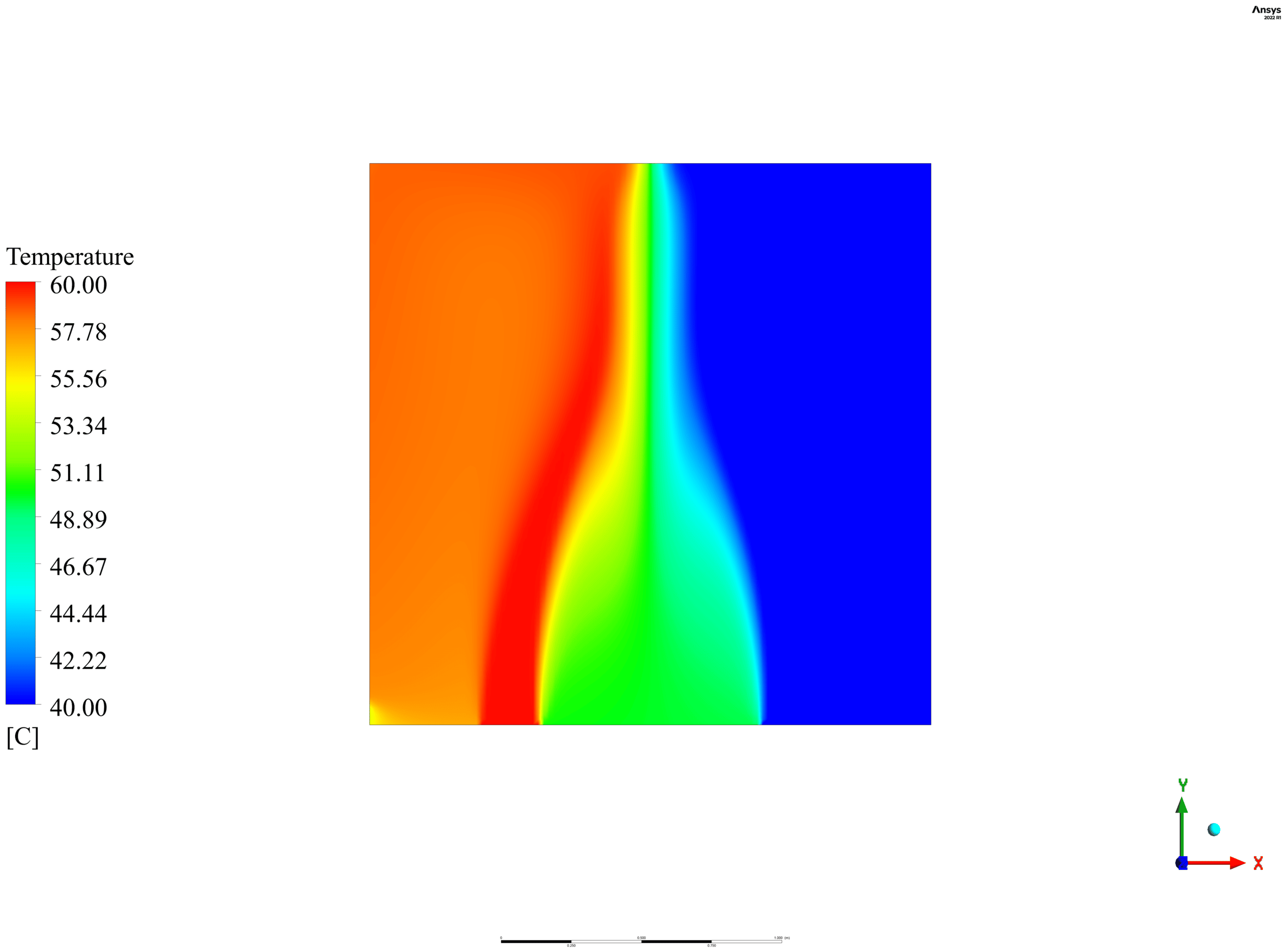

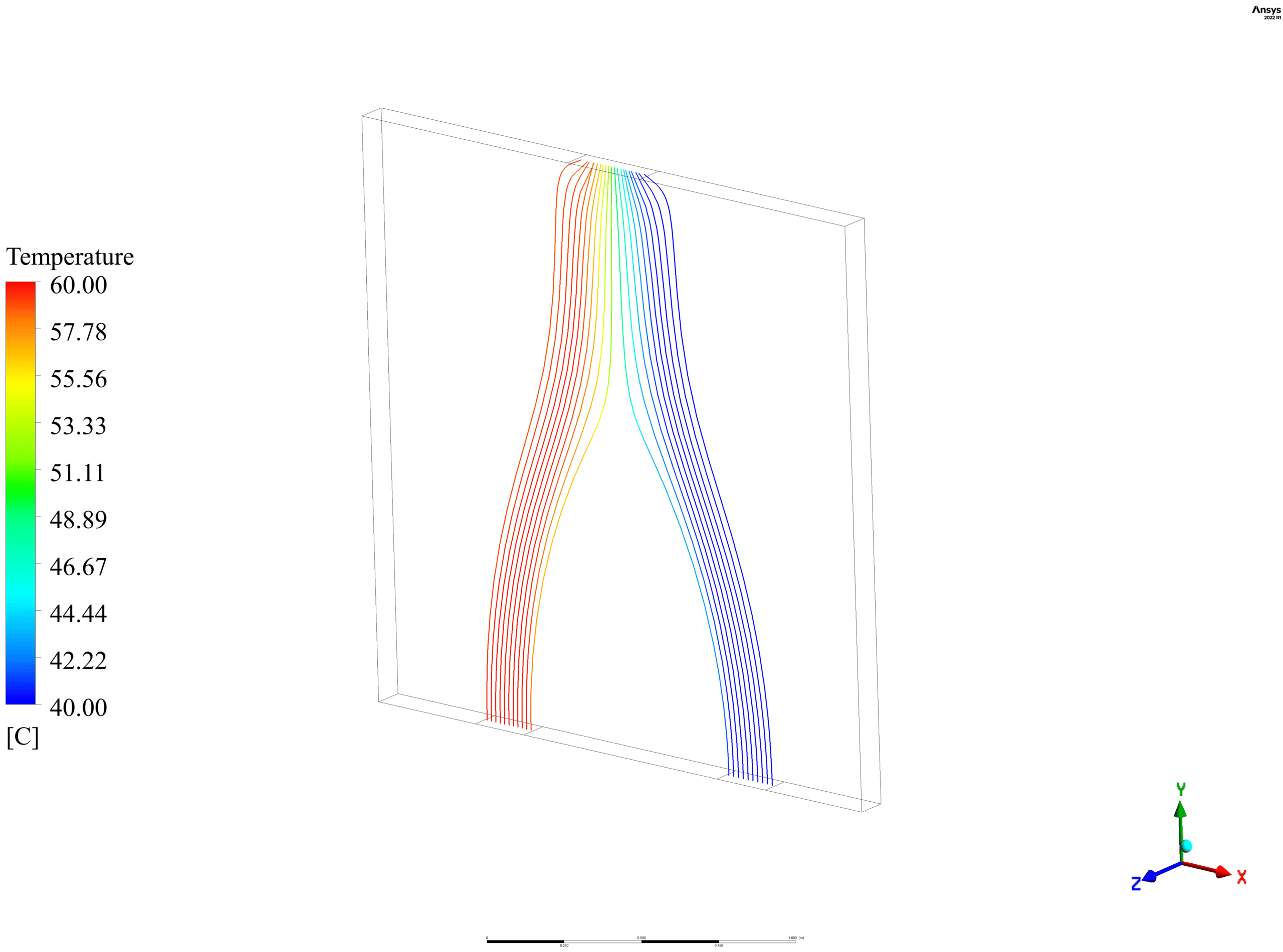

In this project, a square-shaped storage tank is modeled. The water is in a 300 k thermal condition while there are two inlets underneath the tank, with different temperatures. The Temperature of input flows to control the outlet temperature located above the tank.

Two inlets mix, and their temperature and velocity affect each other.

The 2.5D geometry of the solution is modeled in Design Modeler software. Also, the meshing process is done in ANSYS Meshing software. The elements type is Structured and their number is 10100.

Methodology: Storage Tank CFD Simulation with ANSYS CFX

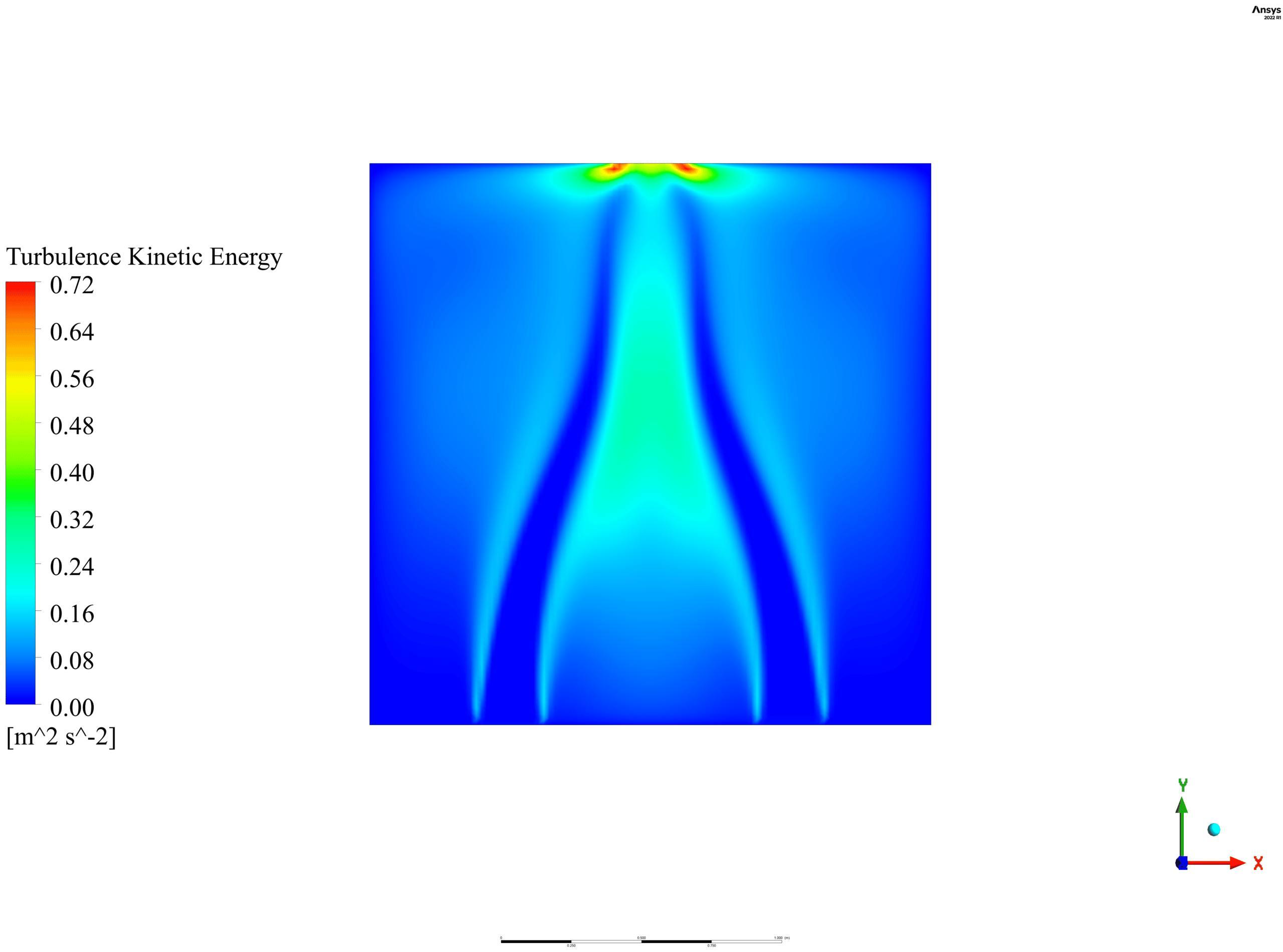

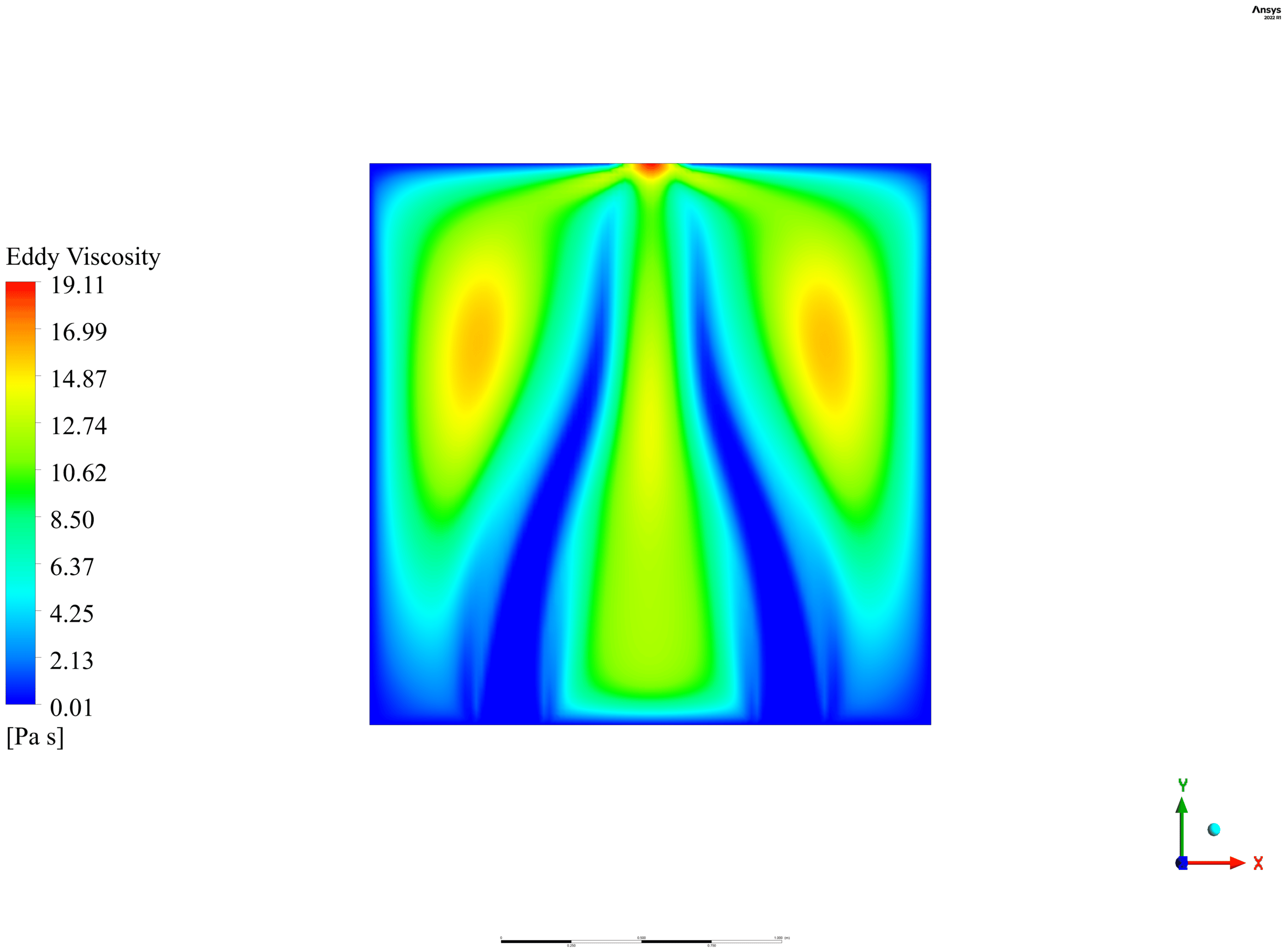

Heat Transfer is captured by Thermal Energy option and the turbulence model is k-Epsilon with Scalable Wall Function.

The Advection Scheme and Turbulence Numerics is set to High Resolution.

Results

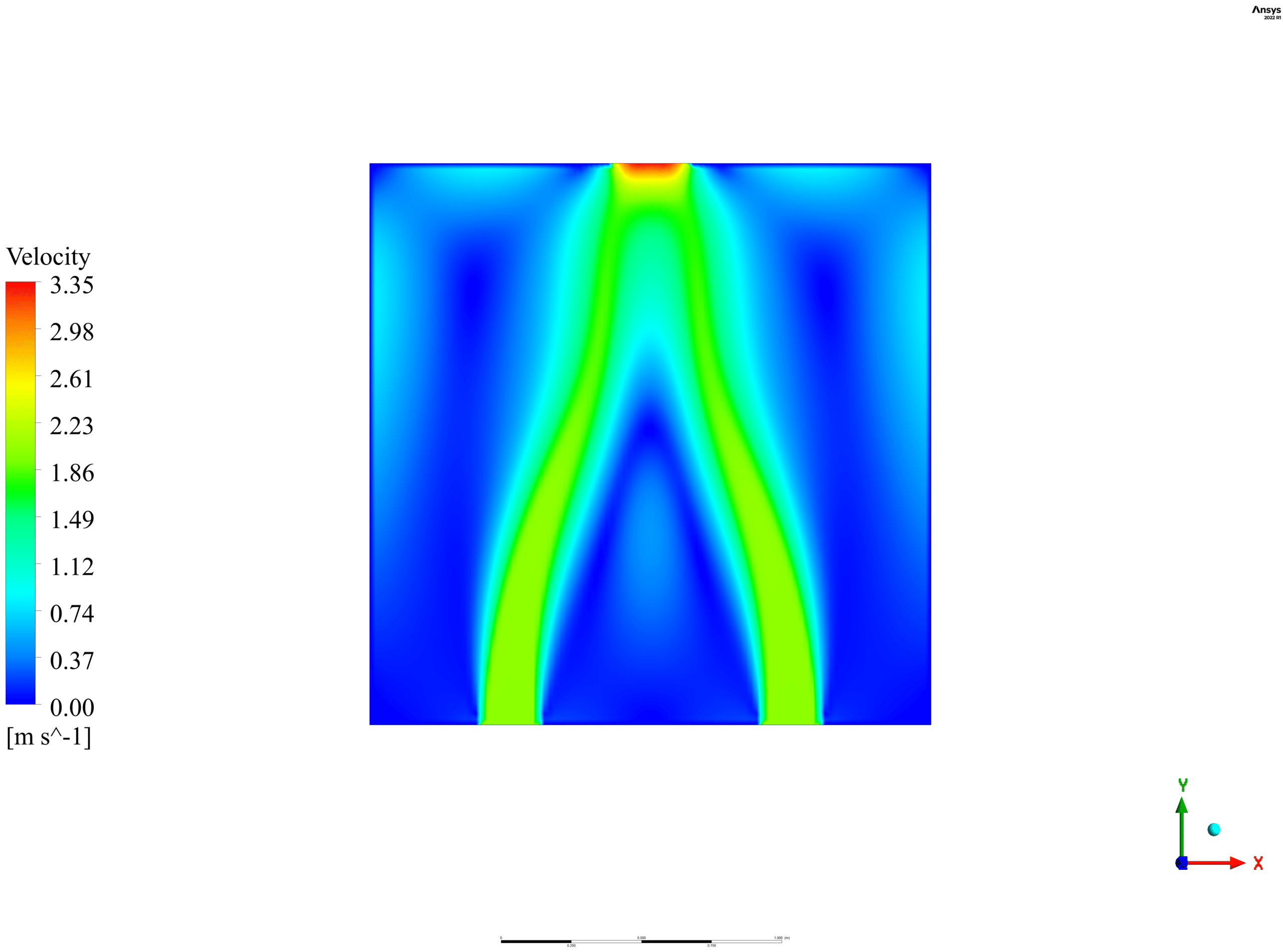

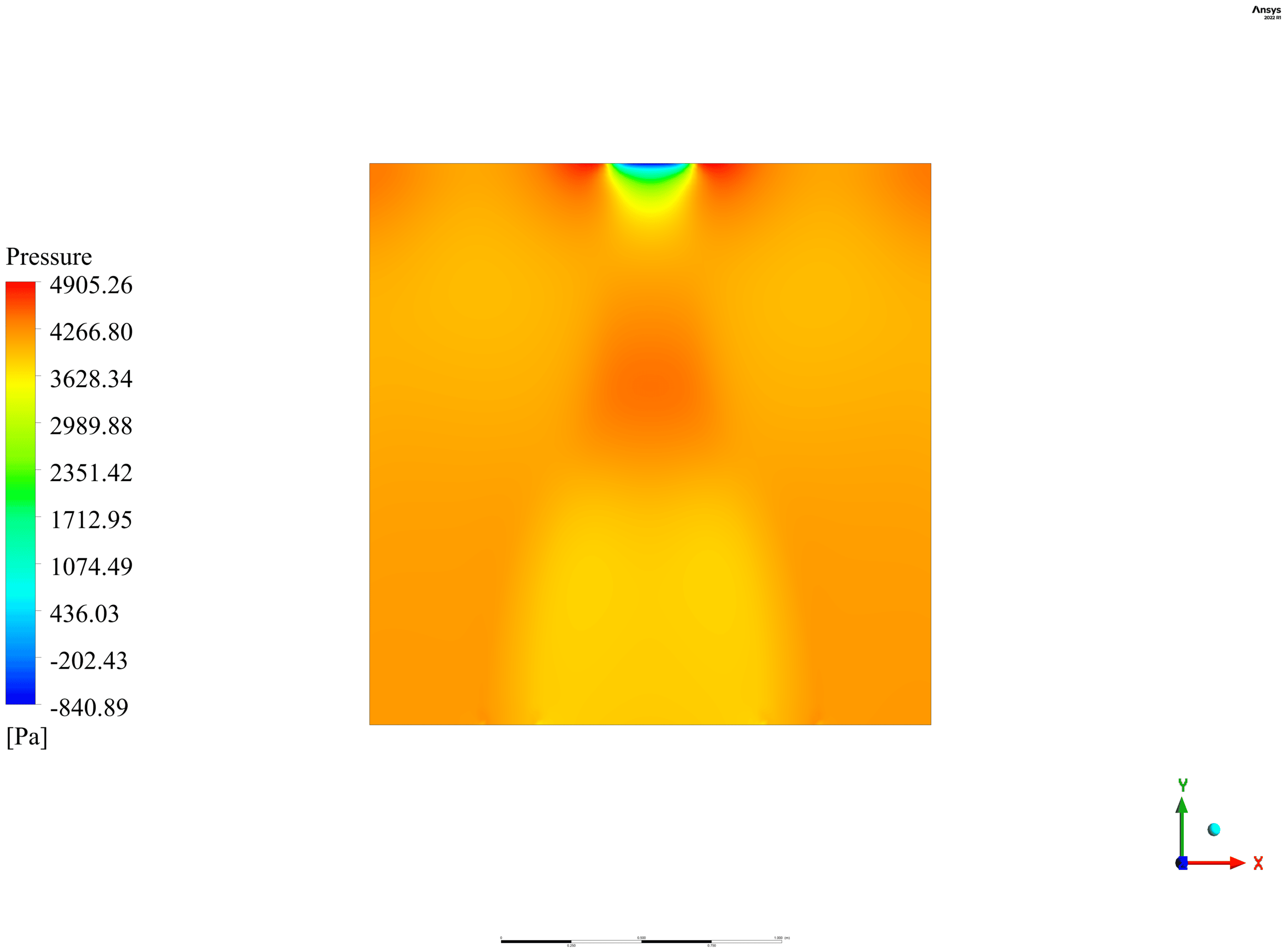

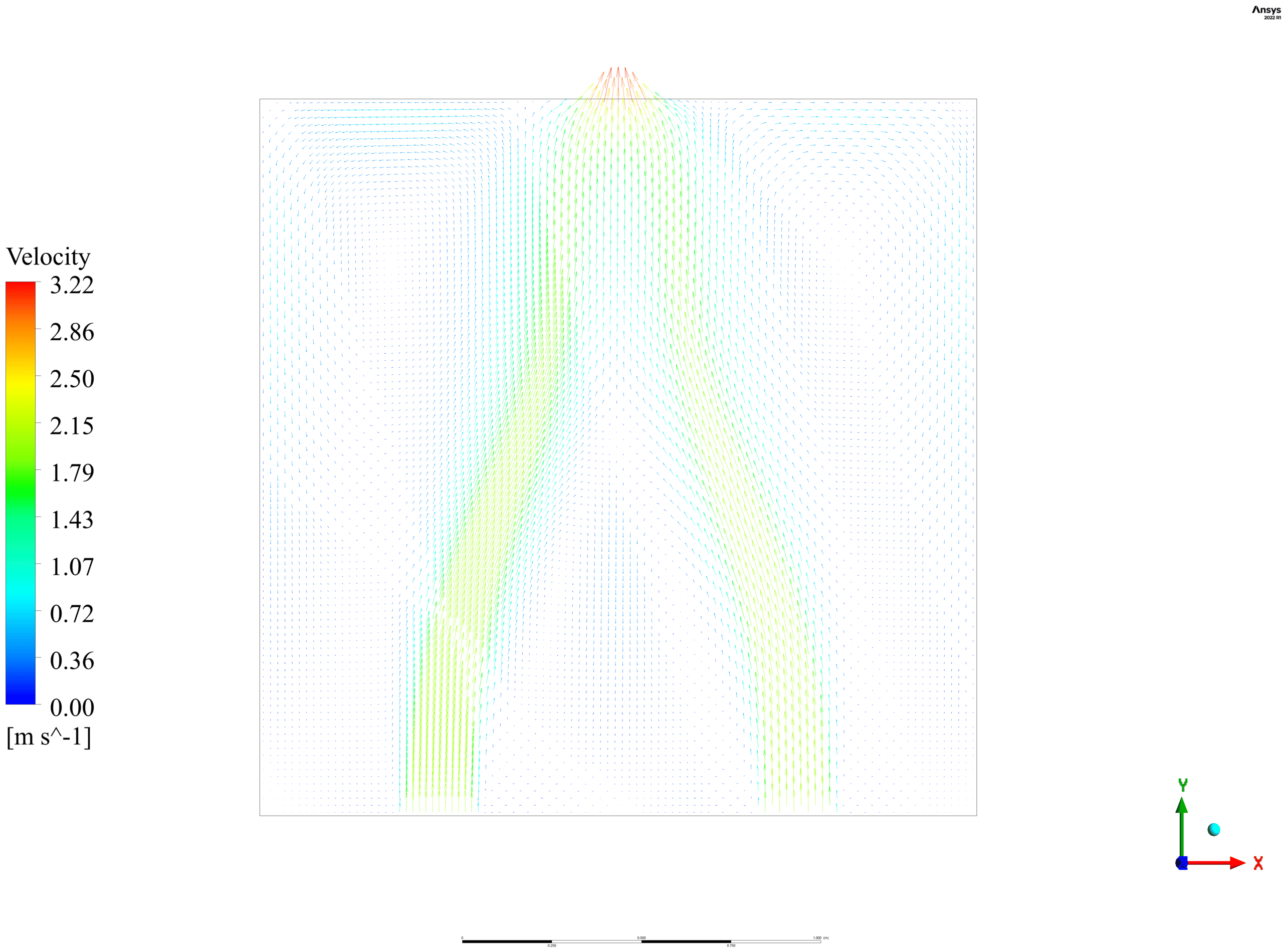

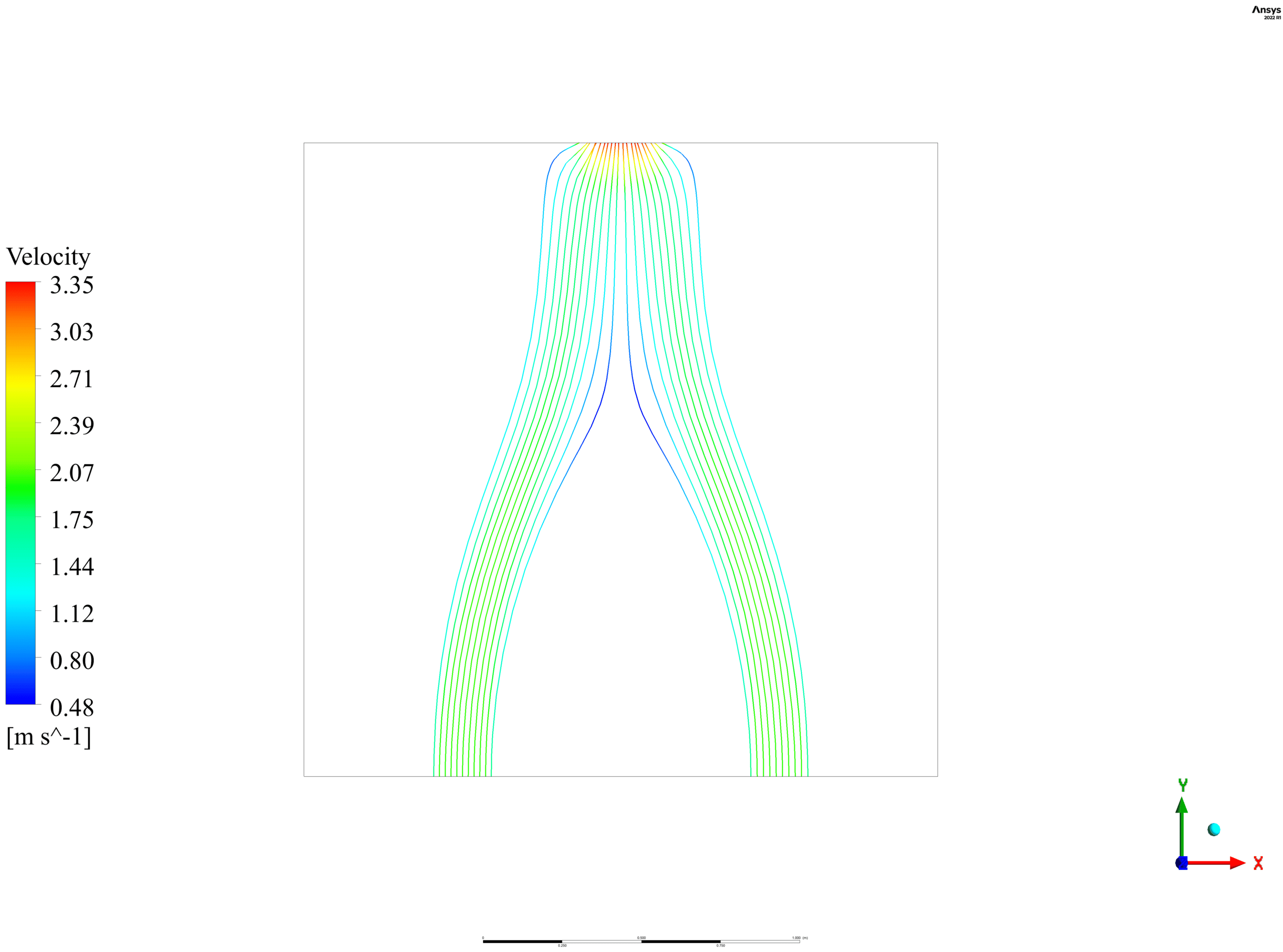

Water pressure, temperature, Eddy viscosity, and velocity-related two-dimensional contours and vectors are obtained at the end of the solution procedure in CFD-Post software.

Water flow initially comes from the inlet face and travels quickly to the output face. The figures prove that both flows tend to mix and have a central outlet direction, and has an impact on their temperature and velocity.

Additionally, fluid enters the duct at high pressure and exits with gauge pressure of zero.

Kelsi Ledner –

I’m impressed by the way the simulation seems to capture the complex interactions between inlet temperatures and flow dynamics within the storage tank. It seems particularly useful for process optimization.

MR CFD Support –

Thank you for your feedback! We’re glad to hear that our simulation has met your expectations and you find it useful for process optimization. We strive to provide accurate and detailed simulations to assist our customers in understanding complex fluid dynamics and improving their systems. If you have any further questions or need assistance with your projects, please feel free to reach out.

Prof. Arlene Purdy V –

I learned so much about heat transfer and turbulence models thanks to this product. The CFD simulation was insightful and the visuals made the concepts clearer.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our Storage Tank CFD Simulation in ANSYS CFX has enhanced your understanding of heat transfer and turbulence modeling. We strive to provide clear and engaging learning materials. Don’t hesitate to explore more of our products to continue learning.

Gerald Mann MD –

The structured mesh and detailed turbulence modeling seem to contribute to the accuracy of the CFD results. I appreciate how both cold and hot fluid streams were simulated realistically to give insight into thermal mixing within the storage tank. Well done on this comprehensive approach!

MR CFD Support –

Thank you for your positive feedback about our Storage Tank CFD Simulation product. We’re glad to hear that our attention to mesh quality and accurate turbulence modeling has provided you with useful insights. Our team continuously strives to deliver realistic and comprehensive simulations, and it’s rewarding to know that our efforts have been well received.

Travon Medhurst Jr. –

The simulation for the storage tank was fantastic! The results really highlighted the intermixing of inlets with different temperatures and how they affect the outlet temperature. Great use of boundary conditions too.

MR CFD Support –

We are thrilled to know the storage tank simulation met your expectations and that you found the results insightful! It’s great to see appreciation for the careful setup of boundary conditions. Thank you for the positive feedback!

Jefferey Waters –

I was really impressed with the temperature control approach in the Storage Tank CFD Simulation by ANSYS CFX. The clear visualizations and explanations of the water flow mix were helpful and it was great to see how the inlet temperatures impact the outlet condition. Great job on modeling and meshing that accurately captures the flow dynamics in the tank!

MR CFD Support –

Thank you for your positive feedback! We always strive to provide clear visuals and accurate simulations to help users understand complex flow dynamics. It’s great to hear that our efforts in modeling and meshing were well-received and useful to you.

Santa Trantow –

The colors in the temperature contour plots were very helpful in illustrating how the inlet temperatures mixed throughout the tank. I could easily understand which areas of the tank had hotter or cooler water. Great job interpreting the results.

MR CFD Support –

We are thrilled to hear that the thermal contour plots in our Storage Tank CFD Simulation have contributed to a clear understanding of temperature distribution within the tank. Thank you for your feedback and appreciation. We strive to deliver comprehensive simulations that can be easily interpreted and applied.

Ignatius Waters –

I really liked how the storage tank simulation took into account thermal conditions and multiple inlets. It was very helpful in understanding fluid mixing.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our Storage Tank CFD Simulation has provided you with a clear understanding of fluid mixing under different thermal conditions. If you need any further assistance or more detailed insights into such simulations, feel free to reach out!

Mr. Ignatius Adams –

I recently used the Storage Tank CFD Simulation learning product by MR CFD, and I must say, the insight it provided on fluid dynamics within storage tanks was enlightening. The simulation perfectly demonstrated how varying inlet temperatures and velocities impact the final exit temperature at the outlet. I appreciate the fine meshing and detailed analysis that showcased significant details such as Eddy viscosity, water pressure, and temperature gradients. It’s a valuable educational resource for understanding complex thermal interactions within storage systems.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Storage Tank CFD Simulation provided you with valuable insights and detailed analysis of fluid dynamics in storage tanks. It’s great to know that our product could enrich your educational experience. If you have further inquiries or need assistance with another project, don’t hesitate to contact us. Your success is our priority!

Mr. Jillian Renner –

The intricate design of the tank beautifully merges functionality with visual appeal. Watching the fluids mix with precision substantiates exceptional simulation work.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear you found both the design and simulation results of the storage tank impactful and satisfactory. Your appreciation fuels our commitment to excellence.

Damien Jones –

I’m really impressed with the level of detail in the Storage Tank simulation! The temperature control and flow dynamics sound incredibly realistic.

MR CFD Support –

Thank you for the positive feedback on our Storage Tank CFD simulation! We are thrilled to hear you appreciate the intricacy and accurate representation of temperature control and flow dynamics in the model. Your satisfaction with our product means a lot. If you ever have any further questions or require assistance with our simulations, please do not hesitate to reach out.

Ricky Skiles –

The storage tank simulation sounds quite comprehensive. Was the effect of thermal stratification considered in this model, given the different temperatures of the inlets?

MR CFD Support –

Yes, the effect of thermal stratification can indeed influence the behavior of the storage tank, especially when dealing with fluids with varying inlet temperatures. In the simulation, the k-Epsilon turbulence model and High-Resolution Advection Scheme are used to accurately capture temperature gradients and mixing effects, which would include thermal stratification phenomena.

Monty Rutherford –

I appreciated learning about the storage tank CFD simulation using ANSYS CFX. It was quite insightful to see how the inlet temperatures can be used to control the overall temperature of the outlet. The details in the results showcased the mixing effectiveness of the dual inlets which was a great takeaway for my studies.

MR CFD Support –

Thank you for your kind feedback! We’re thrilled to hear you found the storage tank CFD simulation insightful and effective for your studies. If you have any more questions or need further assistance in your CFD learning journey, feel free to reach out to us.