Lime Kiln Combustion CFD Simulation, ANSYS Fluent

$180.00 Student Discount

- The problem numerically simulates Lime Kiln Combustio using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 2219550.

- We use the Species Transport model to define combustion reactions.

- We use the Porous medium inside the lime kiln.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Lime Kiln Combustion CFD Simulation by ANSYS Fluent, Tutorial

The present problem simulates the combustion process of methane gas in a vertical lime kiln using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The present model is designed in three dimensions using Design Modeler software. The model is a semi-designed vertical furnace due to its symmetrical geometric structure and to reduce the computational cost.

The model has four fuel inlets in the middle of the side surface of the lime kiln and one fuel inlet in the center of the furnace and has a primary air inlet in the center of the lime kiln, and a secondary air inlet in the lower part of the furnace, and an outlet for products in the lower part of the furnace.

Furthermore, a particular outlet for discharging gases in the upper part of the furnace is considered.

The meshing of this present model has been generated by Ansys Meshing software. The element number is 2219550.

CFD Methodology

The present problem simulates the combustion process of methane gas in a vertical lime kiln using ANSYS Fluent software. The construction of a vertical lime kiln consists of two main parts, including the combustion zone and the preheating zone.

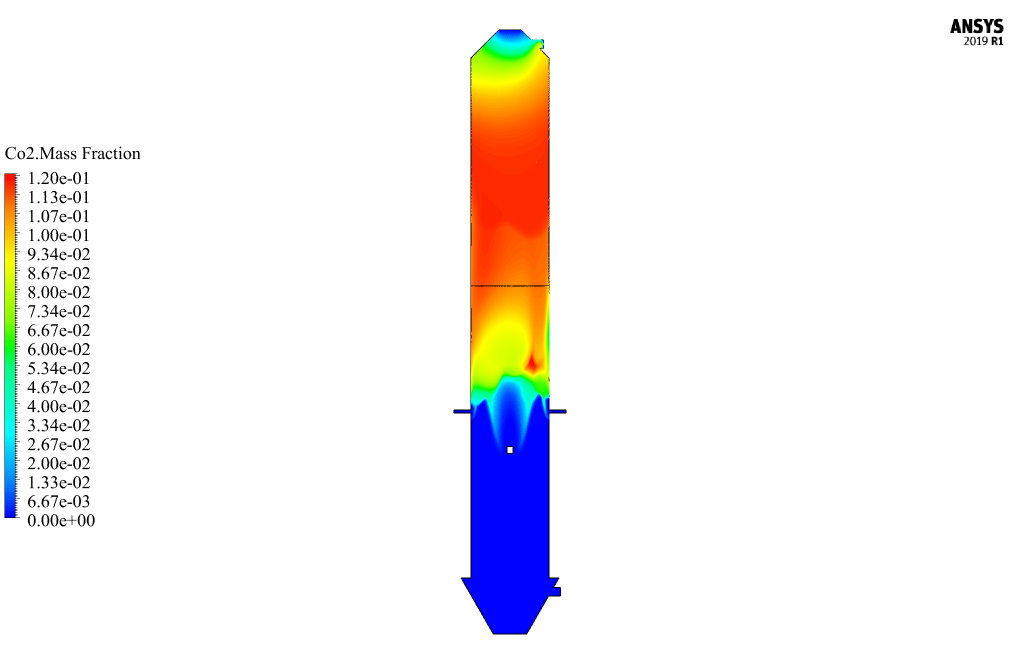

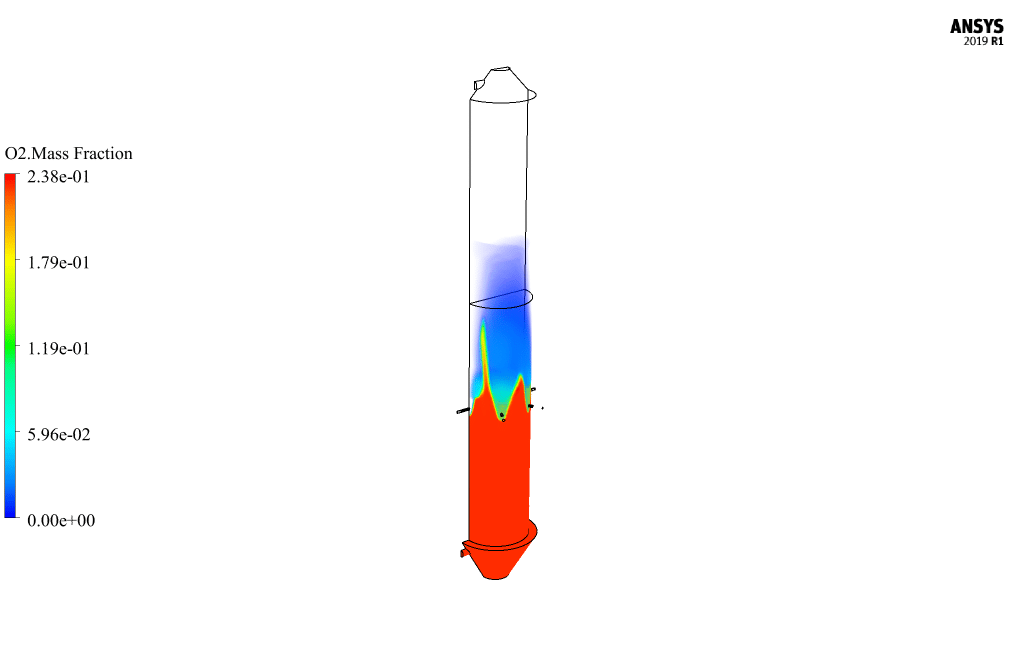

The fuel and air enter the building from the middle of the lime kiln and form a combustion reaction. As a result of the chemical reaction of combustion, a significant amount of heat is produced, increasing the temperature inside the lime kiln.

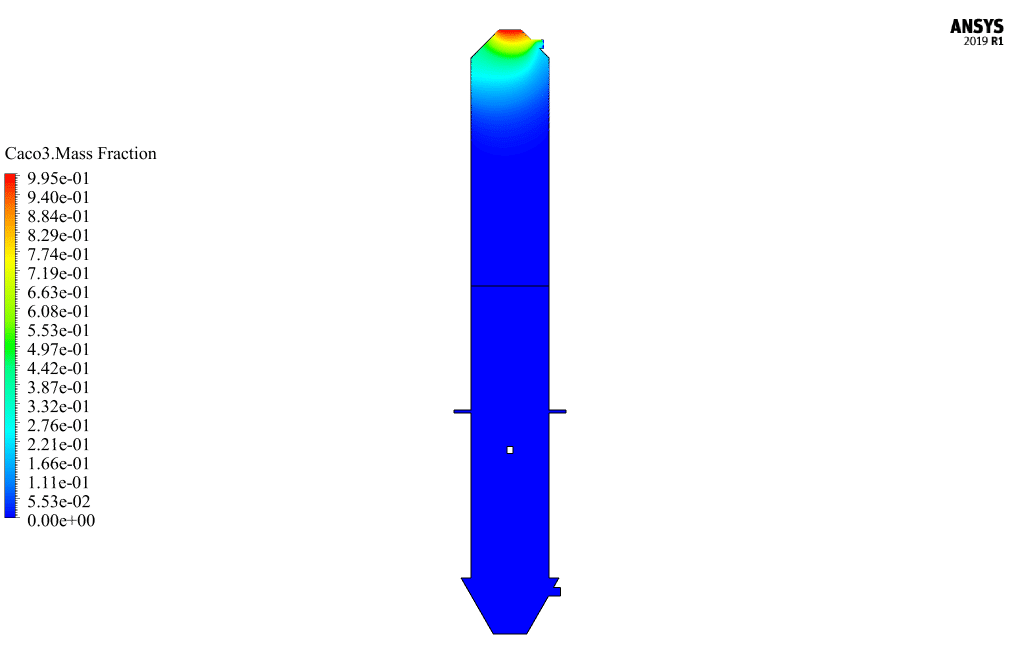

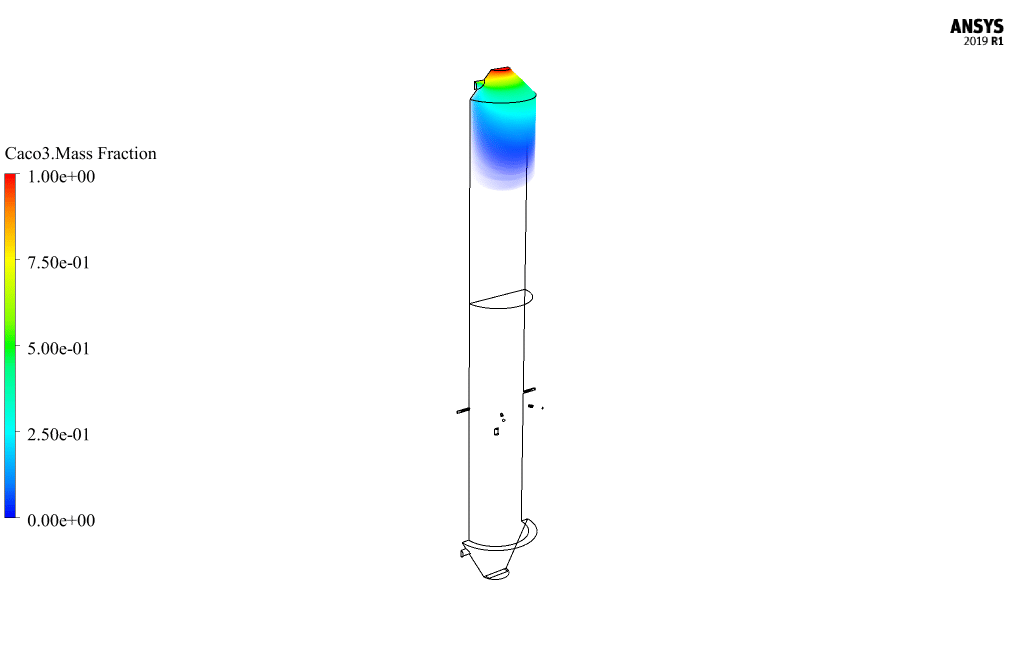

On the other hand, some calcium carbonate enters the lime kiln from the upper part. This calcium carbonate or limestone reacts separately by receiving heat from the combustion of the desired fuel and carbon dioxide production.

As a result, it can produce calcium oxide or the same as quicklime and separate it from carbon dioxide. In this project, only the occurrence of the chemical reaction of burning inside a lime kiln is investigated.

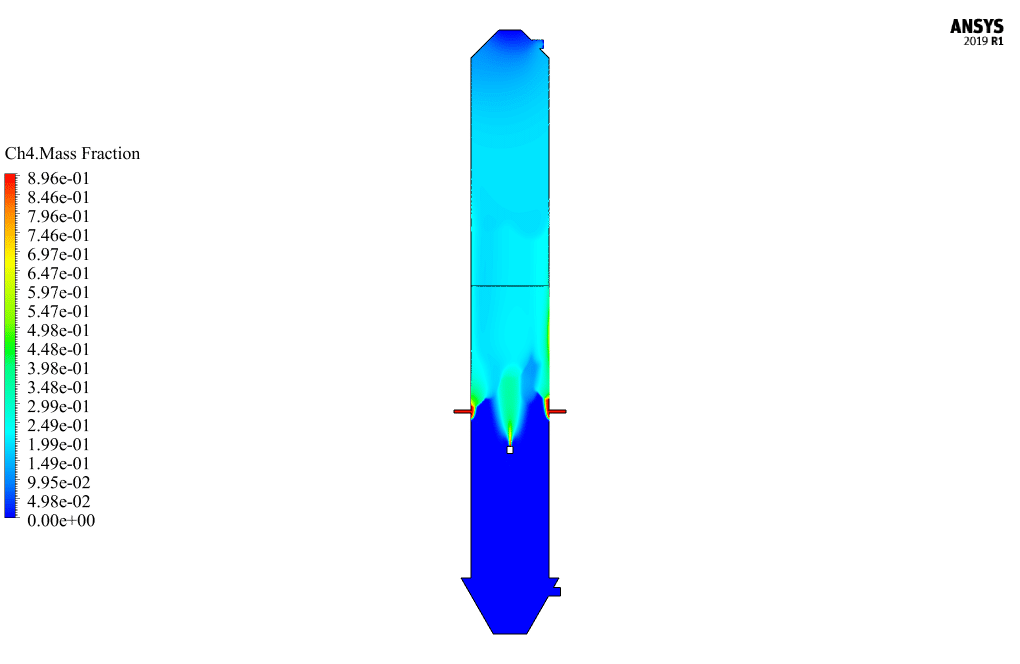

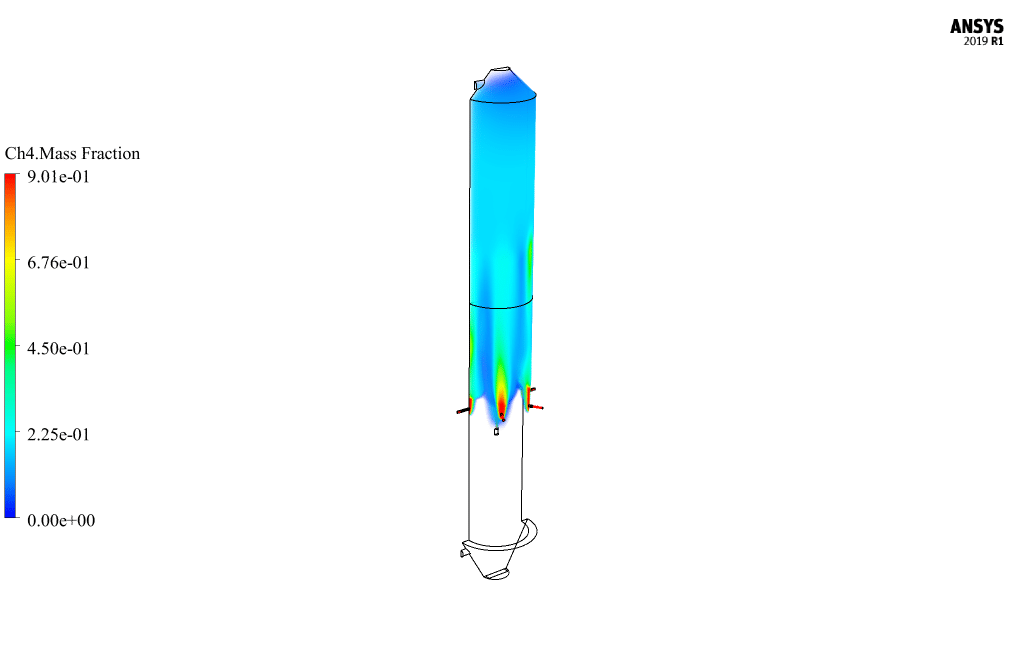

The combustion reaction defined in the model consists of performing a chemical reaction between air and methane. Thus, the species transport model and the volumetric sub-model can simulate the combustion.

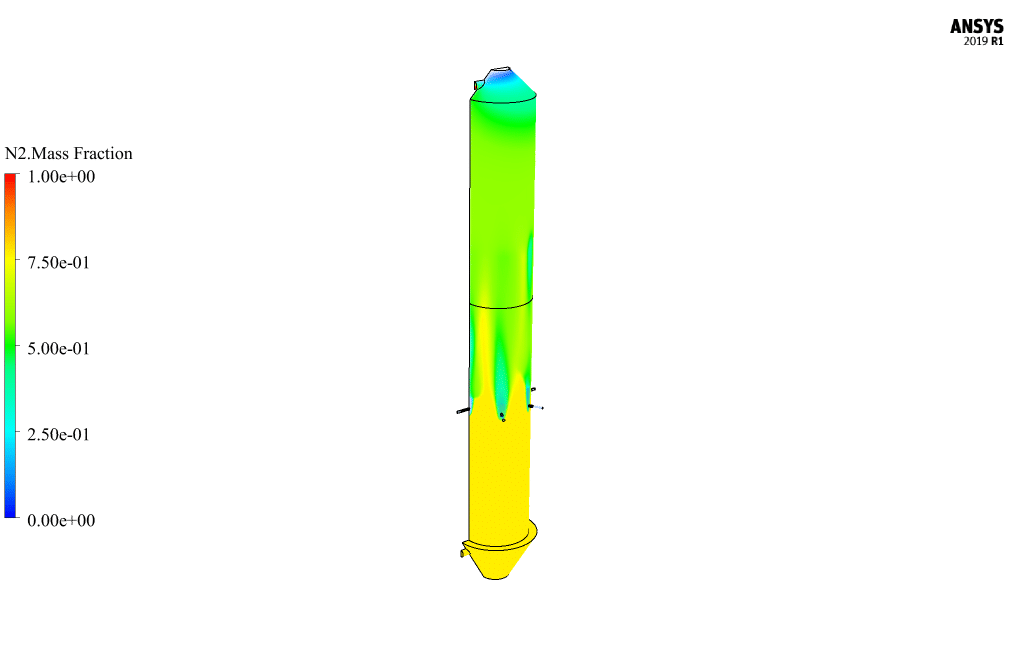

In the middle part of the lime kiln and from four side inputs, the flow, including 0.9 methane (CH4) and 0.1 nitrogen (N2), enters the lime kiln with speed equal to 1.357 m/s and a temperature equal to 300 K.

Simultaneously, an initial airflow and a fuel flow enter the furnace from the central area in the middle of the lime kiln.

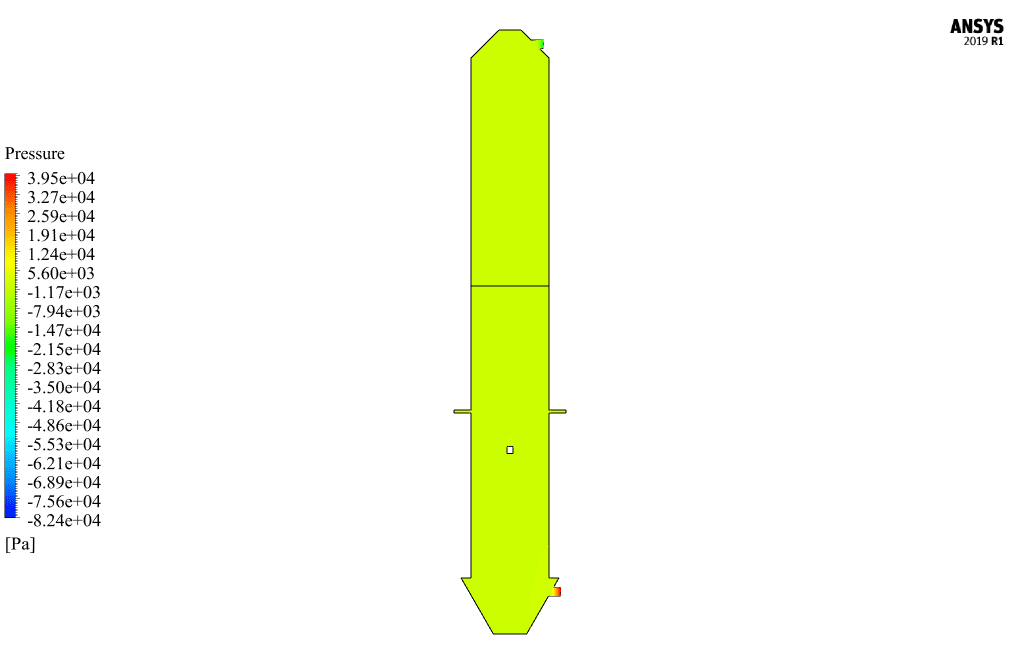

There are also two outputs for the model; Thus, the reaction products are discharged from the outlet at the bottom of the vertical lime kiln at atmospheric pressure, and the excess gases produced are sucked into the outside space by a suction fan.

In addition, porous materials have been used inside the lime kiln. The porous area is made of aluminum with a porosity coefficient of 0.3 and has an inertial resistance equal to 907.4 1/m and a viscous resistance equal to 1100000 1/m2.

Moreover, the standard k-epsilon model and energy equation are used to solve the turbulent fluid equations and calculate temperature change within the domain.

Lime Kiln Combustion CFD Simulation Conclusion

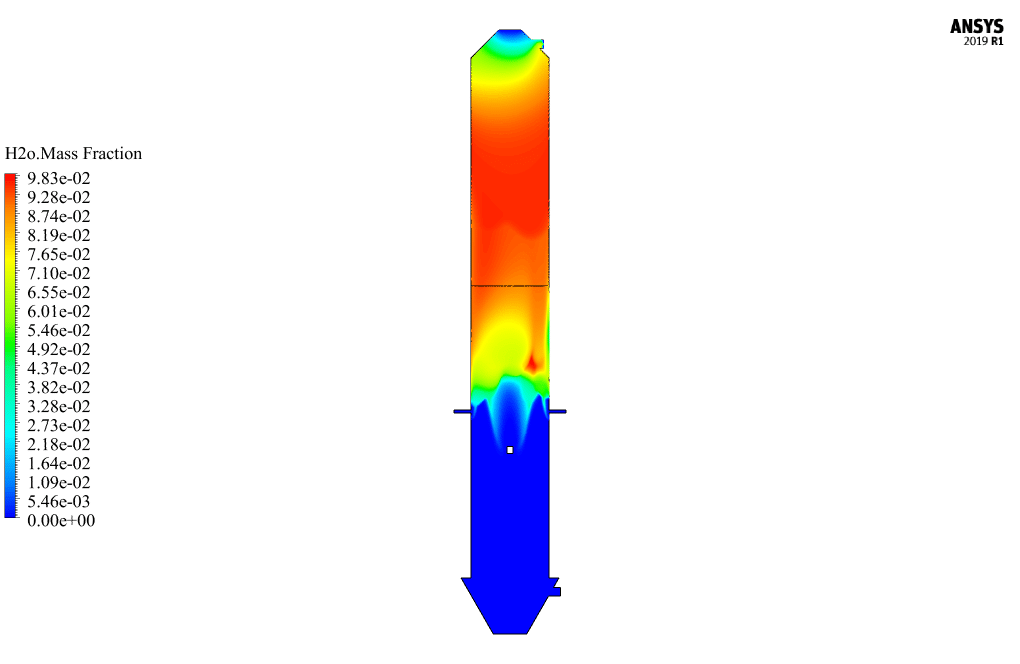

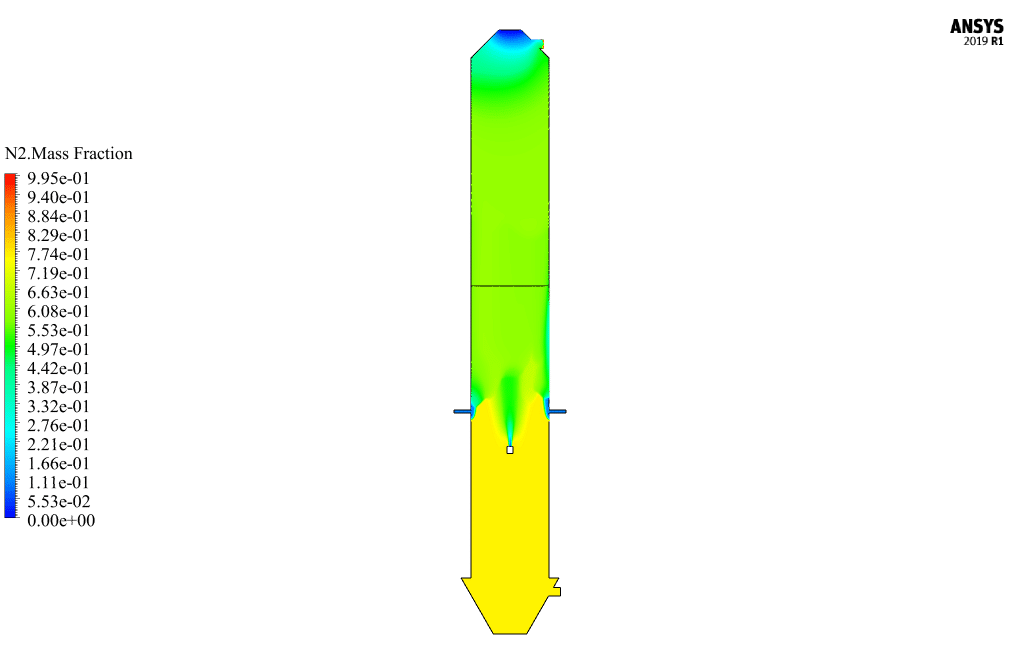

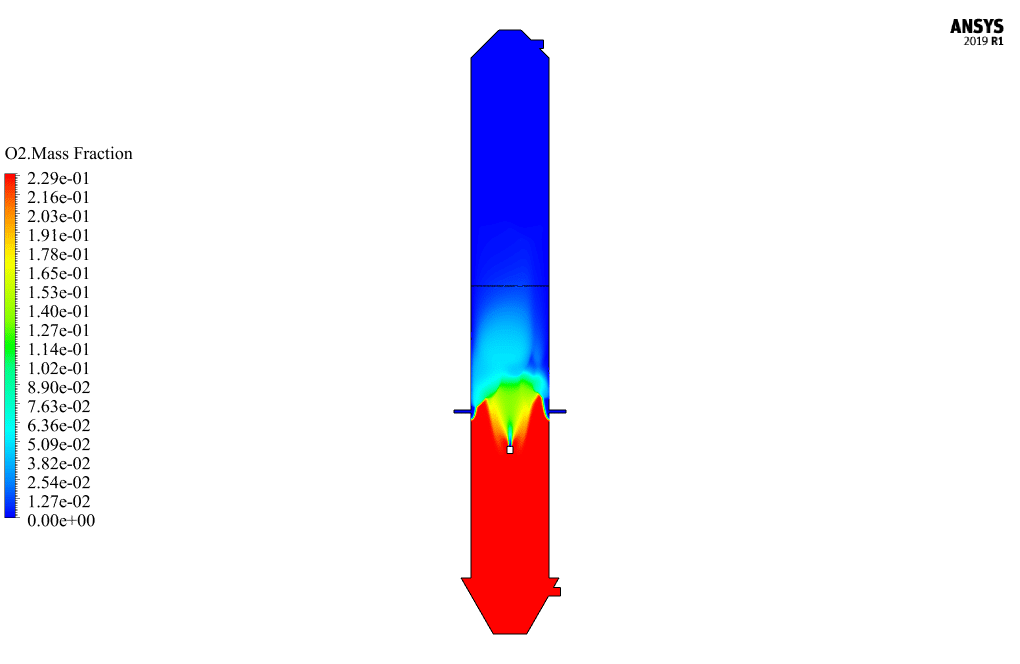

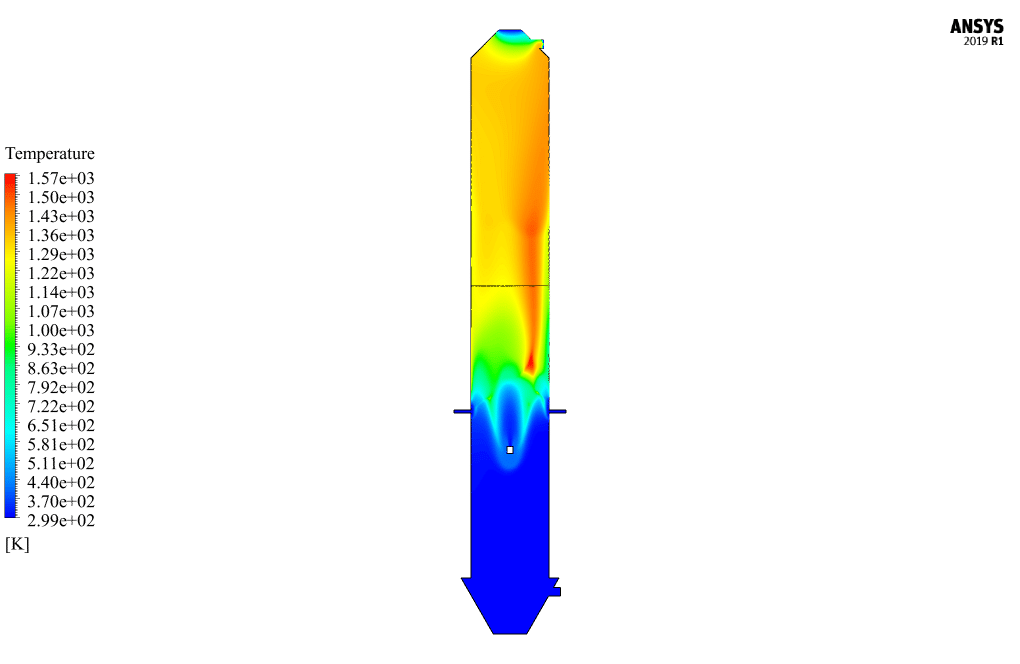

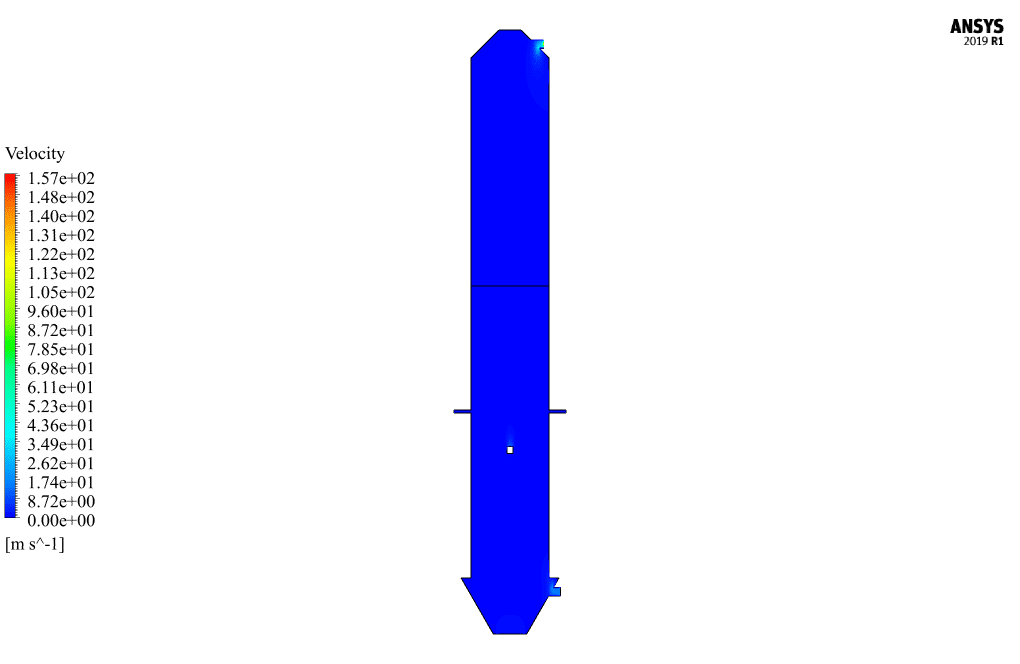

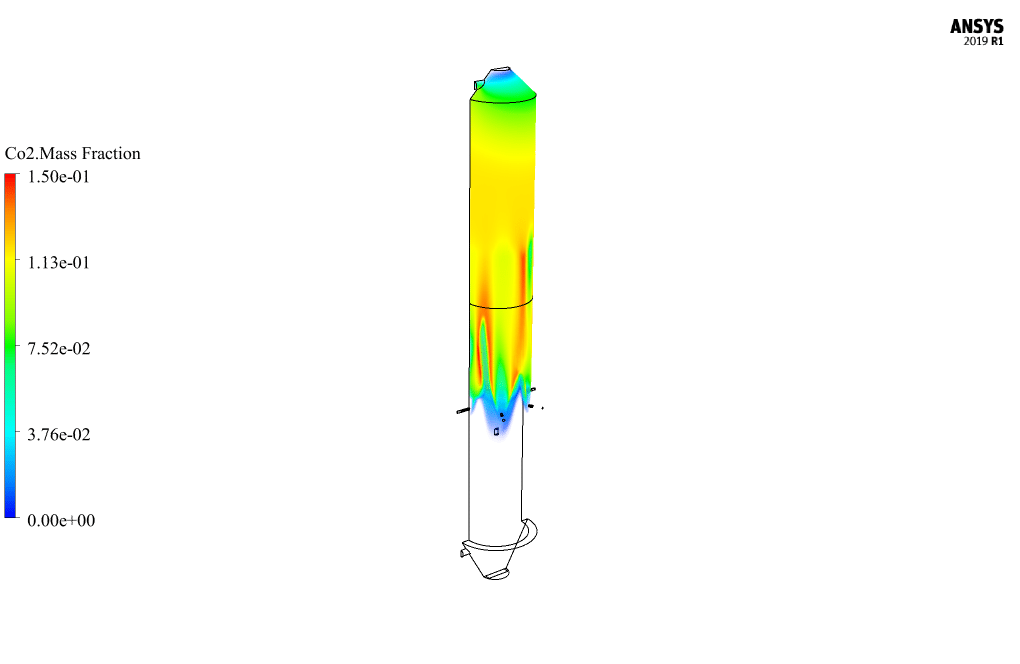

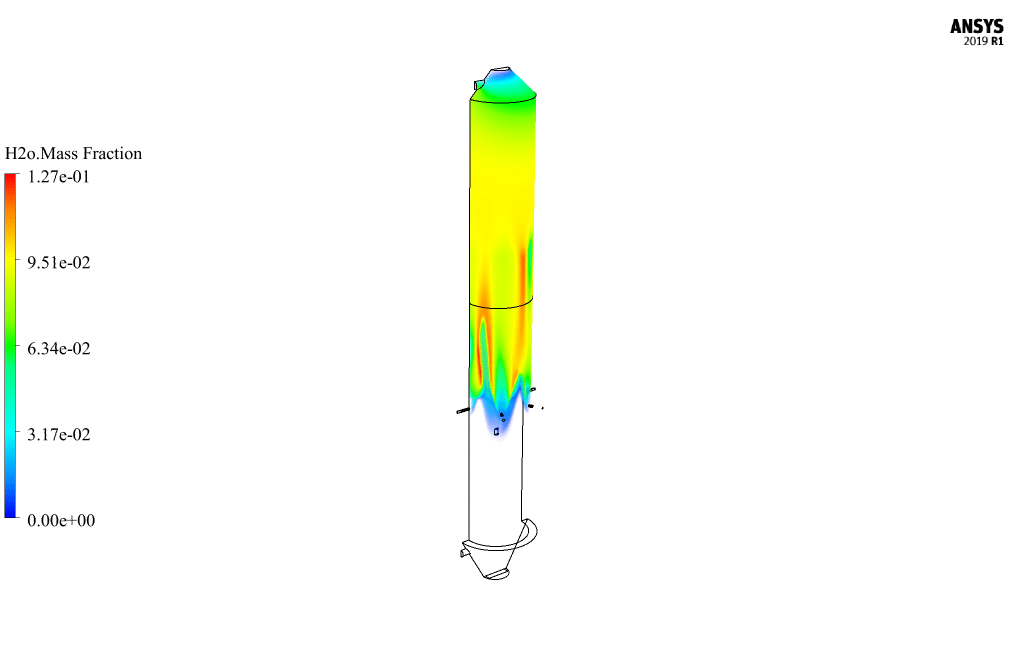

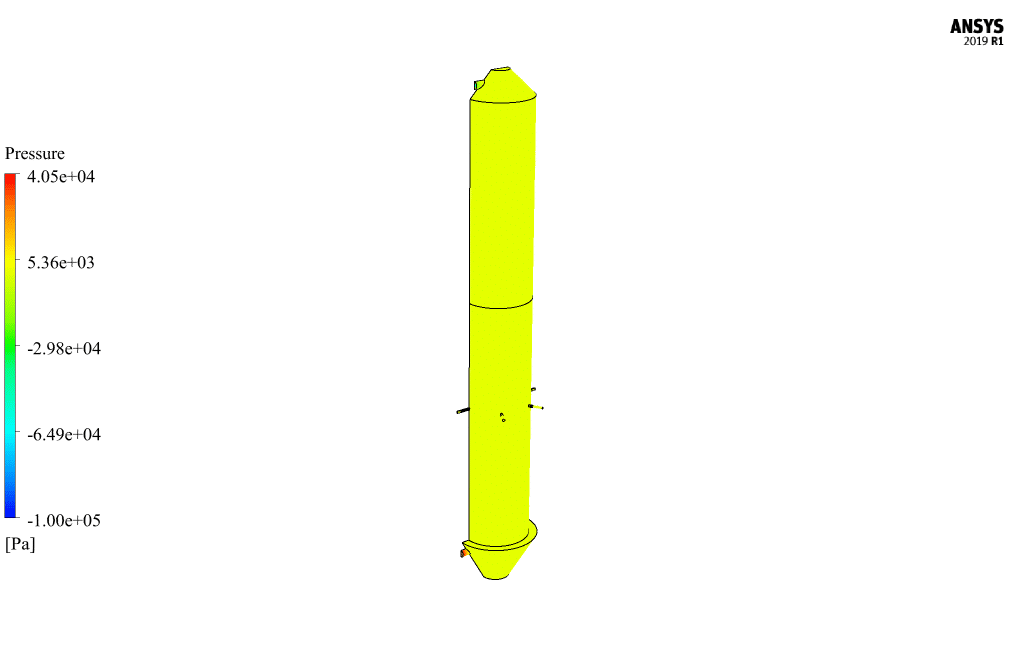

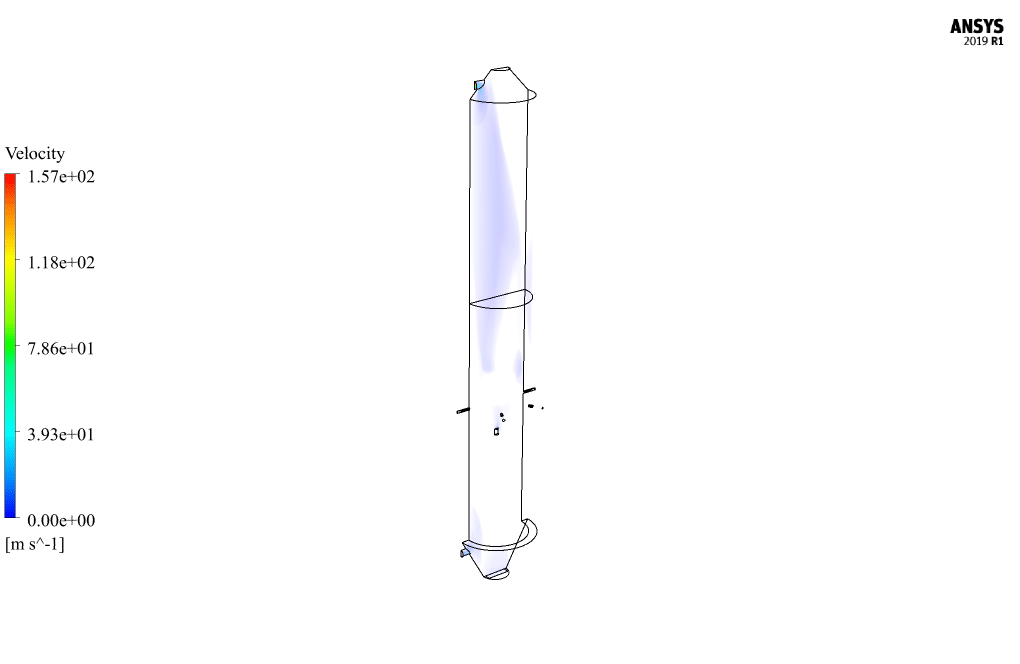

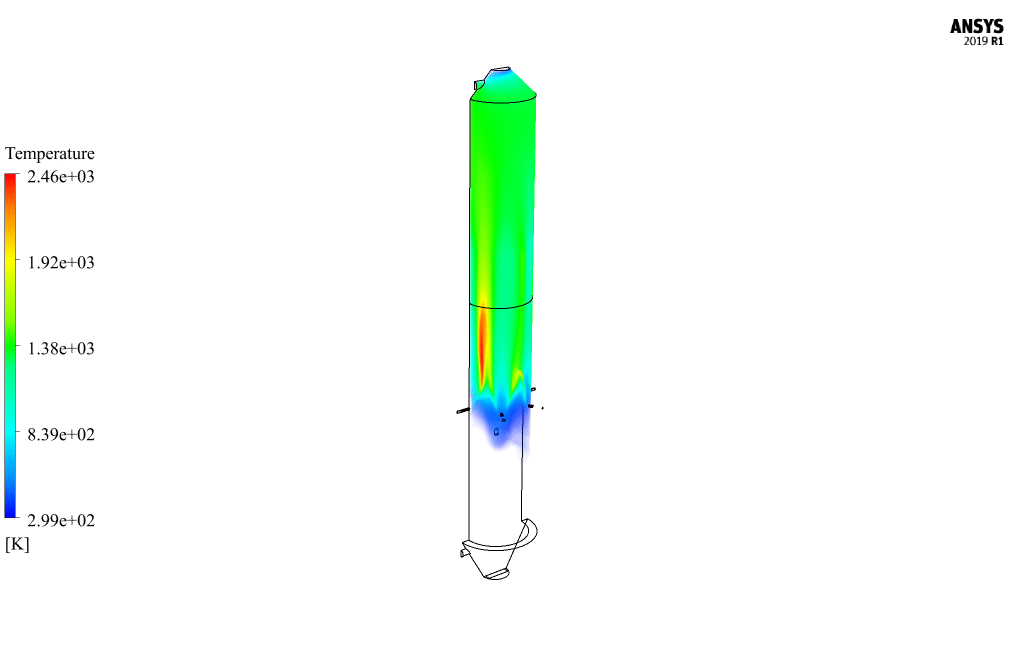

At the end of the solution process, two-dimensional and three-dimensional contours related to pressure, temperature, velocity, and mass fraction O2, CH4, H2O, CO2, N2, and CaCO3 were obtained.

The resulting images show that the reaction products, including carbon dioxide and water vapor, are produced due to the combustion reaction between the reactants (methane fuel and airflow). Significant heat is also generated when a combustion reaction occurs.

The heat generated by the combustion reaction can contribute to the dissociation of calcium carbonate or limestone and the production of quicklime.

Nels Hills –

I’m truly impressed by the detailed simulation process. The visualization of reactants and products across two-dimensional and three-dimensional contours must be quite illuminating. Understanding such complex phenomena and processing shows the power of CFD in real-world applications. The comprehensive analysis, along with the generation of significant aspects like temperature, pressure, and velocity, undoubtedly provides invaluable information for the operation and optimization of lime kilns.

MR CFD Support –

Thank you so much for your review and for recognizing the detail and complexity of our simulation process. We strive to deliver high-quality and comprehensive CFD analysis to enhance understanding and facilitate real-world applications. Your feedback is greatly appreciated, and we’re glad to know our efforts in visualizing and analyzing the combustion process within the lime kiln were helpful and insightful. If you have any more observations or need further assistance, please feel free to reach out to us.

Gabrielle Bruen –

I am fascinated by the CFD methodology used here. However, I wonder how the standard k-epsilon model affects the prediction of turbulence for this lime kiln combustion simulation, as opposed to using a different turbulence model?

MR CFD Support –

The standard k-epsilon model is one of the most common turbulence models used in simulating industrial processes like lime kiln combustion due to its robustness and reasonable accuracy for a wide range of flows. It is particularly effective in predicting the overall behavior of turbulence in fully turbulent flows and jets, which are typically observed in combustion systems. By utilizing this model, the simulation can adequately capture the averaged turbulent kinetic energy and its dissipation rate, thus providing a decent approximation for the distribution of temperature, species, and velocity within the kiln. When compared to other turbulence models that may capture specific flow characteristics more precisely, like the Realizable k-epsilon or the Reynold Stress Model (RSM), the standard k-epsilon is still preferred for its computational efficiency and simpler setup, making it suitable for initial design studies or scenarios where the exact specifics of the turbulence are less critical.

Adriel Reynolds –

I’m impressed with the detail of the Lime Kiln Combustion simulation results. Can you tell me which elements of the post-processing were most helpful in understanding the combustion efficiencies within the kiln?

MR CFD Support –

The post-processing elements that provided key insights into the combustion efficiencies within the kiln were the temperature contours and species mass fractions. These outputs allowed for visualizing hot zones and reaction patterns, revealing where the combustion might be more or less efficient. Additionally, velocity vectors highlighted flow streams ensuring proper mixing of reactants and exposure to desirable temperature regions.

Jeanne Halvorson –

I am impressed with the level of detail that goes into studying the combustion process in the lime kiln simulation. How does the simulation ensure that the temperature distribution inside the kiln is accurately represented?

MR CFD Support –

Thank you for your kind words! The accuracy of the temperature distribution in the simulation is achieved through the careful setup of relevant physical models inclusive of species transport to account for chemical reactions, heat transfer via the inclusion of the energy equation, and appropriate turbulence modeling with the standard k-epsilon model. Additionally, the boundary conditions are meticulously defined to represent the inflow of reactants and the outflow of products, ensuring a realistic flow and heat generation picture within the lime kiln that ultimately gives an accurate temperature distribution.

Petra Boehm –

Amazing detail in the Lime Kiln Combustion CFD Simulation. I learned a lot about combustion processes in industrial environments. The inclusion of different species in the flow and the interaction between the inlet streams and the combustion zone was really insightful. The use of porous materials also adds a layer of complexity to the simulation. Well done on a comprehensive tutorial!

MR CFD Support –

Thank you for such a positive review. We are glad to hear that you found the Lime Kiln Combustion CFD Simulation comprehensive and insightful. At MR CFD, we strive to provide detailed and accurate representations to support learning and industry applications. Your feedback is valuable to us, and we look forward to providing you with more useful tutorials.

Demarco Ritchie –

The description is detailed but doesn’t mention how the k-epsilon model was calibrated. Were there any experiments that this was compared to for validation, or any specific reason to choose the standard k-epsilon over other turbulence models?

MR CFD Support –

In the process of simulating complex flows such as combustion in a lime kiln, the choice of a turbulence model is crucial. The standard k-epsilon model is a widely used and robust model that predicts the averaged effects of turbulence, and it offers a good balance between accuracy and computational expense. Benchmark and parametric studies are typically conducted to compare the simulated results with experimental data to validate the model’s predictive accuracy. While specific details on experimental validations for this particular simulation are not provided, choosing the standard k-epsilon model might be due to its suitability for fully turbulent flows and industrial applicability for internal aerodynamics, which is characteristic of a lime kiln environment.

Maude Quigley –

I am delighted with how detailed the Lime Kiln Combustion CFD simulation project was designed to mimic actual process conditions, and the results obtained are quite comprehensive. The use of porosity coefficients and resistance specifications for porous materials is particularly impressive and informative.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the simulation details thorough and reflective of a real-world process. Our goal is to provide comprehensive and accurate simulations that aid understanding and meet our customer’s needs. Your satisfaction is our top priority, and we appreciate you taking the time to recognize the effort put into the Lime Kiln Combustion project. If you have any more questions or need further assistance, feel free to reach out!

Clare Orn –

I was impressed with the detailed analogies and flow dynamics! I’m curious, how did you account for the potential limestone particle size variations and their effect on the reaction kinetics within this simulation?

MR CFD Support –

The limestone particle size variations and their effects are typically accounted for using granular flow models and discrete phase models. These discrepancies are simulated to ensure accuracy in reaction kinetics, heat transfer, and mass transfer. For this simulation, the reaction kinetics could be modeled using either Arrhenius rate equations or probability density functions, depending on how detailed your inputs are.

Prof. Alana Harber MD –

The tutorial provided for the Lime Kiln combustion simulation seems comprehensive. I appreciate how you’ve detailed both the construction of the vertical lime kiln and the chemical reactions occurring inside. What really enhances understanding is the simulation of species transport alongside the combustion process, as it allows for a clear visualization of gas interactions and heat production. Kudos on including the effects of combustion on limestone dissociation, utilizing species transport model to monitor both primary and secondary products. Great work incorporating porous media into the model to simulate realistic lime kiln conditions,

MR CFD Support –

Thank you for your positive feedback on the Lime Kiln Combustion CFD Simulation tutorial utilizing ANSYS Fluent. We are delighted to hear that you found the tutorial comprehensive and effective in conveying the intricacies of the chemical reactions and heat transfer processes within a lime kiln. It’s gratifying to know that the simulations effectively demonstrated the interactions and contributed to a thorough understanding of the process. Your appreciation for the inclusion of porous media and detailed visualization is highly encouraging. We strive for clarity and depth in our training materials, and we’re glad it has been helpful to you.

Jaiden Carter –

The complexity and depth of the simulation are impressive. It seems thorough in its treatment of the combustion and calcination processes inside a lime kiln. The multi-physics approach dealing with fluid dynamics, chemical reactions, porous media, and thermal effects should provide comprehensive insights for engineers and researchers working on improving the efficiency of lime kilns. Well-done on a detailed and technically rich simulation.

MR CFD Support –

Thank you for recognizing the intricacies and comprehensive nature of our Lime Kiln Combustion CFD Simulation. We put considerable effort into capturing the nuances of such a complex process, and it’s gratifying to see that it can deliver valuable insights for professionals in the field. We appreciate your feedback and are glad that the product has met your expectations. Your satisfaction with our simulation is extremely important to us!

Izabella Pacocha –

I’m impressed by how the simulation can replicate the complex environment in a lime kiln and discern the separate reaction pathways! Does this product include recommendations for efficiency improvements on the operational lime kiln based on the CFD results?

MR CFD Support –

Thank you for your compliments! As the simulation focuses on replicating the combustion process and examining the resulting chemical reactions, this software analyzes these complexities in detail. However, while it can provide detailed insights into the combustion process, efficiency improvement recommendations based on CFD results are typically beyond the scope of a standard simulation product, and usually require tailored consultancy services taking into account the specifics of an actual operational kiln.

Mr. Ryleigh Grimes DDS –

I’m impressed with the level of detail in the simulation’s methodology for the Lime Kiln Combustion process. The incorporation of species transport and the understanding of the combustion reaction’s impact on temperature elevations demonstrate an advanced approach to the problem. This case study shows a strong comprehension of combustion dynamics and would be extremely helpful for anyone looking to understand how CFD is applied in chemical processing applications. Well done on structuring a comprehensive tutorial!

MR CFD Support –

Thank you for your positive feedback and recognition of our detailed approach. We’re delighted to hear that the tutorial was comprehensive and beneficial for understanding the application of CFD in chemical process simulations. MR CFD is committed to providing high-quality, in-depth educational materials in computational fluid dynamics, and your satisfaction with the methodology encourages us further. Should you have more queries or require assistance in future projects, feel free to reach out. We’re here to help!

William Price PhD –

I am curious about the post-processing stage. How do you visualize and interpret the vast amount of data from the simulation? Seems like it would be quite complex with all the different variables involved.

MR CFD Support –

The post-processing stage of a CFD simulation typically involves using software visualization tools to create meaningful and detailed graphical representations. Through various techniques like contour, vector, and streamline plots, we interpret temperature, pressure, velocity fields, and species concentrations. Advanced options like iso-surfaces or pathlines can also depict 3-dimensional flow structures. These visual tools aid in understanding the interaction between variables and in identifying key areas within the simulation for further analysis or optimization.

Prof. Lenora D’Amore Jr. –

The limestone in the simulation seems critical for heat absorption, yet the main focus is on gas combustion. Is the effect of the heated limestone on the kiln’s temperature profile considered in the simulation?

MR CFD Support –

The primary aim of this simulation is to investigate the combustion of methane; however, the effects of heat transfer to the corresponding porous material, representing limestone, are inherently considered in the overall thermal analysis. The temperature contours produced as part of this simulation do inherently take into account the heat absorption of the limestone, and its influence on the temperature profile within the kiln is factored into the final results.

Jimmy Wiza –

The description of the Lime Kiln simulation is thorough, but I would like to know whether dead zones where combustion is incomplete are observed in the simulation, and how are such areas addressed?

MR CFD Support –

In a simulation like this, it’s common to look for areas with low oxygen or poor mixing that could result in incomplete combustion, typically known as dead zones. The simulation may utilize additional monitoring points to check for low-temperature spots or regions with unreacted methane. If such regions are identified within the simulation data, strategies like modifying the position or rate of air input, changing the geometry of the kiln, or adjusting the properties of the porous media can be employed to reduce these dead zones and promote better mixing and combustion.

Aimee Stamm –

I am pleased with the detailed analysis of the lime kiln combustion simulation! However, I am wondering if any measures have been implemented in the simulation to account for ash or particulate matter that would realistically be produced during the combustion process?

MR CFD Support –

In this type of simulation, the production of ash and particulate matter can indeed be of interest. The inclusion of such elements typically depends on the modeling approaches and specific goals of the analysis. In this particular case, since the focus is on the combustion process and its primary products, further details on the tracking of ash or particulates are required to determine their integration within the model. It would be noteworthy to implement a Particle Tracking model or Discrete Phase Model (DPM) to simulate the behavior of particulate matter if data from actual industrial processes or experimental setups were used as input. Since these aspects were not highlighted, additional information on your objectives or requirements could help tailor the response more accurately.

Dr. Keon Luettgen III –

The tutorial for the Lime Kiln Combustion CFD simulation was fantastic! Applying the porous media and intricate boundary conditions to a real-world scenario solidified my understanding of combustion simulations in ANSYS Fluent. Would you be able to provide additional advanced tutorials covering different types of industrial furnaces or chemical reactors with complex reactions?

MR CFD Support –

Thank you! We’re thrilled to hear that our tutorial on Lime Kiln Combustion CFD simulation was helpful to you. We continuously strive to expand our range of tutorials, and we definitely plan to include more advanced simulations featuring various types of industrial furnaces and chemical reactors. Keep an eye on our learning resources for updates on future content, and feel free to suggest any specific topics you are interested in!

Dr. Beau Ratke Jr. –

I am highly impressed by the scope and detail of the CFD simulation of the lime kiln combustion process. The inclusion of two parts of the combustion zone and the preheating zone demonstrates a well-thought-out approach, and it’s clear that the investigation provides comprehensive insight into the combustion dynamics within a kiln. Moreover, using methane for combustion and incorporating the reaction that produces quicklime from limestone exemplifies an advanced and realistic simulation. Truly praiseworthy effort!

MR CFD Support –

We’re thrilled that you’ve noticed the depth of our lime kiln combustion simulation. Thank you for your kind words and for recognizing the effort we put into creating a realistic CFD simulation that aids in understanding the combustion process in detail. We appreciate your feedback and are glad that our work contributes positively to your perspective on the simulation. If you have further questions or need more information about our CFD projects, feel free to reach out!

Dr. Haskell Streich DVM –

Can you tell me more about the role of the porous materials within the lime kiln, particularly regarding the simulation results?

MR CFD Support –

In the simulation, porous materials within the limekiln, such as aluminum with a specific porosity coefficient, act to increase resistance to flow. This feature mimics the drag and heat transfer characteristics of actual materials in a limekiln, where materials’ presence affects the flow patterns and temperature distribution within the kiln. The porous zone’s viscous and inertial resistances play key roles in predicting how the combustion gases flow and transfer heat within the kiln. The impacts of this are reflected in the simulation results, such as the velocity and temperature profiles, giving us insight into the efficiency of combustion and heating within the kiln.

Callie Durgan –

I’m impressed by the comprehensive explanation of the CFD methodology and combustion simulation in a lime kiln. How do you ensure that combustion and chemical reactions are accurately simulated?

MR CFD Support –

In the simulation, we ensure the accuracy of combustion and chemical reactions by employing the species transport model combined with the volumetric reaction sub-model. Parameters such as the correct stoichiometry of the chemical reactions, appropriate reaction rate coefficients, and accurate boundary conditions (such as temperature and velocity profiles at the inlets) are meticulously defined. Additionally, validation of the simulation results against experimental data or theoretical predictions is conducted when available to enhance the reliability of the simulation outcomes.

Dr. Karley Watsica –

The 3D analysis of the lime kiln provided a comprehensive understanding of the combustion process. Very impressed by the detailed presentation of the temperature contours and the distribution of gas species!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that the 3D analysis of the Lime Kiln Combustion CFD Simulation was enlightening and that you found the temperature contours and gas distribution insightful. Your feedback is appreciated and motivates us to continue delivering high-quality CFD analyses.

Ms. Imogene Padberg –

This simulation sounds complex and incredibly detailed! I’m curious about how you factored in the real-life inefficiencies and variations within the lime kiln that might affect the combustion process. Would you mind shedding some light on how Ansys Fluent accounts for real-life operation conditions?

MR CFD Support –

In Ansys Fluent, real-life operation conditions within the lime kiln are accounted for by implementing a variety of boundary conditions and physical models. These can include temperature gradients, variations in fuel and air flow rates, turbulence models like the standard k-epsilon for predicting the flow turbulences, and the energy equations for heat transfer. Porous media modeling is used to simulate the resistance of the material inside the kiln and the effect of pressure and temperature through these materials. Species transport models and volumetric reactions replicate the chemical processes, including the imperfections in mixing and reaction rates. Furthermore, dynamic mesh adjustments could also be used to account for mechanical changes or movements that might occur during the process. All these factors combined provide a realistic simulation where inefficiencies and variations are considered to predict the device’s actual performance as closely as possible.

Bianka King –

I’m impressed by the complexity of the Lime Kiln Combustion simulation in ANSYS Fluent. The detail oriented approach to evaluate combustion and heat production for material processing like limestone calcination is intriguing. Great utilization of CFD to understand industrial processes!

MR CFD Support –

Thank you for taking the time to leave such a thoughtful review! We’re thrilled to hear that you’re impressed by the detail and complexity of the Lime Kiln Combustion CFD simulation. Our goal is always to provide comprehensive and realistic simulations to help users understand industrial processes better. Your feedback confirms that we are achieving this goal. If you ever have more questions or need further assistance with CFD simulations, don’t hesitate to reach out!

Charley Runolfsson –

This Lime Kiln Combustion CFD Simulation tutorial sounds incredibly comprehensive. Is there any consideration of heat losses through the kiln walls in the simulation, or is it assumed to be adiabatic?

MR CFD Support –

In this CFD simulation of Lime Kiln Combustion, heat transfer to the kiln walls can be integral as it affects the temperature distribution and the combustion process efficiency. The tutorial specifies that heat is generated by the combustion reaction, so typically, in such detailed simulations, heat loss mechanisms might be included to reflect a more realistic scenario. However, I would need to review the simulation settings to confirm if heat losses have been considered in this particular model or if it’s indeed treated adiabatically.