Multiphase Flow in Porous Medium, Filter Cake Formation, ANSYS Fluent CFD Simulation Training

$160.00 Student Discount

- The problem numerically simulates the Multiphase Flow in Porous Medium using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- the mesh type is Structured, and the element number equals 572852.

- We perform this simulation as unsteady (Transient).

- We use the Eulerian Multiphase model to define a two-phases flow.

- We use the Porous medium in cell zone condition.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The problem simulates multiphase flow in a porous medium using ANSYS Fluent software.

The model is designed in two parts: In the upper part of the column, there are water-soluble particles, and in the lower part of the column, the porous medium is located. Initially, there is a solution with a volume fraction of 0.185 of the particles in the water.

By entering the water flow from the top of the column, applying pressure to the mixture inside the column, and passing through the pores of the porous medium, the soluble particles are separated from the water flow.

The present model is designed in two dimensions using Design Modeler software. The model is designed as a column with a height of 0.08 m and a width of 0.0125 m. The computational area is divided into two parts So that the lower part of the column is related to the porous medium.

Due to the symmetrical structure of the model geometry, only half of the geometry is modeled, and a symmetry boundary condition is used.

We carry out the model’s meshing using ANSYS Meshing software, and the mesh type is structured. The element number is 572852.

Multiphase Flow Methodology

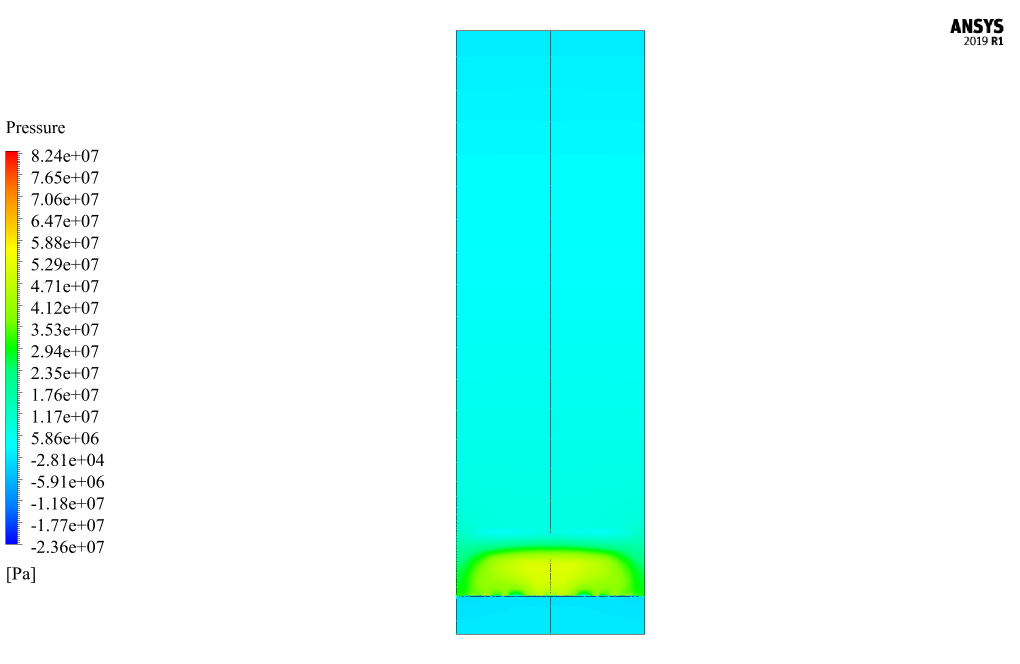

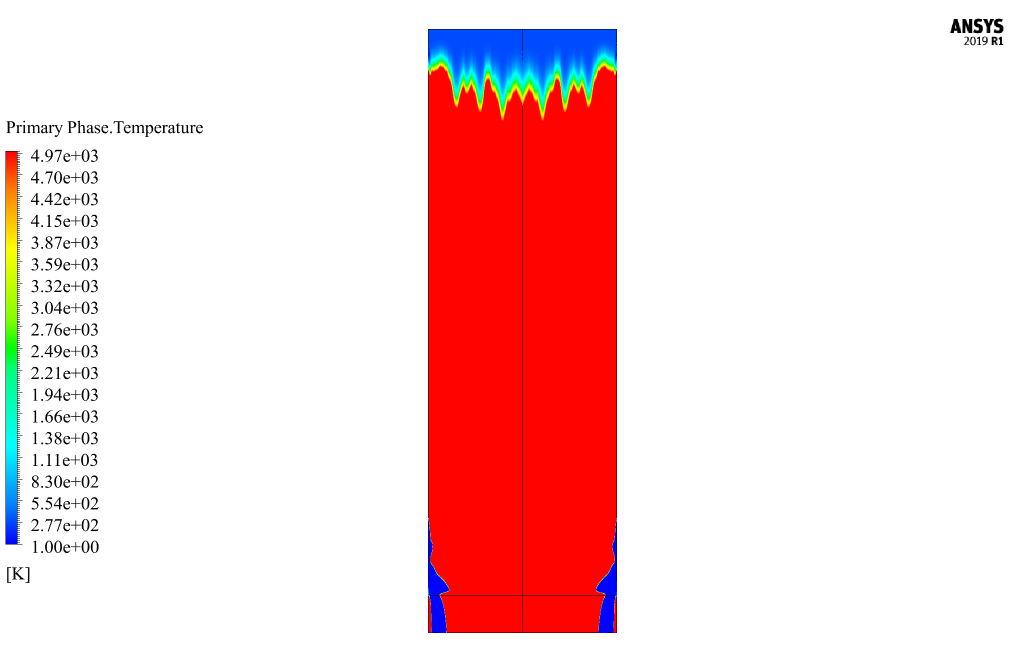

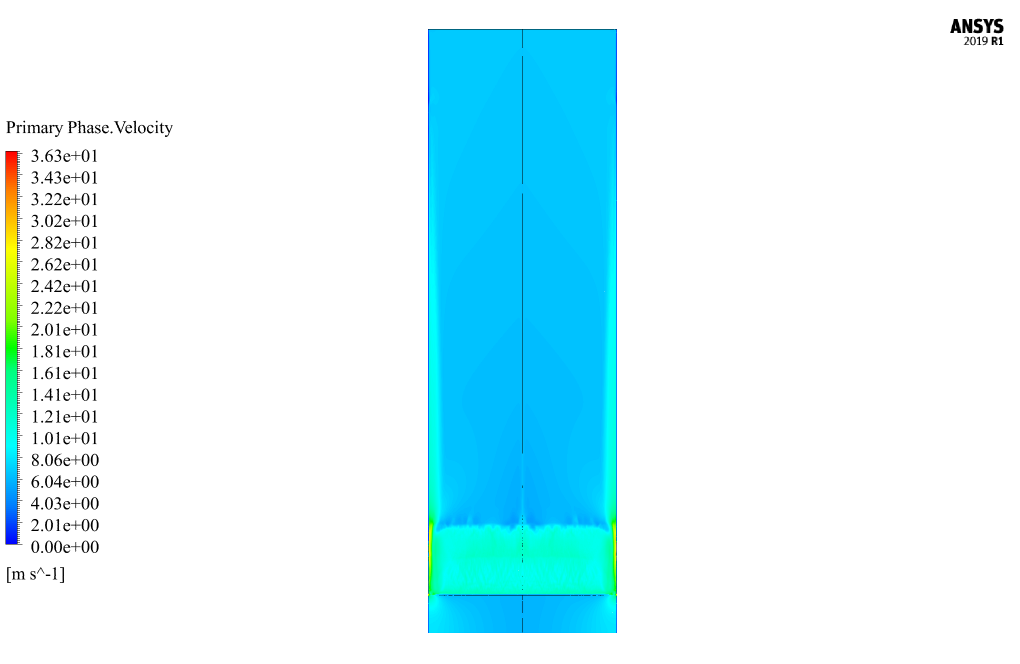

Water flow with a relative pressure of 100,000 pascals and a temperature of 288.15 K enters from the top of a vertical column. It enters a porous medium at the end of the column.

This porous medium is made of aluminum and has a porosity coefficient (ratio of the volume of cavities or fluid space to the total volume) equal to 0.6. Since two phases are mixed in this project, a multiphase flow must be defined.

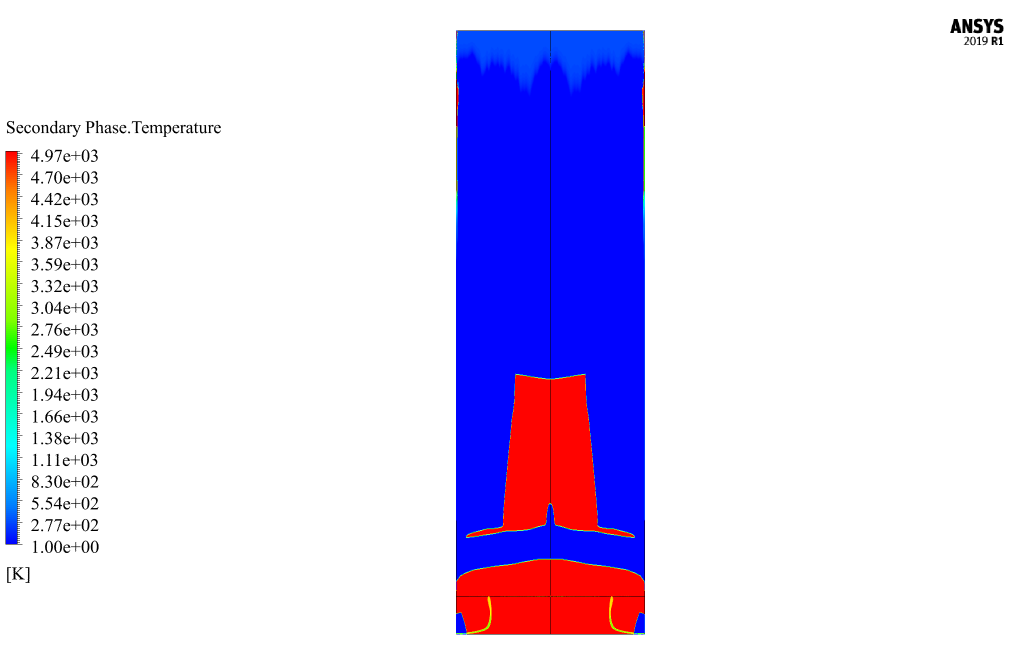

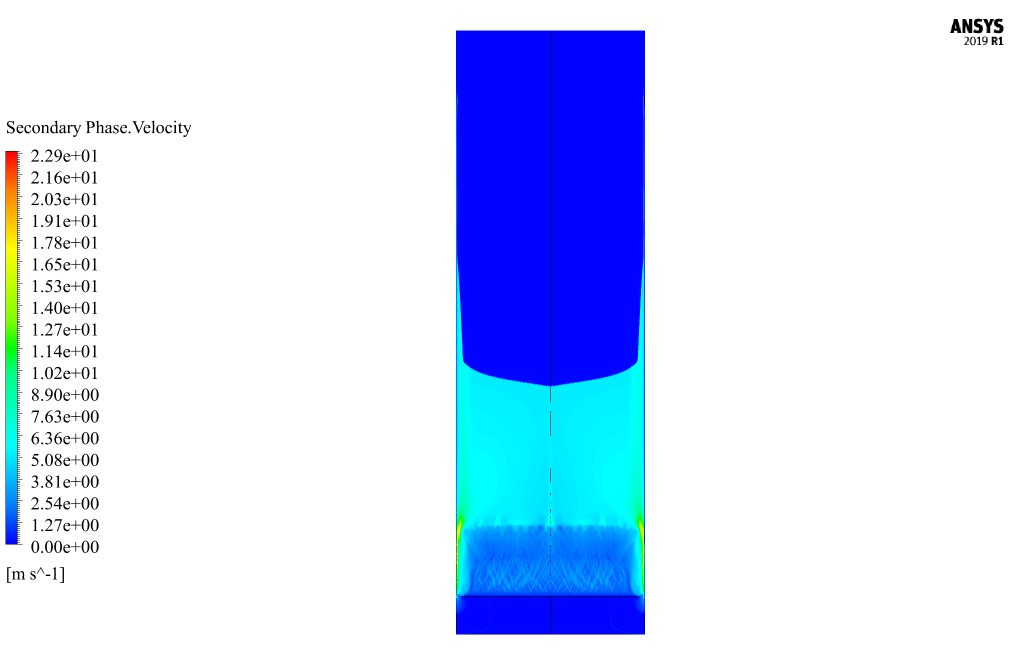

Therefore, in the present simulation, a multiphase model is used, So that its primary phase is liquid water and its second phase is water-soluble particles (sludge).

The secondary phase is defined as having a density of 2400 kg/m3, a specific heat capacity of 4180 j/kg.K, a thermal conductivity of 0.0454 W/m.K, and a viscosity of It is based on the power law. To define the multiphase model, the Eulerian model is used.

This model is the most complex multiphase software model and can solve a set of momentum and energy equations for each phase separately.

The eulerian multiphase model simulates such things as bubble flows, droplet flows, vertical risers, cyclones, fluidized beds, bubble columns, slurry flows, sedimentation phenomena, and particle suspension phenomena. Also, the simulation is Transient.

Multiphase Flow Conclusion

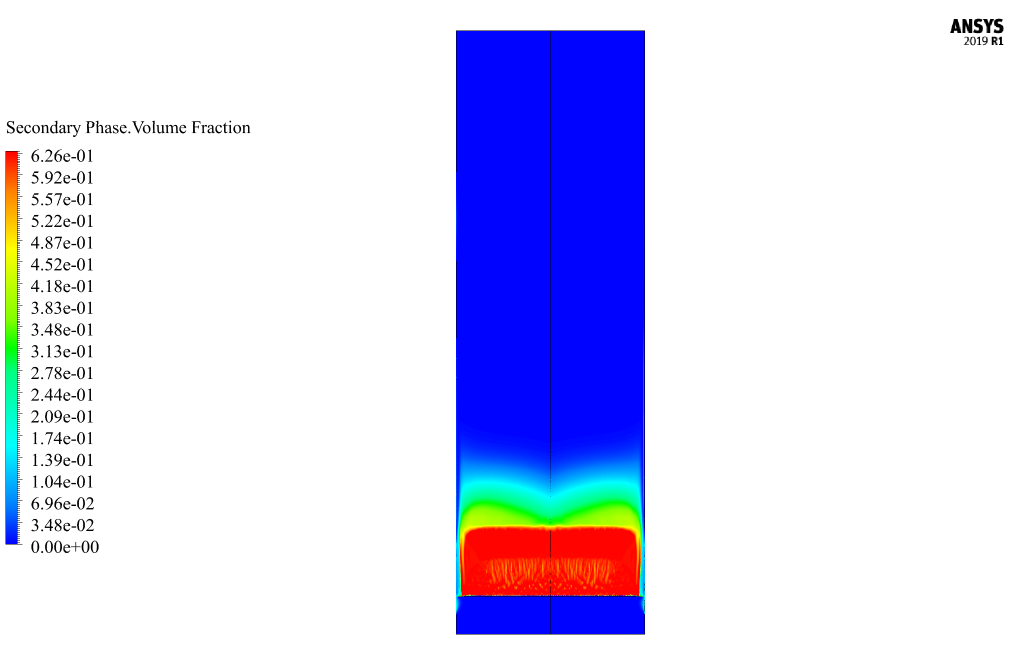

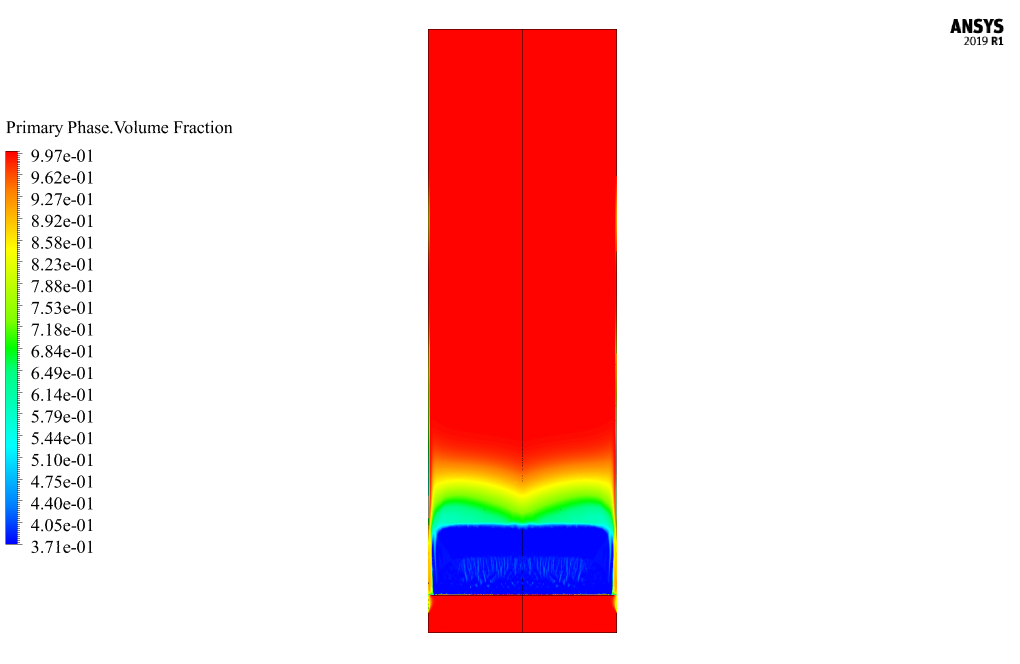

At the end of the solution process, two-dimensional contours related to the mixture pressure, primary phase velocity, primary phase temperature, primary phase volume fraction, secondary phase velocity, secondary phase temperature, and secondary phase volume fraction are obtained.

The results show that when the water flow inside the column moves downwards, the mixed flow moves towards the porous medium. The behavior of the mixture indicates that the water-soluble particles do not pass through the porous medium and only the water flow passes.

As a result, the soluble particles are separated from the water flow, leading to cake filtration.

Koby Stanton –

What are the potential applications of this simulation?

MR CFD Support –

This simulation has a wide range of applications, including but not limited to, oil recovery, groundwater remediation, and chemical processes. It can help in understanding and optimizing these processes.

Otilia Veum –

How can I customize the simulation for my specific needs?

MR CFD Support –

The simulation can be customized by changing the properties of the fluids and the porous medium according to your needs. You can also modify the boundary conditions to match your specific situation.

Lucius Bechtelar –

I have some ideas to improve this simulation. Can I contribute?

MR CFD Support –

We are always open to contributions and would love to hear your ideas. Your insights could help us improve our simulations and provide better solutions to our users. Thank you for your interest and support!

Mia Boyle –

Thanks so much for providing a comprehensive training product on multiphase flow in porous media! The details were clear and the simulation steps were easy to understand, especially appreciating the real-time detail on filter cake formation!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that the training on multiphase flow in porous media was clear and understandable for you. We always strive to provide detailed and comprehensive instruction to help our customers succeed in their simulations. Should you have any further questions or need additional assistance, please don’t hesitate to reach out.

Naomi Johns –

The review content itself was refreshing and the detailing on methodology and conclusion provides a clear insight into the scope and results of the simulation training. Well done MR CFD Company for a comprehensive educational package! Thumbs up!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the information provided in the tutorial helped you gain a clear understanding of multiphase flow in porous media simulation using ANSYS Fluent. We appreciate your acknowledgment of our efforts to produce comprehensive educational materials. If you have any further queries or require additional learning resources, feel free to reach out!

Ms. Andreanne Wyman –

This simulation sounds quite detailed. Which step in the process calculates the filter cake formation exactly, and how do we visualize this in the results?

MR CFD Support –

Filter cake formation is calculated during the passage of the mixed flow through the porous medium. As the water flow carries the particles downwards, the porous medium traps the water-soluble particles, leading to the formation of a deposit layer or ‘filter cake’ on its surface. We visualize filter cake formation using the secondary phase volume fraction contours. These contours clearly show the area where particles are filtered out from the water, indicating the thickness and uniformity of the filter cake over time.

Mrs. Maiya Casper DDS –

The process for separating particles from the water flow was clear and well-explained. Your expertise in simulating such complex phenomena certainly shines through in your training product. It sounds like a comprehensive and informative resource for understanding filter cake formation in porous media. Great job!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our simulation training on multiphase flow in a porous medium and filter cake formation was helpful and clear. Our goal is to provide insightful and practical learning experiences through our CFD simulations. If you have any more feedback or require further assistance, don’t hesitate to reach out. We appreciate your support!

Jamal Mann –

The tutorial was incredibly comprehensive and well-structured. I specifically appreciated the clear breakdown of different phases and the simulation of filter cake formation, which mirrored actual industrial processes accurately. Great job translating a complex subject into an accessible learning experience!

MR CFD Support –

Thank you so much for your positive feedback! We are delighted to hear that you found the tutorial comprehensive and helpful for understanding the complex process of filter cake formation using CFD simulation. Your appreciation motivates us to continue providing high-quality learning materials. If you ever have any questions or need further assistance, please don’t hesitate to reach out. Thank you for choosing our training!

Heather Pfeffer –

Could you explain how the multiphase flow in porous medium CFD simulation works?

MR CFD Support –

The multiphase flow in porous medium CFD simulation models the behavior of different phases – like gas, liquid, and solid – within a porous structure. The simulation uses mathematical equations to describe the interaction between the phases and the porous medium, providing valuable insights into the process.

Prof. Arlie Roberts –

This training sounds complex! Could you elaborate on how the power law is applied to the viscosity of the secondary phase in this scenario?

MR CFD Support –

In this simulation, the power law is used to describe the rheological behavior of the sludge—the secondary phase consisting of water-soluble particles. The power law model for viscosity allows for the variation of viscosity with the shear rate, accounting for non-Newtonian behavior common in sludges and similar materials. In ANSYS Fluent, this involves defining Power Law indices and constants that dictate how the viscosity changes in response to different flow conditions within the porous medium.