Cohesion and Adhesion on the Surface of Two Cylinders, ANSYS Fluent Training

$60.00 Student Discount

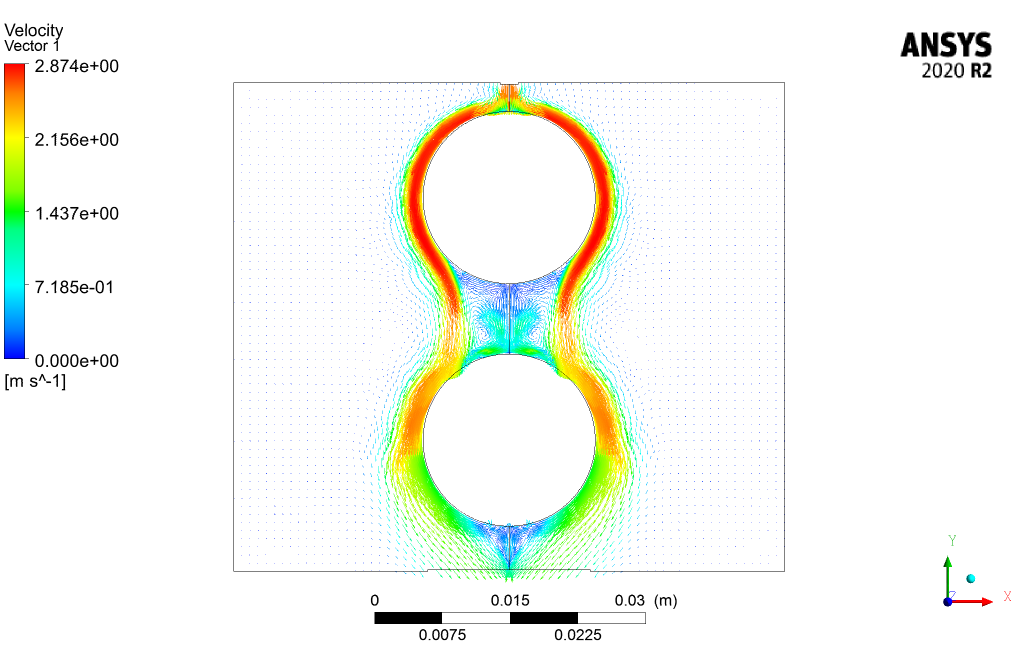

In this project, two phase flow of water and air flowing over two cylinders is simulated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Cohesion and Adhesion Project description

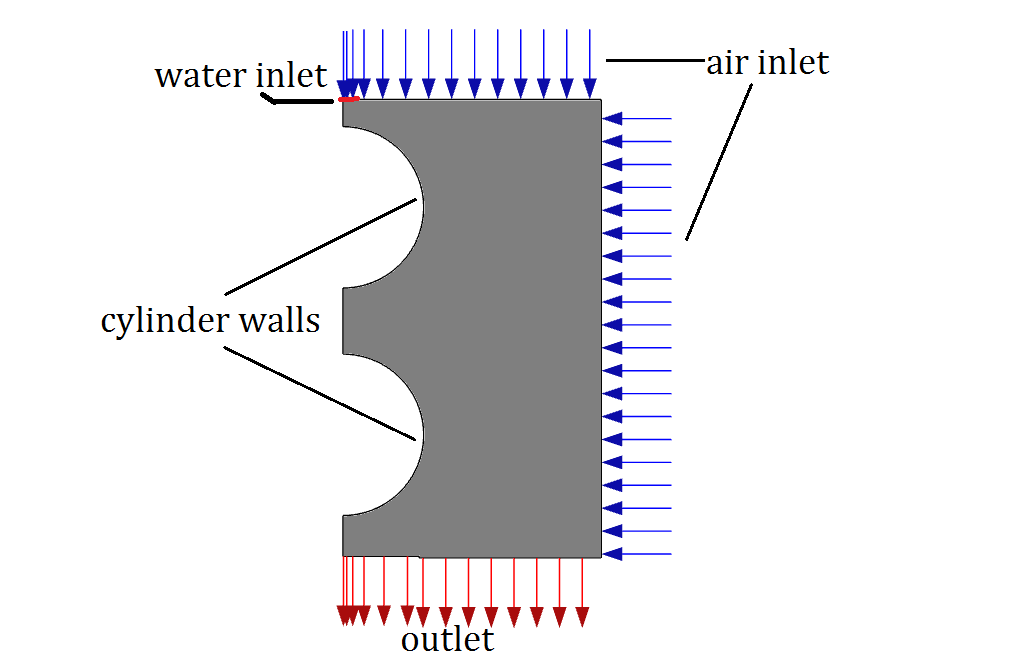

In this project, two phase flow of water and air flowing over two cylinders considering cohesion and adhesion is simulated by ANSYS Fluent software. The water will enter the computational domain with a velocity of 2.6m/s and it flows over the cylinders’ surfaces. The realizable k-epsilon model is exploited to solve fluid flow equations and VOF multi phase model is used to investigate the phase interactions.

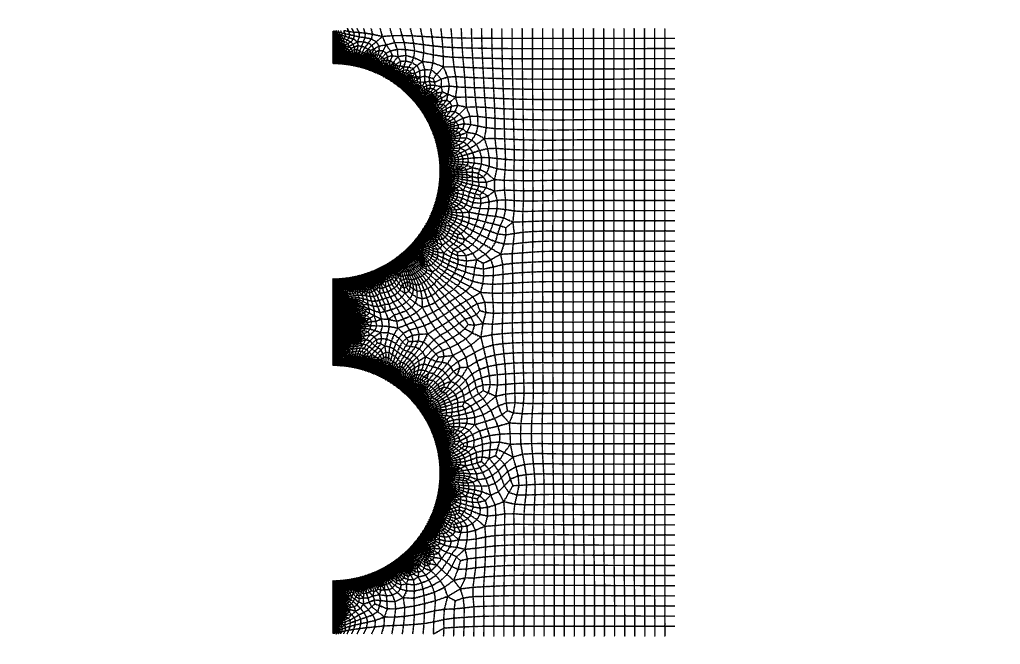

Geometry and mesh

The geometry of this model is designed in ANSYS design modeler® and is meshed in ANSYS meshing®. The mesh type used for this geometry is structured and smaller mesh is used in the proximity of cylinders’ walls. The total element number is 8048.

Cohesion and Adhesion CFD Simulation Settings

The key assumptions considered in this project are:

- Simulation is done using pressure-based solver.

- The present simulation and its results are steady.

- The effect of gravity has been taken into account and is equal to -9.81 m/s2 in Y direction.

The applied settings are summarized in the following table.

| (Two-Phase Flow) | Models | |

| Viscous model | k-epsilon | |

| Model | Realizable | |

| Wall treatment | Standard wall functions | |

| Multiphase | VOF | |

| Body force formulation | Implicit body force | |

| Surface tension Coeff. | 73.5 dyn/cm | |

| Phase 1 | air | |

| Phase 2 | water | |

| (Two-Phase Flow) | Boundary conditions | |

| Inlets | ||

| Ambient | Pressure inlet | |

| Gauge pressure | 0 Pa | |

| Water volume fraction | 0 | |

| back | Pressure inlet | |

| Gauge pressure | 0 Pa | |

| (VOF) | Water volume fraction | 0 |

| Inlet | Velocity inlet | |

| Velocity magnitude | 2.6 m/s | |

| Water volume fraction | 1 | |

| Outlets | Pressure outlet | |

| Gauge pressure | 0 Pa | |

| Walls | stationary | |

| Contact angle | 90 | |

| (Two-Phase Flow) | Solution Methods | |

| Pressure-velocity coupling | PISO | |

| Spatial discretization | pressure | PRESTO! |

| Volume fraction | compressive | |

| momentum | second order upwind | |

| energy | second order upwind | |

| Turbulent kinetic energy | first order upwind | |

| Turbulent dissipation rate | first order upwind | |

| (Two-Phase Flow) | Initialization | |

| Initialization method | Standard | |

| gauge pressure | 0 Pa | |

| velocity (x,y) | (0,0) m/s | |

| water volume fraction | 0.01182033 | |

| Turbulent kinetic energy | 0.000191773 m2/s2 | |

| Turbulent dissipation rate | 0.02866952 m2/s3 | |

Cohesion and Adhesion Results

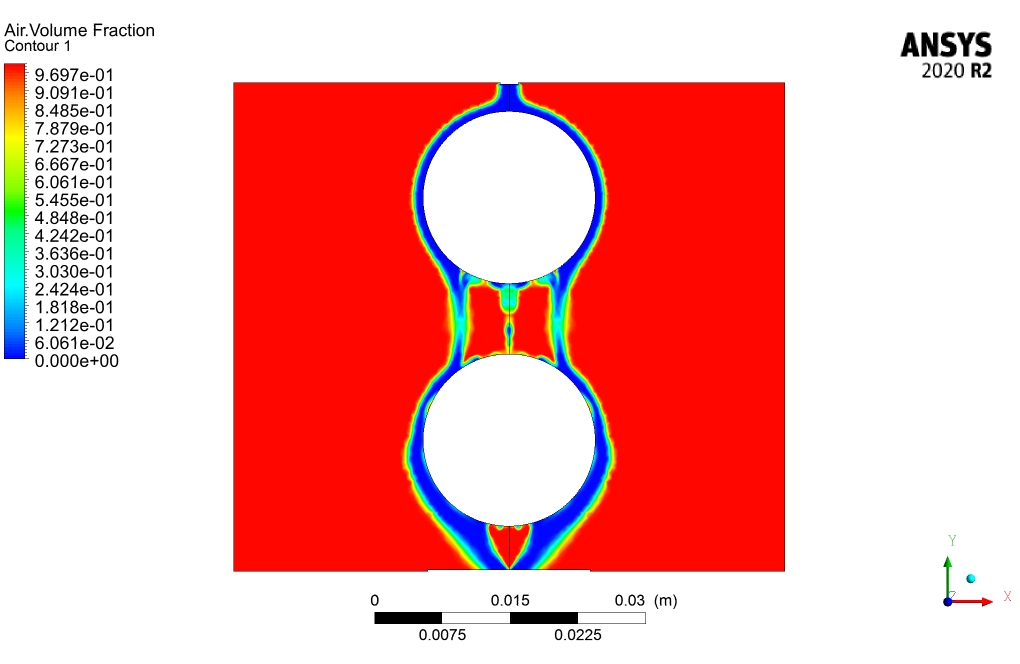

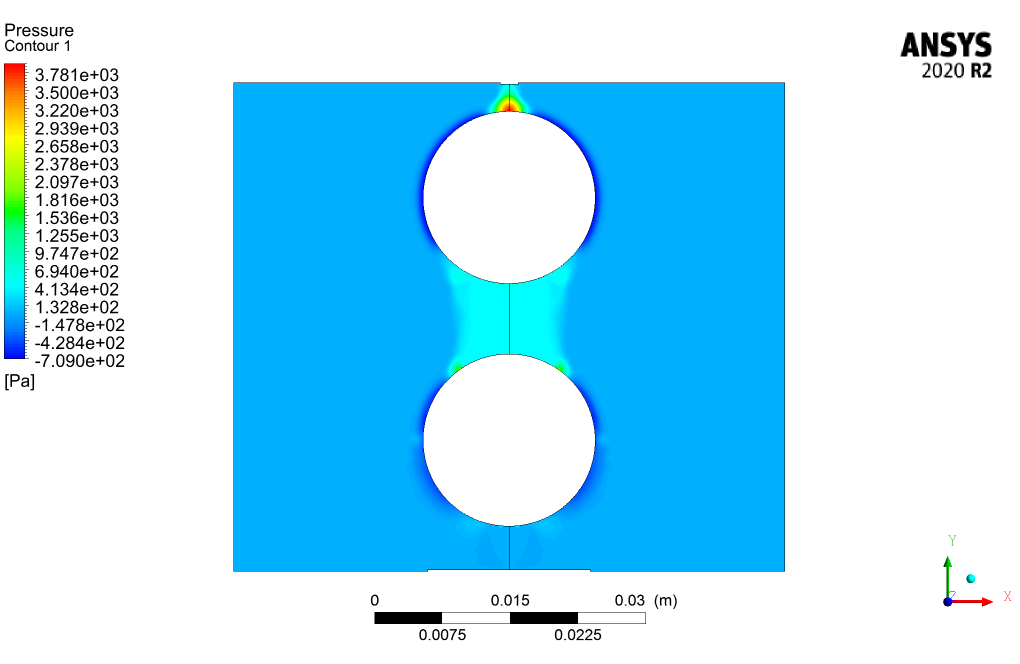

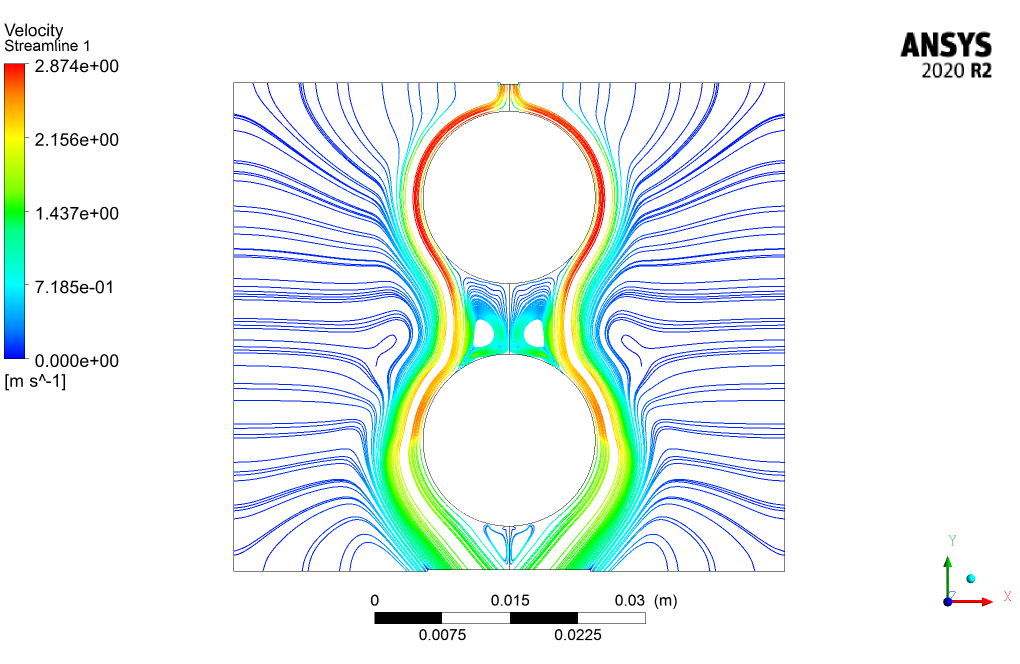

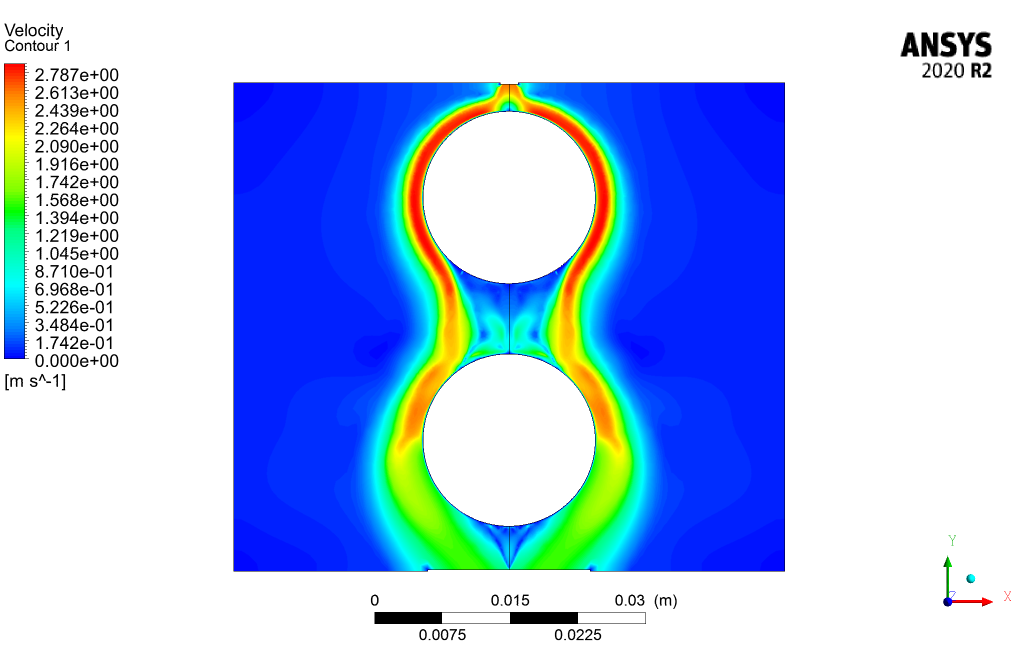

The contours of pressure, velocity, streamlines, etc. are presented.

Dr. Gavin Langosh –

The training was insightful and comprehensive. The step-by-step approach with detailed settings made it easier to understand the intricacies involved in simulating cohesion and adhesion effects on the surface of two cylinders. Excellent use of the VOF multiphase model.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that our training material on cohesion and adhesion simulation was helpful for you. We aim to provide clear and thorough guidance to ensure a deep understanding of the CFD processes. If you need any further assistance or have more questions in the future, please do not hesitate to reach out.

Dr. Janice Goodwin IV –

Is it visually possible to distinguish the effects of cohesion and adhesion on the flowing water’s interactions with the cylinders’ surfaces in the results?

MR CFD Support –

Yes, the simulation results include detailed contours of pressure and velocity, as well as streamlines that visually depict the behavior and interaction of water with the cylinder surfaces, highlighting the effects of cohesion and adhesion.

Ms. Amanda Nikolaus I –

I was absolutely captivated by the clarity of the results, especially the smooth mesh around the cylinders that obviously took a great deal of consideration. Well done!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you appreciated the attention to detail in the meshing and the clarity of the results. Your satisfaction is our priority, and we’re glad we met your expectations.

Jerod Rice –

The training material looks incredibly thorough! Could an absolute beginner in CFD benefit from this course, or is it intended for users with intermediate knowledge?

MR CFD Support –

Thank you for your interest in the course! This training course is designed in such a way that it caters to both absolute beginners as well as those with intermediate knowledge. It includes fundamental concepts and gradually progresses to more complex simulations, ensuring a comprehensive learning experience for all participants.

Vivian Lebsack –

This training seems quite comprehensive. However, I was wondering if there will be content covering how to set the contact angle for different materials in the simulation?

MR CFD Support –

In this training, the contact angle set for the cylinders is 90 degrees, which is a common assumption for a neutral wetting surface. If you need to set different contact angles for various materials, this can be done under the ‘wall’ boundary conditions in ANSYS Fluent. You can specify different contact angles in the ‘phase’ tab for each wall boundary corresponding to your materials. The training will guide you through the process based on the principles underlying the cohesion and adhesion phenomena.

Kayleigh Aufderhar I –

Exactly how does the software handle the contact angle boundary condition on the cylinders’ surfaces to simulate cohesion and adhesion?

MR CFD Support –

In the simulation, the contact angle boundary condition is set to a value of 90 degrees on the surface of the cylinders. This determines the interaction of the multiphase fluid flow with the surface. ANSYS Fluent uses this boundary condition to calculate the interface forces accurately, capturing the balance between cohesion within the fluid and the adhesion to the solid surface.

Roy Runolfsdottir –

The training mentions the use of a ‘contact angle’ of 90 degrees. How does this specific angle influence the simulation of cohesion and adhesion on the surface of the cylinders?

MR CFD Support –

Adopting a contact angle of 90 degrees signifies that the surface of the cylinders is considered to be neutral in terms of wettability; hence neither hydrophilic nor hydrophobic. In practical terms, when water comes in contact with the surface, this angle determines the shape and behavior of the water droplets. The simulation hierarchy employs this setting to gauge the interaction between the water and cylinder surfaces, which concomitantly affects the distribution and flow patterns expected in the scenarios presented.

Cornell Schmidt –

I’m intrigued by the cohesion and adhesion effects shown on the cylinders’ surfaces. Can you elaborate on how adhesion is modeled and its tangible effects on the simulation outcomes?

MR CFD Support –

Adhesion in ANSYS Fluent is typically modeled using the contact angle parameter, where a contact angle of 90 degrees signifies neutral behavior in terms of hydrophobicity or hydrophilicity. Adhesion influences the distribution and behavior of the water phase on the cylinder surfaces in the simulation. It dictates how the water interacts with the cylinder surface, affecting the flow pattern and phase distribution around the cylinders. The tangible effects include changes in local flow dynamics, such as velocity profiles and pressure distribution, which are critical for understanding the characteristics of multiphase flow around the objects.

Darien Mann –

I’m fascinated by the simulation of two-phase flow, particularly how cohesion and adhesion effects are modeled around the cylinders. Can you elaborate on how the contact angle setting impacts the adhesion behavior in the results?

MR CFD Support –

The contact angle setting in the simulation is crucial for modeling the wetting behavior between the fluid and the surface of the cylinders. A contact angle of 90 degrees implies that the surface is neither hydrophilic nor hydrophobic, representing a neutral wetting condition where the adhesive and cohesive forces are balanced. This setting influences the shape and behavior of water as it comes in contact with the cylinder surfaces and affects the fluid distribution in the simulation results, especially at the interface between water and air.

Dianna Schmeler –

The training content was immensely helpful. The progression from basic concepts to the complex interplay of surface tension, coupled with the use of both pressure and velocity inlets, made the theory behind cohesion and adhesion very clear.

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that our training materials effectively clarified the complex theory behind cohesion and adhesion for you. We aim to present content that builds understanding step by step, and we’re delighted to know it’s appreciated!

Melany Bashirian –

In the results, how do cohesion and adhesion affect the air-water interaction around the cylinders?

MR CFD Support –

In the results, cohesion and adhesion properties influence how the water droplets coalesce and stick to the surface of the cylinders, as well as how they interact with the airflow around the cylinders. One may observe differences in flow patterns, pressures, and velocities due to these effects.

Prof. Kade Ward MD –

The selection of the contact angle is very interesting! Could you explain the impact of the contact angle on the results in this simulation, specifically relating to cohesion and adhesion effects?

MR CFD Support –

The contact angle in this simulation defines how the water droplets interact with the cylinder surfaces—essentially representing the wetting properties of the surfaces. A contact angle of 90 degrees is indicative of neither hydrophilic nor hydrophobic behavior. This neutrality impacts the cohesion within the water, which is the attractive force between water molecules, and adhesion, which is the attractive force between the water molecules and the cylinder walls. The choice of contact angle therefore alters the fluid’s wetting properties, potentially affecting the flow behavior around the cylinders as well as capillary effects, which can be significant in multiphase simulations like this one.