Multiphase Models Training Course, ANSYS Fluent

Original price was: $1,100.00.$370.00Current price is: $370.00. Student Discount

Chapter 1:

Chapter 2:

Chapter 3:

Chapter 4:

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Comprehensive Multiphase Models Training Course

Multiphase flows involve two or more phases: liquid, gas, and solid. These flows are complex and can be challenging to model accurately. Fluent is a computational fluid dynamics (CFD) software package that can be used to simulate multiphase flows.

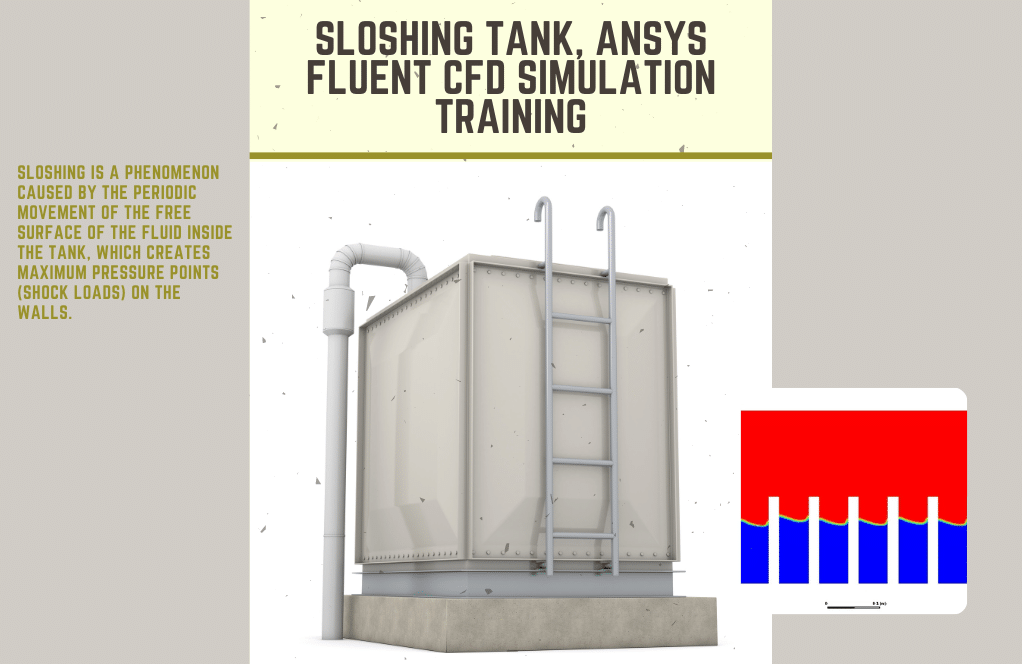

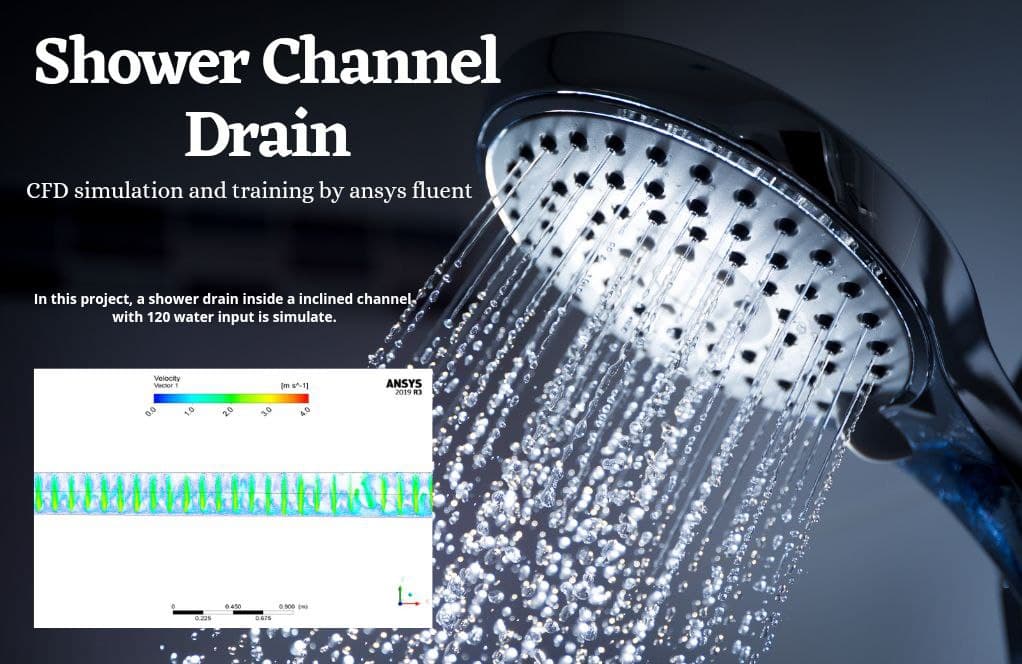

Fluent offers several different models for simulating multiphase flows, including the Volume of Fluid (VOF), Eulerian, Mixture, and Wet Steam models.

The VOF model simulates flows with two or more immiscible fluids, such as oil and water. It tracks the interface between the two fluids and can be used to simulate a wide range of multiphase flows, such as droplet and bubble formation.

The Eulerian model simulates flows with a single fluid containing dispersed particles, such as a gas with solid particles. It tracks the motion of the particles and can be used to simulate flows such as dust clouds and sprays.

The Mixture model simulates flows with two or more miscible fluids, such as air and water vapor. It tracks the motion of the fluids and can be used to simulate flows such as fog and steam.

The Wet Steam model simulates flows with a single fluid containing both liquid and vapor phases, such as steam. It tracks the motion of the liquid and vapor phases and can be used to simulate flows such as boiling and condensation.

In summary, Fluent offers several different models for simulating multiphase flows, including the VOF, Eulerian, Mixture, and Wet Steam models. Each model is designed to simulate a specific type of multiphase flow and can be used to accurately model a wide range of multiphase flows. The Comprehensive Multiphase Flow Training Course will teach you how and where to use them.

Training Course Syllabus

This course contains video lessons and final projects to get a certificate after finishing the course.

Chapter 1: Introduction to Multiphase Flows and their Applications

In the first chapter, we will discuss the basics of Multiphase flows and explain what a multiphase flow is. We will then briefly introduce each of the VOF, Eulerian, Mixture, and wet steam models and bring some examples of their applications in real life or industry. This chapter contains the following subsections:

- Overview of Multiphase flows

- Classification of Multiphase flows

- Multiphase flow regimes

- Eulerian-Lagrangian vs. Eulerian-Eulerian approaches

- VOF model and its applications

- Eulerian model and its applications

- Mixture model and its applications

- Choosing among Eulerian, Mixture, and VOF

- Summary

Chapter 2: VOF Multiphase Model

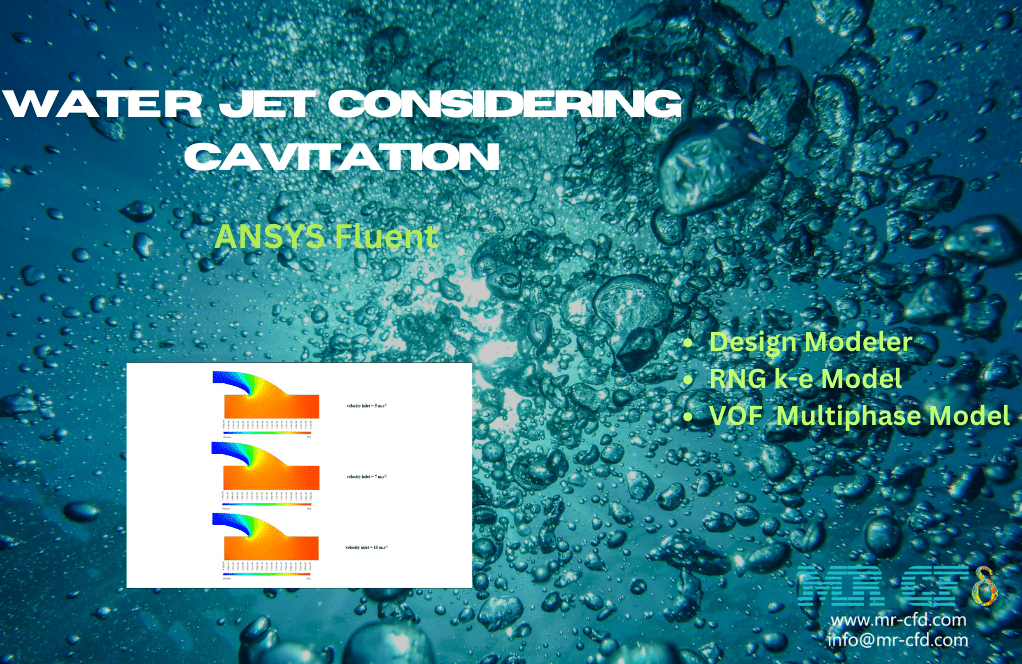

This chapter will cover the basics and physics behind the VOF model. You will first be familiarized with different options and sub-models of the VOF model and some tips and tricks on using them. Thus, based on the taught topics, we will provide practical examples and solve realistic problems using the VOF model. This section contains the following sub-lessons:

Lesson 1

In this lesson, you will first see a general introduction to the VOF Multiphase model. Then an overview of available simulation techniques and sub-models of the VOF in ANSYS Fluent is explained. This section contains the following subsections:

- VOF applications & applicability

- VOF general settings

- Implicit vs. Explicit formulations

- Available discretization methods

- Body force formulation

- Open channel BC

- Interface modeling

- Level set method

- Surface tension modeling

- Mass transfer mechanisms

Lesson 2

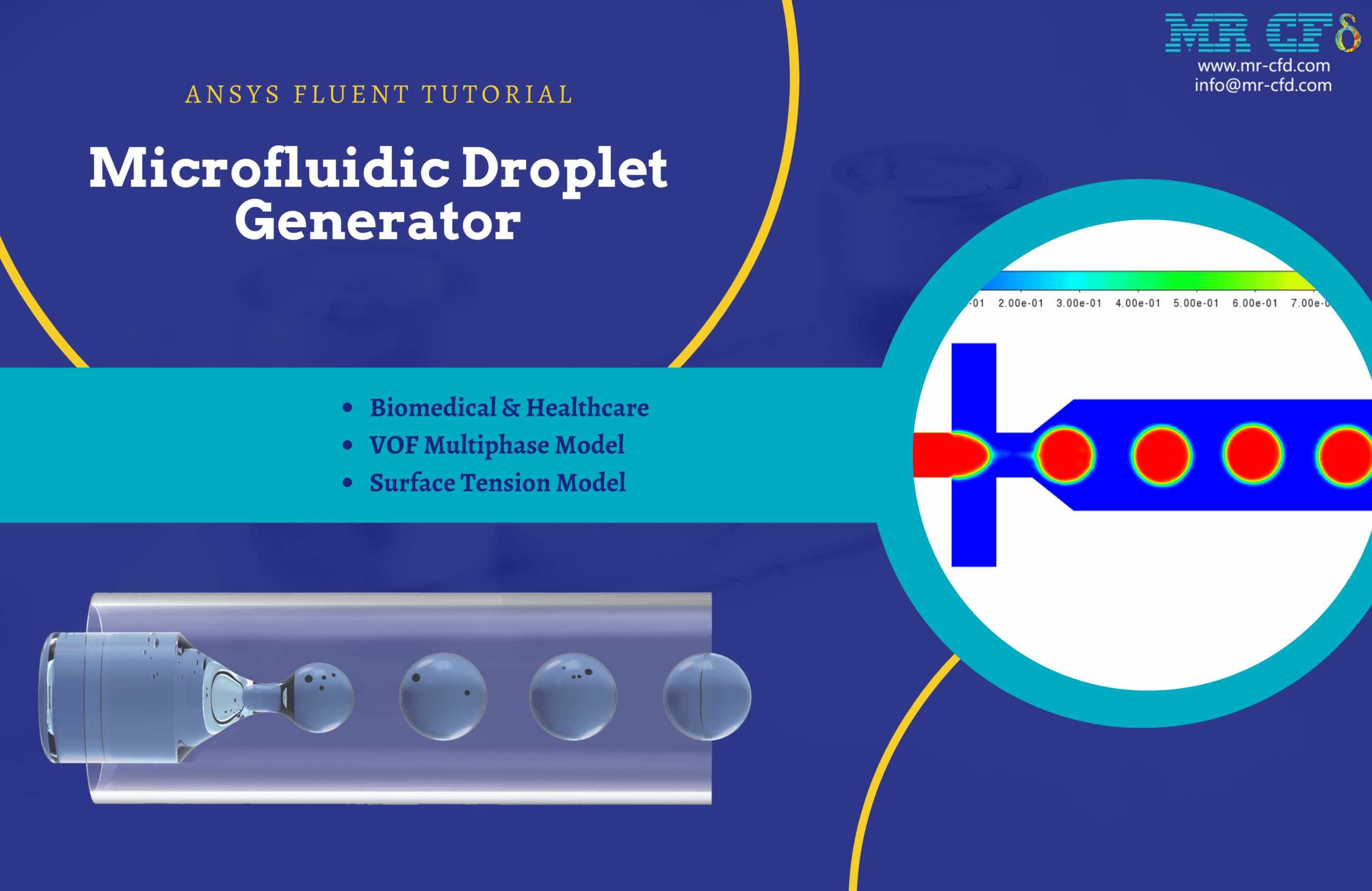

In this lesson, we present a simple, practical example to you. This problem examines the effect of surface tension on flow formation. Namely, we aim to simulate a real-life problem of microfluidic droplet generators.

They are devices used in the biomedical engineering field for quantifying the volume of fluid into micrometer-sized spherical droplets for different types of analyses. You can see how the definition of surface tension will cause a phase to take up a completely different form from its initial state.

Lesson 3

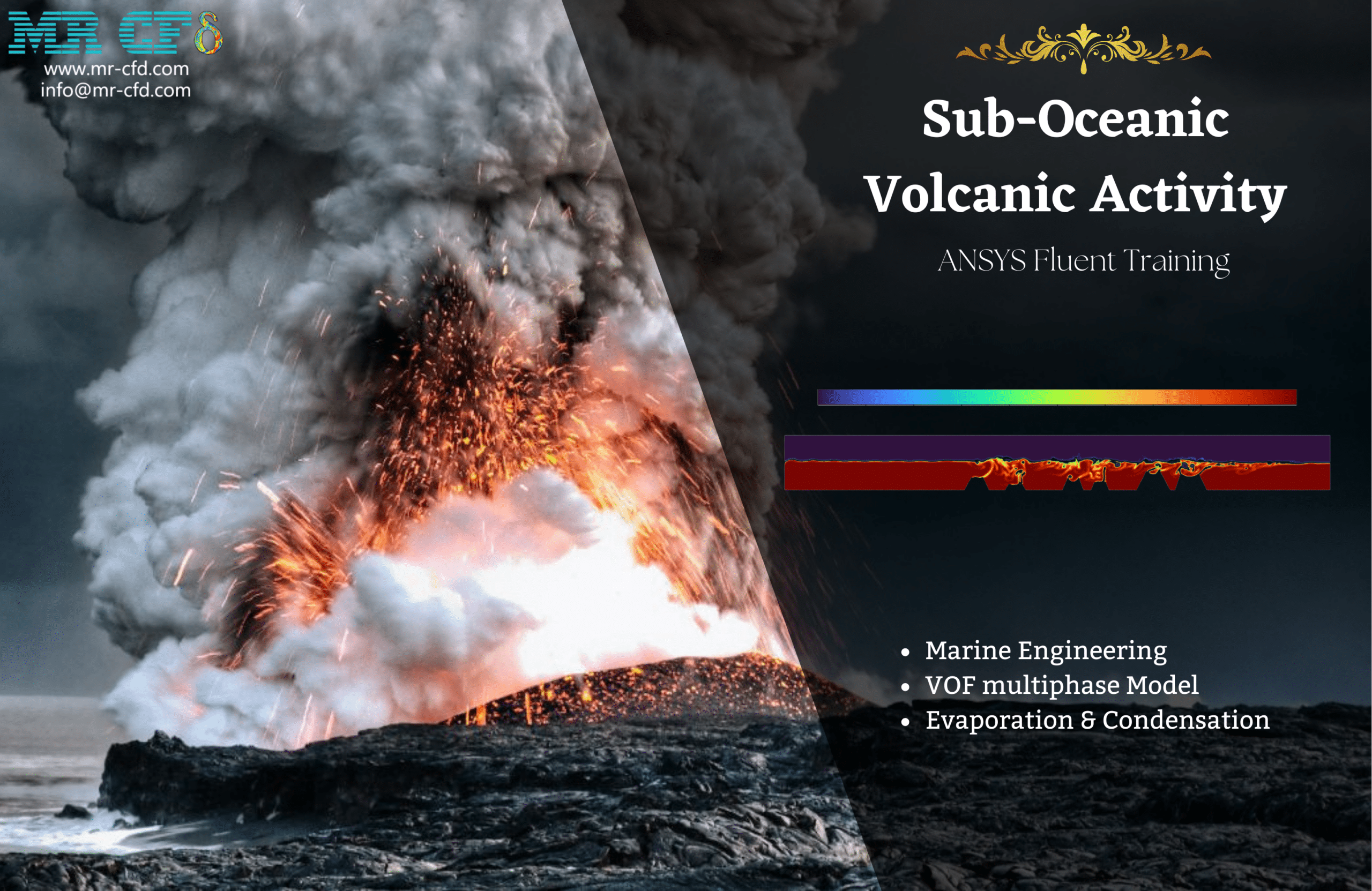

In this lesson, we present a different example from the previous example. This time we are focusing on a very large-scale fluid domain. We will consider a large fluid where multiple sub-oceanic volcanic mountains are placed. The scenario is that the water adjacent to these mountains will reach a boiling state and evaporate due to the volcanic activity of the sub-oceanic mountains.

The formed vapor bubbles will then reach the surface of the water, where the wavy surface will be disrupted due to the motion of vapor bubbles, rupturing the interface of air and water.

Chapter 3: Eulerian Multiphase Model

This chapter will provide an overview of the Eulerian model, including its different options and sub-models. Additionally, we will offer some advice on how to use them. We will provide practical examples and use the Eulerian model to solve real-world problems to demonstrate the concepts. The topics covered in this chapter include:

Lesson 1

In this lesson, you will first see a general introduction to the Eulerian Multiphase model and an overview of available simulation techniques and sub-models of the Eulerian in ANSYS Fluent. This section contains the following subsections:

- Eulerian model applications & applicability

- Regime transition modeling

- AIAD submodel

- GENTOP submodel

- Boiling model

- Interfacial area concentration VS. Algebraic interfacial area

- Applicable forces

- Turbulent interaction & models

- Euler-Granular model

- Summary

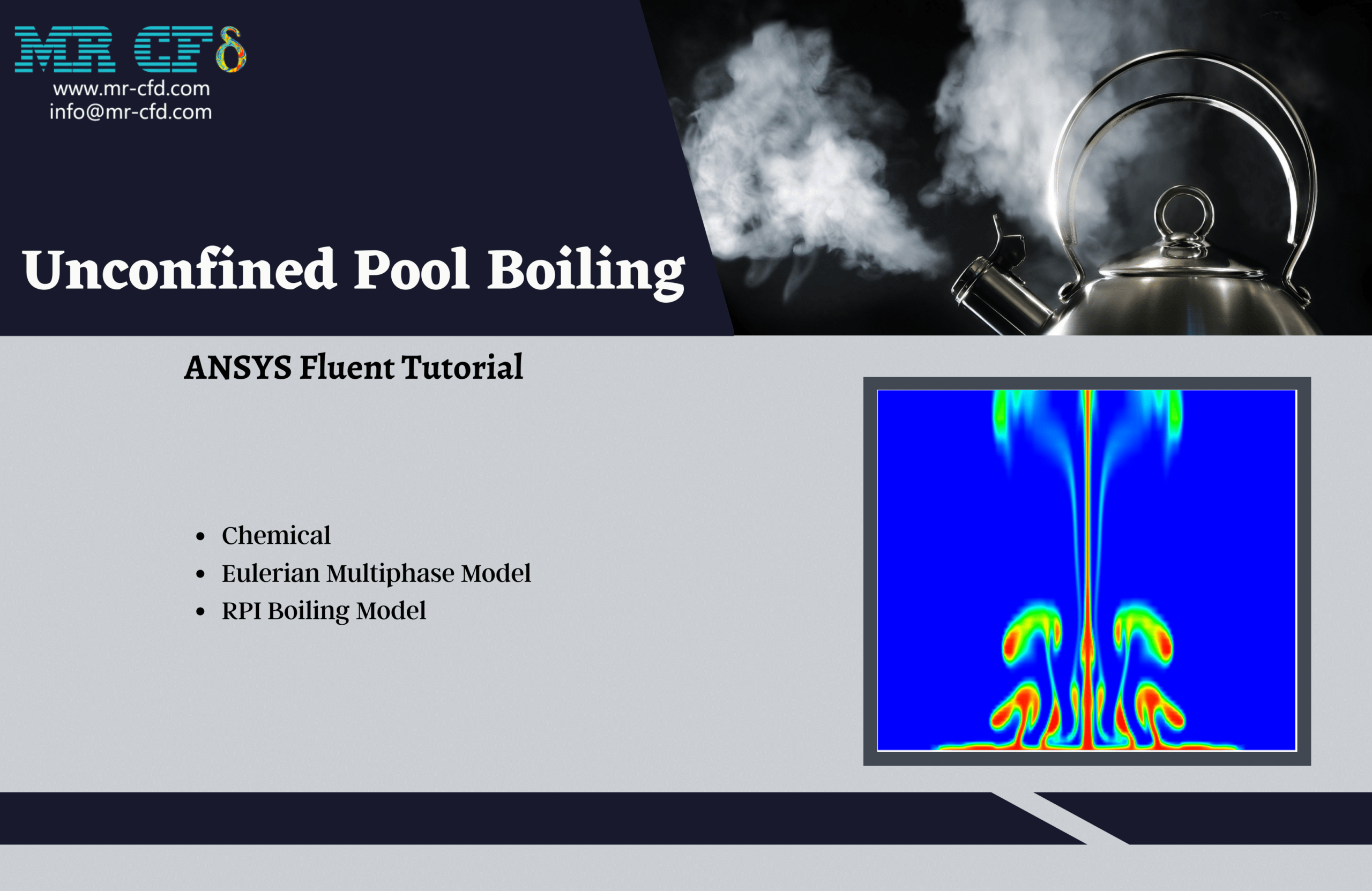

Lesson 2

In this lesson, we present a practical example to you. We will examine the boiling phenomenon in a 2D cylinder (axisymmetric rectangle) and try to observe the generated vapor’s motion.

You will see how to enable the basic RPI boiling model and set up a proper boiling simulation by enabling the mandatory forces and their respective models. We will also show you some tips on obtaining correct numerical results from this simulation, as the boiling simulations are generally a bit tricky to handle.

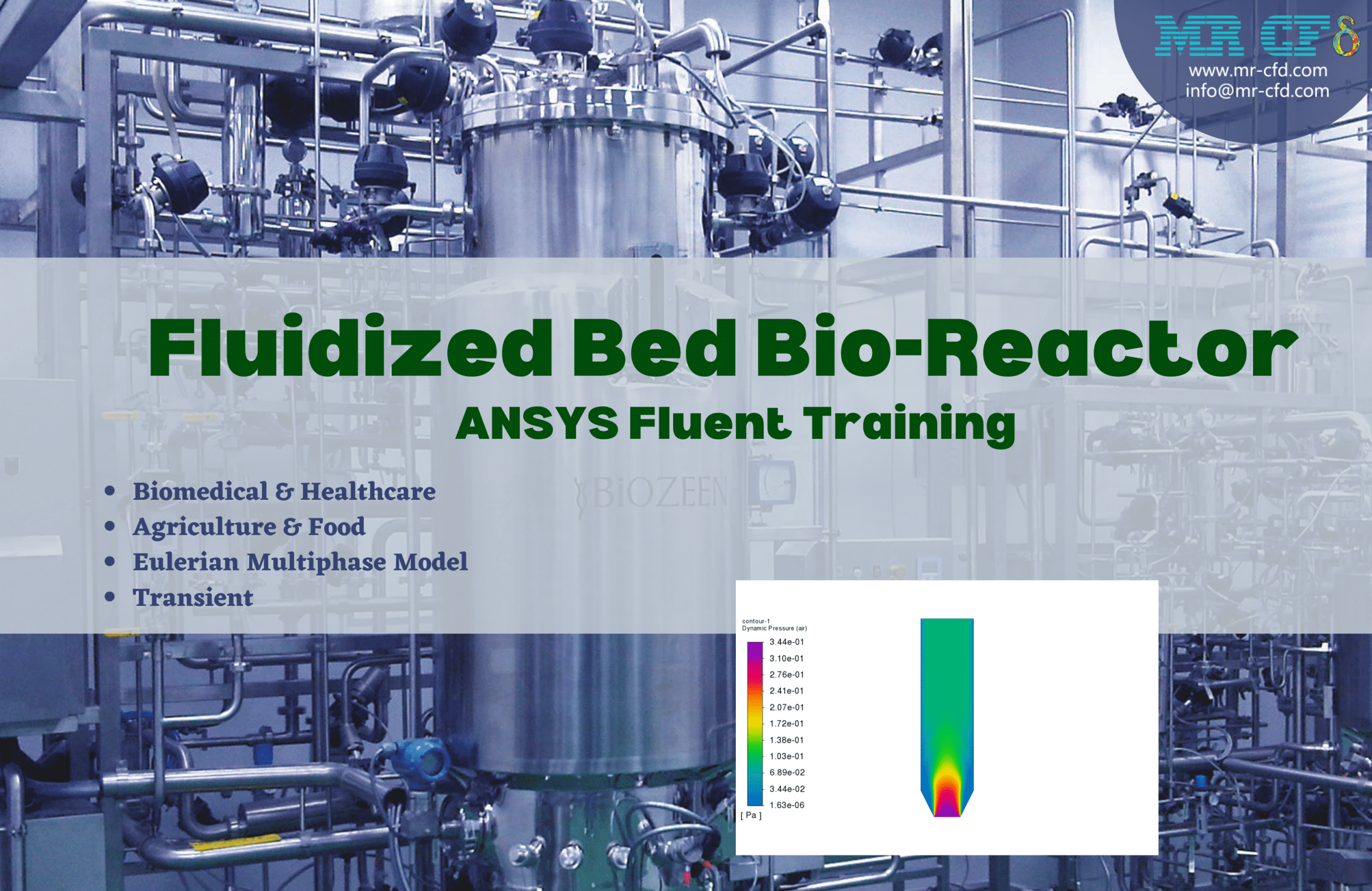

Lesson 3

In this lesson, we present a different example from the previous example. This session will investigate the granular material behavior inside a bio-reactor. We will show you how to set up the proper conditions for granular matter and the available settings and models for granular flows.

Lesson 4

In this lesson, we will delve deeper into the simulation of granular flows by providing an example of packed bed flows. Packed bed flows are fixed regions of solid matter. Here, you will see how the packed bed region, simulated through a granular flow model, can filter another normal granular flow.

This type of application is named the cake filtration process in the industry, where a layer of solid (accumulated particles) accrues on the filter (packed bed region).

Chapter 4: Mixture and Wet Steam Multiphase Models

This chapter will review the fundamentals and science behind the Mixture and Wet Steam models. You will be introduced to the various options and sub-models of the Mixture and Wet Steam models and some helpful hints on how to use them.

Using the Mixture and Wet Steam models, we will then use the topics we learned to provide practical examples and solve real-world problems. This section includes the following sub-lessons:

Lesson 1

In this lesson, you will first see a general introduction to the Mixture and Wet Steam Multiphase models and an overview of available simulation techniques and sub-models of the Mixture and Wet Steam in ANSYS Fluent. This section contains the following subsections:

- Introduction

- Mixture model

- Equations

- Assumptions and Restrictions

- Applications

- Wet steam model

- Assumptions and Restrictions

- Summary

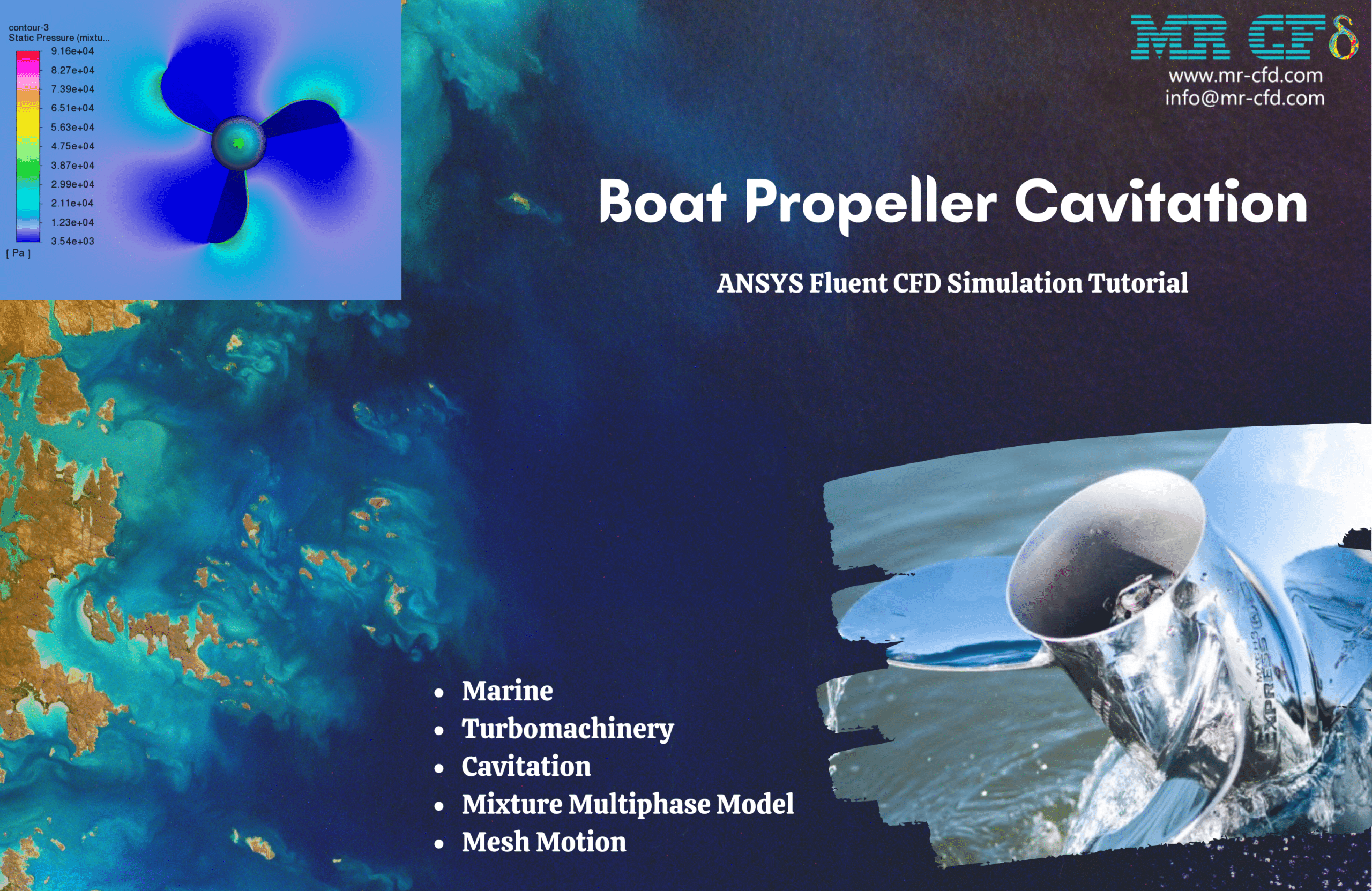

Lesson 2

In this lesson, we will teach you how to simulate the practical problem of cavitation on a boat propeller. The cavitation phenomenon can wear and erode the surface of propellers or pump blades, leading to their destruction sooner than the predicted time.

Hence, by simulating this phenomenon, engineers can alter their design to prevent such incidents from happening. In this session, you learn how to apply the cavitation model using the Mixture multiphase model and how to apply correct boundary conditions to employ this model.

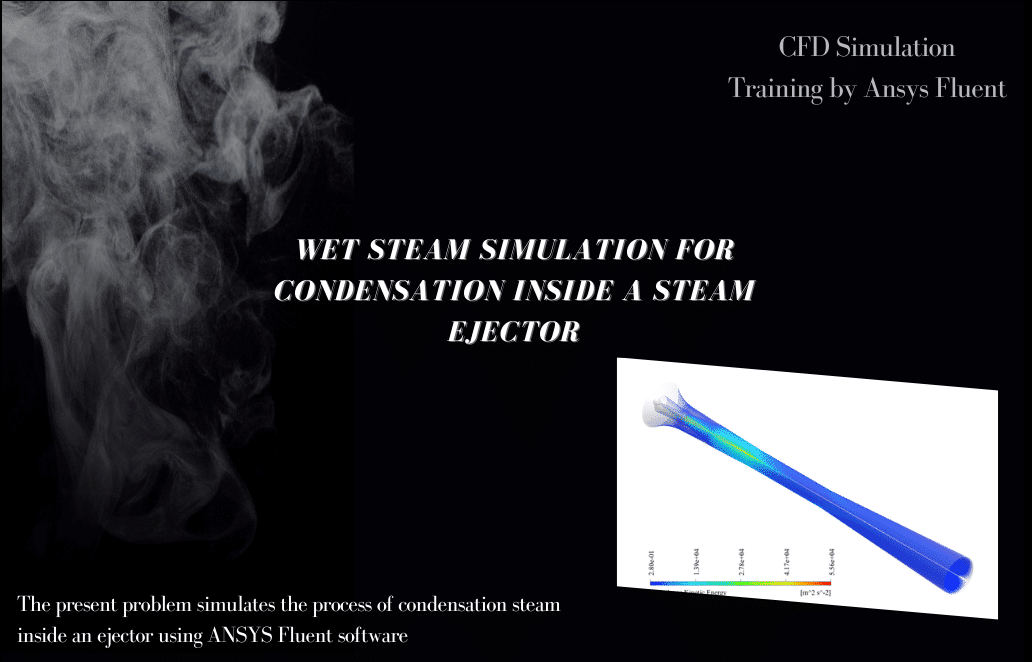

Lesson 3

In this lesson, we present another realistic industrial problem: the formation of water liquid droplets inside a converging-diverging nozzle. The Wet steam model can be used to predict the formation rate of water droplets as the supersaturated dry vapor passes through the throat of a converging-diverging nozzle.

As the supersaturated dry vapor passes through the neck of the nozzle, a sort of shock is applied to the fluid stream, causing the dry vapor to condense into liquid droplets. This phenomenon is studied extensively for many applications such as power plants, biomedical, and food industries.

Mr. Stephon Watsica –

This course seems very comprehensive! For someone new to CFD, would this course be appropriate, or is it meant for users with more experience in fluid dynamics?

MR CFD Support –

The Multiphase Models Training Course is designed to cater to a range of users, from those new to CFD to those with some experience. It builds up from the basics of multiphase flow and progresses to more complex applications, with step-by-step lessons and practical examples. For a beginner, there may be a learning curve, but the course is structured to support that learning process effectively.

Layla Marks V –

The course sounds comprehensive! Is there a way to get support or ask questions if I encounter challenges during the assignments?

MR CFD Support –

Yes, our training course offers support to all learners. If you face any challenges with the assignments, you can reach out through the provided channels in the course platform to get your questions answered by an expert.

Mr. Israel Hauck DVM –

The course content seems very detailed. Can you tell me if it includes any hands-on projects for each multiphase model to apply what’s been learned?

MR CFD Support –

Absolutely! The course includes final projects with practical applications for each multiphase model, where you can apply the concepts and techniques you’ve learned. Completion of these projects will help solidify your understanding and is a requisite for the course certificate.

Dr. Nasir Schmidt –

I enjoyed learning about the different multiphase models, particularly the Wet Steam Model. How important is the accuracy of the initial conditions for these simulations in impacting the final results?

MR CFD Support –

The admin thanks you for your interest. They explain that the accuracy of initial conditions is crucial as it sets the stage for the entire simulation. Any errors or inaccuracies can propagate and lead to significant deviations in the outcome, thus proper validation and verification of input parameters are key for reliable simulations in multiphase models.

Clair Kuhn –

Extremely comprehensive course! The balance between theory and practical examples in the Multiphase Models Training was just right for a hands-on learning experience. Especially useful were the lessons on dealing with complex simulations, like the boiling illustration and granular material handling which were meticulously detailed. Overall, this course has notably boosted my confidence in tackling multiphase simulations in ANSYS Fluent. Highly recommend for anyone looking to delve into multiphase CFD!

MR CFD Support –

Thank you so much for your kind words! We are thrilled to hear that our Comprehensive Multiphase Models Training Course helped enhance your knowledge and skills in multiphase simulations with ANSYS Fluent. We strive to provide detailed and practical examples to ensure a deep understanding of the subject matter. Your recommendation means a lot to us, and we look forward to providing you with more valuable learning experiences. Keep acing those simulations!

Ben Murazik –

Just wanted to say this course on multiphase models is excellent! The combination of theory with practical, hands-on examples really helped deepen my understanding. The step-by-step guidance through various conditions and models, like VOF and Eulerian, is great for complex CFD tasks.

MR CFD Support –

We’re thrilled to hear that you found the Multiphase Models Training Course to be valuable and practical! Thanks for your positive feedback. It is wonderful to know that the structured guidance and real-life examples enhanced your learning experience. We appreciate your enthusiasm for the course, and it’s encouraging for us to hear about its impact on your understanding of CFD. Thank you for taking the time to share your experience.

Golda Ondricka DVM –

I completely enjoyed the Multiphase Models Training Course by MR CFD and found the mix of theoretical backgrounds, practical tutorials, and industry-based examples invaluable. Because of this course, I can now confidently apply multiple phases’ modeling techniques in a variety of real-life situations. The instructors explained complex models like VOF, Eulerian, and Mixture with such clarity that it enhanced my understanding manifold. I will certainly recommend this course to my colleagues.

MR CFD Support –

Thank you for your thoughtful review, and we’re thrilled to hear that you found the course comprehensive and valuable. At MR CFD, we strive to provide content that balances theory and practical application, and it’s wonderful to know that you can now confidently apply the models to real-world situations. We appreciate you recommending the course to others and look forward to continuing to support your learning journeys in the field of CFD.

Susanna Wiegand –

I really enjoyed the Multiphase Models Training Course by MR CFD. The lessons were informative, and the practical examples helped me understand the complex concepts of multiphase flows.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you found the course informative and helpful. It’s always our goal to provide clear and practical examples to enhance understanding. We appreciate your review and are glad to have been able to assist in your learning journey.

Clyde Waelchi –

Initially, I encountered difficulties understanding how to implement the VOF model’s settings correctly. The training course did an excellent job teaching that, but one thing I am still struggling with is how to choose the right values for the surface tension coefficient in different situations. Could you provide me with some guidance on this?

MR CFD Support –

The choice of the surface tension coefficient in simulations using the VOF model depends on the fluid properties and the system you are studying. Typically, values are taken from experimental data or literature. For common fluid pairs like air-water, standard values can be used directly. However, for complex fluids or when precise simulation is necessary, experimental measurements specific to your setup should be applied. If you’re unsure about the values, sensitivity tests can help in determining the impact of the surface tension coefficient on your simulation outcomes.

Murl Turner –

This course sounds comprehensive, but I’m wondering if it includes any kind of user support or forum for discussion in case I have questions while going through the material.

MR CFD Support –

The course indeed provides user support. You’ll have access to a forum for discussion, where you can ask questions, get technical support, and interact with other users and experts who can assist with your inquiries throughout the learning process.

Mrs. Ally Shields –

I’m quite intrigued by the various multiphase models, but I’m curious if the Mixture and Wet Steam models account for changes in phase due to temperature variations within the flow?

MR CFD Support –

Yes, the Mixture and Wet Steam models do take into account the phase change that occurs due to temperature variations within the flow. The Wet Steam model, in particular, is designed to handle the transition between liquid and vapor phases, and it includes mechanisms for boiling and condensation based on temperature changes. The Mixture model is typically applied to miscible fluids and can also model temperature effects on phase distribution within the flow.

Reginald Schuster –

What exactly does the ‘Mixture model’ cover, and is it suitable for industrial multiphase problems like oil and water pipeline simulation?

MR CFD Support –

The Mixture model in ANSYS Fluent is designed to handle multiphase flows with miscible components. It uses a mixture average approach to solve the conservation equations based on mixture properties. While suitable for industries, whether it’s the best fit for oil and water pipeline simulations would depend on the specifics of the interaction between the fluids. In some cases of immiscible fluids like oil and water, the Volume of Fluid (VOF) model might be recommended instead due to its ability to track the interface between immiscible fluids. The Mixture model is generally used for fully mixed or partially mixed flows where phases are not separated by sharp boundaries.

Laury Paucek DVM –

I find the scope of the Multiphase Models Training Course really comprehensive. It addresses a broad spectrum of simulation scenarios. Are the lesson examples based on generalized cases, or do they include industry-specific studies?

MR CFD Support –

The course combines both generalized cases and industry-specific studies to give students a broad understanding of the multiphase models as well as direct applications in real-world scenarios. With each example presented, the course strives to link the theories and models to tangible applications in various industries such as engineering, biomedical, and food industries to ensure a practical learning experience.

Antone Von –

The course content is comprehensive and well structured, providing all the tools to model complex multiphase problems. Kudos to the team for putting together such quality resource material!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear our Comprehensive Multiphase Models Training Course met your expectations and provided valuable insights into CFD multiphase simulations. Your appreciation means a lot to us!

Brandi Treutel –

I just finished the Multiphase Models Training Course and am blown away by the depth and clarity of the content! The lessons were well-structured, with practical examples that solidified my understanding. The numerous real-world applications have definitely boosted my confidence in using the models for my work in CFD.

MR CFD Support –

Thank you for sharing your positive feedback on the Multiphase Models Training Course! We are thrilled to hear that you found the course well-structured and filled with relevant examples that enhanced your understanding and confidence in using CFD multiphase models. It’s our goal to provide high-quality and practical learning experiences for our customers, and we are pleased to know we’ve succeeded with you. Thank you for choosing our course for your learning needs!

Dr. Larissa Keeling II –

Does the course include materials or tutorials on how to deal with phase change in multiphase flow models, like the boiling and condensation processes?

MR CFD Support –

Yes, the course does cover phase change phenomena. For example, in the lesson on the Eulerian Multiphase Model, you’ll explore the boiling phenomenon with a practical example involving a 2D cylinder. The course will demonstrate setting up a proper simulation for boiling using the RPI model, and it includes guidance on handling the complexities of boiling simulations in ANSYS Fluent.

Rebecca Romaguera –

This course looks extensive! I’m wondering though, does the course offer any hands-on training or practical exercises to solidify the learning?

MR CFD Support –

Yes, the Multiphase Models Training Course provides practical examples and lessons where you can apply the theories you learn. You have the opportunity to work on final projects which are essential for reinforcing the knowledge and skills gained from the course.

Brendon Batz –

After completing this course, will participants also receive hands-on guidance for setting up their own CFD simulation projects in ANSYS Fluent?

MR CFD Support –

Yes, the training course provides video lessons, practical examples, and projects allowing learners to apply the theoretical knowledge into setting up their own CFD simulation projects in ANSYS Fluent. Participants can gain hands-on experience, which is essential for understanding and mastering the multiphase models.

Dr. Tre Schulist –

I’ve just completed the Multiphase Models Training Course and it was simply fantastic! The course was thorough, well-structured, and provided a deep dive into the theoretical concepts and practical applications of multiphase flows. What I appreciated most were the real-world examples given in each chapter which made the complex topics very relatable and easier to grasp. The step-by-step guidance for setting up the simulations in ANSYS Fluent was also exceptional. It helped me to not only understand how to use each model but also when to apply them. The video lessons were clear and the lecturers are truly knowledgeable. A job well done by the MR CFD team!

MR CFD Support –

We’re overjoyed to receive such positive feedback! Your satisfaction as a customer is paramount to us, and we are thrilled that the Multiphase Models Training Course met your expectations. Thank you for recognizing the efforts we’ve put into creating comprehensive and applicable content. If there is more we can support you with or another course you’re interested in, don’t hesitate to reach out. Looking forward to your continued engagement with our products!