DPM CFD Simulation Training Package, INTERMEDIATE Users,10 Learning Products

$1,260.00 Original price was: $1,260.00.$420.00Current price is: $420.00. Student Discount

This product includes Geometry & Mesh file and a comprehensive Training Movie.

There are some free products to check our service quality.

To order your ANSYS Fluent project (CFD simulation and training), contact our experts via [email protected], online support, or WhatsApp.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Discrete Phase Model (DPM) – ANSYS Fluent Training Package, 10 Practical Exercises for INTERMEDIATE Users

This CFD training package is prepared for INTERMEDIATE users of ANSYS Fluent software in the Discrete phase Model (DPM) area. You will learn and obtain comprehensive training on how to simulate medium projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

This package trains the necessary proficiency you will require to start doing average computational fluid dynamics (CFD) Discrete Phase Modeling simulations on your own using Ansys Fluent software. Qualified training movies and comprehensive CFD concepts explanations, including setup, solution, results, and all perspectives of carrying out CFD simulations in Ansys Fluent.

Ventilation considering Coronavirus (Covid-19)

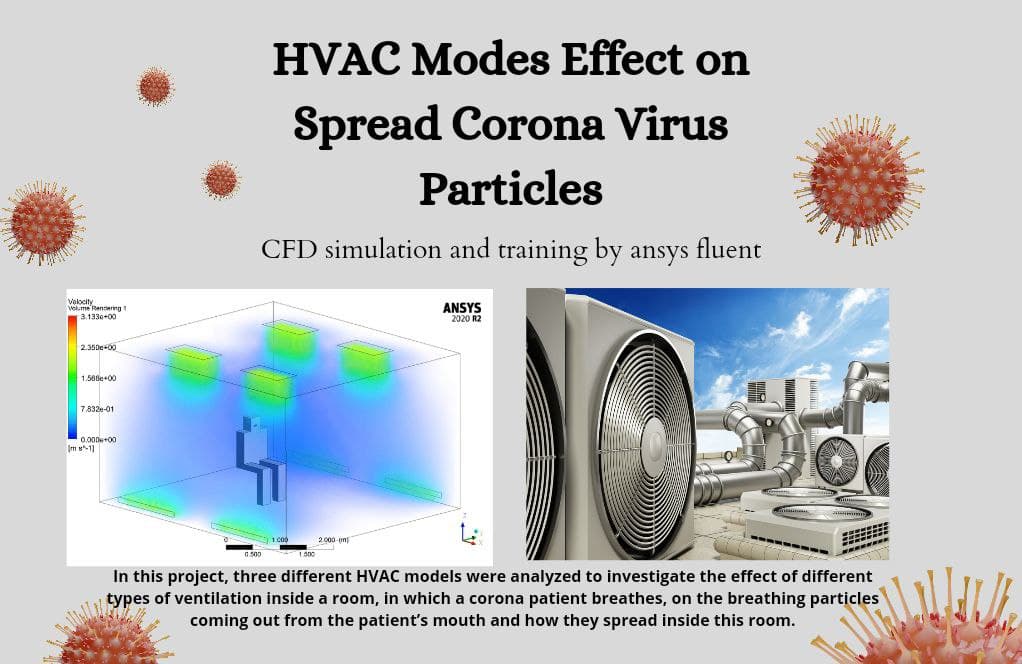

Corona (COVID 19) is currently recognized as the most significant human challenge globally; Because this disease, in addition to being dangerous to human health, has a high transmission power between a sick person and healthy people. The breathing of a person without a mask with coronavirus in a closed public environment transmits the disease to their neighbors.

In project number 1, three different HVAC models were analyzed to investigate the effect of different types of ventilation inside a room. A corona patient breathes on the breathing particles coming out from the patient’s mouth and how they spread inside this room. These types of HVAC include one-sided, cross-sided, and lateral ventilation. In each case, the airflow enters the domain through the window(s) placed on the wall boundary of the room with a velocity of 2 m/s.

In project number 2, based on the CFD method, an attempt has been made to simulate the respiration of viral air from the mouth of sick coronavirus carrier students in the Classroom. This model includes a computational domain in the form of a classroom and chairs inside which a student is modeled on each chair. For each of these students, a surface is defined as the mouth as the source of the virus’s respiration and transmission. This work aims to investigate the effectiveness of the ventilation system installed in the classroom to eliminate polluted air (DPM) and clean the air.

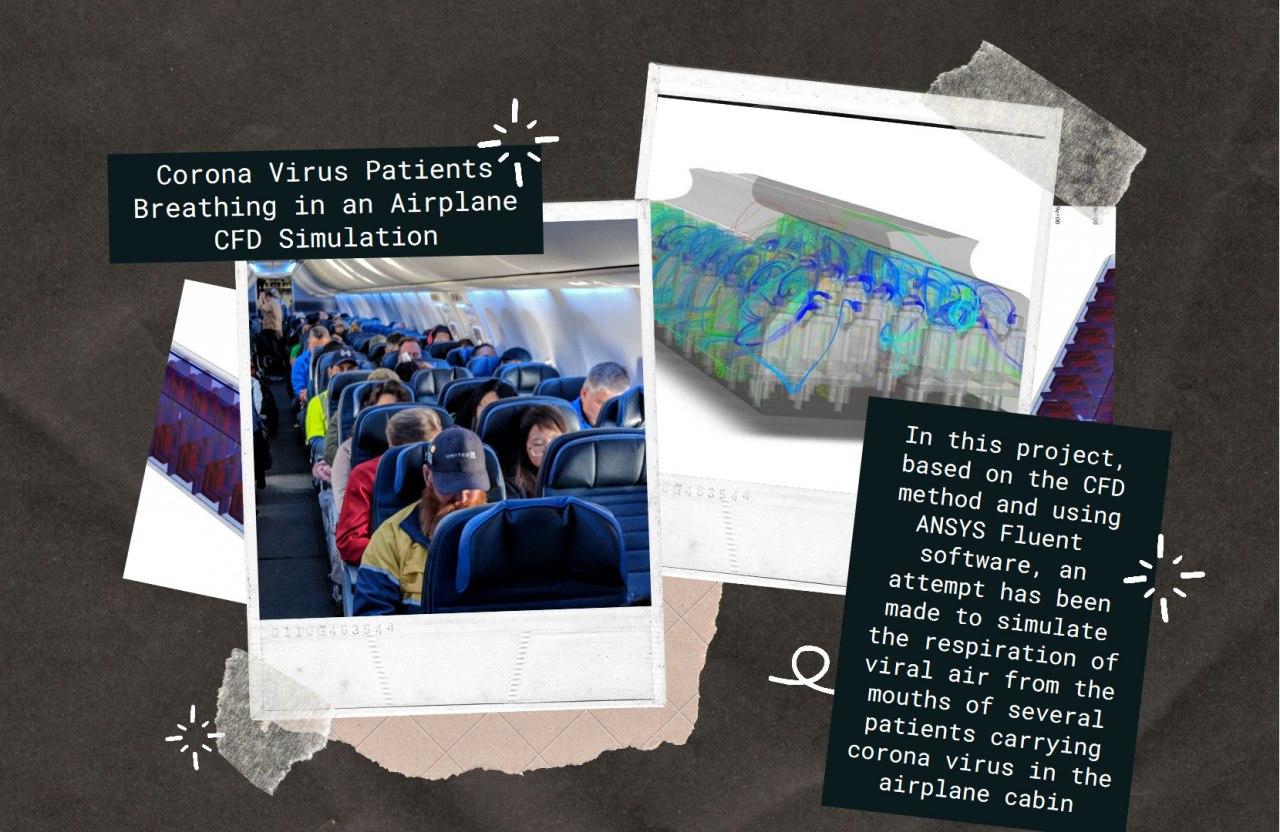

In Project number 3, an attempt has been made to simulate the respiration of viral air from the mouths of several patients carrying the coronavirus in the Airplane. This model includes a computational domain in the form of an airplane and seats inside it, on which a passenger is modeled. This study aims to investigate the transmission of the coronavirus between passengers caused by Breathing at short distances. The virus particles are defined as INERT particles and the injection type is SURFACE and through the inner surface of the mouth of each passenger (inlet-mouth).

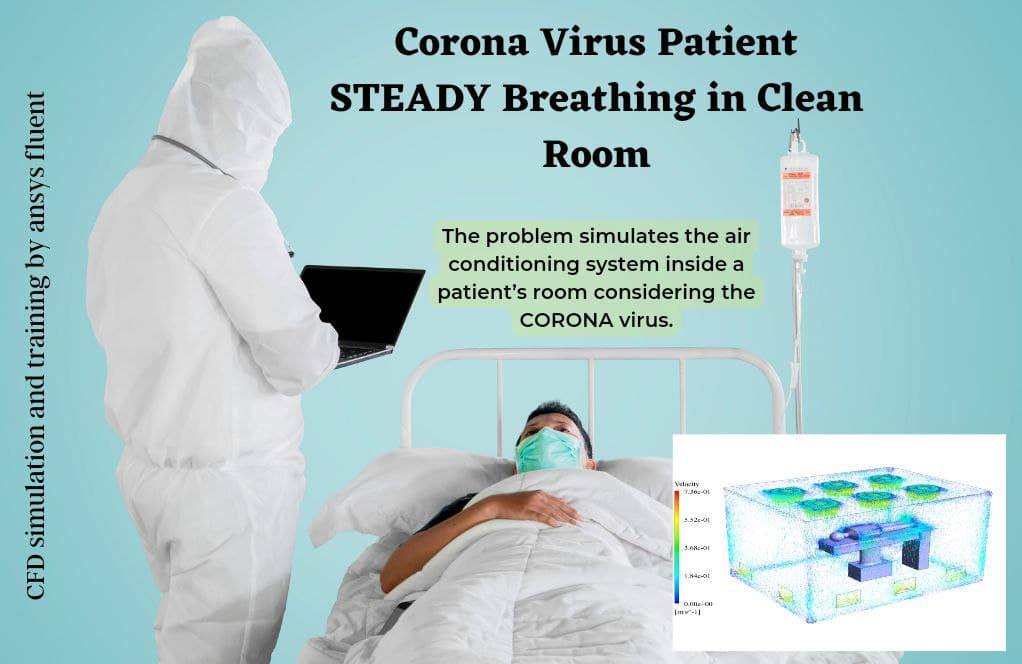

Project number 4 simulates fresh airflow through the Air Conditioning System inside a Patient’s Room, considering the coronavirus. We place the patient on a bed in a room with a high temperature on his body and constantly spread the coronavirus particles by breathing through his mouth into the room’s interior. In the present model, the fresh airflow from the upper vents of the room has a velocity equal to 0.58 ms-1 and a temperature of 294 K; the patient’s body surface temperature is equal to a constant value of 308 K.

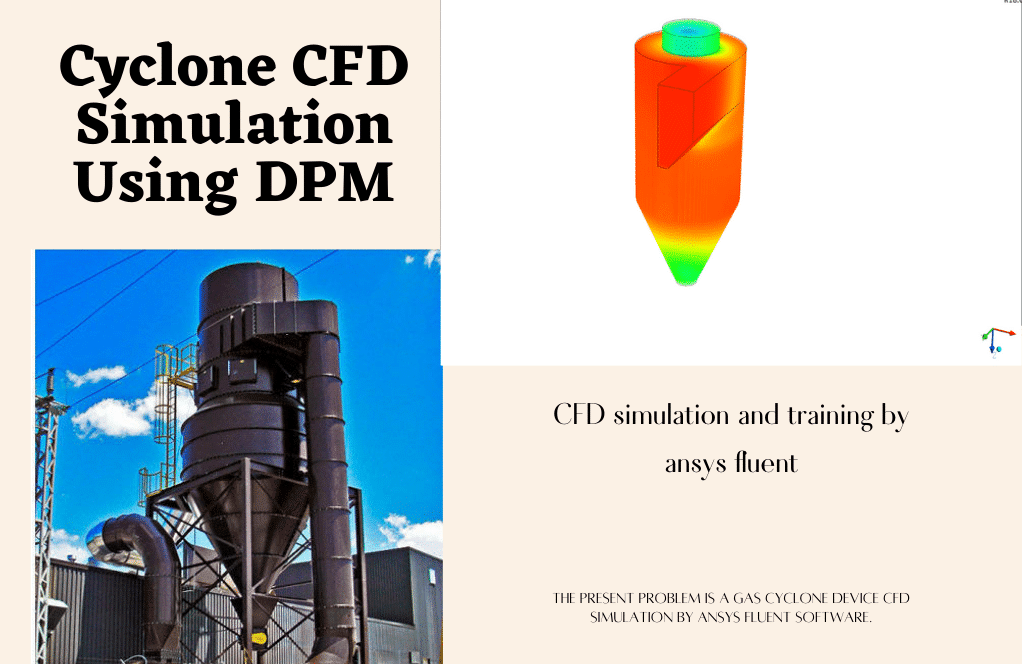

Industrial Equipments

Many industrial types of equipment need to be investigated using the lagrangian approach. Cyclones are one of the most widely used industrial systems in air dewatering, dust disposal, or separation of solid particles from the gas flow. In these types of systems, separating solid particles from gas flows is carried out with the help of centrifugal and gravity forces, without the use of filters. Project number 5 is a Gas Cyclone device. In this device, the gas flow continuously enters from the top to the inner space between the two cylinders and the partial cone. Also, the solid particles enter the cyclone interior from the top as the discrete phase. The contact between these two flows and centrifugal force results in separating these two phases.

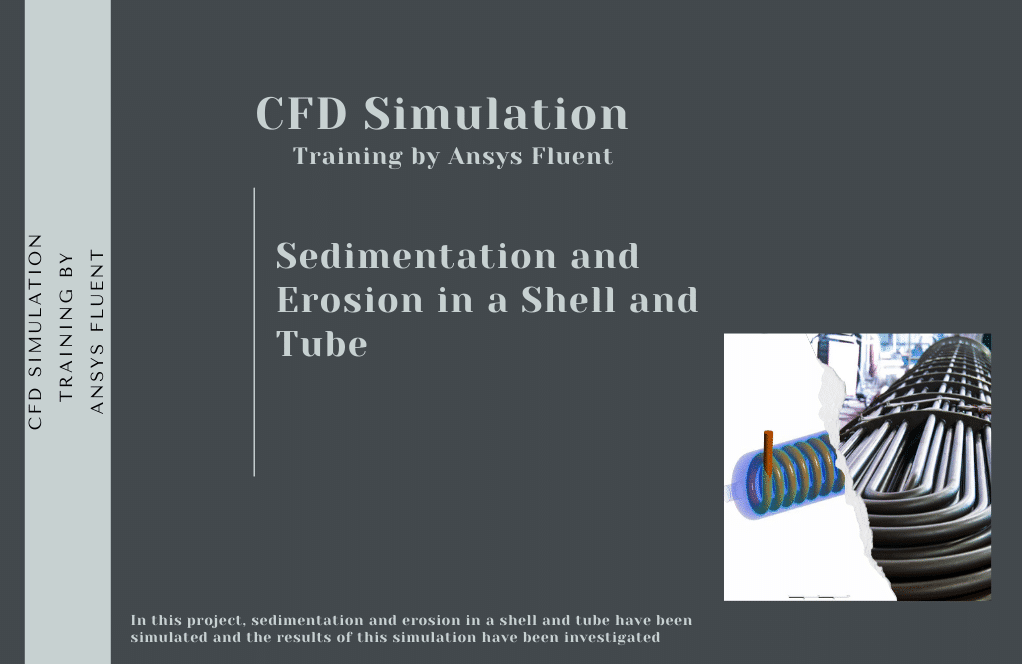

In project number 6, Sedimentation and Erosion in a shell and tube heat exchanger were investigated. The system consists of two different fluids, including oil and water (Water flows in the shell and oil in the tube). The software’s different erosion models help correctly predict the erosion effect in other cases according to different working conditions. The velocity inlet of oil and water enters the domain with the speed of 1 m/s with gravity considered as -9.81 m/s-2 on the z-axis.

In project number 7, the effect of impurities in the working fluid on the body Gas Splitter is investigated. A splitter is a device for uniformly distributing incoming fluid flow through the placement of outlets of the same shape and size. The impurity gas entered at a speed of 5 meters per second vertically and was directed out through 3 outlets.

Sprays (DPM)

Sprays have a wide range of industrial and domestic applications. The simulation of sprays has its specific settings and properties and can be counted as a unique category of simulations related to the DPM module.

Project number 8 simulates the process of Water Spray into a cubic space. The present study investigates the behavior of water flow during the spraying process from a very small circular section to the inner space of an area with a larger volume, which examines the behavior of water flow by tracing every particle.

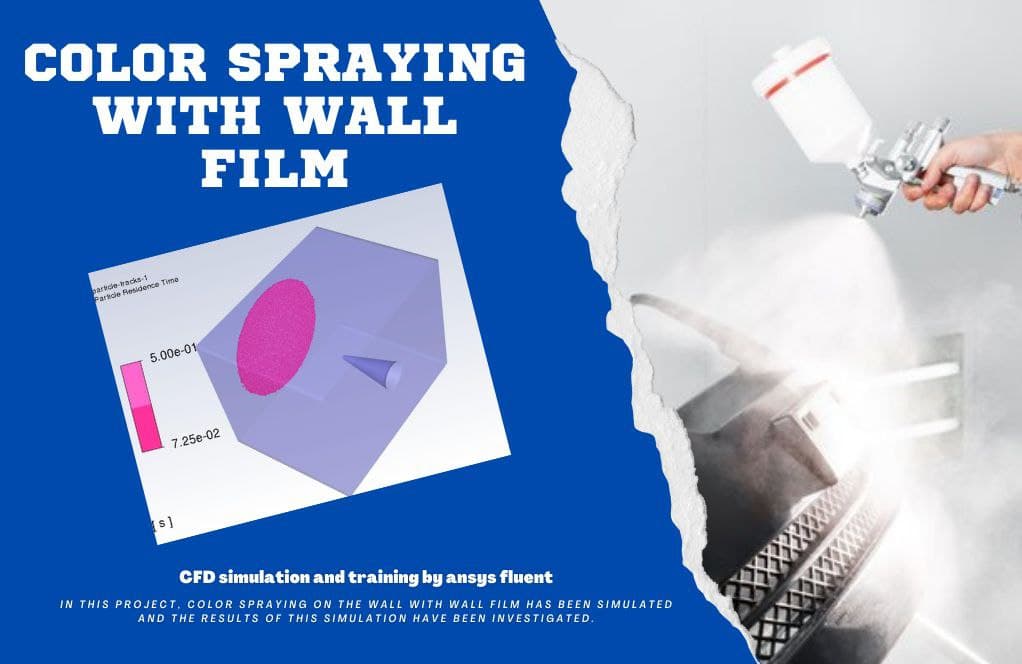

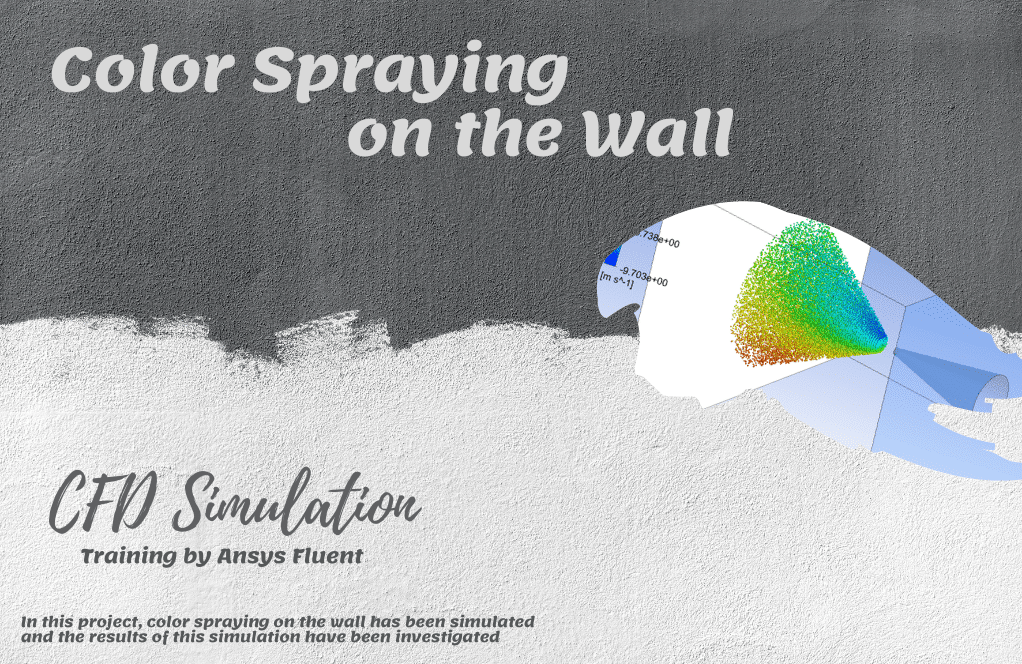

In project number 9, Color Spraying on the wall has been simulated. We have used the one-way DPM to simulate the discrete phase. The injection type is a cone, and the velocity of the particles is equal to 10 with a cone angle of 30 degrees. To put one step further, in project number 10, a similar project has been done considering a WALL FILM. The cone injection and particle velocity equal the first simulation 10 with a particle diameter of 0.001 m and a spray angle of 45 °. This project aims to determine whether velocity and particle diameter affect the staining. The velocity is 20 meters per second for the second simulation, and the particle diameter is 0.1m. Also, the cone angle is 45 degrees. The DPM Boundary condition type is wall film so that the color particles stick to the wall.

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.

Shawn Walker –

I’m interested in simulating particle-wall interactions. Does the package cover that?

MR CFD Support –

Absolutely. The package includes exercises that focus on particle-wall interactions. This is particularly useful in predicting erosion or deposition in various industrial equipment.

Marcia Shanahan –

Does the package cover the effect of turbulence on particle dispersion?

MR CFD Support –

Certainly. The package includes exercises that delve into the effect of turbulence on particle dispersion. Understanding this is vital in predicting particle behavior in various flow conditions.

Dr. Matteo Barton –

Can the package simulate particle-particle interaction?

MR CFD Support –

Yes, indeed. The package includes advanced exercises that cover particle-particle interactions. This is a crucial aspect in many industrial applications, and our package ensures you’re well-equipped to handle such simulations.

Kelley Roberts –

Absolutely impressed with the variety of practical examples in the DPM CFD Simulation Training Package. The hands-on experience with different types of ventilation and analysis of particle behavior in various environments has boosted my confidence in conducting CFD simulations using ANSYS Fluent. Kudos to the team for curating such detailed and practical learning materials!

MR CFD Support –

Thank you so much for your kind words and positive feedback! We are thrilled to hear that our DPM CFD Simulation Training Package has been beneficial to you and has helped in enhancing your CFD simulation skills. We always aim to provide comprehensive learning experiences through practical examples, and it’s rewarding to know we’ve succeeded. If you have any more questions down the line or need further assistance in mastering ANSYS Fluent, please do not hesitate to reach out to us. Keep up the fantastic work!

Victor Legros –

Fantastic training package—really solidified my understanding of DPM in Ansys Fluent! The real-world applications, especially the Covid-19 ventilation scenarios, made the learning process extremely relevant and practical. What impressed me the most was the clarity of explanations provided throughout the training movies. Great job on the didactics!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that the DPM training package met your expectations and was instrumental in enhancing your knowledge of Ansys Fluent. It’s especially rewarding to know that the real-world scenarios and training movies brought clarity and value to your learning experience. If you ever have any follow-up questions or need further assistance, please don’t hesitate to reach out!

Dr. Reid Conroy II –

I really appreciated the level of detail in the DPM CFD Simulation Training Package. As an intermediate user of ANSYS Fluent, I felt the training was perfectly pitched for me. The step-by-step guide through different types of projects, especially the ventilation analysis considering COVID-19 scenarios, was extremely insightful and highly relevant.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the training package met your needs as an intermediate user and that you found the real-world applications, like the COVID-19 ventilation analysis, to be insightful and relevant. It’s our pleasure to provide resources that help enhance your CFD skills with ANSYS Fluent.

Mrs. Erika Davis Jr. –

The DPM CFD Simulation package seems incredibly comprehensive, covering a fascinating range of scenarios from ventilation in the context of virus transmission to industrial applications. I’m especially interested in how the simulations can replicate fluid and particle interactions in complex environments like classrooms or airplanes. The realism and practical implications are deeply impressive.

MR CFD Support –

Thank you for your positive feedback on the DPM CFD Simulation Training Package! We are thrilled to hear that you find the range of scenarios and the depth of interaction detail impressive. Our goal is to provide users like you with realistic simulation experiences that can help in understanding and solving complex fluid dynamics challenges in various environments.

Dr. Garth White –

How does the package handle non-spherical particles?

MR CFD Support –

The package includes exercises that deal with non-spherical particles. Real-world particles are often non-spherical, and being able to accurately simulate their behavior is a valuable skill.

Audreanne Heidenreich –

The DPM training package sounds intensive. How do you ensure that intermediate users can effectively understand and apply the DPM concepts presented in these exercises?

MR CFD Support –

Our DPM training package is designed with the intermediate user in mind. It includes comprehensive training movies and detailed expenses of the setup, solution, and results. We guide you step by step and ensure clear explanations of CFD simulations in ANSYS Fluent are provided. Also, by tackling practical exercises, users can apply what they’ve learned directly, enhancing understanding and retention.

Viva Cormier –

I’m blown away by the extensive range of practical exercises in the DPM CFD Simulation Training Package. It covers so much—from modeling various ventilation scenarios for COVID-19 safety to industrial applications like cyclones and sprays. The detailed studies on virus particle behavior in different environments seem especially timely and beneficial.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear you appreciate the range and depth of the exercises in our DPM CFD Simulation Training Package. It’s our goal to provide relevant and practical learning experiences that can be directly applied to real-world problems, such as managing air quality related to COVID-19. We are glad you find it useful for your learning journey!

Dr. Jess Dare –

I’ve been really impressed with the comprehensive DPM CFD Simulation Training Package for intermediate users. The variety of projects spanning ventilation considerations in light of COVID-19 to industrial equipment simulations like cyclones has provided a thorough understanding of Discrete Phase Model applications. Each project’s detailed approach to modeling, with well-presented movies and instruction, has very effectively enhanced my proficiency in conducting medium complexity CFD simulations using Ansys Fluent. I’m excited to apply these skills in my own projects, and I feel much more confident in choosing the correct modeling techniques thanks to this package.

MR CFD Support –

Thank you very much for your positive review of our DPM CFD Simulation Training Package. We are delighted to hear that it has significantly helped enhance your understanding and application of various CFD simulations and that our instructional materials have been valuable in your learning process. Your enthusiasm to implement the skills into your personal projects is the best feedback we could hope for. Should you have any further questions or need guidance in your projects, please reach out for assistance. Happy simulating!

Mason Will –

This training package sounds incredibly detailed. Was the particle tracking algorithm employed for all exercises able to cope well with collisions and rebounds of particles from the walls and any inclusions in your simulations?

MR CFD Support –

In the case of simulations within the INTERMEDIATE DPM CFD Simulation Training Package, advanced particle tracking algorithms were implemented, catering to collisions and rebounds according to the Discrete Phase Model properties. The particle-wall interaction and its effect on the overall system behavior were well accounted for throughout every exercise. This ensures trainees receive an accurate understanding of particle dynamics within CFD environments.

Prof. Garrett Lubowitz DVM –

Just finished the DPM CFD Simulation Training Package for intermediate users and wanted to share my thoughts. The variety of practical exercises across different applications, from healthcare ventilation to industrial equipment analysis, ensured a well-rounded experience with CFD applications in ANSYS Fluent. In particular, the real-life relevance of performing airflow simulations in environments such as classrooms and airplanes in the context of COVID-19 spread, brings a sense of urgency and importance to the skills learned. Moreover, the step-by-step guidance through geometry and meshing to solutions and result extraction is excellent for reinforcing foundational knowledge while also revealing advanced features of DPM simulation. Definitely a beneficial training package for anyone looking to deepen their understanding of discrete phase modeling in diverse environments.

MR CFD Support –

Thank you so much for your encouraging review! We’re thrilled to hear that our DPM CFD Simulation Training Package has contributed to enhancing your understanding and skills in ANSYS Fluent’s Discrete Phase Modeling. We pride ourselves in creating comprehensive training material that is both educational and relevant to current global challenges, like the COVID-19 pandemic. It’s great to know that the variety and level of detail in our practical exercises have been effective for you. We look forward to supporting your continued growth in CFD. Keep up the fantastic work!

Camryn Bosco –

I’m impressed with the comprehensive nature of the DPM training package and how it addresses a combination of current health concerns and industrial applications! It seems well-constructed for intermediate users lik me who are eager to broaden their understanding of CFD applications in different scenarios.

MR CFD Support –

Thank you for your kind words! We’re glad to hear the DPM CFD Simulation Training Package has met your expectations and we’re excited to help expand your knowledge of CFD applications. If you have any further questions or need assistance, don’t hesitate to reach out. We’re here to support your learning journey!

Lura Gaylord –

What a comprehensive training package! The range of topics from coronavirus particle spread in indoor scenarios to industrial equipment and spray simulations is impressive. I’m confident this package would significantly boost proficiency in CFD with Fluent for INTERMEDIATE users.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you appreciate the variety and depth of the DPM CFD Simulation Training Package. Your confidence in the value it provides to users looking to enhance their skills in computational fluid dynamics with ANSYS Fluent means a lot to us. If you have any more questions or need further assistance with your CFD learning journey, please feel free to reach out.

Dr. Adalberto Lesch IV –

I just finished the DPM CFD Simulation Training Package for INTERMEDIATE users, and I can honestly say it was fantastic! The diversity of projects, from ventilation in closed environments to industrial equipment studies, really helped me understand the complexities of DPM simulations. Particularly, the COVID-19 ventilation scenarios felt timely and relevant. The step-by-step video tutorials were incredibly helpful in guiding me through each stage of the simulation setup and execution. Glad I chose this package to level up my ANSYS Fluent skills.

MR CFD Support –

Thank you for your kind words! We’re pleased to hear that you found the training package to be comprehensive and beneficial. It’s especially rewarding to know that the step-by-step tutorials facilitated your learning process and that you were able to gain valuable insights into complex DPM simulations. We strive to make our content as relevant and accessible as possible, and feedback like yours motivates us to continue providing high-quality learning materials. If you ever have any questions or need further assistance in your CFD journey, feel free to reach out to us.

Myrtle Farrell –

I was impressed by the application of DPM for analyzing ventilation systems in environments pressent with COVID-19. The relevance of your studies to current global issues clearly provides learners with practical modeling experiences. Kudos to the MR CFD team for curating such an insightful package.

MR CFD Support –

Thank you for your kind words! We are glad to hear that our DPM training package met your expectations and provided valuable insight into simulation applications related to pressing global issues. We appreciate your positive feedback, and it motivates us to continue delivering high-quality educational materials. If you have any more questions or need further assistance, feel free to reach out!

Jammie Blanda –

This DPM CFD training package sounds very comprehensive, but does it also include guidance on post-processing techniques for visualizing the discrete phase?

MR CFD Support –

Yes, the training package includes complete guidance on setting up, solving, and also post-processing, which encompasses techniques for visualizing both the continuous and discrete phases effectively by using ANSYS Fluent.

Alexandro Harris –

I’m midway through the DPM CFD Simulation Training Package and it’s brilliant how detailed and precise the examples are. Particularly the Coronavirus ventilation simulations and the Industrial Equipment projects have drastically improved my understanding of the real-world application of DPM in ANSYS Fluent. Thanks to the team for such a meticulous approach!

MR CFD Support –

Dear user, we are thrilled to hear that you’re enjoying the DPM CFD Simulation Training Package! It’s rewarding to know that it’s significantly aiding in your understanding of practical applications in ANSYS Fluent. We appreciate your positive feedback and we’ll continue to provide high-quality and informative training material. Thank you for choosing our product!

Tierra Bartoletti –

Can you clarify how the software accounts for different types of particles in the simulations? Particularly how it differentiates between inert particles and those that might react or behave differently due to temperature or other environmental changes?

MR CFD Support –

In DPM simulations using ANSYS Fluent, various types of particles are defined through boundary conditions and material properties. Each particle type can have its own size, material density, specific heat, and other relevant properties. For inert particles, reactions, vaporization, and other transformations are typically disabled. However, in the case of reactive particles, additional models, such as surface reaction or species transport, can be activated to account for the particles’ behavior due to temperature or chemical changes in the environment. Users can define these settings during the setup phase of the simulation.

Abe Wolf –

I’ve gone through the training package and simulations thoroughly, I must say I’m really impressed by the depth and clarity of the explanations. I’m more confident in setting up and running my own DPM analyses now. The variety of applications included in the package, especially relating to current health concerns like COVID-19, is very insightful

MR CFD Support –

Thank you for your positive feedback. We are delighted to hear that you found our DPM CFD Simulation Training Package comprehensive and helpful. It’s great to know that it has boosted your confidence in conducting your own simulations, and that you appreciated the range of applications covered. If you have any further questions or require additional support as you continue to apply the skills in your work, please feel free to reach out to us.

Asha Kuhn V –

I am new to intermediate level DPM simulations in ANSYS Fluent, would this training package suit a person at my level, considering I’ve done only a couple of simple exercises?

MR CFD Support –

Absolutely, the DPM CFD Simulation Training Package for INTERMEDIATE Users is designed to take someone with a basic understanding of ANSYS Fluent to a more advanced level of proficiency. It includes a variety of medium-complexity exercises and comprehensive guidance so you’ll be well-equipped to tackle such simulations on your own after completing this package.

Hilario Grimes –

The DPM CFD Simulation Training Package was invaluable for enhancing my understanding of intermediate-level CFD simulations using the DPM method in ANSYS Fluent. Each of the 10 exercises offers unique scenarios that are relevant to contemporary issues, like virus spread in enclosed spaces and industrial particle separation. I particularly appreciated the mix of applications, from consideration of virus transmission in closed environments to wear and tear in industrial equipment. The clear instructions and step-by-step tutorials have been instrumental in improving my CFD skills.

MR CFD Support –

Thank you for your feedback! We are thrilled to hear that our Discrete Phase Model (DPM) CFD Simulation Training Package has contributed significantly to your CFD knowledge and skills development. It’s gratifying to know that the varied practical exercises and detailed guidance enhanced your experience with intermediate-level simulations in ANSYS Fluent. We look forward to providing you with more fruitful learning experiences in the future!

Daija Renner –

I have watched all the training videos and completed the simulations. DPM simulations were explained in a detailed and comprehensible manner. This package enhanced my understanding of medium complexity CFD challenges significantly.

MR CFD Support –

Thank you for the kind words! We are thrilled to hear that our DPM CFD Simulation Training Package for INTERMEDIATE users has enhanced your understanding of CFD and met your expectations. We appreciate your feedback and hope you will continue to find our products and services helpful for your future projects!

Mrs. Norma McCullough –

The DPM CFD Simulation Training Package sounds incredibly thorough and practical. Each project seems to be carefully designed to provide realistic scenarios that users could potentially encounter in their future work. I appreciate the diversity of applications covered, from dealing with airborne coronavirus transmission in various environments, such as classrooms and airplanes, to industrial equipment simulations like cyclones and splitters. It’s particularly useful to see attention to details such as erosion in a heat exchanger or the specific settings for simulating sprays. The inclusion of instructional videos is a great touch to strengthen understanding.

MR CFD Support –

Thank you for such a thoughtful review! We’re so pleased to hear that you found the DPM CFD Simulation Training Package to be comprehensive and practical. It is indeed our goal to provide a wide range of simulations that mimic real-world scenarios to help users develop the necessary skills to tackle complex issues. We’re glad you also valued the inclusion of instructional videos, as they are a core part of our commitment to ensuring users get the most out of our training. Your feedback is appreciated!

Dr. Armani Goldner –

I have gone through the intermediate DPM CFD simulation package and found the insights on the spread of coronavirus in different environments to be particularly impressive. Could you specify how the ventilation’s effectiveness is assessed in the simulation settings?

MR CFD Support –

In the DPM CFD simulations related to coronavirus transmission, the effectiveness of ventilation systems is assessed by tracking the dispersion and concentration of virus-laden particles through the domain. The airflow patterns are analyzed to see how well they dilute and remove aerosol concentrations in specific regions, thereby assessing the purification performance of the ventilation setup.

Loma Schoen IV –

Just finished the Intermediate DPM CFD Simulation Training Package — simply fascinating! The examples not only cover vital concepts, but the practical exercises solidify understanding immediately. Mastery over DPM in Ansys Fluent is no easy feat, but this package makes it incredibly accessible. Particularly found the virus dispersion projects timely and thought-provoking in understanding airflow within shared spaces.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that you found the training package helpful and that it has improved your understanding of DPM simulations in Ansys Fluent. If you ever have any questions or need further support with your simulations, please don’t hesitate to reach out. Happy simulating!

Floy Jakubowski –

I am impressed by the range of exercises in the intermediate DPM training package and the focus on practical applications like ventilation in the context of COVID-19 spread. Not only is it professionally relevant, but it shows a commitment to current and socially impactful engineering challenges.

MR CFD Support –

Thank you for your thoughtful words. We are pleased to hear that you appreciate the practical applications and real-world relevance of our DPM training package. It’s great to know that our commitment to addressing contemporary engineering challenges is recognized and valued by our customers.

Theo Lowe DDS –

The training package seems thorough. Could you explain if it includes guidance on the initial setup for beginners before diving into the intermediate exercises?

MR CFD Support –

The DPM CFD Simulation Training Package is geared towards intermediate users and assumes a fundamental understanding of ANSYS Fluent. However, each exercise typically includes step-by-step instructions that cover every aspect of the simulation process. The package may not specifically detail the initial setup process for beginners, but with the training materials and movies included, users with a basic grasp of the software should be able to follow along effectively.

Kavon Bailey –

Fantastic intermediate DPM training package! I could efficiently advance my CFD skills with practical exercises. The solidity of the knowledge base for setting up a wide variety of scenarios surpassed my expectations. From the vital analysis of ventilation systems to the specificity of industrial equipment simulations, this material is impeccably structured.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the training package to be practical and that it helped to enhance your CFD skills. We always aim to provide comprehensive materials that meet the needs of our users. We appreciate your positive feedback and are glad to have been a part of your learning journey!

Korey Zemlak –

Fantastic set of training materials for DPM simulation in ANSYS Fluent! Each project tackles a unique and practical scenario, which provides insights into real-world applications.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the DPM training package met your expectations and provided valuable insights. Your satisfaction with our learning materials is our highest priority. If you have any more questions or need further assistance with your simulations, please feel free to reach out to us.

Jeanette Boyer –

This package has been instrumental in enhancing my understanding of DPM simulations. Not only have the practical exercises broadened my skill set, but the focus on different applications, from health-related scenarios to industrial equipment, has also provided a well-rounded perspective. Each project brought new insights and the provided training materials such as the Geometry & Mesh files and instructional videos have been indispensable. Excellent resource!

MR CFD Support –

Thank you for your kind words and for choosing our DPM CFD Simulation Training Package. We are thrilled to learn that the exercises and materials have been valuable to you across different applications. It’s our pleasure to support you in your journey of mastering CFD simulations. If you have any further queries or need assistance with new simulation challenges, our team is always here to help!

Ruthe Waelchi –

I’ve completed the DPM CFD Simulation Training Package and really appreciate how it merges theory with practical applications. The case studies, especially on ventilations relating to virus transmission, were spot on and highly informative. The step-by-step guidance through the tutorials gave me the confidence to start my own simulations. Great resource for anyone looking to extend their knowledge in CFD using ANSYS Fluent.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the training package to be comprehensive and practical. It’s great to know that the case studies and tutorials proved valuable in enhancing your knowledge and skills in CFD simulations with ANSYS Fluent. We appreciate your recommendation, and we look forward to offering you more quality learning materials in the future. Thank you for choosing MR CFD for your educational needs!

Prof. Judson Lakin –

I’m fascinated by the practical applications of the projects included in the DPM CFD Simulation Training Package. However, I’m wondering if the simulations account for particle-particle interactions or agglomeration effects, especially in the cases involving spray simulations?

MR CFD Support –

In the described training package, while some of the simulations focus mainly on the tracking and behavior of discrete particles, some comprehensive models also take into account interaction effects such as collision and coalescence, which is part of the parcel of studying spray dynamics. The details on whether particle-particle interaction or agglomeration is modeled depends on the individual project settings and goals, but typically, such phenomena can be included using advanced DPM features in ANSYS Fluent to capture these important effects for more accurate results.