Project Outsourcing

Outsource your project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including Consultation, Training, and CFD Simulation. The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is Agricultural and Food Engineering?

Agricultural and Food engineering is a branch of engineering that focuses on the design, development, and improvement of agricultural and food production systems. It combines the principles of engineering, biology, and chemistry to develop efficient and sustainable solutions for food production, processing, storage, and distribution. Agricultural and Food Engineers work to improve the safety, quality, and efficiency of food production and processing, while also considering environmental and economic factors.

How CFD simulation can be applied in the Agricultural and Food Industries?

CFD simulation can be applied in the Agricultural and Food Industries in a variety of ways. For example, CFD can be used to simulate the flow of air in a food processing plant, helping to optimize the design of the plant and improve the efficiency of the process. CFD can also be used to simulate the flow of liquids in a food production line, helping to optimize the design of the line and improve the efficiency of the process. Additionally, CFD can be used to simulate the flow of heat in a food storage facility, helping to optimize the design of the facility and improve the efficiency of the process. Finally, CFD can be used to simulate the flow of gases in a food packaging plant, helping to optimize the design of the plant and improve the efficiency of the process.

Computational fluid dynamics (CFD) and simulation tools of fluid flow processes have appeared from the development stage and become robust design tools nowadays. The CFD tools offer a cost-effective way of carrying out equipment and process design and optimization and reducing equipment modification and scale-up risk. CFD modeling has been gaining attraction from the agri-food industry in recent years. This article reviews various CFD applications to improve crop farming systems such as soil tillage, sprayers, harvesting, machinery, and greenhouses.

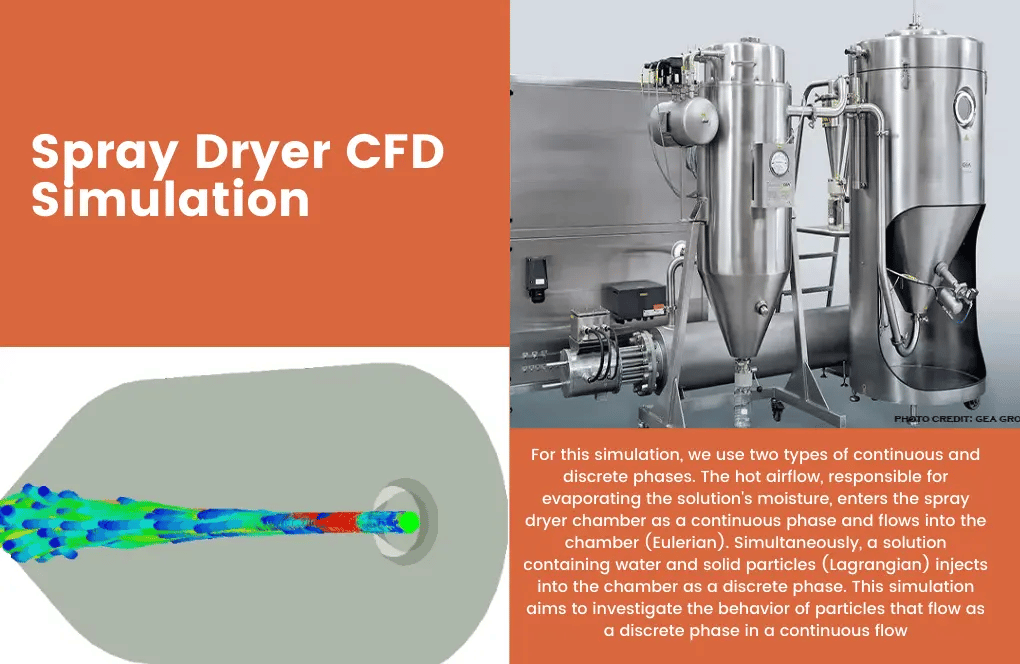

spray dryers are widely used in the agricultural and food industry. They are used to dry a variety of products, including milk, eggs, proteins, starches, and other food ingredients. Spray dryers are also used to dry agricultural products such as grains, fruits, and vegetables.

greenhouses are widely used in the agricultural and food industry. Greenhouses are used to grow crops, vegetables, and fruits, as well as to raise livestock. Greenhouses can also be used to extend the growing season, protect crops from extreme weather, and reduce the need for pesticides and other chemicals.

How to Improve the Performance of Agriculture in CFD Simulation?

Although CFD application in the food industry will assist in understanding the dynamics and physics of a food processing procedure and thus aid in the optimization and design of existing and new processing equipment, constrictions are necessary for faster, easier, and less expensive CFD techniques. In the new era, the application of CFD in the food industry has reached a critical juncture since it is becoming more and more apparent that the future growth in CFD will be qualitative, quantitative, and effective in work.

Numerous food processing operations such as chilling, drying, freezing, pasteurization, and sterilization rely on fluid flow. The transfer of CFD approaches to the food industry has provided food engineers with new insight and understanding of the likely performance of food equipment at the design stage and confidence in the quality or safety of food products. Equipment such as ovens, heat exchangers, refrigerated display cabinets, and spray dryers has been improved by applying CFD techniques to understand their operation and design process. CFD has become a powerful tool for developing, troubleshooting, and optimizing food processes.

CFD for Improving the Sterilization Procedure

It is known that consumer demand for food products focuses on safety, quality, and cost. Therefore, it is of great necessity to enhance quality and assure the safety of the food supply. Sterilization is an essential technique for food storage and preservation. CFD can be used to study both temperature distribution and flow pattern of food in the process of sterilization to optimize the quality of food products. Thermal processing remains the most effective sterilization technique, resulting in microbial inactivation, but in the meantime, quality loss and flavor development. Excessive heating will affect food quality and its nourishing properties.

In recent years, food pouches have been introduced to the market; therefore, little or no study has been executed on the sterilization of food in pouches. CFD code was used to simulate the transient temperature, velocity profiles, and the shape of the slowest heating zone in the sterilization of pouches.

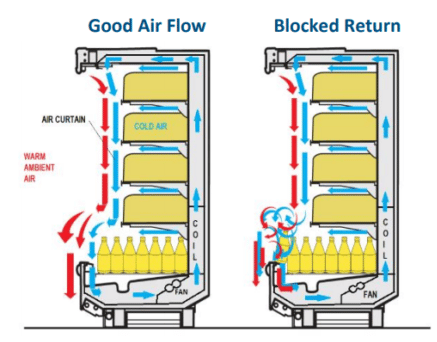

CFD in Case of Food Refrigeration

The consumption of frozen foods has increased continually in the past years because frozen foods have demonstrated good food quality and safety records. Refrigeration can slow down bacterial growth and preserve food.

Since refrigerated foods require strict temperature control, the design of equipment or stores for refrigerated foods is crucial. With the utilization of CFD, designers can examine the whole range of modifications before manufacturing and designing at a minimal cost and in a short time.

CFD in Improving Heat Exchanger Devices

A Heat Exchanger is a systematic device constructed for the successful heat transfer between two fluids of non-identical temperatures. The media might be separated through a solid wall to intercept mixing or be in direct contact. Heat exchangers are fully used in the food processing industry, dairy industry, biochemical processing, chemical plants, and petroleum plants, to name a few. They are ubiquitous in the bioprocess industry, from high-temperature pasteurization to low-temperature freezing. Heat exchangers have long been a required tool for pasteurization, sterilization, and other food processing needs. And while the technology is fully-fledged, there’s still enough innovation occurring.

There are mainly three heat exchangers: shell, tube, and plate exchangers. However, plate exchangers tend to be preferred in the food processing industry. CFD has been used to simulate and study the flow and temperature distribution of the fluid to predict and control food quality during the heating process.

It is necessary to maintain cleanliness and ventilation in the food processing industry. Designers have used CFD to simulate the airflow within a cleanroom. The particle tracking techniques can predict the movement of air and other particulate matter in the cleanroom.

The design of suitable ventilation equipment, the air supply, and extraction duct position, and the optimal location of working areas and machines can benefit from using the CFD. Applying CFD to control cleanroom conditions will provide a good working environment and enhance sanitary in the food processing industry.

MR CFD services in the Agricultural and Food

MR CFD conducted numerous outsourced simulation projects for industrial and research Agricultural and Food engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, we are ready to offer extensive services of simulation configurations.

CFD (Computational Fluid Dynamics) services can be used in the agricultural and food industry to improve the efficiency of processes, reduce costs, and improve product quality. CFD can be used to simulate the flow of air, water, and other fluids in agricultural and food processing systems. This can help to identify areas of inefficiency and optimize the design of the system. CFD can also be used to analyze the effects of changes in temperature, pressure, and other environmental factors on the performance of the system. Additionally, CFD can be used to simulate the behavior of particles in the system, such as the movement of food particles in a drying process. CFD can also be used to analyze the effects of different materials on the performance of the system, such as the effects of different coatings on the flow of air or water. Finally, CFD can be used to analyze the effects of different operating conditions on the performance of the system, such as the effects of different temperatures on the flow of air or water.

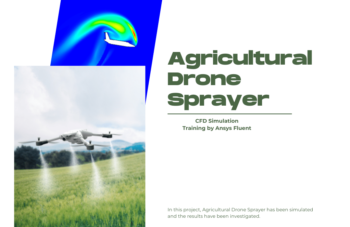

Drones are now recognized tools in the agriculture industry, enhancing the productivity of farms with timely aerial data. But aside from meeting vital insights on crop health and enabling the production of detailed maps, flying robots are taking a vibrant role in day-to-day actions. Agricultural Spraying Drones are being used for the following applications:

Fertilizers

Herbicides

Pesticides

Fungicides

Seeds, and more.

The other example of a CFD project that MR CFD has simulated successfully is the investigation of Watering the Lawns. In this project, MR CFD experts simulated the injected water jet from the sprinkler nozzle to the domain and obtained the jet’s length.

One of the other great applications of CFD in the food industry is its capability to simulate phase changes. For example, in another project carried out by the MR CFD, we tried to remove moisture from the grain called drying.

The seed drying process should reduce the moisture content of the seeds to a safe moisture level to maintain their viability and stability during storage; otherwise, the seeds may spoil quickly due to mold growth, heating, and increased microbial activity.

Agricultural and Food MR CFD Projects

With several years of experience in simulating various problems in different CFD fields using ANSYS Fluent software, the MR CFD is ready to offer extensive modeling, meshing, and simulation services. Our simulation Services for Agricultural and Food simulations are categorized as follows:

Following is a brief list of the CFD simulation projects for Agricultural and Food engineering by MR CFD:

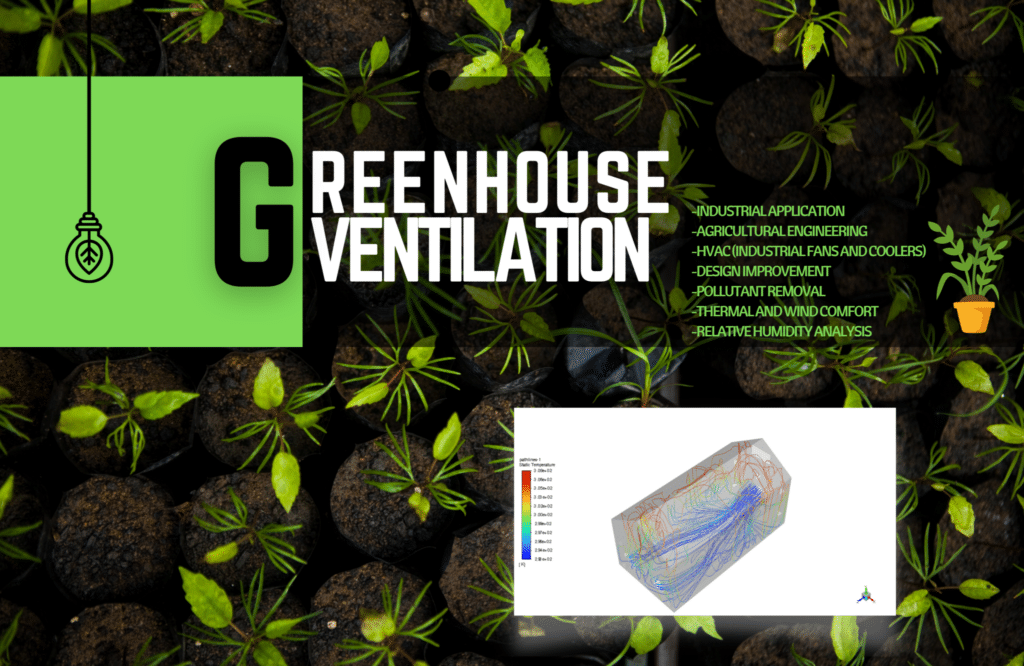

Developing a CFD Model for the Optimization of Greenhouse Ventilation Systems: This project would involve developing a CFD model to optimize the ventilation systems of greenhouses, improve crop yields and reduce energy costs.

CFD Modeling of Food Processing Equipment: This project would involve developing a CFD model to analyze the flow of food products through various types of food processing equipment, such as mixers, blenders, and extruders. The goal would be to optimize the design of the equipment for maximum efficiency.

CFD Modeling of Crop Irrigation Systems: This project would involve developing a CFD model to analyze the flow of water through various types of crop irrigation systems, such as sprinklers, drip irrigation, and furrow irrigation. The goal would be to optimize the design of the systems for maximum efficiency.

CFD Modeling of Livestock Housing Systems: This project would involve developing a CFD model to analyze the flow of air through various types of livestock housing systems, such as barns, sheds, and pens. The goal would be to optimize the design of the systems for maximum efficiency.

CFD Modeling of Agricultural Machinery: This project would involve developing a CFD model to analyze the flow of air and other fluids through various types of agricultural machinery, such as grain dryers, rice dryers, tractors, harvesters, and threshers. The goal would be to optimize the design of the machinery for maximum efficiency.

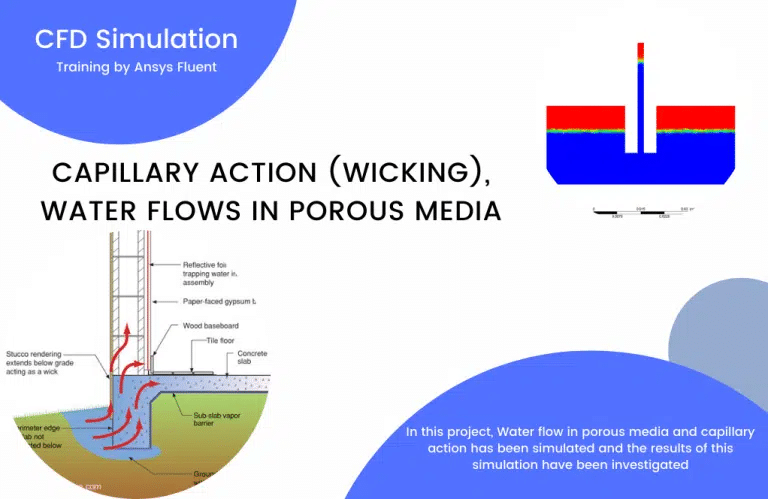

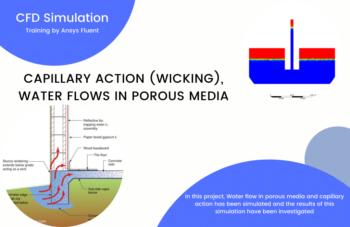

CFD Modeling of Capillary Action (wicking), Water flows in porous media: Capillary action, also known as wicking, is a phenomenon in which liquid moves through a porous material due to the forces of adhesion, cohesion, and surface tension. This phenomenon is used in a variety of applications, including agricultural and food engineering.

In agricultural engineering, capillary action is used to move water and nutrients from the soil to the roots of plants. This helps to ensure that the plants can access the water and nutrients they need to grow and thrive.

In food engineering, capillary action is used to move liquids, such as oil, through food products. This helps to ensure that the food products are evenly cooked and that the flavors are evenly distributed. Capillary action is also used to move liquids through food packaging materials, such as paper and cardboard, to help keep the food fresh.

With several years of experience in simulating various problems in different CFD fields using ANSYS Fluent software, the MR CFD is ready to offer extensive modeling, meshing, and simulation services. Our simulation Services for Agriculture & Food simulations are categorized as follows:

- Storage systems and facilities

- Wastewater recycling

- Fans, ventilators, ducts, nozzles, and pumps

- Drying, heating, cooling, phase changes, etc.

- Ovens, heat exchangers, refrigerated display cabinets, etc.

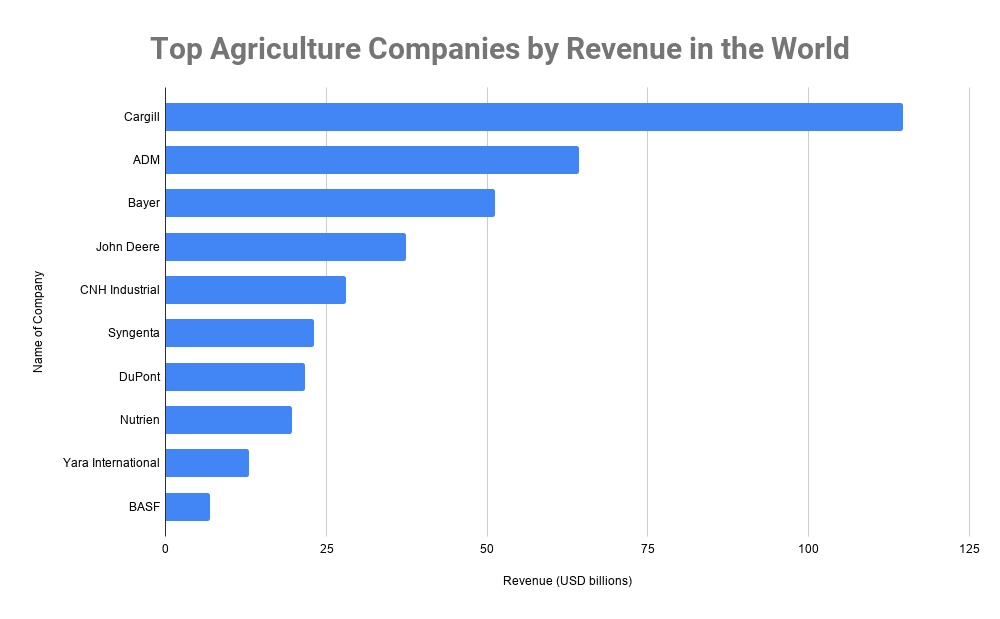

Agricultural and Food Industrial Companies

Agricultural and Food Industrial Companies are increasingly turning to Computational Fluid Dynamics (CFD) to help them optimize their processes. CFD can be used to simulate the flow of air, water, and other fluids to identify areas of inefficiency and to develop strategies for improvement. CFD can also be used to analyze the impact of changes in the environment on the production process, such as temperature, humidity, and airflow. By using CFD, companies can reduce costs, improve product quality, and increase efficiency.

The pioneer Agricultural and Food companies that apply CFD simulations are:

Cargill

Archer Daniels Midland

Bunge

Tyson Foods

Nestle

Kraft Heinz

Unilever

Sysco

ConAgra

General Mills

MR CFD Industrial Experience in the Agricultural and Food Field

Following is an example of an Agricultural and Food industrial project that is recently simulated and analyzed by MR CFD in cooperation with a related company.

Greenhouse Ventilation and Design Improvement

- In this project, an industrial Greenhouse has been numerically simulated by ANSYS Fluent.

- Studying relative humidity, airflow velocity, and thermal condition.

- Removing Ammonia as a pollutant.

- Greenhouse design improvement.

- HVAC analysis.

Greenhouse ventilation and design improvement are important parts of greenhouse management. Proper ventilation and design can help to reduce the risk of disease, pests, and other problems.

Increase air circulation: Increasing air circulation in the greenhouse can help to reduce the risk of disease and pests. This can be done by installing fans, vents, and other devices that will help to move air around the greenhouse.

Improve insulation: Improving insulation in the greenhouse can help to reduce the amount of heat that is lost through the walls and roof. This can be done by adding insulation to the walls and roof, or by using double-paned windows.

Install shading: Installing shading can help to reduce the amount of direct sunlight that enters the greenhouse. This can be done by using shade cloths, awnings, or other materials that will block the sun’s rays.

Install a ventilation system: Installing a ventilation system can help to reduce the risk of disease and pests by providing fresh air to the greenhouse. This can be done by using fans, vents, and other devices that will help to move air around the greenhouse.

Improve drainage: Improving drainage in the greenhouse can help to reduce the risk of disease and pests by preventing water from pooling in the greenhouse. This can be done by installing drainage systems, such as gutters and downspouts.

Install pest control systems: Installing pest control systems can help to reduce the risk of disease and pests by preventing them from entering the greenhouse. This can be done by using traps, screens, and other devices that will help to keep pests out.

MR CFD conducted numerous outsourced CFD simulation projects for industrial companies, and research in Agricultural and Food engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR CFD is ready to offer extensive services of CFD Simulation, Training, and Consultation.

You may find the learning products in the Agricultural and Food CFD simulation category in Training Shop.

Our services are not limited to the mentioned subjects, and the MR CFD is ready to undertake different and challenging projects in the Agricultural and Food Engineering modeling field ordered by our customers. We even carry out CFD simulations for any abstract or concept design you have in your mind to turn them into reality and even help you reach the best design for what you may have imagined. You can benefit from MR CFD expert consultation for free and then outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your project to MR CFD as a CFD simulation consultant, you will not only receive the related project’s resource files (Geometry, Mesh, Case & Data, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings(pre-processing, processing, and post-processing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.