Water Spraying Considering Breakup and Evaporation

$180.00 Student Discount

- The problem numerically simulates the Water Spraying using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- We use the discrete phase model (DPM) to define a Spray process.

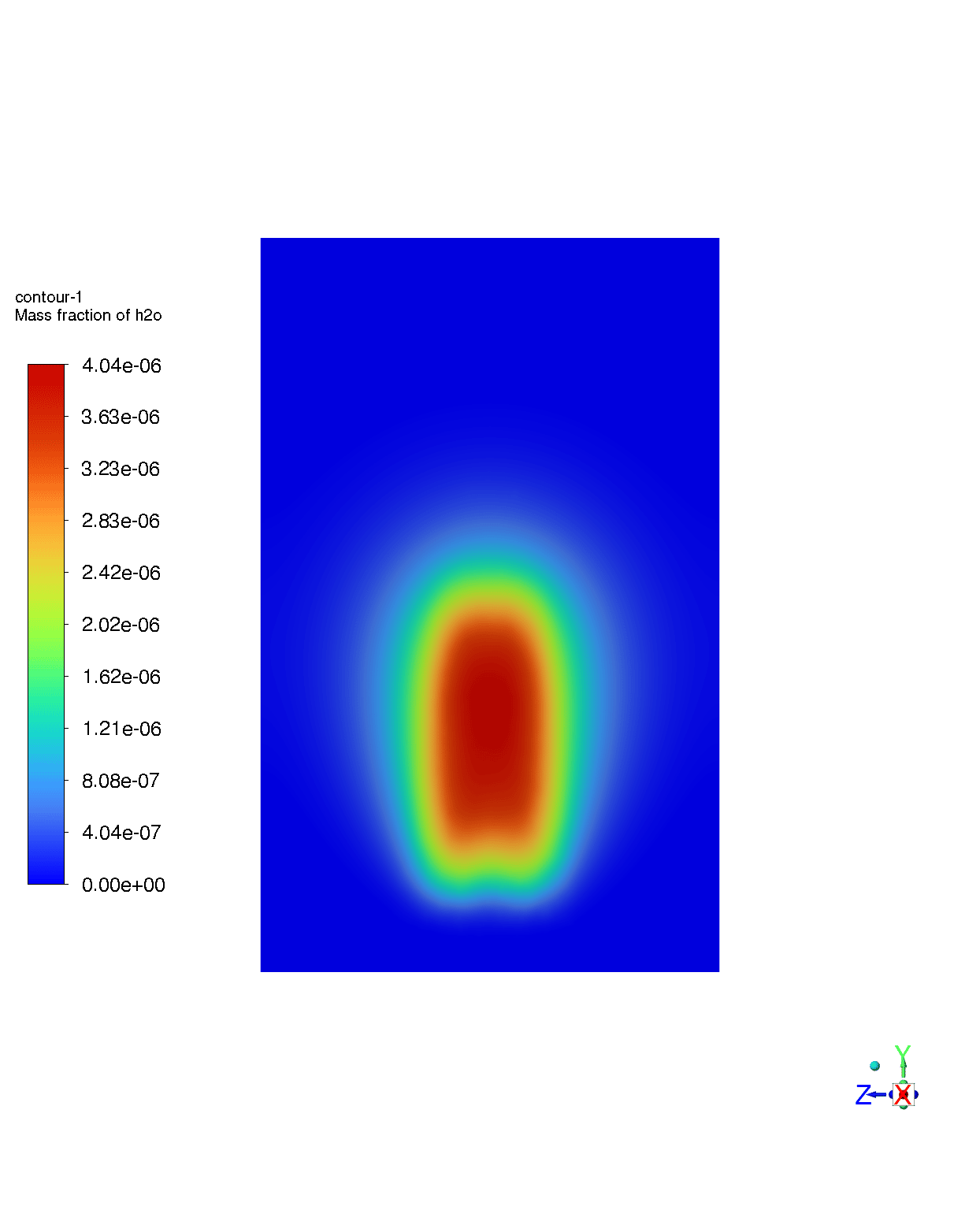

- The Species Transport is defined to select Evaporative Droplet injection for particles.

- Breakup & Coalescence are considered.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description(Water Spraying Considering Breakup and Evaporation Using Discrete Phase Model (DPM)), ANSYS Fluent Tutorial

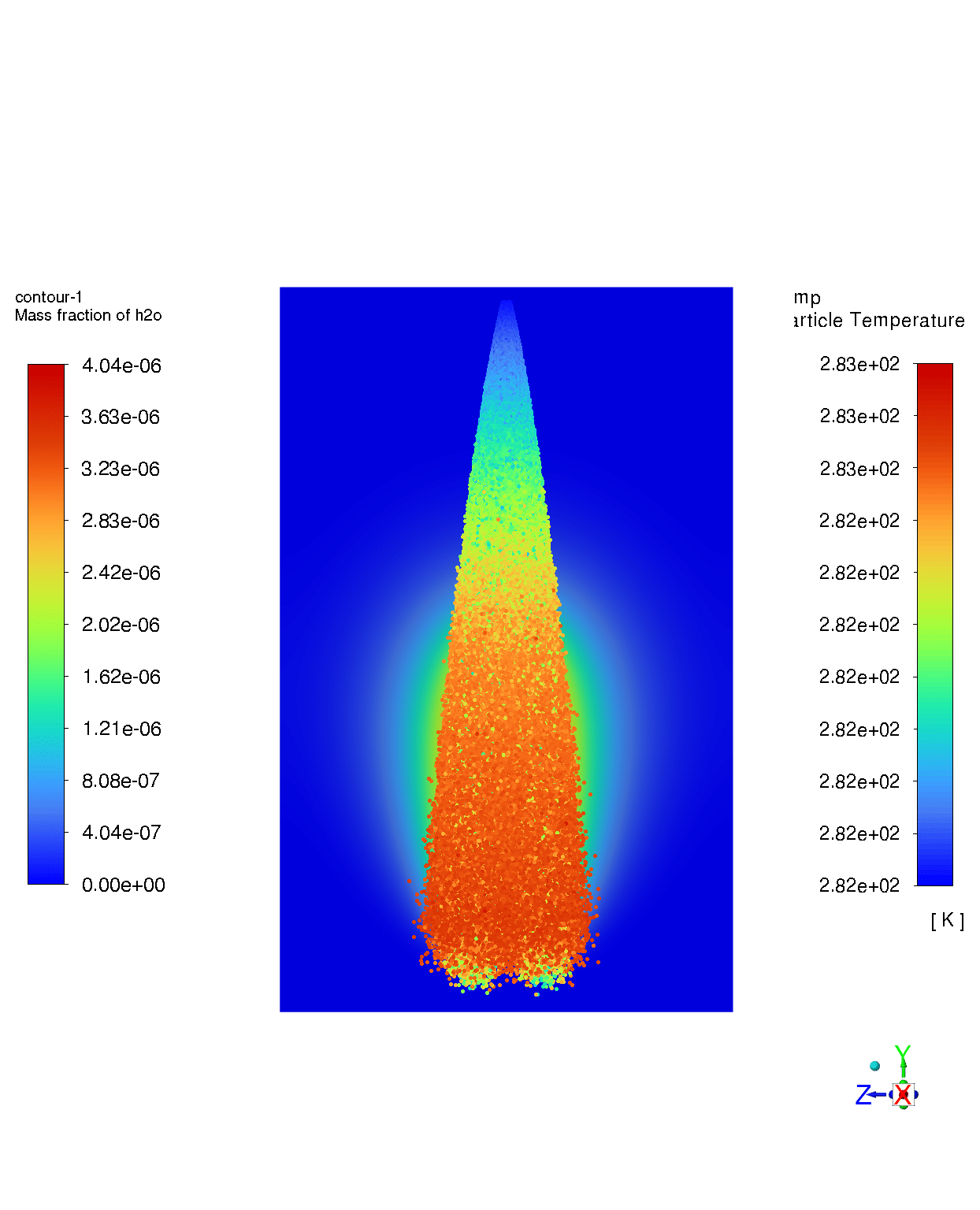

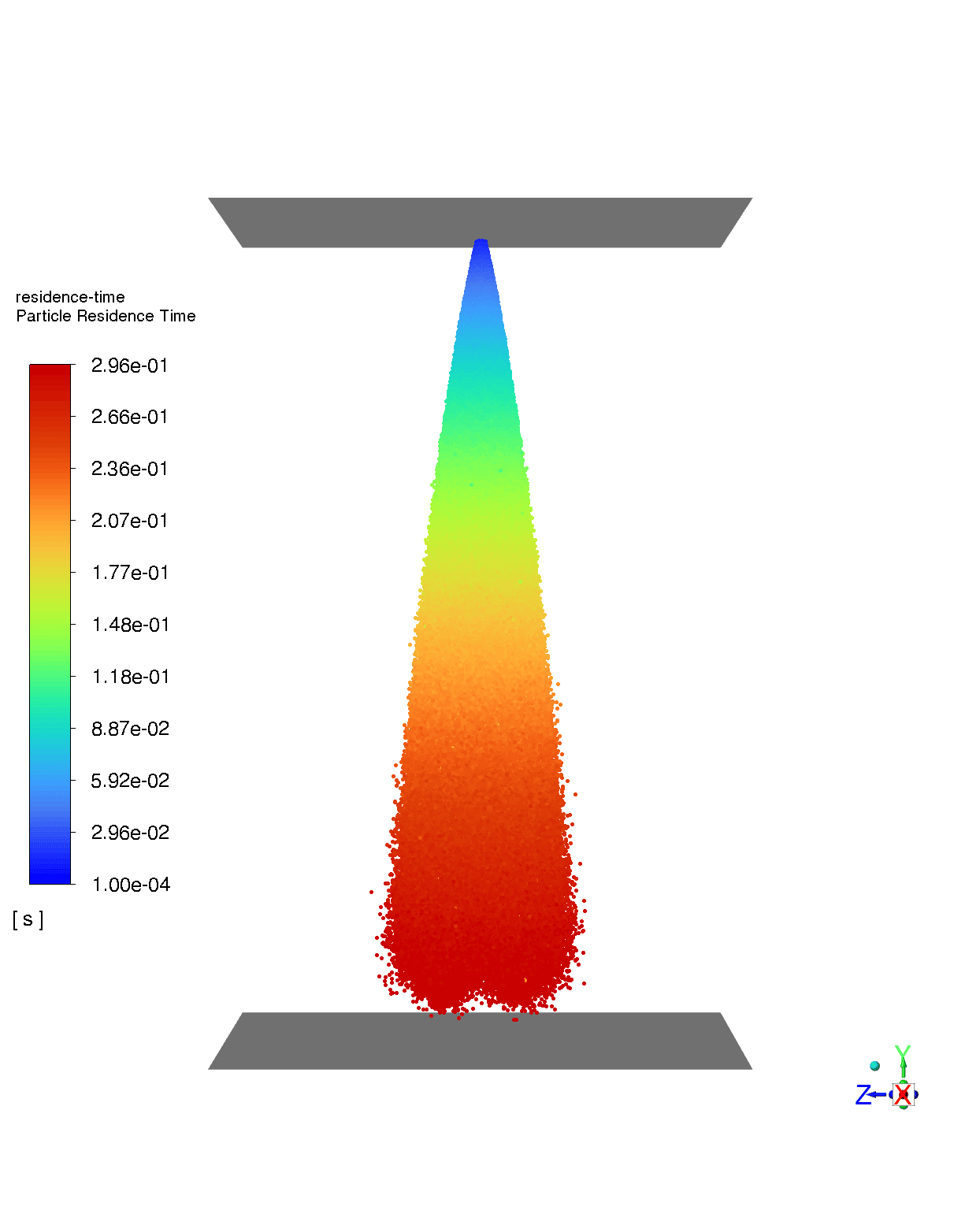

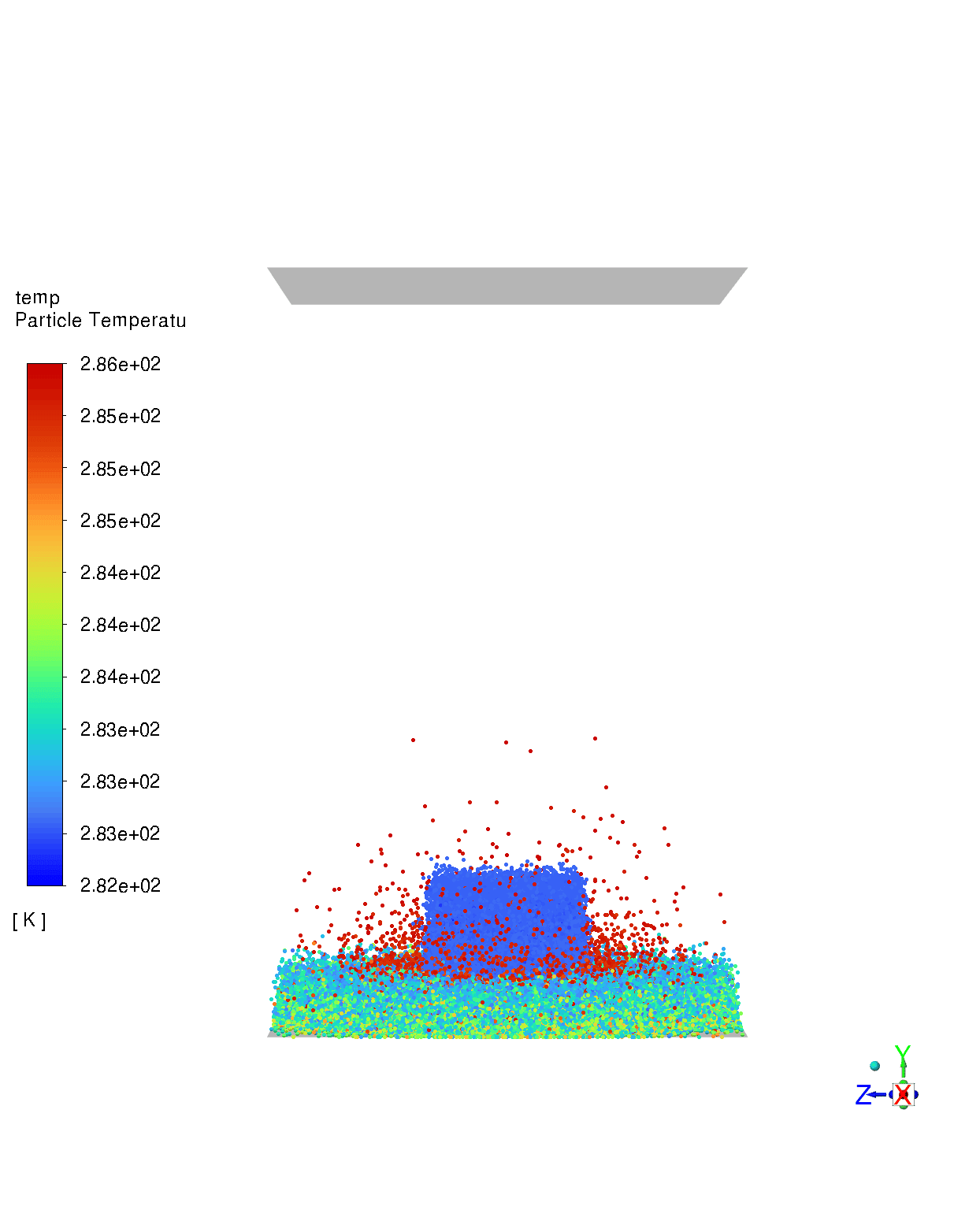

In this project, we aim to simulate the water spraying from a nozzle considering the breakup of droplets and evaporation using the Discrete Phase Model (DPM) and Species Transport model. It can be claimed that this simulation is the most accurate spraying procedure modeling which considers all details.

This product is the 3rd chapter of the DPM training course.

Methodology: Water Spraying DPM simulation

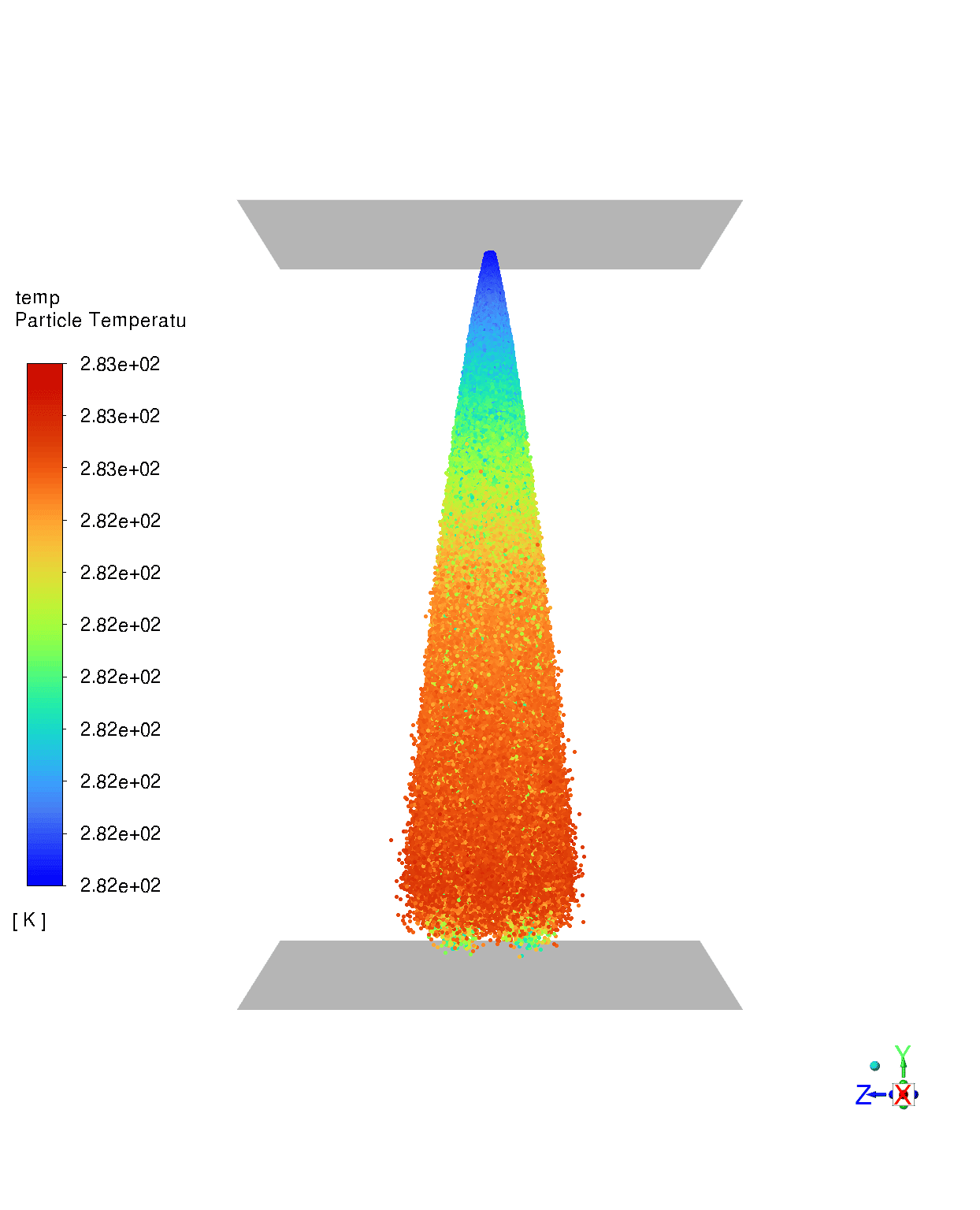

The 2 mm diameter water droplets are injected with 1.25 m/s velocity from the nozzle. The environment is warmer than the droplets, so when the temperature of the droplet reaches 282.5K, evaporation takes place. In addition, stochastic collision & coalescence, and droplet breakup are considered by using the Taylor analogy breakup model (TAB).

In the spraying process, the droplets are distorted and their shape doesn’t remain spherical. On the other hand, the drag coefficient strongly depends on droplet shape. Thus, dynamic-drag drag law and Discrete Random Walk Model are used. Furthermore, the floor has a Wall-film DPM boundary condition leading to film formation instead of terminating trajectory calculations.

Conclusion (Water spraying DPM simulation)

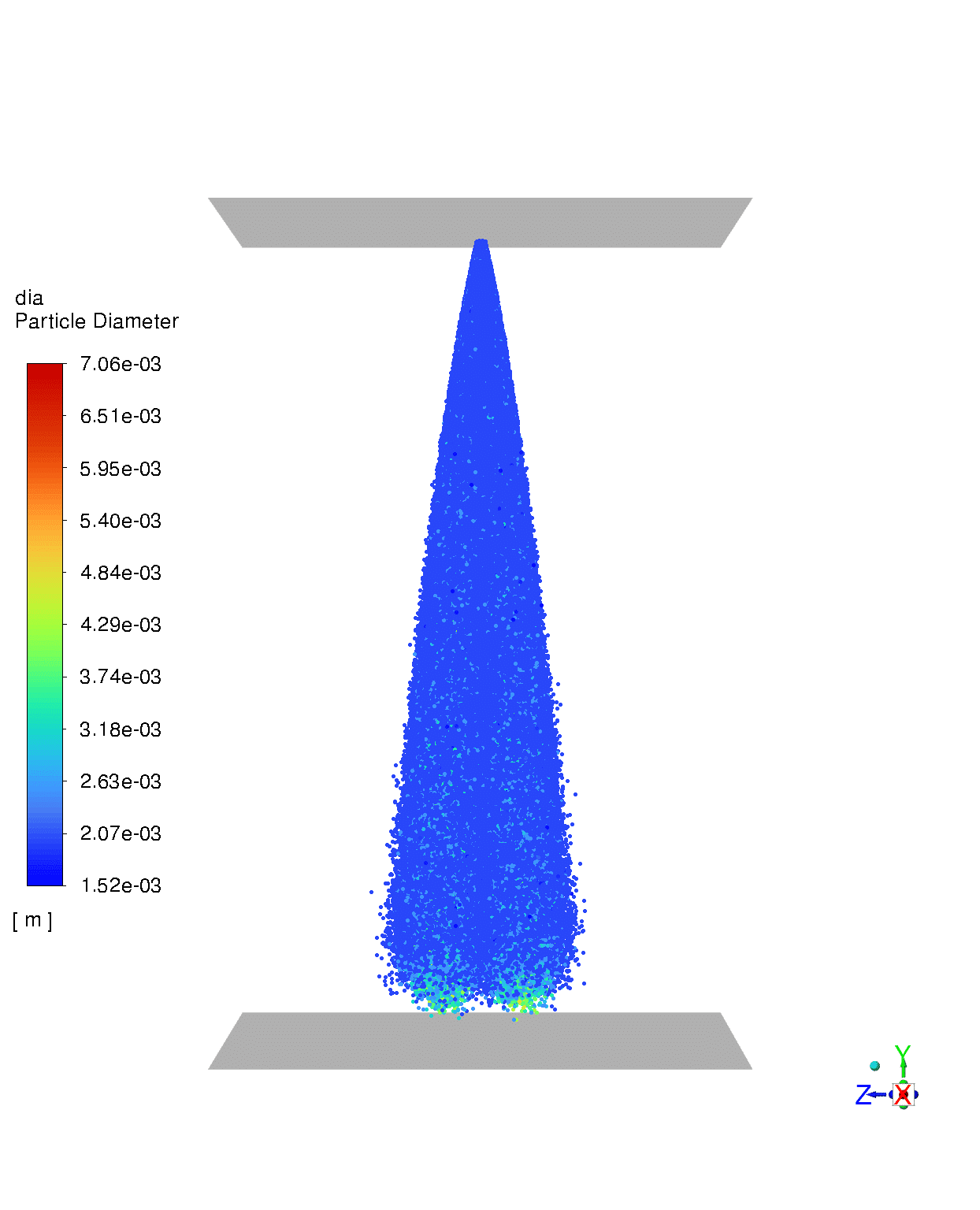

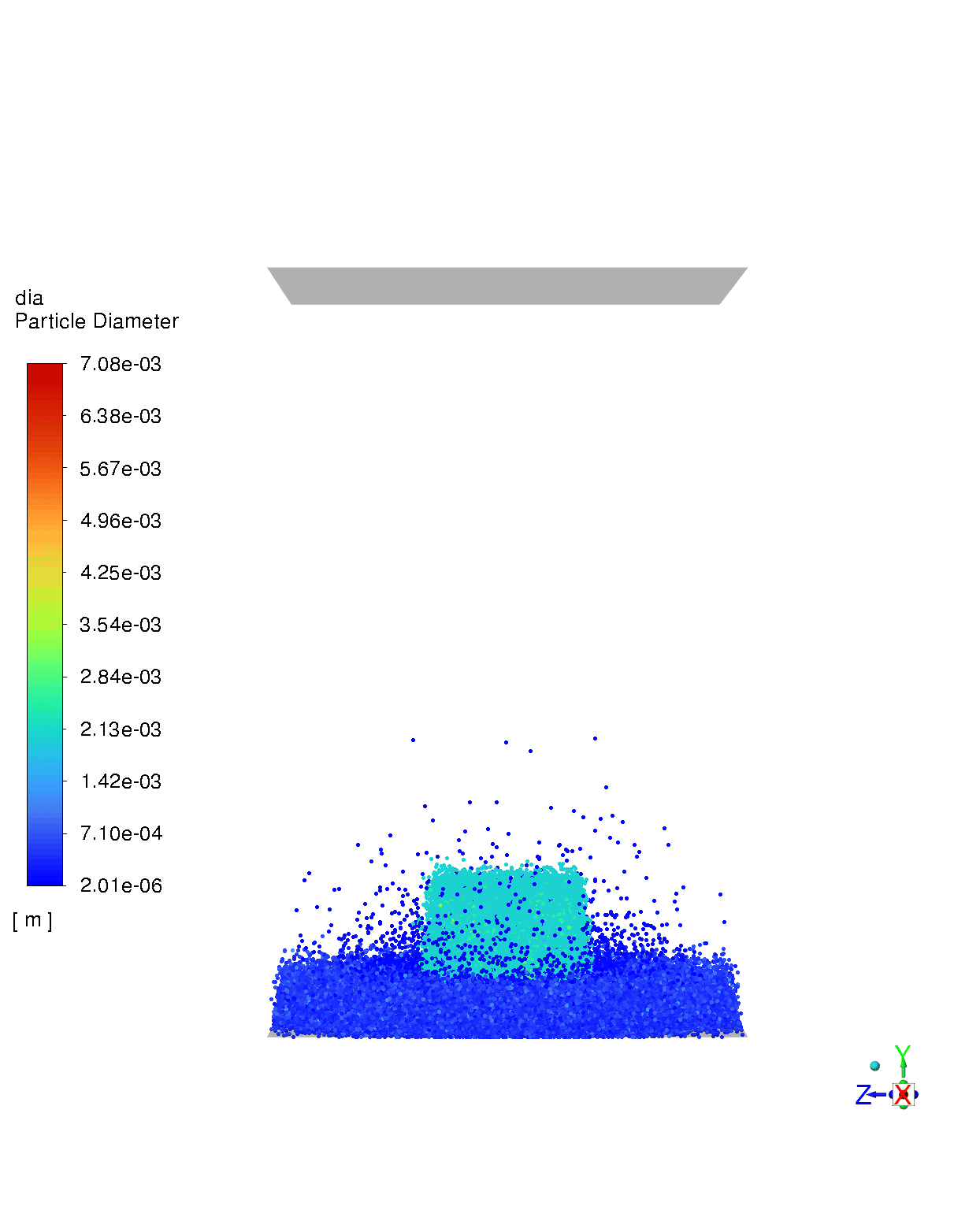

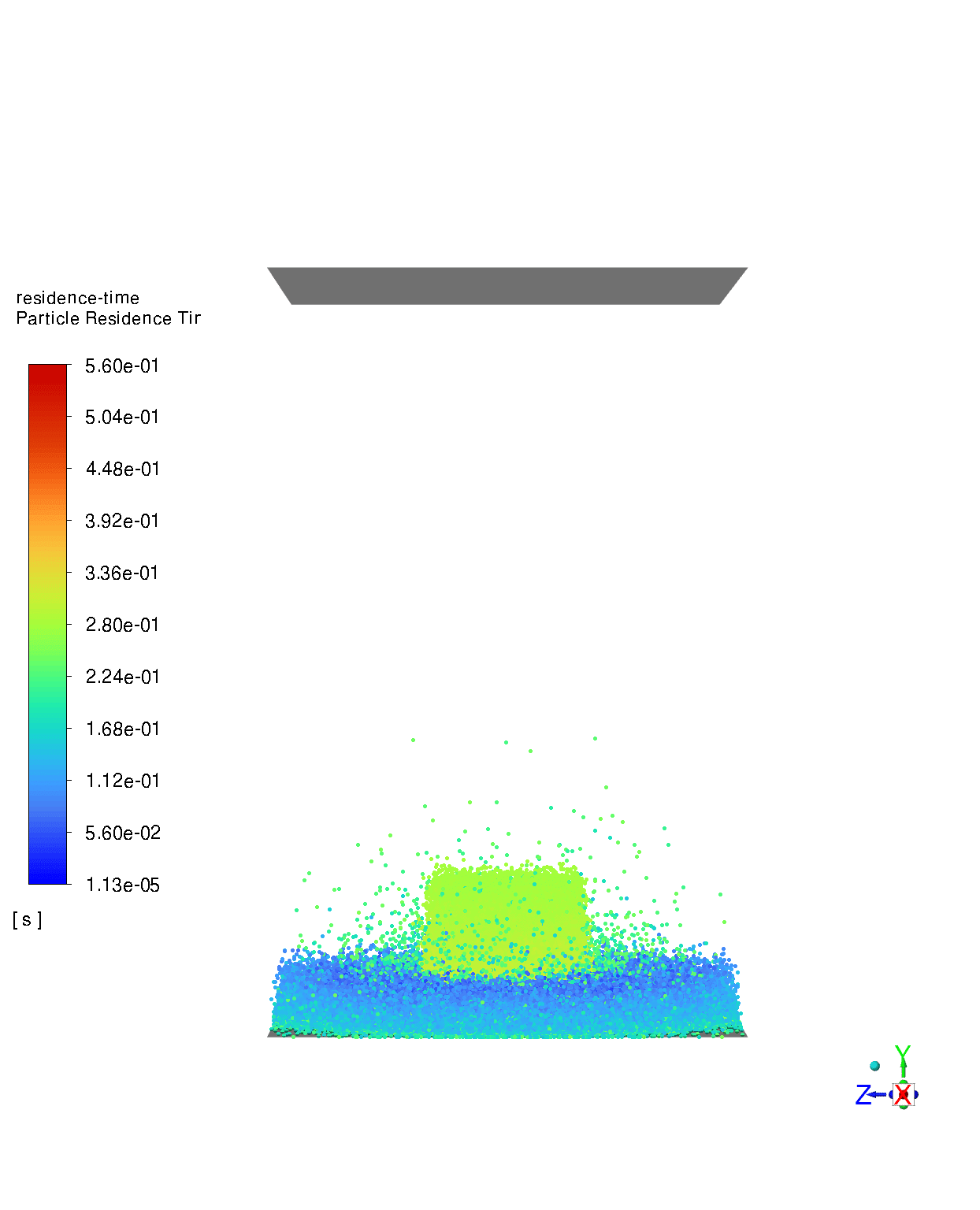

As mentioned in the previous section, the injection starts with a 1.25 m/s velocity. Due to consecutive collisions of the droplets, some of them break up and some of them join each other (accumulation). It is crystal clear in diameter distribution contour as shown below. Although the initial diameter is 2mm, the range is between 0.002mm and 7mm.

When the droplets reach the floor surface, their trajectory calculation doesn`t terminate. They can stick, rebound, spread or splash depending on the impact energy ( This is fully described in the DPM boundary condition article). The animations and contours can help understanding better.

Reviews

Related products

-

-

HAWT (Horizontal Axis Wind Turbine) ANSYS Fluent CFD Simulation Training

Rated 4.00 out of 5$140.00 Student Discount

Luisa Reinger –

I recently purchased and went through your tutorial on Water Spraying Considering Breakup and Evaporation. I was impressed with the comprehensive approach to simulating water spray, and the DPM model explanations were clear. However, could you tell me more about how you evaluated the droplets’ breakup and their distribution in the simulation? Did you analyze this over time or at particular intervals?

MR CFD Support –

In the simulation, the break up of water droplets and distribution was evaluated using the Taylor Analogy Breakup model (TAB) which dynamically simulates these events over the course of the whole spraying process. Droplet interactions such as collision, coalescence, and breakup were analyzed continually as part of the simulation up to a predetermined simulation time or steady state. Typically, such data is observed through generated animations and droplet diameter distribution contours, which can show how the droplet sizes vary over time or at specific intervals set within the simulation parameters.

Dr. Rodger Heidenreich –

I really appreciate the level of detail in this simulation, especially the thorough approach taken to model droplet breakup and evaporation using DPM. Well done!

MR CFD Support –

We’re thrilled to hear that you found the droplet breakup and evaporation simulation detailed and informative! Your feedback is valuable to us, and we’re glad we could provide a comprehensive learning experience. Thank you for your compliments!

Eldora Veum –

The tutorial sounds helpful! After simulating the water spraying, does the software provide any recommendations for optimizing nozzle design to improve droplet distribution and evaporation rates?

MR CFD Support –

No, the software provides the means to simulate different designs and see the outcomes of different nozzle shapes and configurations, but it does not automatically provide optimization recommendations. The user has to analyze the results manually or with custom scripts to find the optimal design.

Dr. Ervin Predovic –

I just finished the Spraying Consideration Breakup and Evaporation CFD tutorial, and I must say this is top-grade learning material! Every detail from droplet breakup to evaporation was thoroughly covered using the Discrete Phase Model and understanding the Species Transport model was a breeze with your guidance. Dynamic drag law and DRW model – all well-explained which made implementing the DPM boundary conditions really straightforward. The distribution contour was quite eye-opening, divulging droplet behaviors during collision and separation. Kudos to the MR CFD team for creating such a comprehensive and engaging tutorial!

MR CFD Support –

Thank you so much for your kind words! We’re overjoyed to hear that our Spraying Considering Breakup and Evaporation tutorial met your expectations and contributed to your understanding of the CFD simulation process. Your success is our top priority, and it’s exhilarating to learn that you found the materials comprehensive and helpful, especially when working with challenging models like droplets behavior. We aim to deliver valuable and enriching learning experiences, so your feedback is incredibly rewarding for the whole MR CFD team. Don’t hesitate to reach out for more advanced studies and insights into the realm of CFD!

Ransom Dietrich Sr. –

I am impressed with the complexity and attention to detail in the spraying simulation! The use of the TAB model and the dynamic drag law must create very realistic droplet behavior.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you’re appreciating the complexity and detail we’ve put into our water spraying simulation. Our goal is to provide the most accurate and realistic modeling possible, and we’re glad you find the use of the Taylor Analogy Breakup model and the dynamic drag law helpful in achieving a realistic depiction of droplet behavior. If you have any more questions or need further assistance, feel free to reach out!

Edd Koelpin –

The tutorial sounds comprehensive, but I’d like to know if the impact of droplet size variation due to breakup and evaporation is included in the resultant distribution within the simulation?

MR CFD Support –

Yes, the impact of droplet size variation due to breakup and evaporation is included in the simulation. The Discrete Phase Model (DPM) accounts for these effects, which is evident in the provided size distribution contours where you can observe a range from 0.002 mm up to 7 mm, despite the initial diameter being 2 mm.