Double Pipe Heat Exchanger with Dish-Shaped Strip Inserts, ANSYS Fluent

$80.00 Student Discount

The heat transfer inside a double pipe heat exchanger with dish-shaped strip inserts is investigated in this project.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Introduction

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. A solid wall may separate the fluids to prevent mixing, or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine. (Double Pipe Heat Exchanger with Dish-Shaped Strip Inserts)

A circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

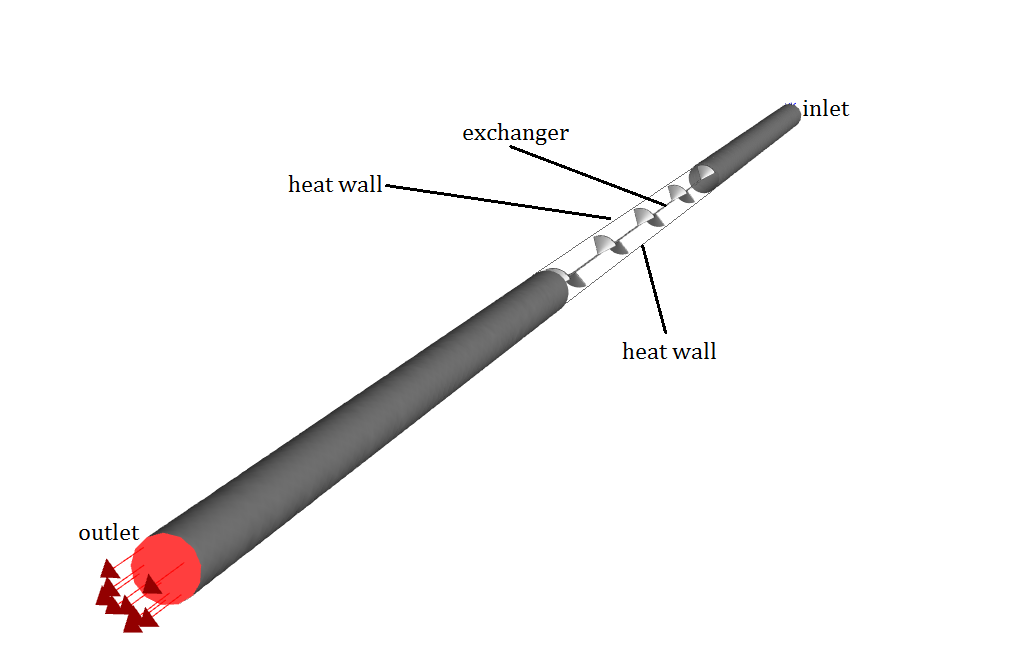

Double Pipe Heat Exchanger with Dish-Shaped Strip Inserts Project Description

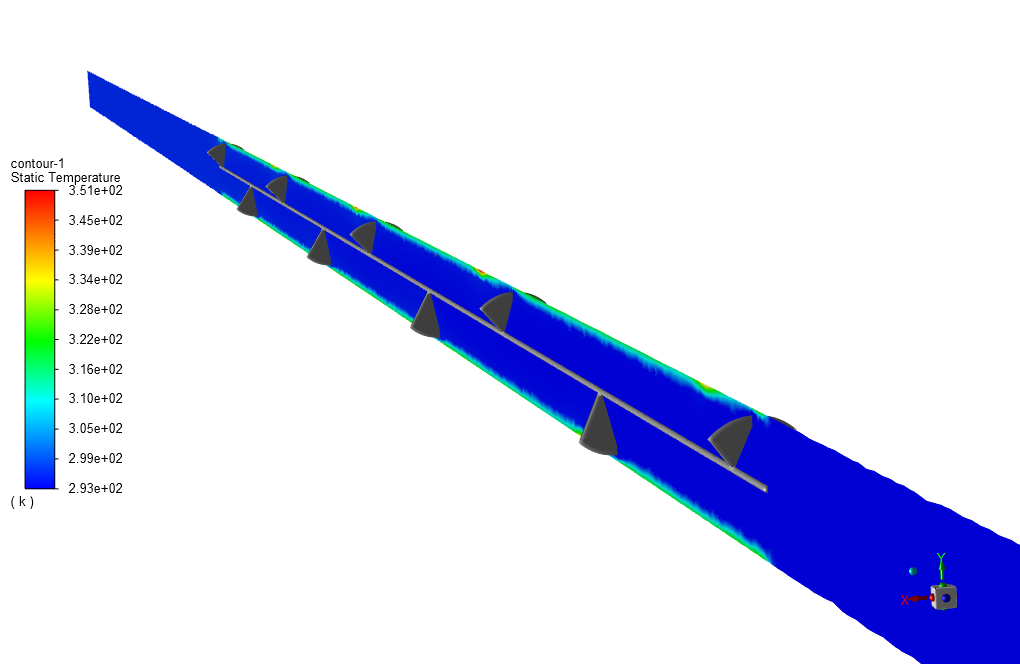

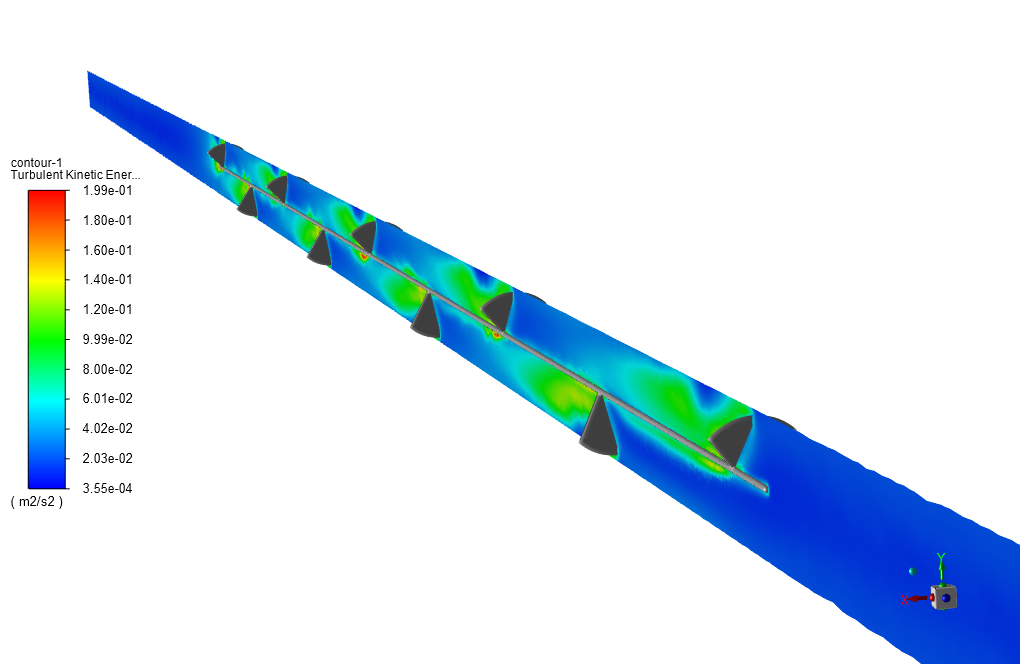

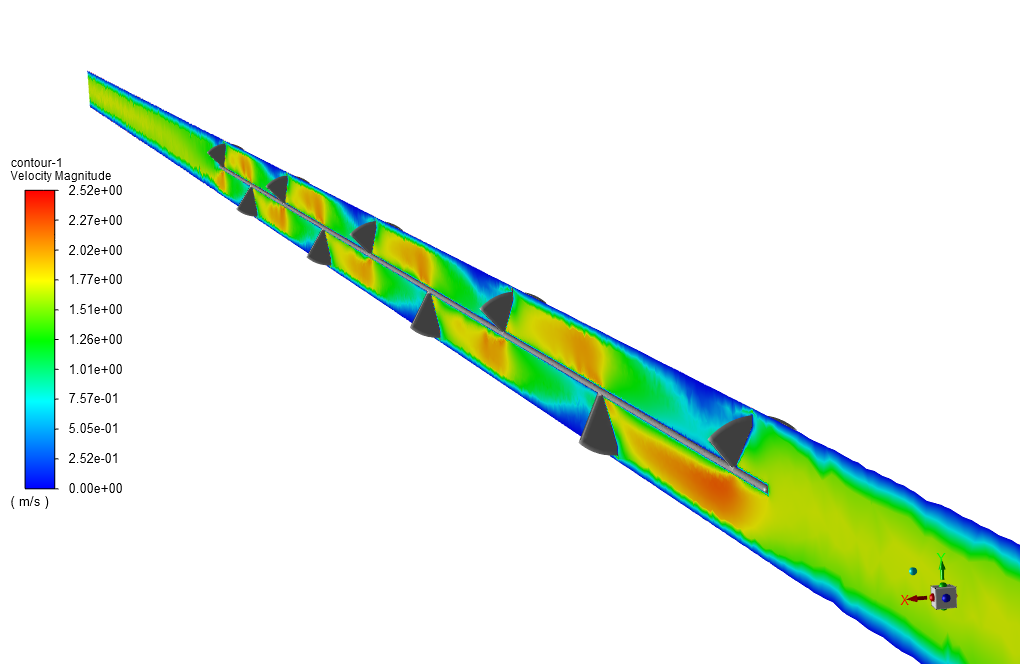

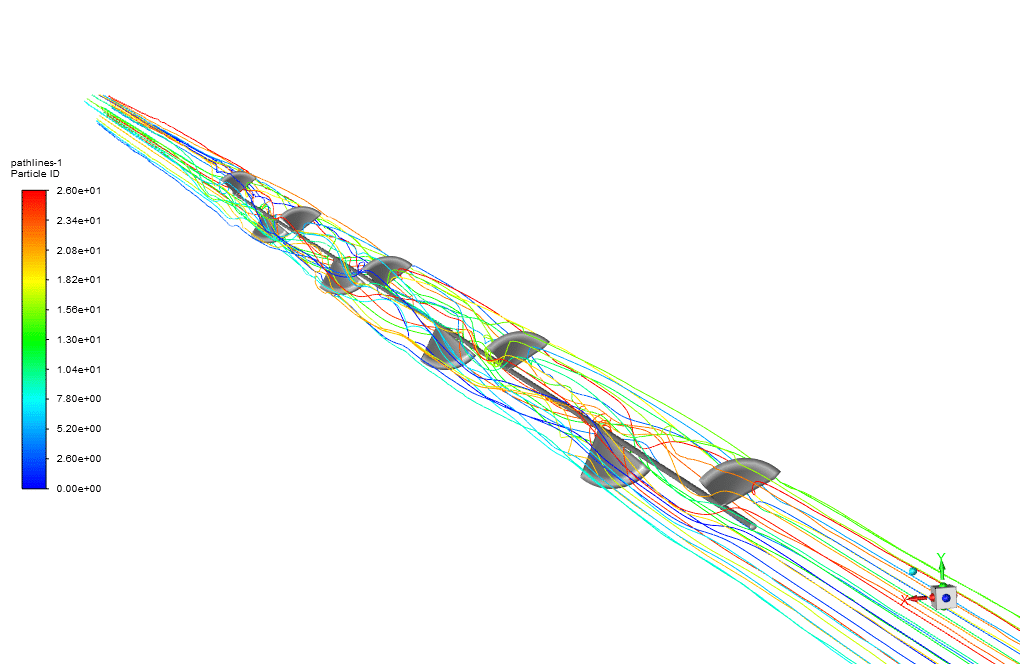

The heat transfer inside a double pipe heat exchanger with dish-shaped strip inserts is investigated in this project by ANSYS Fluent software. The double heat exchanger consists of several baffles (dish-shaped strip) with a heated wall. The water flow enters the pipe with an initial temperature of 293K and a velocity equal to 1.537972m/s. Also, the heated wall is exposed to a heat flux of 200000W/m2. The energy equation is activated to obtain temperature distribution inside the computational domain, and the RNG k-epsilon model is exploited to solve turbulent flow equations.

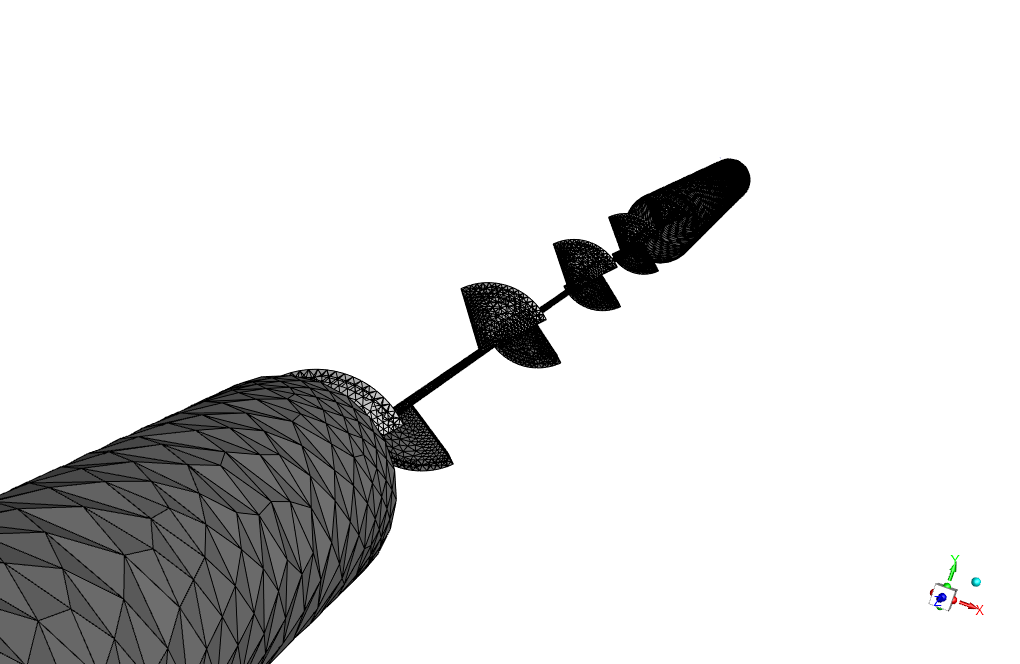

Double Pipe Heat Exchanger Geometry & Mesh

This project’s geometry is designed in ANSYS Design Modeler and consists of dish-shaped strips and a heating wall. The geometry has then meshed in ANSYS Meshing software, and the mesh type used for this geometry is unstructured, and the element number is 649800.

CFD Simulation Settings

The critical assumptions considered in this project are:

- Simulation is done using a pressure-based solver.

- The present simulation and its results are considered steady and do not change as a function of time.

- The effect of gravity has not been taken into account.

The applied settings are summarized in the following table.

| Models | ||

| Viscous model | k-epsilon | |

| k-epsilon model | RNG | |

| near wall treatment | standard wall function | |

| Energy | on | |

| Boundary conditions | ||

| Inlet | Velocity inlet | |

| Inlet | 1.537972 m/s | |

| Temperature | 293 K | |

| Outlet | Pressure outlet | |

| Gauge pressure | 0 Pa | |

| Walls | Stationary wall | |

| exchanger | Heat flux | 0 W/m2 |

| Heat wall | Heat flux | 200000 W/m2 |

| wall | Heat flux | 0 W/m2 |

| Solution Methods | ||

| Pressure-velocity coupling | SIMPLE | |

| Spatial discretization | Pressure | Second order |

| Momentum | second order upwind | |

| Energy | second order upwind | |

| turbulent kinetic energy | second order upwind | |

| turbulent dissipation rate | second order upwind | |

| Initialization | ||

| Initialization method | Standard | |

| gauge pressure | 0 Pa | |

| Velocity (x,y,z) | (1.537972,0,0) m/s | |

| temperature | 293 K | |

| Turbulent kinetic energy | 0. 0003548039 m2/s2 | |

| Turbulent dissipation rate | 0.0007634331 m2/s3 | |

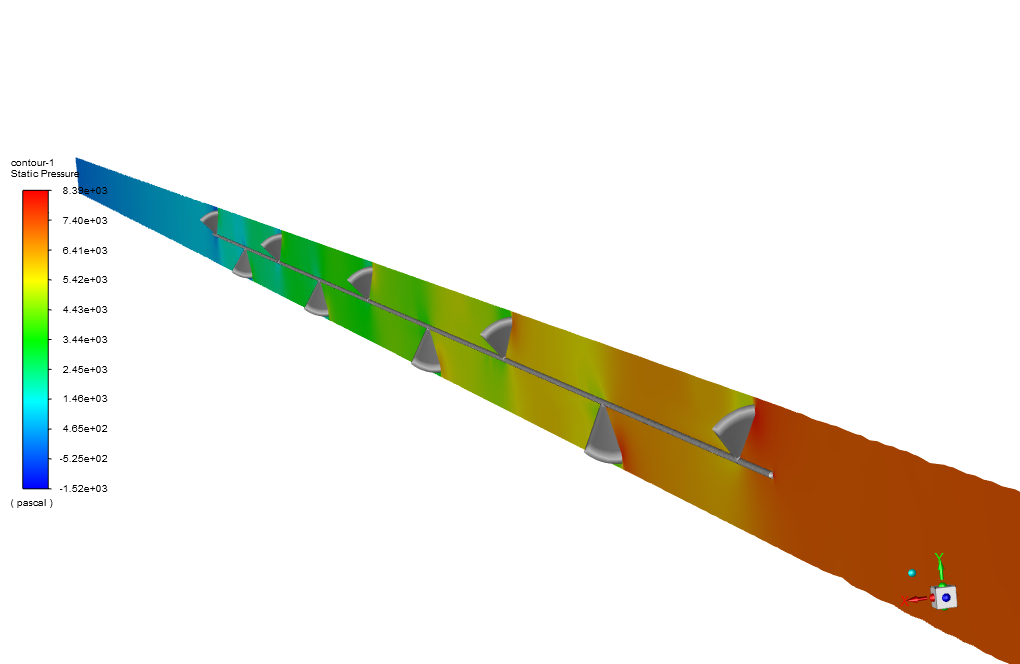

Results

After the CFD simulation process, contours of pressure, velocity, temperature, etc., are obtained and presented.

Mr. Delmer Senger –

What a thorough simulation! The detailed design of the heat exchanger with dish-shaped strip inserts seems to be precisely modeled for optimum heat transfer analysis. Impressive use of the RNG k-epsilon model for turbulence and excellent choice in managing the boundary conditions to obtain accurate temperature distributions within the system. It’s fascinating how computational tools like ANSYS Fluent can be utilized to enhance the performance of classic engineering systems. Kudos on a well-executed project!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to know that our Double Pipe Heat Exchanger project with dish-shaped strip inserts met your expectations. It’s great to hear that the precision of the modeling and the thoughtful application of turbulence models in ANSYS Fluent contributed to your compelling analysis. We appreciate the time you took to recognize our efforts, and your satisfaction is our biggest reward.

Ms. Rosella Gerhold –

I’m truly fascinated with the level of detail in this double pipe heat exchanger simulation! The inclusion of dish-shaped strip inserts for studying heat transfer demonstrates an advanced application of CFD. I’m impressed by the marriage of sophisticated geometry and meshing with complex physical models to achieve meaningful results.

MR CFD Support –

Thank you for your kind words! We are pleased to hear that you appreciate the complexity and the detail in our double pipe heat exchanger simulation. Delivering accurate and comprehensive simulations is what we constantly strive for. If you have any further questions about this product or any other, please don’t hesitate to ask.

Skyla Koch –

I’m floored by the fantastic results garnered from the Double Pipe Heat Exchanger CFD project! It is exceptional to see how effectively the dish-shaped strip inserts improve heat transfer. Outstanding work!

MR CFD Support –

Thank you so much for your kind review! We’re thrilled to hear that the project’s results impressed you. Enhancing heat transfer efficiently within such systems is at the core of our CFD simulations, and your acknowledgement really validates our efforts in this area.

Mr. Devonte Eichmann –

The project description mentions dish-shaped strip inserts. Can you explain how these impact the heat transfer process in the double pipe heat exchanger?

MR CFD Support –

The dish-shaped strip inserts are placed within the inner tube of the double pipe heat exchanger to enhance the heat transfer process. These inserts act as turbulence promoters, disturbing the laminar boundary layer and increasing the fluid’s mixing level, which improves heat conduction from the heated wall to the flow. The increased turbulence also reduces the thermal resistance and thus, significantly enhances the heat transfer coefficient, leading to a more efficient heat exchange process.

Urban Ullrich –

I just completed studying the project about the Double Pipe Heat Exchanger with Dish-Shaped Strip Inserts using ANSYS Fluent that you guys provided. Impressed by the level of detail in the simulation process and results. The heat transfer insights with the dish-shaped strip inserts give a great understanding of the efficiency improvements that can be applied in actual heat exchanger design. Kudos to the team for such an intricate and well-explained simulation project!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the project detailed and helpful. It’s great to know that the simulation provided you with a clear understanding of the heat transfer processes in the heat exchanger, and how such inserts can improve design efficiency. Should you have any further questions about heat exchanger design or other projects, feel free to reach out. Your feedback is highly appreciated, and we are here to support your learning journey!

Denis Berge –

I found the information about dish-shaped stirp inserts fascinating. Have these inserts proven to be more efficient in heat transfer compared to other types of inserts?

MR CFD Support –

Yes, dish-shaped strip inserts have been shown to improve the turbulence of the flow and therefore can enhance heat transfer. The increased turbulence helps disrupt laminar flow behavior and promotes better mixing of the fluid, which aids in the heat exchange process.