Time Step Size effect on Particle Injection in Combustion Chamber, ANSYS Fluent CFD Simulation Tutorial

$100.00 Student Discount

- The current CFD project simulates the injection of solid particles as fuel inside the combustion chamber via ANSYS Fluent software.

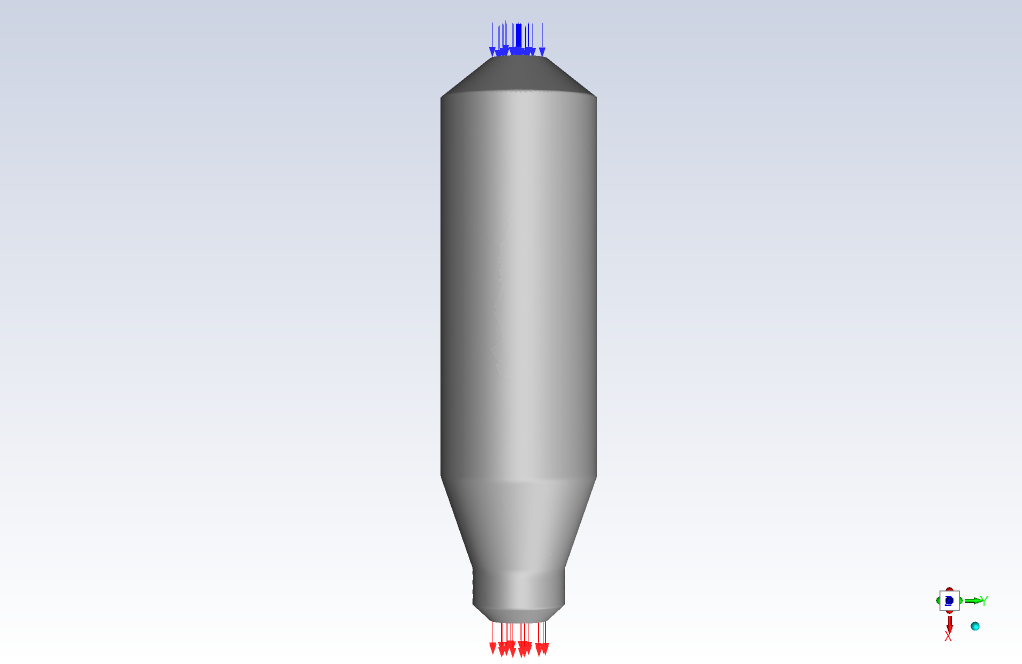

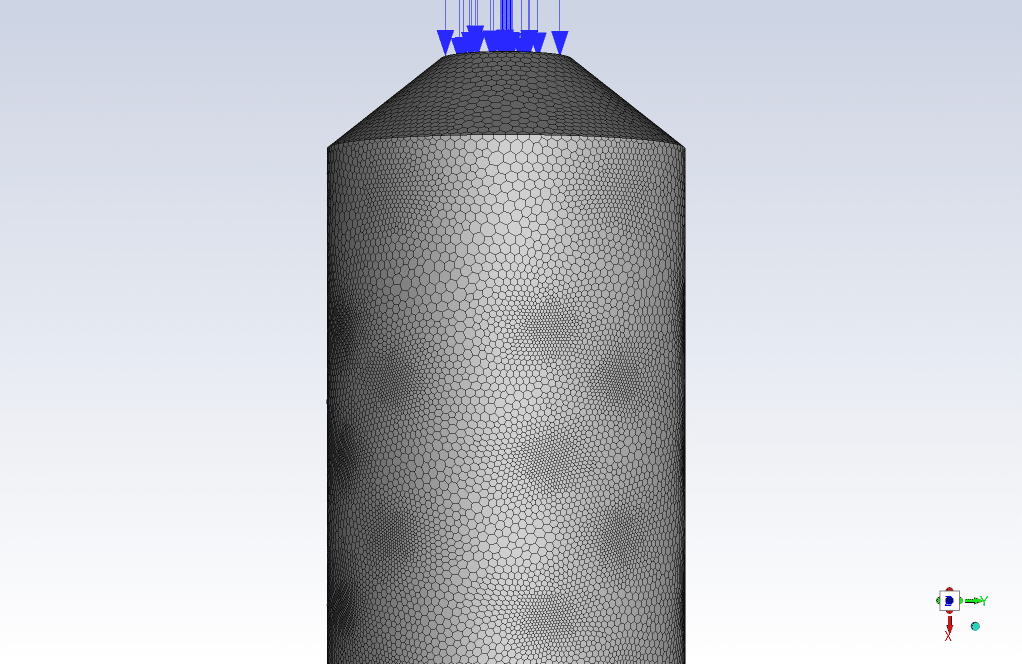

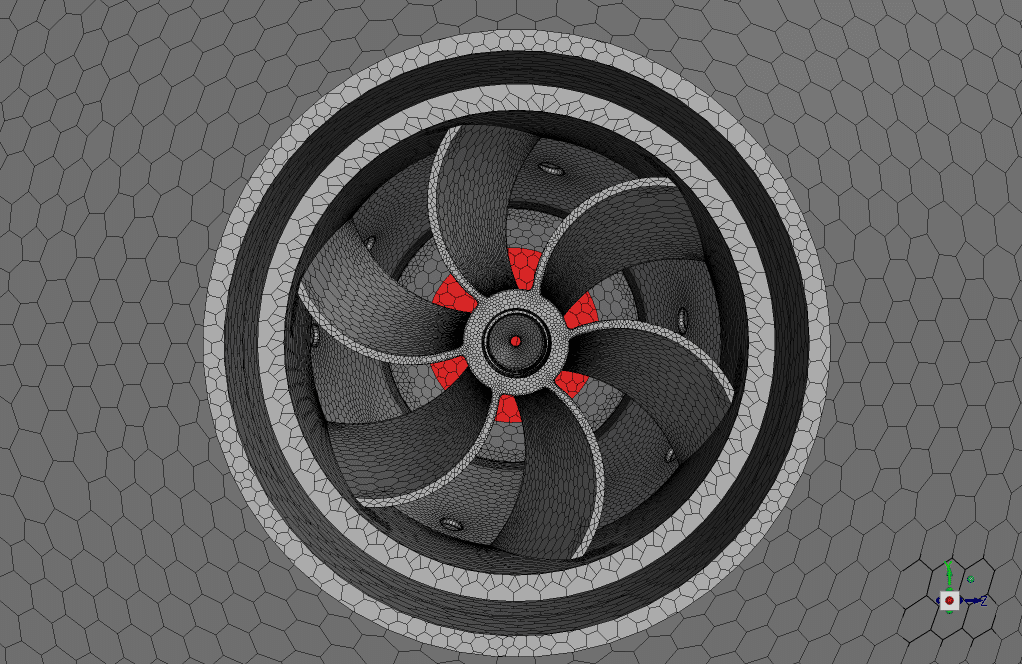

- We have designed the geometry using ANSYS Design modeler software and created the mesh on this geometry using ANSYS meshing software. The mesh type is Polyhedra with 859,934 cells.

- The Discrete Phase Model (DPM) determines the particle’s movement.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

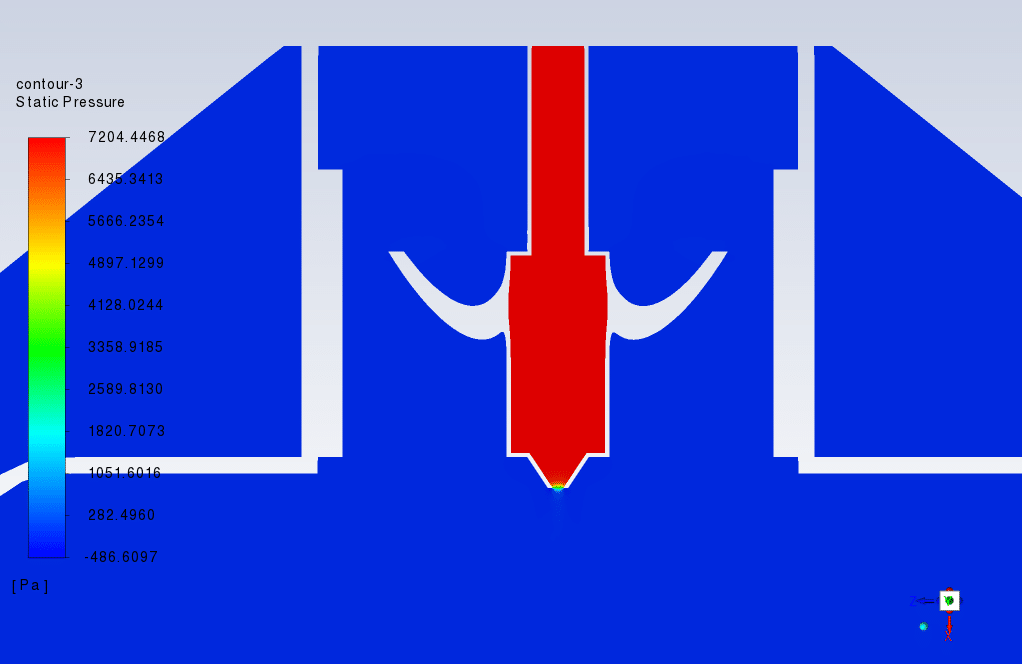

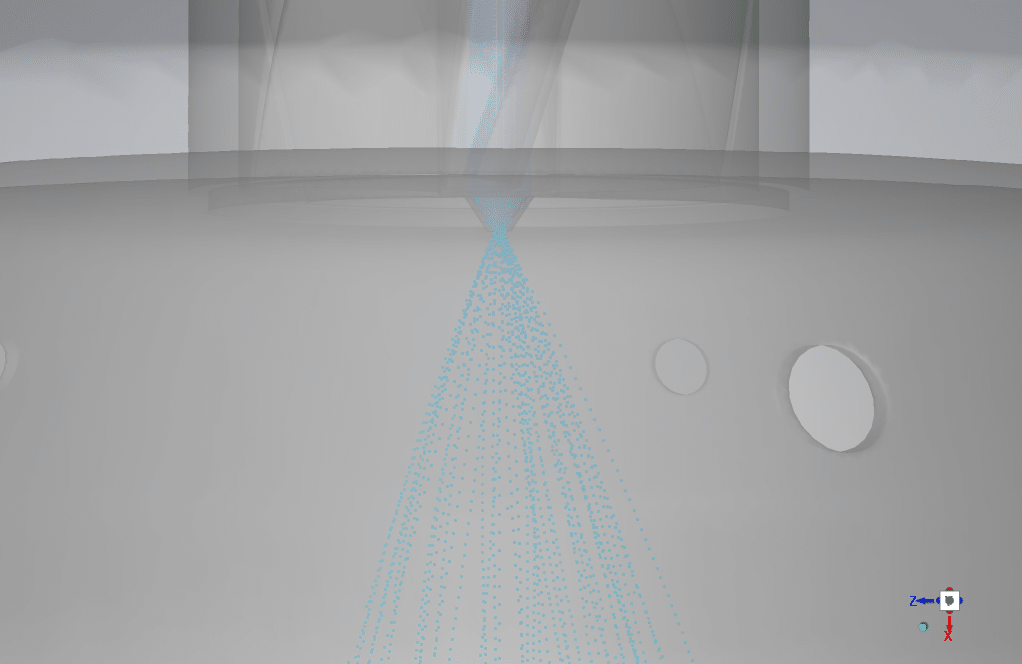

The purpose of this simulation is to show the entry of solid particles as fuel inside the combustion chamber. In this simulation, we intend to inject the particles from the nozzle exit into the combustion chamber with high accuracy.

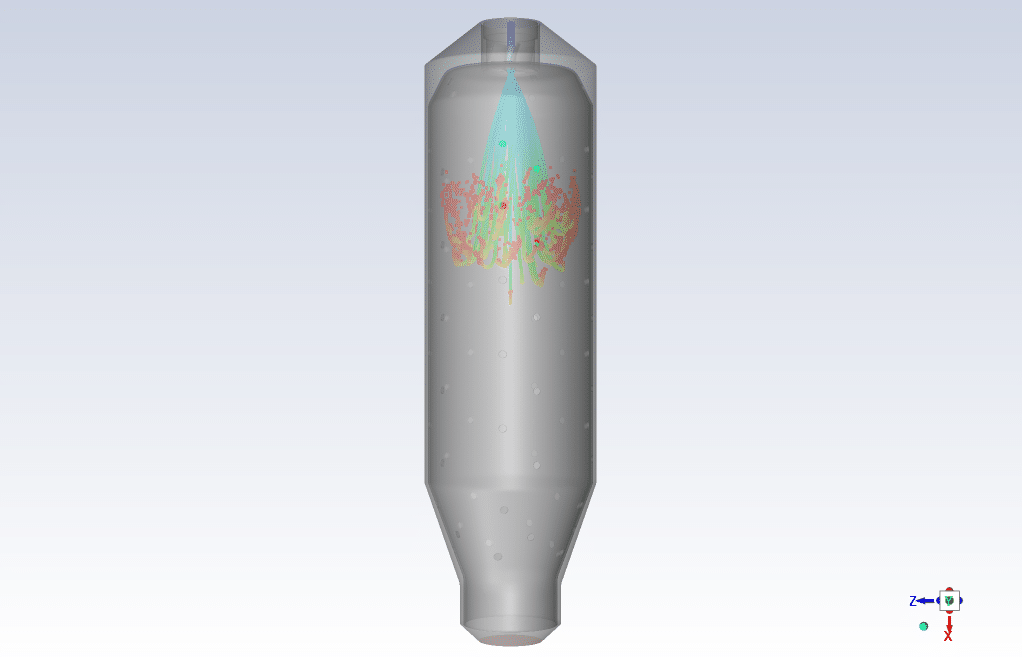

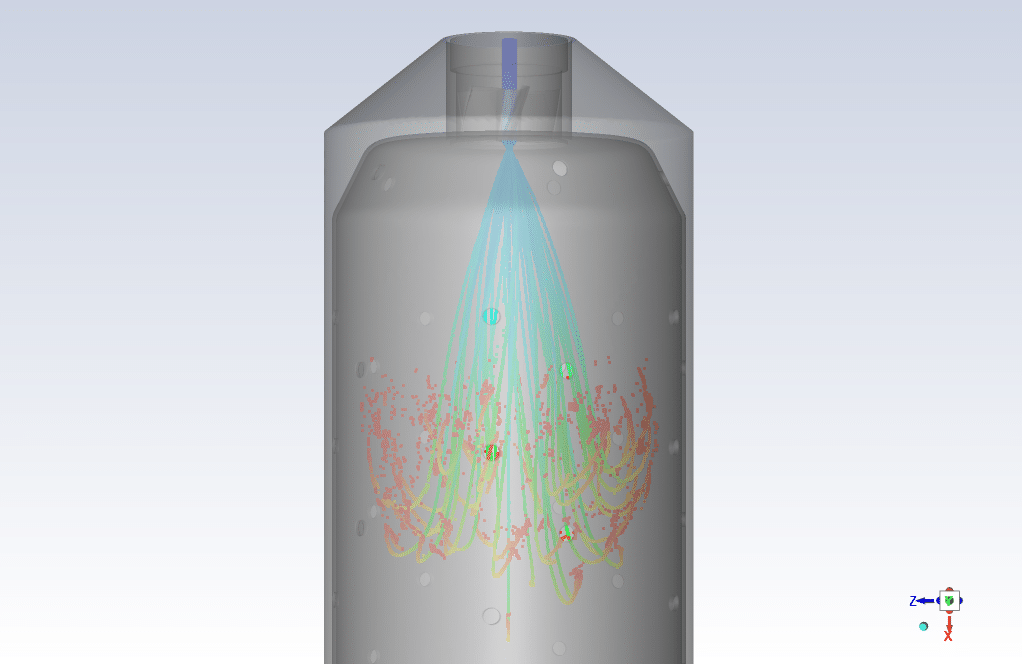

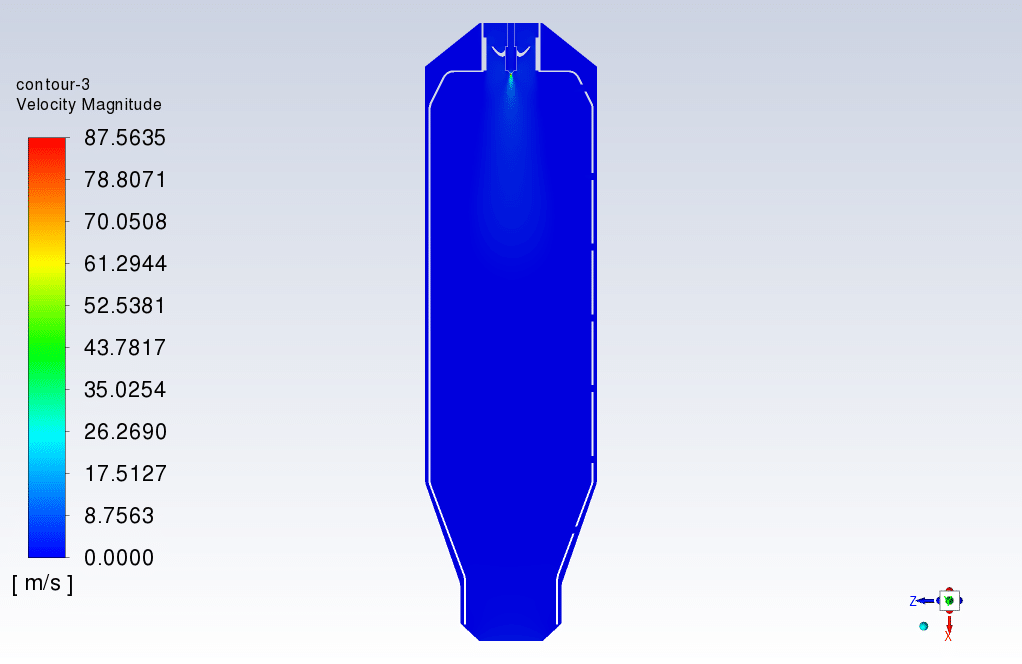

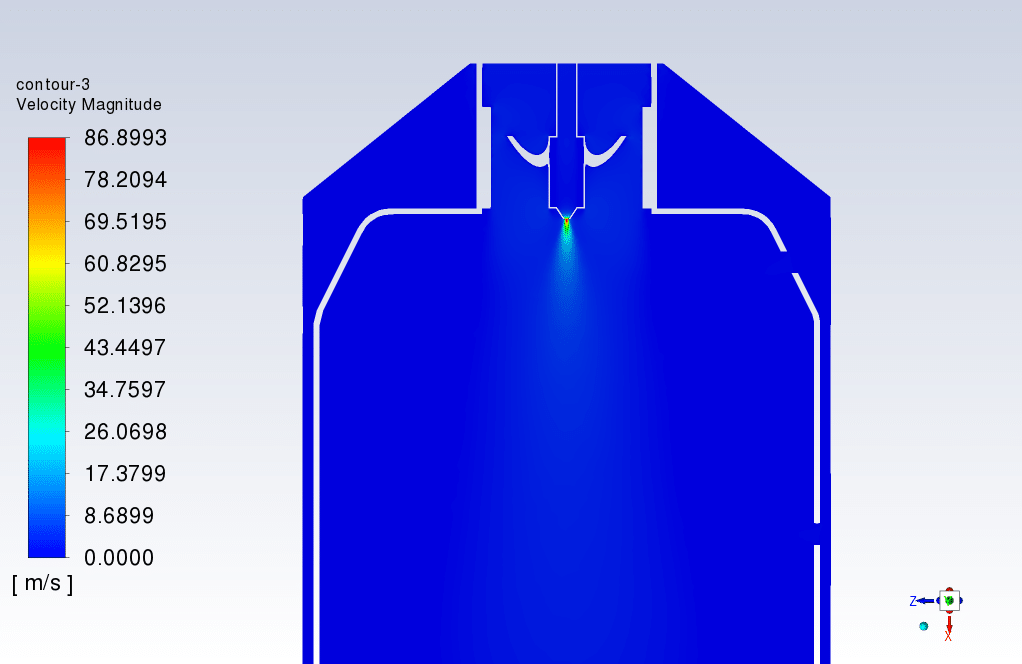

For this reason, the effect of time steps on the movement of particles in two different time steps is investigated. Two simulations have been performed with the final time step of 0.0005 and 0.001.

The boundary conditions are considered as inlet velocity and outlet air pressure. In this CFD simulation, combustion is not modeled, and only particle injection is considered.

The geometry of the present model is three-dimensional and has been designed using Design Modeler software. We do the meshing of the present model by ANSYS Meshing software. The mesh type is Polyhedra, and the element number is 859,934.

Methodology: Time Step Effect on Particle Injection

The Discrete Phase Model (DPM) is used to simulate the Injection of solid particles (Inert) in the combustion chamber-Surface injection Type.

Conclusion

Considering two simulations with different time steps, this problem provides more realistic and tangible results of particle injection at time steps between 0.0001 and 0.0005. While at the time step size between 0.0005 and 0.001, the particle collision with the wall is shown schematically incorrect.

From the results of this simulation, we realized that the effect of the time step size parameter on the behavior of particles is very effective. In such problems, it is necessary that the injection of particles is independent of the time step.

Kali Bechtelar –

What advantages does the Polyhedra mesh type have in simulating the particle injection in this case?

MR CFD Support –

The Polyhedra mesh type provides a couple of advantages in simulating particle injection. It yields more accurate results in capturing the complex fluid dynamics inside the combustion chamber, especially with solid particle motion. Furthermore, Polyhedra meshes generally offer better convergence and robustness due to their geometrically inclusive shape, which can efficiently adapt to the various angles and nuances of a combustion chamber’s internal geometry. They can handle the irregularities that might be present around the injection nozzle and within the chamber, ensuring that particle pathways are computed correctly.

Lavinia Kovacek –

This product seems incredibly detailed and helpful! The differentiated time step analysis must have provided profound insights into particle behaviors!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you find our product detailed and insightful, especially with regards to the time step analysis for particle behaviors. If you have any further insights or queries, don’t hesitate to contact us.

Lela Langworth –

I have a question about the simulation setup. Why is it important to choose the correct time step size for particle injection analysis, and how does it affect the accuracy of the simulation results?

MR CFD Support –

Choosing the correct time step size is crucial for accurately capturing the dynamics of particle injection. A smaller time step allows for a more precise calculation of particles’ trajectories, interactions, and collisions with the combustion chamber walls. It ensures that rapid changes in particle movement are resolved, reducing numerical errors. Too large a time step could lead to schematic inaccuracies, as it might miss some particle-wall interactions, leading to unrealistic modeling of particle behavior. In summary, time step size directly impacts the fidelity and reliability of simulation results.

Weston Green –

I followed the tutorial step by step, and the simulations are so detailed and clear. The comparison across time steps really helped understand the influence on particle behavior. Now my simulations are more accurate, thanks to this excellent resource!

MR CFD Support –

We are thrilled to hear that our tutorial provided you with the clarity and detail you needed! Understanding the effect of time step size on particle injection is crucial for the accuracy of simulations, and we’re glad our resources could be a part of your successful simulation journey. Thank you for taking the time to share your positive experience with us!

Mrs. Raina Kautzer V –

I really love how well the tutorial showed the effect of time step size on particle injection!

MR CFD Support –

We are delighted to hear that our tutorial on the ‘Time Step Size effect on Particle Injection in Combustion Chamber’ was helpful and met your expectations. Thank you for your feedback! If you have any questions or need further assistance in your CFD learning journey, feel free to reach out.

homayoun –

In this project, the effect of time on particles is well shown.

Freddie Jacobson –

Is it possible to observe the trajectory of the particles with different time step sizes in the results?

MR CFD Support –

Yes, the trajectory of the particles is observable in the simulation results, and you can compare the differences between the trajectories at different time step sizes to understand the impact of the time step on the particle movement and predict the outcome in a real scenario.

Lorine Goodwin –

The tutorial was very insightful. Understanding the time step size’s effect on particle injection has greatly improved my grasp of combustion simulations.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our tutorial has enhanced your understanding of particle injection in combustion simulations. If you have any further questions or need assistance with your projects, feel free to reach out to us.

Major Spinka –

What do you mean by the particle collision with the wall being ‘schematically incorrect’?

MR CFD Support –

In the context of a CFD simulation, ‘schematically incorrect’ refers to the computational representation of particle collision with the wall that does not accurately reflect the expected physical behavior under the simulated conditions. When the time step size is too large (between 0.0005 to 0.001), the simulation may not capture the transient phenomena effectively, leading to inadequate or unrealistic modeling of particle-wall interactions, such as particle rebound, adhesion, or deposition.

Veda Kertzmann –

Thank you for explaining the effect of time step size on particle injection. The comparison between the two simulations was especially helpful. I noticed you mentioned collisions with the wall. Could you elaborate on how the time step size affects the accuracy of wall collisions in the simulation?

MR CFD Support –

In this simulation, the time step size significantly affects the accuracy of wall collisions because with smaller time intervals, the positions and velocities of particles are updated more frequently. This leads to better predictions of when and where particles will collide with the wall. A smaller time step size allows the simulation to capture the transient behaviors more accurately, making it paramount to use an adequately small time step to prevent non-physical behaviors, such as incorrect particle paths shown at larger time steps.

Jabari Flatley –

Were the simulations with smaller and larger time steps executed with the same computation resources, or did the larger time step simulation require less computational power?

MR CFD Support –

In general, a simulation with a smaller time step usually requires more computational resources because it has more iterations to compute, thus providing more detailed results. Conversely, a simulation with a larger time step may require less computational power and time as it has fewer data points to calculate. However, the accuracy of the simulation could be compromised.

Coty Osinski –

Why isn’t combustion modeled in this simulation? I’m curious about how it would affect the behavior of the particles.

MR CFD Support –

Combustion was not modeled in this simulation to focus on the accuracy and behavior of particle injection independent of the complex chemical reactions and thermal effects present in a combustion process. Understanding how particles move and disperse due to injection conditions and airflow can be critical before including the additional complexity of combustion reactions.

Prof. Madeline Corkery –

Great tutorial! I noticed the realistic impact of the finer time step on simulation accuracy. What size of solid fuel particles was considered for this injection simulation?

MR CFD Support –

Thank you for your kind words and your curiosity! In our tutorial simulation, we considered fuel particles with specific diameter and material density parameters to ensure the accuracy of the DPM injection results in the combustion chamber. Based on our modeling requirements and predefined specifications, these served to illustrate the importance of time step selection in capturing particle behavior.