Mixture and Wet Steam Multiphase Model Training Course

Original price was: $380.00.$249.00Current price is: $249.00. Student Discount

Lesson 1: Concepts

Lesson 2: Example 1

Lesson 3: Example 2

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Mixture and Wet Steam Multiphase Model Training Course

The Mixture Multiphase Model in Fluent is a numerical simulation tool used to model the behavior of multiphase flows. It is based on the Eulerian-Eulerian approach, which considers each phase as a continuous medium and tracks the motion of each phase separately.

The model can be used to simulate a wide range of multiphase flows, including bubbly, dispersed, and stratified flows. It can also be used to simulate the interaction between different phases, such as heat and mass transfer, and chemical reactions. The model is highly accurate and can be used to predict the behavior of complex multiphase flows.

The Wet Steam model in Fluent is a two-phase flow model that accounts for the effects of condensation and evaporation on the flow. It is based on the conservation equations of mass, momentum, and energy for both the vapor and liquid phases. It can be used to simulate a wide range of two-phase flow problems, such as condensation in a steam turbine or evaporation in a heat exchanger.

There are various CFD methods to employ these models. One of the most renowned methods is the Finite volume method implemented in ANSYS Fluent. ANSYS Fluent is a powerful tool that can simulate Mixture and Wet Steam-based multiphase flows. The implemented options and existing capabilities of this software can predict even the slightest alteration of phases when interacting with each other.

Training Course Syllabus

This course contains video lessons and final projects to get a certificate after finishing the course.

Lesson 1: Mixture and Wet Steam Multiphase Models Concepts

In this lesson, you will first see a general introduction to Mixture and Wet Steam Multiphase models and an overview of available simulation techniques and sub-models of the Mixture and Wet Steam in ANSYS Fluent. This section contains the following subsections:

- Introduction

- Mixture model

- Equations

- Assumptions and Restrictions

- Applications

- Wet steam model

- Assumptions and Restrictions

- Summary

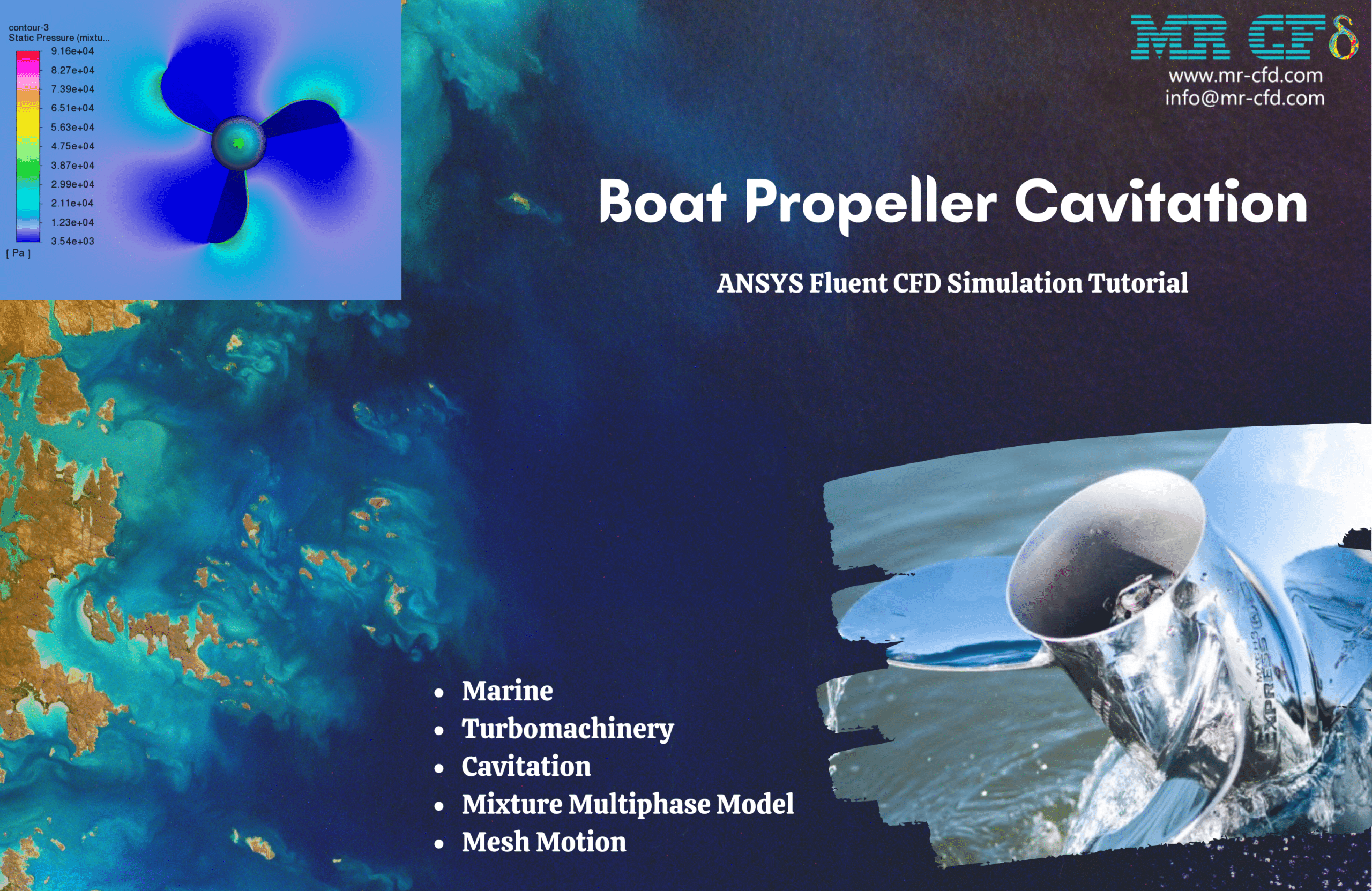

Lesson 2: Boat Propeller Cavitation

In this lesson, we will teach you how to simulate the practical problem of cavitation on a boat propeller. The cavitation phenomenon can wear and erode the surface of propellers or pump blades leading to their destruction sooner than the predicted time.

Hence, by simulating this phenomenon, engineers can alter their design to prevent such incidents from happening. In this session, you learn how to apply the cavitation model using the Mixture multiphase model and how to apply correct boundary conditions to employ this model.

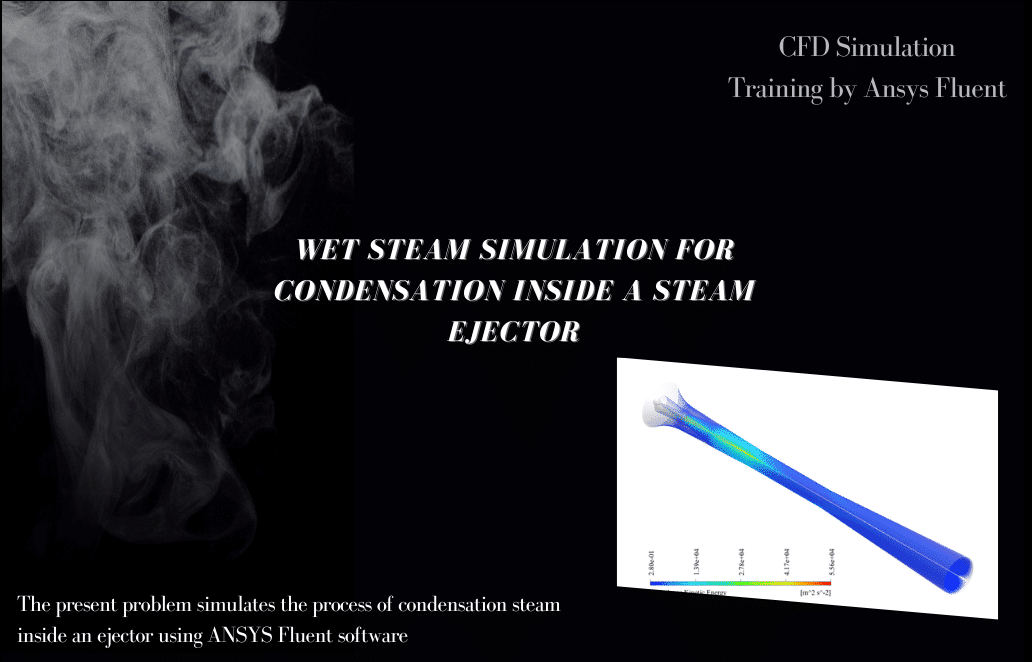

Lesson 3: Wet Steam for Condensation inside a Steam Ejector

In this lesson, we present another realistic industrial problem which is the formation of water liquid droplets inside a converging-diverging nozzle. The Wet steam model can be used to predict the formation rate of water droplets as the supersaturated dry vapor passes through the throat of a converging-diverging nozzle.

As the supersaturated dry vapor passes through the neck of the nozzle, a sort of shock is applied to the flow stream, causing the dry vapor to condense into liquid droplets. This phenomenon is studied extensively for many applications such as power plants, biomedical, and food industries.

Adrain McCullough –

Absolutely terrific training course! I was able to follow along and really grasp the concepts of multiphase modeling in Fluent. The hands-on approach with the final projects definitely cemented my understanding. I’d love to know if there are advanced follow-up courses relating to this topic.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the training course was helpful and engaging for you. Regarding advanced follow-up courses, we do indeed offer higher-level courses that delve further into complex CFD projects and topics. We recommend checking out our course listings or contacting us directly for information about more advanced multiphase modeling courses.

Avis Kirlin –

I found the course content incredibly rich and well-delineated! I especially appreciated how practical industrial challenges like propeller cavitation and steam ejector functions were incorporated. Can anyone with basic knowledge of fluid dynamics take this course, or is it intended for more advanced users?

MR CFD Support –

Thank you for the kind words! The Mixture and Wet Steam Multiphase Model Training Course is designed with both foundational principles and advanced practical applications in mind. Someone with a basic understanding of fluid dynamics should be able to grasp the concepts and gain from this course. However, it may also cover advanced topics, making it valuable for more experienced users seeking to specialize in multiphase flow simulations.

Thomas Emmerich –

I thoroughly enjoyed the Mixture and Wet Steam Multiphase Model Training Course. The comprehensive videos effectively covered the necessary concepts, and the structure of the course allowed for a clear understanding of the material. Applying the lessons to simulate cavitation on a boat propeller provided a practical edge to the theoretical knowledge. The final projects were particularly engaging and culminated in a satisfying sense of accomplishment upon receiving a certificate. Remarkable course content and I am now more confident in using ANSYS Fluent for my simulations.

MR CFD Support –

Thank you for your positive review and feedback on our Mixture and Wet Steam Multiphase Model Training Course. We are thrilled to hear that you found the videos comprehensive and the course structure conducive to learning. It’s great to know that the practical projects added value to your learning experience and that you feel more confident in your simulation skills. We appreciate you taking the time to complete the course and submit such a detailed review. Congratulations on earning your certificate, and we look forward to assisting you in any future learning endeavors!

Sydnee D’Amore –

I’m impressed with the detailed training course syllabus for the Mixture and Wet Steam Multiphase Model. It seems to cover the necessary physics with hands-on applications. Do the final projects include real-world troubleshoot examples to solidify our understanding?

MR CFD Support –

Yes, the final projects are designed to provide practical hands-on experience and typically include real-world examples that require you to apply the concepts learned in the lessons to troubleshoot and solve complex issues. This helps to solidify your understanding and prepares you for applying the models in your professional work.

Dr. Laurel Wisoky –

The learning course about the Mixture and Wet Steam Multiphase Model was fantastic! The structure was easy to follow, the examples were relevant, and I particularly liked lesson 3 on the Wet Steam model’s application in a steam ejector. It connected theory with practice perfectly.

MR CFD Support –

Thank you for your kind review! We are thrilled to hear that the course structure was clear and that you found the real-world examples, especially on the condensation inside a steam ejector, to be helpful in understanding the practical application of the Wet Steam Multiphase Model. We strive to provide valuable and practical learning experiences. It’s wonderful to know we met your expectations!

Elian Jaskolski –

I just finished the Mixture and Wet Steam Multiphase Model Training Course and I’m beyond impressed. The level of detail in explaining the subtleties of each model’s assumptions and applications was immensely helpful. Also, the lesson on boat propeller cavitation not only improved my understanding of the underlying physics but also equipped me with practical skills for my work. Can’t wait to apply these techniques in my upcoming projects! Thank you for such a thorough and insightful course.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the course was not only informative but also practically beneficial for your work. It’s great that you’re eager to apply what you’ve learned to your projects. If you ever need further assistance or have any questions as you implement these techniques, don’t hesitate to reach out. We wish you the best with your upcoming endeavors.

Mae Kirlin –

Just finished the Mixture and Wet Steam Multiphase Model Training Course, and I am greatly amazed by how clearly it explains complex concepts. It bridges the gap between academic theory and practical application superbly. Highly recommended for anyone serious about mastering CFD with ANSYS Fluent.

MR CFD Support –

We’re thrilled to hear that our training course has made a significant impact on your understanding of multiphase CFD analysis with ANSYS Fluent. It’s great to know that the course’s structure facilitated the learning process. Thank you for recommending us — we appreciate your support!

Prof. Hassan Okuneva DVM –

I thoroughly enjoyed the Mixture and Wet Steam Multiphase Model Training Course. The content on modeling cavitation on boat propellers using the Mixture model was incredibly insightful. The video lessons were easy to follow, and the tutorial on condensation within a steam ejector was expertly presented. The section on predicting the formation of water droplets using the Wet Steam model was valuable, and the course was handy for understanding multiphase flow within industrial applications.

MR CFD Support –

Thank you for the review! We’re glad to hear that our Mixture and Wet Steam Multiphase Model Training Course was helpful and met your expectations. It’s great to know that the content and video tutorials were easy to follow. We appreciate your feedback and hope you continue to find value in our learning materials!

Madeline Herman –

I recently completed the Mixture and Wet Steam Multiphase Model Training Course. The detailed explanations of different multiphase models and their applications equipped me with valuable insights. The lesson on cavitation has enabled me to improve design considerations for boat propellers. I must say, this course has been extremely beneficial!

MR CFD Support –

We’re thrilled to hear that you found the Mixture and Wet Steam Multiphase Model Training Course valuable and that it added significant insights to your understanding of multiphase flows and cavitation. We appreciate your feedback and look forward to continuing to support your learning journey. Thank you for choosing our course!

Mr. Deven Stamm –

Great course outline. The practical applications really enhance learning. Will it help in simulating the effects of cavitation on ships’ propellers over long periods to predict maintenance schedules?

MR CFD Support –

Yes, the training course provides a comprehensive understanding of cavitation modeling using the Mixture multiphase model, which helps in simulating the effects of cavitation on ship propellers. This knowledge can assist engineers in predicting maintenance schedules by analyzing the material erosion over time due to cavitation.

Grace Thompson IV –

I recently completed the Mixture and Wet Steam Multiphase Model Training Course. The content was extremely informative, well-structured, and the practical examples significantly enhanced my understanding of multiphase flow phenomena. The lessons on cavitation in boat propellers provided valuable insights into industrial applications, while the wet steam model for condensation inside a steam ejector illustrated complex thermodynamic processes clearly. Really appreciated the clear explanation of using proper boundary conditions and introductory theory presented in the first lesson.

MR CFD Support –

Thank you for your kind review! We’re thrilled to hear that the course was able to deepen your understanding of multiphase flows and their application in real-world scenarios. It’s great to know that the examples and theoretical explanations were beneficial to you. We appreciate your acknowledgment of our efforts to make the course both informative and practical.

Pete Willms –

This training course is a gem! I was especially impressed with how lesson 3 tackles the complex phenomenon present in steam ejectors through the Wet Steam model. The level of detail provided in the practical application of these sophisticated CFD models adds immense value to anyone in the field!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the course on Mixture and Wet Steam Multiphase models to be of high value. Lesson 3 indeed covers vital aspects of industrial applications and we’re glad it impressed you. Your feedback is greatly appreciated and motivates us to keep providing quality education. Keep an eye out for more in-depth training courses from us!