Underfloor Heating System with Spiral Pipe

$80.00 Student Discount

- The problem numerically simulates heat transfer through the underfloor heating system by spiral pipe using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 2936179.

- We use the Ideal Gas option for the air density to consider free convection.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Underfloor Heating System with Spiral Pipe, ANSYS Fluent CFD Simulation Training

The present problem simulates the process of heat transfer through the underfloor heating system by spiral pipe using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

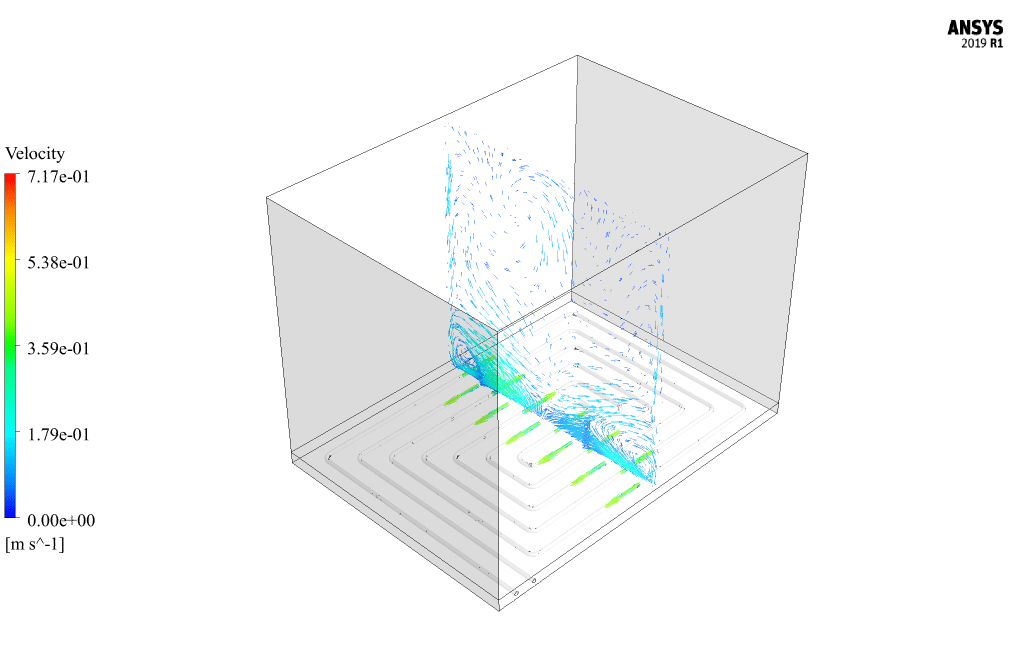

The heat source inside this model is the spiral tubes placed at the bottom of the room. Due to the buoyancy effect, the air near the spiral tubes becomes warmer and starts to move upward, creating a rotating flow inside the room.

The present model is designed in three dimensions using the Design Modeler software.

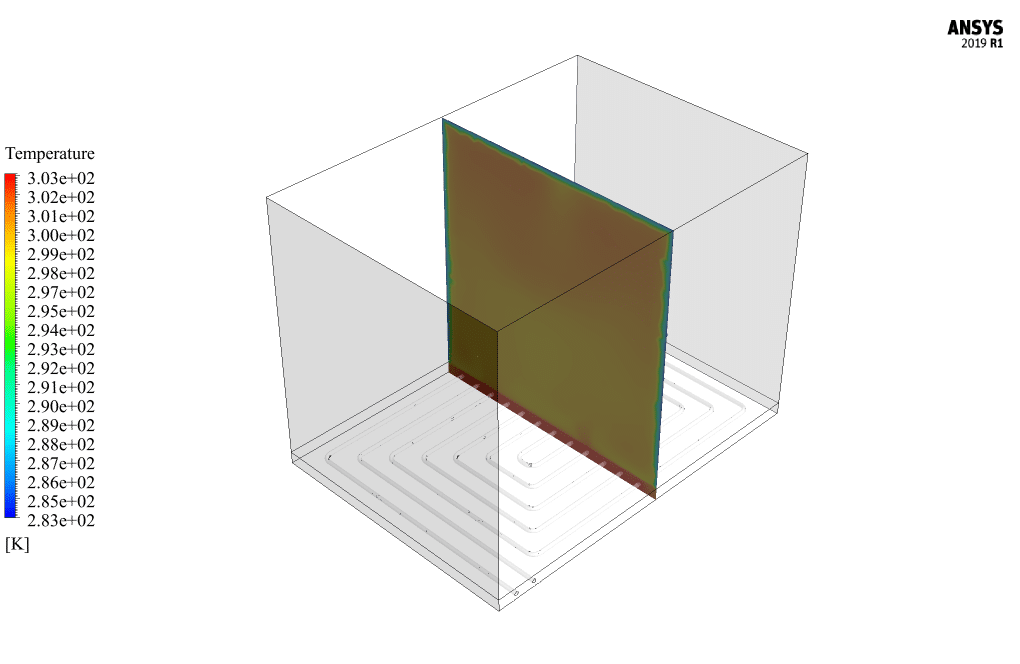

The calculation area of the present model is related to a room with a length of 3.6 m, a width of 2.6 m, and a height of 2.6 m, and a layer of concrete with a thickness of 0.12 m is designed as a solid area in the lower part of this room.

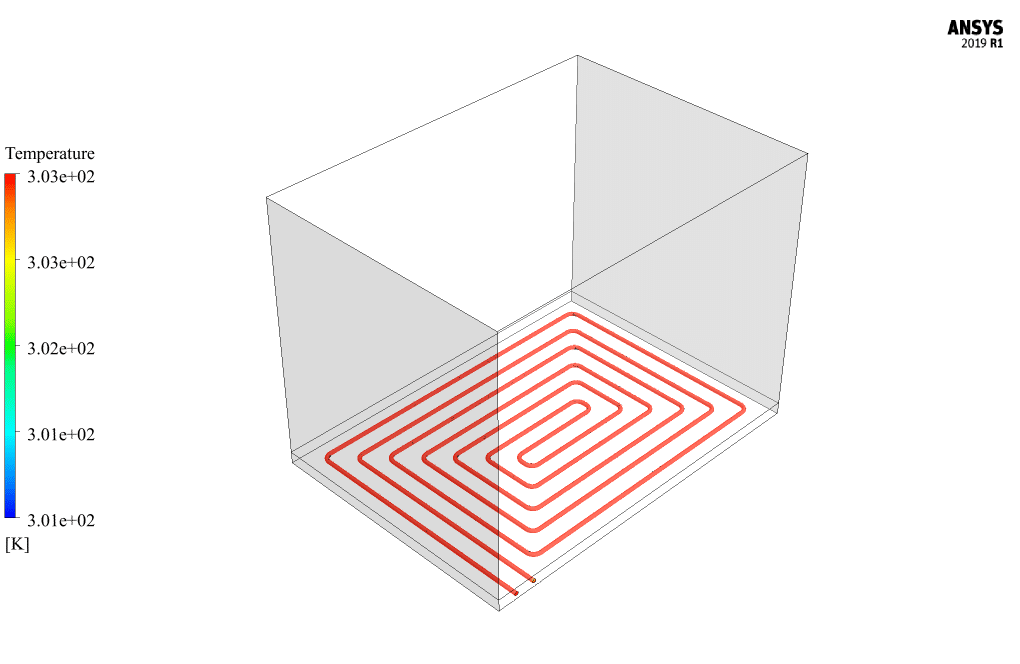

Inside this concrete layer, a 0.04 m diameter spiral pipe is designed to be inserted circumferentially, and after, a spiral path across the floor of the room is led out of the room.

The meshing of the model was done using ANSYS Meshing software. The element number is equal to 2936179.

Underfloor Heating Methodology

In this project, a room is designed in cold winter conditions, and a floor heating system is installed to heat the air inside the room. The underfloor heating system is in the form of a spiral tube that carries the flow of hot water.

The hot water pipe is placed inside a layer of concrete and transfers its heat to the concrete layer of the floor. Then, heat transfer inside the concrete layer occurs in conduction, and finally, heat transfer or convection from the ground floor leads to heating the air inside the room.

Air is defined as the ideal gas for the occurrence of free convection heat transfer in the room’s interior. Hot water flows with a flow rate of 0.5 kg/s and a temperature of 303.15 K enter the pipe to perform the heating process.

This is while for the ceiling and walls of the room, a layer of bricks is defined that transfers heat with the cold air of the surrounding environment; So the ambient temperature is defined as 278.15 K, and the heat transfer coefficient is defined as 20 W/m2K.

Moreover, the RNG k-epsilon model and energy equation are enabled to solve the turbulent fluid equations and calculate the temperature change within the domain.

Underfloor Heating Conclusion

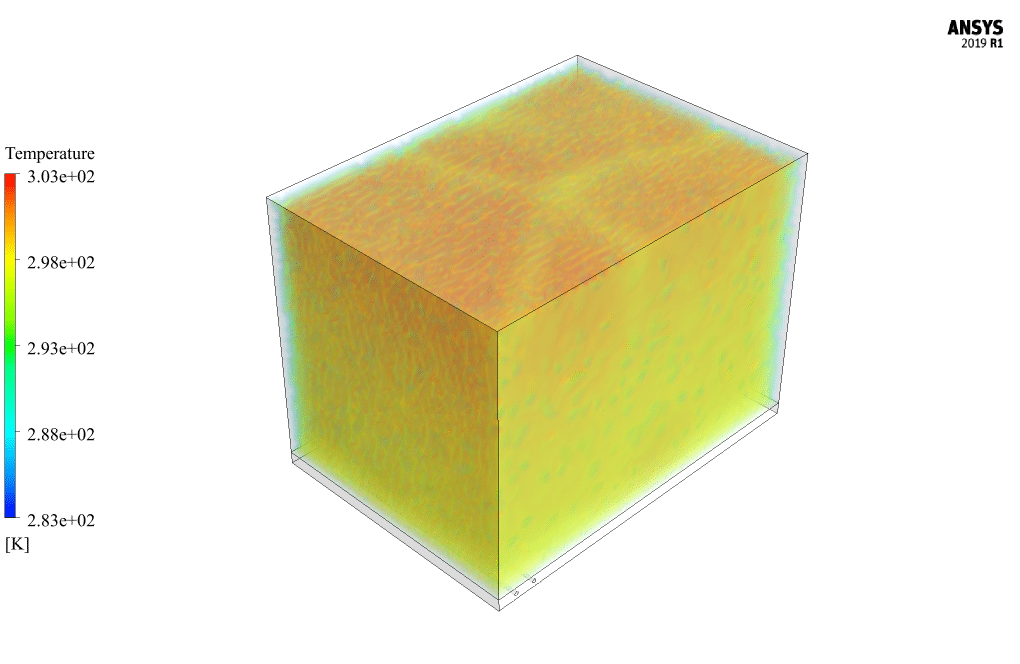

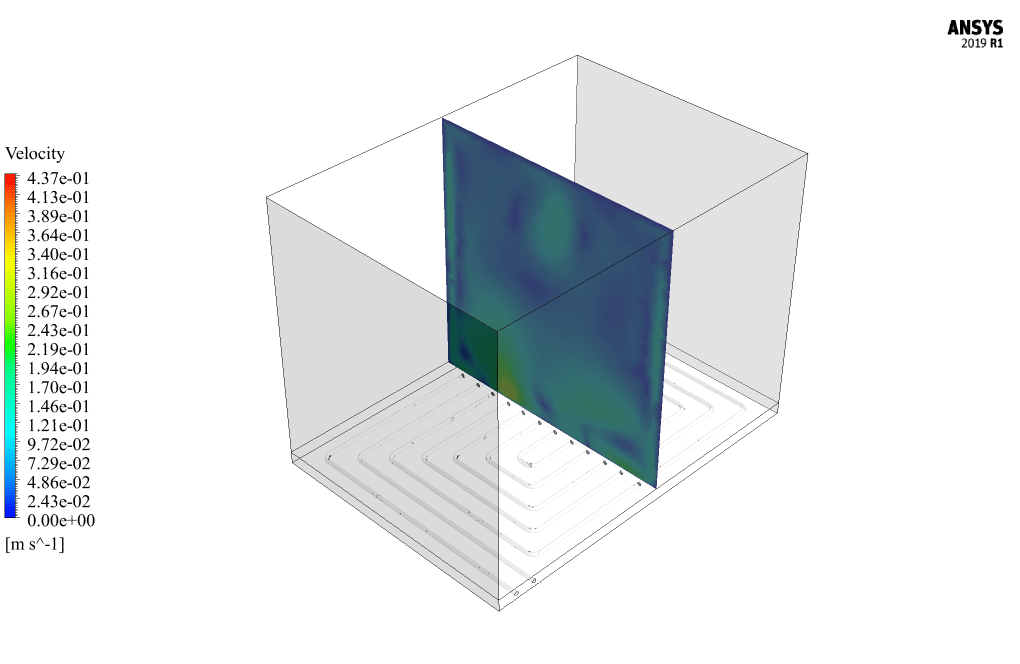

At the end of the solution process, three-dimensional contours related to changes in indoor air temperature and water flow inside the pipe, two-dimensional contours related to changes in temperature and velocity on a vertical plane passing through the middle of the room, and velocity vectors on the same plate Two-dimensional are obtained.

Two-dimensional and three-dimensional temperature-related meters well indicate the increase in indoor air temperature and the positive performance of the heating system in heating the indoor air. Also, velocity contours and vectors indicate natural heat transfer and the effect of buoyancy.

Rebecca Rau MD –

What a wonderful example of heat transfer visualization! The detail provided in your Underfloor Heating System with Spiral Pipe simulation product made it so easy to understand how an underfloor heating system operates. Seeing those temperature changes and the natural heat transfer effect put into such a clear and detailed perspective has really expanded my knowledge in HVAC design principles. Thank you for such a comprehensive and educational simulation!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our Underfloor Heating System with Spiral Pipe simulation has provided you with valuable insights into HVAC design and the principles of heat transfer. We strive to deliver educational content that is not only informative but also easy to grasp and apply. Your feedback is greatly appreciated, and it motivates us to continue creating high-quality learning materials for our customers. If you have any further questions or need more information, please don’t hesitate to reach out.

Violet Konopelski DDS –

This tutorial was super helpful for understanding the heat distribution in underfloor heating systems! The visuals were excellent in bringing the concept to light.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the tutorial effectively conveyed the workings of underfloor heating systems using the spiral pipe setup in ANSYS Fluent. If you ever need more insights on similar subjects, feel free to check out our other learning materials. We appreciate your feedback!

Dr. Heidi Moore –

I thoroughly enjoyed learning from the Underfloor Heating System simulation. The visuals for temperature changes were especially enlightening! The spiral pipe concept seemed very efficient in dispersing heat consistently across the room.

MR CFD Support –

We are so pleased to hear that you enjoyed the Underfloor Heating System simulation! It’s great to know that the visualizations offered clear insight into temperature distribution, and that the efficiency of the spiral pipe system came across well. Thank you for sharing your positive experience!

Prof. Robert Ruecker –

I’m in love with how you have explained the buoyancy effect in the classroom scenario! There’s a warmth to learning about the warmth! Could you please tell me which part of this interesting simulation process binds your fascination the most?

MR CFD Support –

Thank you for your kind words, we are thrilled to hear that you enjoyed learning about the buoyancy effect in the underfloor heating system simulation. Our team takes great joy in visualizing and explaining thermal physics, and the part that fascinates us most is seeing the complex interactions of heat transfer through the floor and how it efficiently warms the air in the room using the principles of convection. It’s both challenging and satisfying to model these real-world phenomena and impart that understanding through our CFD simulations. We greatly appreciate your engagement and enthusiasm!

Alyce Grady –

The Underfloor Heating System with Spiral Pipe simulation seems very thorough! The details provided in the training give me a good idea of how the whole system functions and the buoyancy effect on indoor warming. Thank you for the comprehensive work on the simulation and for providing such insightful results and conclusions.

MR CFD Support –

Thank you so much for your kind words and positive feedback on the Underfloor Heating System with Spiral Pipe simulation. It’s always our goal to provide the most comprehensive and detailed analyses to help users understand complex systems like this one. We’re glad that it has been insightful for you and appreciate your recognition of our efforts!

Prof. Matt Ryan –

The training material made understanding the underfloor heating system manageable. The gradual increase in indoor air temperature indicated by the three-dimensional contours was particularly illuminating.

MR CFD Support –

Thank you for your positive review! We are thrilled to hear that our training material has effectively aided your understanding of the underfloor heating system and that the results of the simulation were clear and helpful. If you have any further questions or need more in-depth knowledge, feel free to reach out.

Manuel Runte –

I was intrigued by the way this training simulates the underfloor heating system using a spiral pipe. The visuals in the output clearly show how efficient the system is. Kudos to the MR CFD team for crafting such an excellent and practical learning experience.

MR CFD Support –

Thank you for your review and compliments! We are thrilled to learn that our training for simulating underfloor heating systems met your expectations and offered valuable insights. Your feedback motivates us to continue delivering high-quality learning experiences. If you have any further questions or need assistance in your future simulations, feel free to reach out. Thank you for choosing MR CFD!

Ettie Runolfsson –

I’m really impressed by how realistic the simulation of the underfloor heating system is! It’s great to see how the spiral pipes can effectively distribute heat across the room.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you’re impressed with the realism and effectiveness of the underfloor heating system simulation. Our goal is to provide accurate and detailed CFD simulations to help users understand and visualize the process. If there’s anything else you’d like to learn about or if you need further assistance, please feel free to reach out.

Clifford Gibson –

I’ve learned so much from this simulation training! The level of detail in the temperature gradients and the velocity vectors really helped me understand the efficiency of the underfloor heating system. Great work on demonstrating the natural heat transfer and effects of buoyancy!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation training was informative and valuable to you. Understanding the physics of underfloor heating systems is critical, and we’re glad we could help clarify this for you. We appreciate your feedback and are eager to continue providing high-quality educational content!

Gust Gusikowski –

Just wanted to say that the simulation training on the underfloor heating system was incredibly detailed and enlightening. The visualization of heat transfer from the spiral pipes and the subsequent air movements really solidified my understanding of how underfloor heating operates, especially in terms of buoyancy and convection currents. Excellent training module!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the simulation training for the underfloor heating system has enhanced your understanding and offered a clear visualization of the heat transfer process. It means a lot to us to know our training module has been helpful to you. If you have any further questions or need additional learning resources, feel free to reach out!

Dandre Dare –

The simulation displayed for the underfloor heating system with spiral pipe in snowy conditions is quite informative. Experimenting with this model would greatly help in home renovation plans, especially when thinking about energy efficiency. Well done on creating such a detailed model!

MR CFD Support –

Thank you for your review! We’re delighted to hear that you found the information on our CFD model for underfloor heating useful for home renovation and energy efficiency considerations. It’s always rewarding to know our work can contribute to practical solutions for everyday needs.

Dominic Romaguera Sr. –

What improvements can be made to the simulation for a more accurate replication of the real underfloor heating scenario?

MR CFD Support –

To enhance the accuracy of the simulation, we could include the presence of furniture or other obstacles in the room to assess the impact on air circulation, as well as consider more detailed boundary conditions, such as window conductivity or insulation quality, which can affect heat loss and gain.

Edmond Larson –

The information about the underfloor heating system simulation is very helpful and detailed! I’m impressed that even the buoyancy effect was considered, adding more realism to the modeling. Great job on the comprehensive approach. Keep it up!

MR CFD Support –

Thank you for your kind words! We are glad to hear that our detailed approach to simulating the underfloor heating system met your expectations. It’s our goal to provide comprehensive CFD analysis that includes all necessary physical effects for accurate results. Your feedback is highly appreciated!

Dr. Watson Mayert –

This training module seems fantastic for practical learning experiences! I successfully managed my project using knowledge from the module, gaining a better understanding of underfloor heating efficiency and flow dynamics. Grateful for the well-structured lessons and effective simulations.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our training module proved to be instrumental in your project success and provided you with clear insights into the nuances of underfloor heating and fluid dynamics. Your feedback motivates us to continue delivering high-quality educational content. If you have any more projects or questions in the future, don’t hesitate to reach out!

Samara Kulas –

I just finished going through the Underfloor Heating System with Spiral Pipe training, and I’m blown away by the level of detail and thoroughness. From the complex geometry setup to the conduction and convection analysis, this CFD simulation training has broadened my understanding of thermal systems. Watching the temperature gradients evolve in the simulation was incredibly insightful.

MR CFD Support –

We’re thrilled to hear that the Underfloor Heating System with Spiral Pipe CFD Simulation Training was so beneficial for you. It’s always inspiring to hear that our customers are getting a comprehensive understanding of the systems we simulate. Your feedback is much appreciated, and we’re glad that the details in the temperature gradient analysis provided you with the insights you were looking for. Thank you for taking the time to share your experience.

Miss Ashley Klein PhD –

I found the underfloor heating system simulation fascinating! The attention to detail in simulating real-world conditions is impressive. Great work on providing insights into how underfloor heating distributes warmth throughout a room. It’s interesting to see how technology can optimize living environments, especially during chilly weather.

MR CFD Support –

Thank you for the kind words and positive feedback! We’re thrilled to hear that you found our underfloor heating system simulation helpful and interesting. We strive to deliver detailed and accurate simulations that provide valuable insights. If you have further questions or need additional information, don’t hesitate to reach out to us!

Jaunita Lynch –

I’m thoroughly impressed with the clarity provided by the velocity vectors and heat transfer patterns in the simulation results. It really illustrates the effectiveness of the underfloor heating system.

MR CFD Support –

Thank you for your kind words! We are pleased to hear that the simulation results were clear and that the visualization of the velocity vectors and heat transfer patterns effectively demonstrated the performance of the underfloor heating system.

Delfina Kuphal –

I just completed my CFD project on the under-floor heating system using MR CFD’s training, and I’m incredibly pleased with the results! The step-by-step guidance and detailed methodology were extremely helpful. My simulated air temperature gradient looks perfect. Thank you for making such a complex topic approachable and easy to understand!

MR CFD Support –

We are thrilled to hear that our training on under-floor heating systems helped make your project a success! It’s fantastic that the temperature gradient in your simulation turned out perfectly. Your feedback is very appreciated, and it motivates us to continue producing quality learning materials. Thank you for choosing MR CFD and for your kind words!

Dr. Abraham Wunsch MD –

I’m really impressed with the Underfloor Heating System with a Spiral Pipe training! The real-world application of CFD analysis on simulating an efficient heating system has greatly enhanced my understanding. The way buoyancy effects were explained, showing how the warm air moves upwards and creates rotation inside the room, was particularly insightful. The attention to detail in designing the room and heating elements, applying appropriate boundary conditions, and analyzing the results has given me a lot of confidence in using simulation tools for thermal management projects.

MR CFD Support –

Thank you for your kind words! We’re glad that our Underfloor Heating System with Spiral Pipe training could provide you with valuable insights. It’s fantastic to hear that it enhanced your understanding and confidence in applying CFD simulation to thermal management scenarios. If you need any further assistance or have more questions about our training materials, please don’t hesitate to reach out. We’re here to help you deepen your knowledge and skills in CFD.

Ms. Cordie Thiel –

Loved the in-depth analysis of the underfloor heating system simulation. The explanation of how hot water influences air movement and heat transfer within the room was enlightening. The learning material made it easy to visualize the process, and I appreciated the detail provided about the modeling and methodology using ANSYS Fluent. Great job on this educational content—it’s made learning complex concepts enjoyable and accessible.

MR CFD Support –

We’re thrilled to receive such positive feedback on our tutorial for simulating the underfloor heating system. It’s wonderful to hear that the explanations of the heat transfer process and the air movements due to buoyancy were clear and informative. Your satisfaction is our top priority, and we’re glad we could facilitate an enjoyable learning experience. Thank you for taking the time to share your thoughts with us!

Mr. Lewis Dibbert PhD –

I’ve received so much value from the ‘Underfloor Heating System with Spiral Pipe’ training. The detailed explanation of the heat transfer process and the use of ANSYS Fluent software offered a comprehensive understanding of how buoyancy affects air movement in a room with an underfloor heating system. Seeing the simulation results, especially the temperature changes, really solidified the concepts for me. The course structure breaks down complex principles into understandable segments, making learning effective and engaging!

MR CFD Support –

We’re thrilled to hear the training provided you with a detailed and comprehensive understanding of the underfloor heating system using ANSYS Fluent. Your feedback about the effective course structure and the clarity of the simulation results is greatly appreciated. Thank you for sharing your positive experience, and we’re glad you found great value in our learning product!

Zoie Berge –

I’m absolutely thrilled with how realistic the simulation was, and it’s fascinating to see the influence of the spiral pipe in distributing heat within the room. Great job on demonstrating the buoyancy effect and comprehensive coverage of temperature and velocity changes.

MR CFD Support –

Thank you so much for your kind words and appreciation! We’re very pleased to know that the realism and thoroughness of the Underfloor Heating System simulation were helpful and informative for you. If you have any more feedback or need further assistance, we’re always here to help!

Tracey Kovacek –

I recently used the Underfloor Heating System with Spiral Pipe CFD simulation training product, and I learned so much about buoyancy effects and thermal comfort. Following the provided material, setting up my underfloor heating simulation in ANSYS Fluent went smoothly, and the results were really accurate regarding temperature distribution. The training highlighted critical aspects like heat source placement and show how convection rates affect room heating efficiency.

MR CFD Support –

Thank you for taking the time to provide feedback on the Underfloor Heating System with Spiral Pipe CFD simulation training. We are delighted to hear that the training was both informative and practically applicable for you, and that it helped you understand and set up your own simulation accurately. It’s great to hear that our product contributed to your learning and success in thermal simulations!

Prof. Maximo Huel –

I am really pleased with the detailed explanation of the heat transfer process and how well the simulation demonstrated the effectiveness of the underfloor heating system. Great job on visualizing the air temperature changes within the room!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the simulation met your expectations and provided clear insights into the heating process. Your satisfaction with our visualization of temperature changes is highly appreciated. If you need further assistance or have more queries in the future, don’t hesitate to reach out.

Hailey Marquardt V –

This training really put into perspective the benefits of an underfloor heating system. Following along, it was easy to grasp how heat transfer works with convection and the conduction process in the concrete layers. As someone who feels the winter chill, seeing the science behind this efficient heating method was illuminating and gives me a greater appreciation for the engineering involved.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that the training enhanced your understanding of underfloor heating systems and the heat transfer process. It’s always rewarding to know our products are not only educational but also applicable in real-world contexts. If you have any further questions or need further insights, feel free to reach out.

Dena Eichmann –

The training content on fluid flow and heat transfer for the underfloor heating system simulation was so informative. The visuals and the methodology explanation were top-notch!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our underfloor heating system simulation training met your expectations and that the visuals and explanation helped clarify the process. We appreciate your enthusiasm for learning with us at MR CFD!

Aletha Torphy –

I am thoroughly impressed with the 3D contours and the clear demonstration of airflow due to the heating system. The specifics of how the underfloor spiral pipe system effectively raised the room temperature during cold conditions are particularly appreciated. It’s evident the simulation provides a strong visualization of convection currents in a practical application.

MR CFD Support –

Thank you for your positive feedback! We strive to provide comprehensive simulations that clearly illustrate the physics behind the concepts, and we’re delighted to hear that you appreciate the level of detail and clarity in our training products.

Halie Miller –

I just finished the underfloor heating system with spiral pipe training, and I am thoroughly impressed with the detailed explanation of heat transfer and the simulation of buoyancy-driven flow. Kudos!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you had an impressive learning experience and found the training detailed and informative. Your feedback is most appreciated, and we are glad that our product met your expectations!

Prof. Jocelyn Nolan Sr. –

I purchased the Underfloor Heating System with Spiral Pipe training, and my experience with the simulation has been fantastic! I found the step-by-step instructions for setting up the heat transfer incredibly informative and easy to follow. The concrete layer’s conduction properties and how they interact with the air in the room are shown clearly in the results. I’ve gained a greater understanding of convection heat transfer in indoor spaces. Watching the air temperature rise due to the underfloor heating in the simulations was especially gratifying. A hearty thanks to the MR CFD team for such a thorough and practical learning tool.

MR CFD Support –

We’re absolutely thrilled to hear about your positive experience with our Underfloor Heating System with Spiral Pipe training! It’s our pleasure to provide instructional content that’s both informative and easy to comprehend. We are glad that the simulation provided clear insights into the convection heat transfer process and that you were able to see the theory in action. Thank you for your kind words, and don’t hesitate to reach out if you have any more feedback or need further assistance. Your success is our success at MR CFD Company!

Dr. Layne Cruickshank I –

I’m blown away by the detail in the simulation for the underfloor heating system. The fluid dynamics and heat transfer are incredibly well-modeled, giving such a clear picture of how these systems operate in real-time.

MR CFD Support –

Thank you so much for your kind words! It’s wonderful to know that the detail and accuracy of the simulation were standouts for you. We strive to ensure that our products are not only informative but also visually descriptive to aid in understanding complex systems. We’re glad that it reflected in your experience with the underfloor heating system simulation. If you have any more feedback or need further assistance with our products, feel free to reach out!

Dr. Roosevelt Hettinger –

The simulation sounds very comprehensive, but I’m wondering how does the introduction of objects like furniture into the room affect the heat distribution? Are there any recommendations for optimizing the layout for even heat spread?

MR CFD Support –

In this simulation, the current setup does not include furniture or other obstructions. However, introducing objects like furniture can affect heat distribution by introducing new surfaces for heat absorption and potentially blocking air flow pathways. To optimize the heat spread, it is advised to maintain a clear gap between the furniture and the floor to allow for unobstructed air circulation. Arranging furniture away from the heating pipes and considering the natural convection currents can help in achieving a more even heat distribution. In real-world scenarios, additional simulations would be necessary to study the impact of furniture placement.

Ms. Dariana Strosin –

Absolutely thrilled with the knowledge I’ve gained from the underfloor heating system course! Understanding how a practical application like this functions has improved both my analytical and simulation skills. The implementation of hot water flow rate and detailed conduction through the concrete layer was particularly insightful.

MR CFD Support –

We’re so glad to hear that you found our underfloor heating system CFD course valuable! We aim to provide comprehensive knowledge that can be applied to real-world applications. Thank you for recognizing the efforts put into explaining the complex physics of heat transfer within such systems. We appreciate your feedback!

Dr. Patricia Pollich –

This underfloor heating simulation you offer seems quite comprehensive and detailed! Can this simulation take into account different materials for the pipe or concrete, to simulate how they would affect the heat distribution?

MR CFD Support –

In our simulation training, different materials for the pipe and concrete can indeed be considered to analyze their impact on heat distribution. The thermal properties, such as conductivity and heat capacity, of the materials would be configured to closely represent specific materials chosen for the simulation. This leads to an evaluation of varied responses to the implemented underfloor heating system.

Tyrel Bode –

The attention to detail in the CFD simulation for the underfloor heating system with a spiral pipe is impressive. It is clear that there was a considerable level of expertise and meticulous work involved in crafting such a realistic model.

MR CFD Support –

Thank you very much for your kind words! We are delighted to hear that you appreciate the intricacy and expertise that went into the CFD simulation. Your recognition of our hard work is greatly valued, and we’re glad that our efforts have resonated with you. If you need any further assistance or have more interest in our simulations, please feel free to reach out to us.

Reuben Schoen Sr. –

The simulation sounds thorough, but I am curious about the type of insulation used. Does the training provide information on how insulation materials could affect the efficiency of the underfloor heating system?

MR CFD Support –

The training focuses on the simulation of heat transfer in an underfloor heating system with a given set of conditions, including the assumption of a layer of brick as insulation for the ceiling and walls. While it demonstrates the effect of this setup on thermal efficiency, detailed variation of insulation materials and their specific impact may not be covered extensively. You would need to refer to the provided learning materials or reach out to the MR CFD support team for more detailed insights into various insulation options and their simulation results.

Gabe Bashirian –

The Underfloor Heating System with Spiral Pipe simulation training provided by MR CFD sounds intriguing. Great work on setting up such a detailed computational model. The explained methodology is thorough, and it appears that the CFD project covers critical factors involving heat transfer and fluid dynamics in a comprehensive manner. Waiting to dive into the results and visuals available in the training material!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear you found the Underfloor Heating System with Spiral Pipe simulation training detail-oriented and comprehensive. We strive to ensure our training materials are well-researched and informative, covering all necessary computational aspects. We hope you will find the results and visuals engaging and helpful in understanding the complex interactions in the system. If you have any questions after reviewing the material, feel free to reach out!