Vortex Flame Combustion Chamber with Four Inlets

$140.00 Student Discount

- The problem numerically simulates the Vortex Flame Combustion Chamber using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 725521.

- We use the Species Transport model to define the chemical reaction between air and methane.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Vortex Flame Combustion Chamber, 4-Inlet (Methane and Air), ANSYS Fluent CFD Simulation Training

In this project, the vortex flame inside a combustion chamber is simulated using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The current model is designed in three dimensions using the Design Modeler software model is a cylindrical combustion chamber.

Four inlet sections for airflow are radially around the combustion chamber, and four inlet sections for fuel flow are axially at the top of the chamber. One outlet section for combustion reaction products is determined at the bottom of the combustion chamber.

The meshing of this project has been done with ANSYS Meshing software. The mesh type is structured, and the element number is 725521.

Vortex Flame Methodology

The present problem simulates the vortex flame inside a combustion chamber using ANSYS Fluent software.

The combustion chamber has a cylindrical structure. The reactants, including fuel flow and airflow, enter the combustion chamber separately from four different inlet sections from the upper part. The products resulting from the reaction leave the bottom part of the combustion chamber.

The airflow enters the chamber in a radial direction from four inlet sections with angles of 90 degrees relative to each other located on the outer circumference of the combustion chamber; While the flow of methane gas as fuel from the other four inlets is sprayed directly into the interior of the combustion chamber.

The species transport model has been used to define the chemical reaction between air and methane.

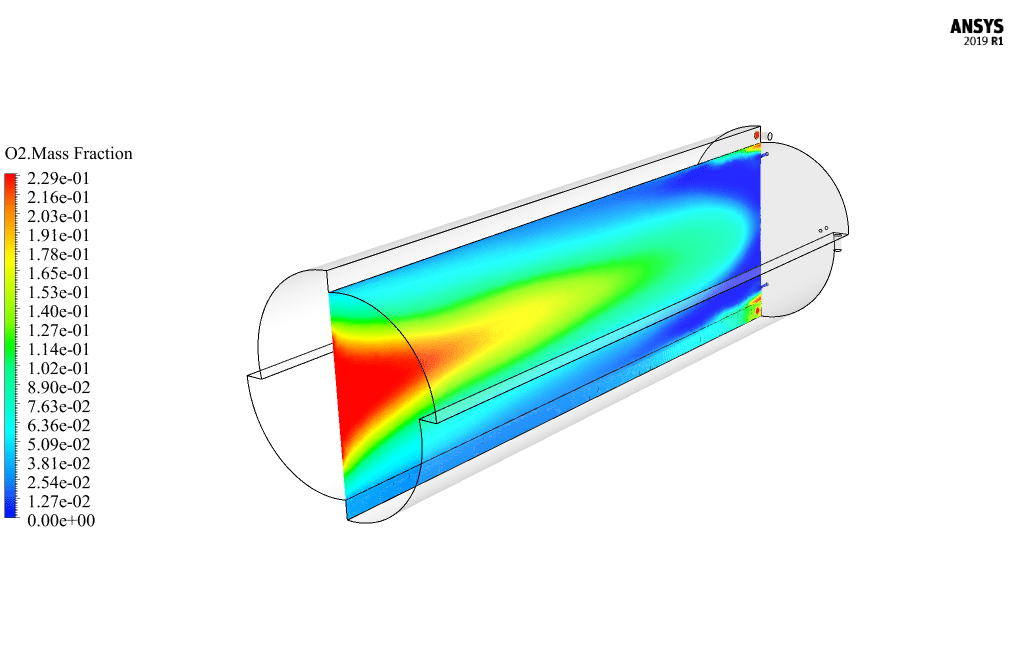

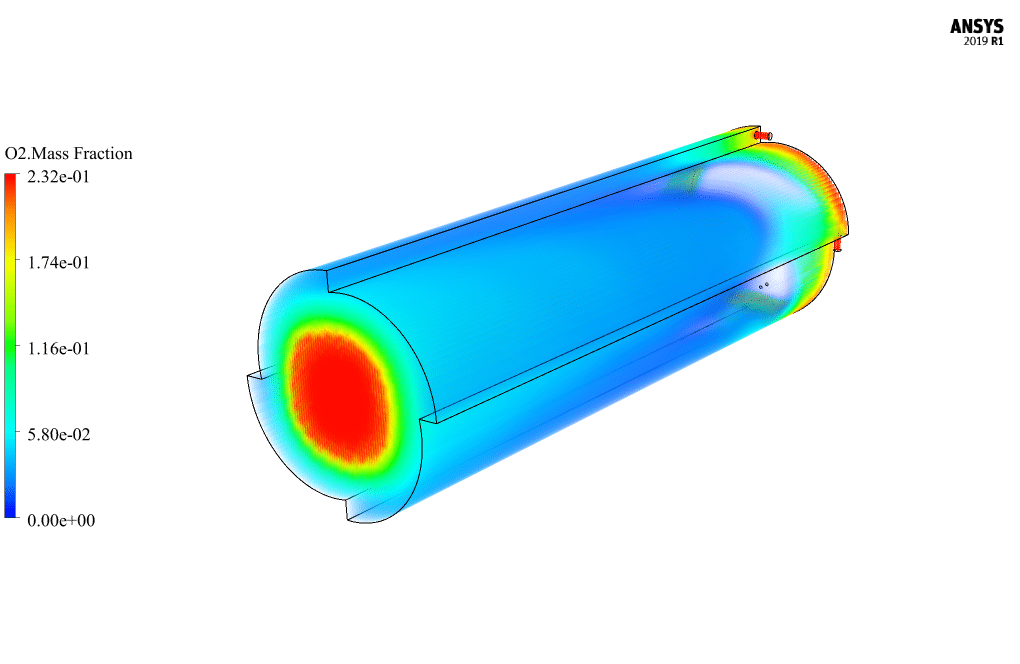

This chemical reaction consists of five species, including O2, N2, CH4, CO2, and H2O. The airflow consists of 0.23 oxygen with a flow rate of 0.001135845 kg/s and a temperature of 300 K entering the combustion chamber, and the fuel flow enters the combustion chamber with a flow rate of 0.0000645kg/s and a temperature of 300 K at the same time.

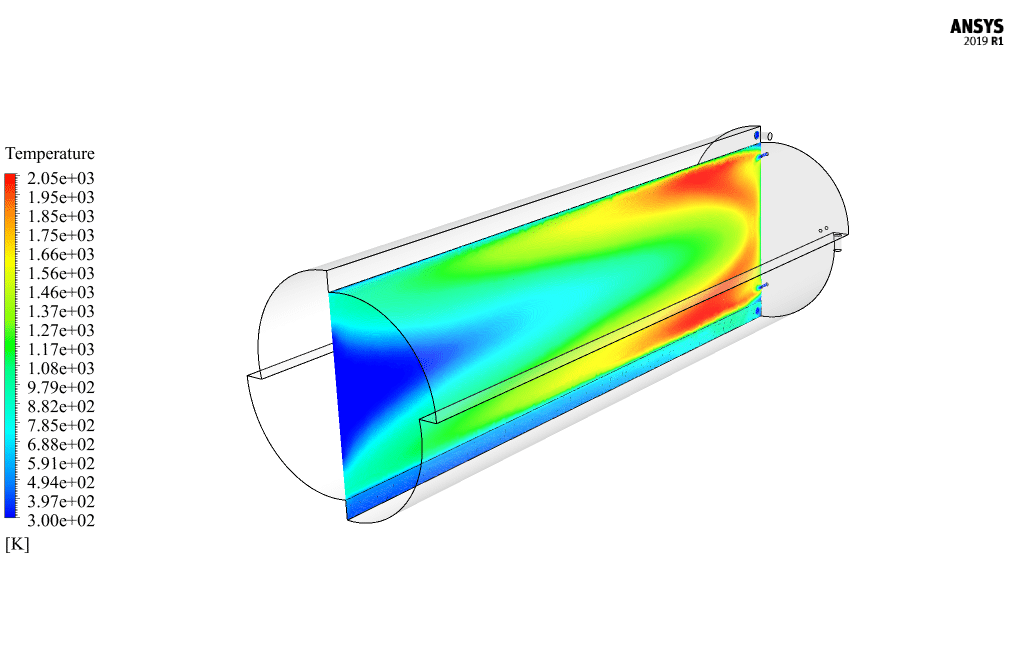

It is also assumed that the outer wall of the combustion chamber has a convection heat transfer with the free stream of its surroundings; Thus, the ambient temperature is equal to 300 K, and the heat transfer coefficient is equal to 25 W/m2K.

Moreover, the RNG k-epsilon model and energy equation are enabled to solve the turbulent fluid equations and calculate temperature distribution inside the domain.

Vortex Flame Conclusion

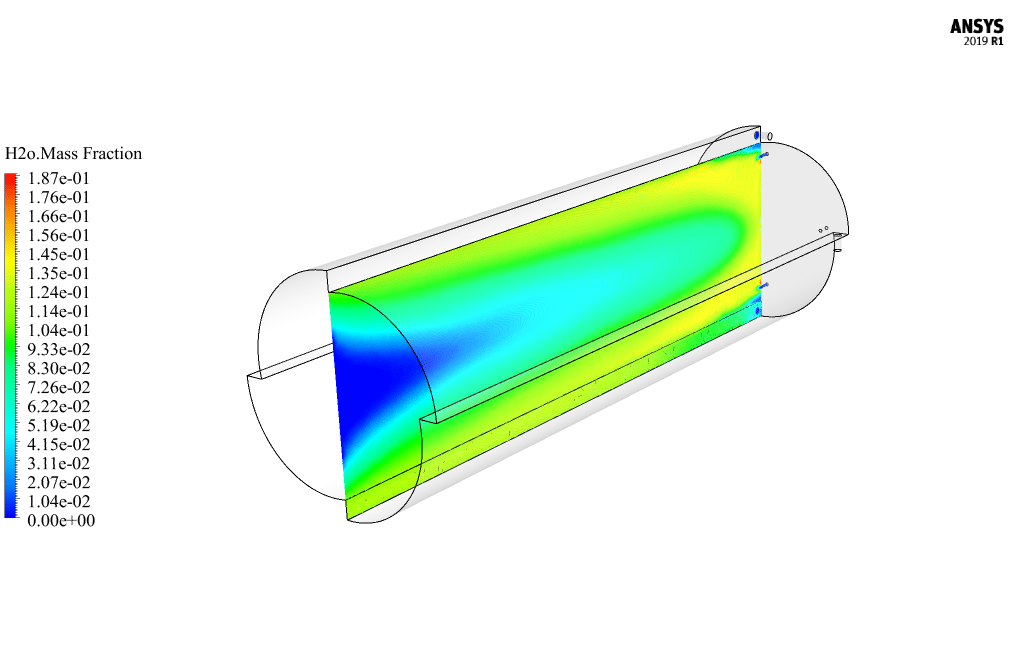

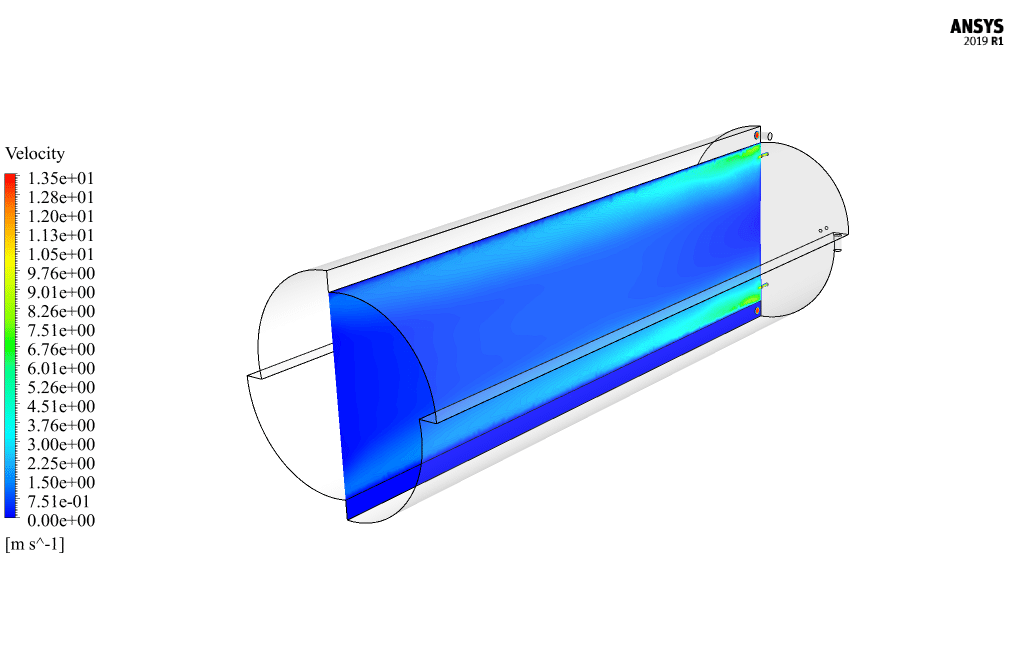

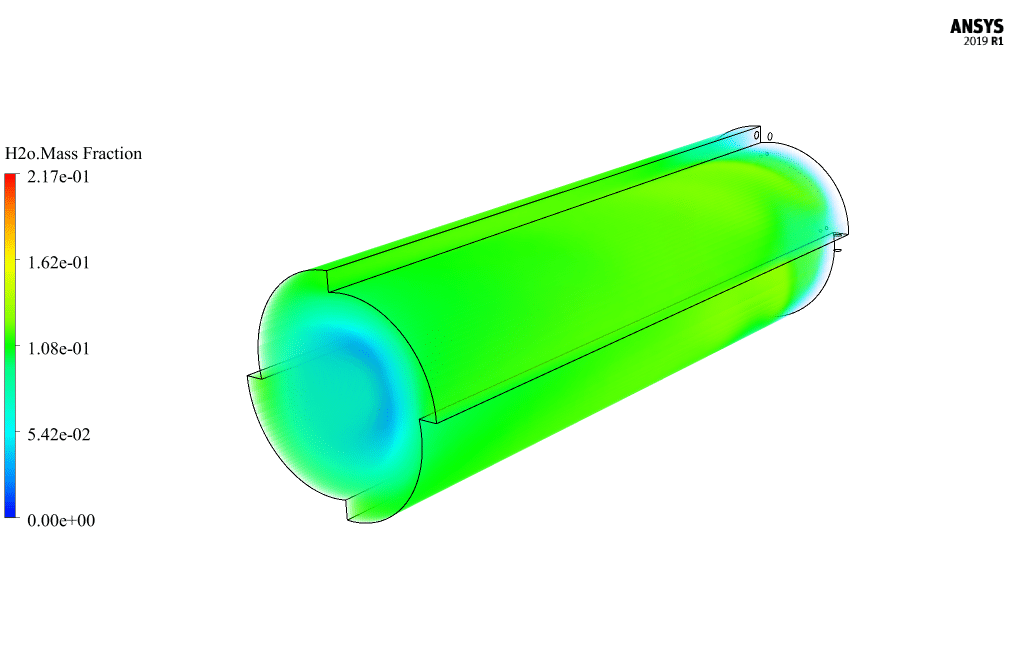

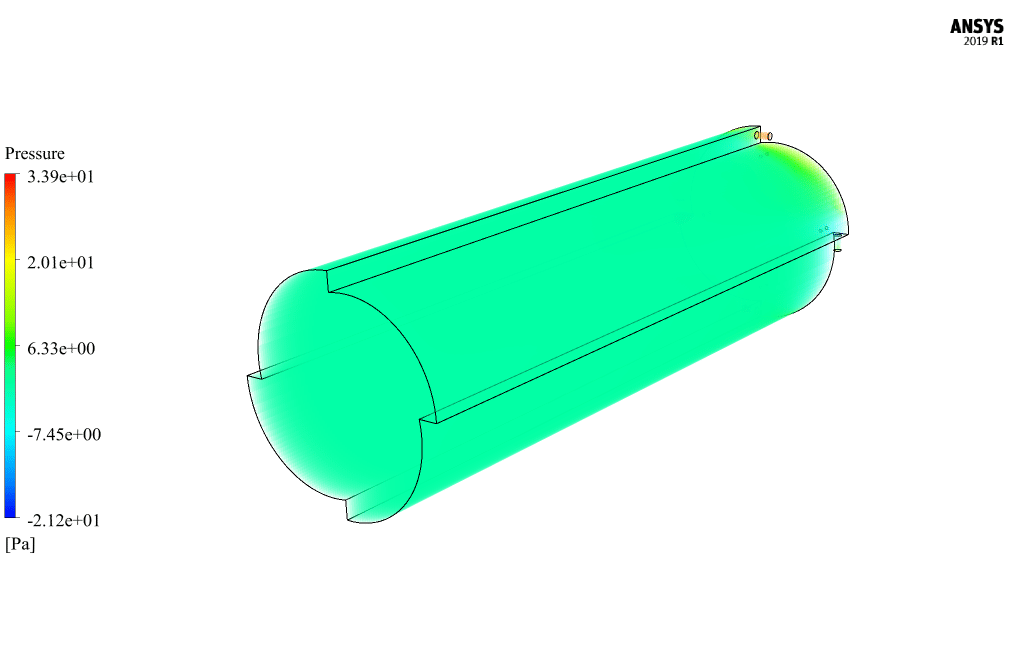

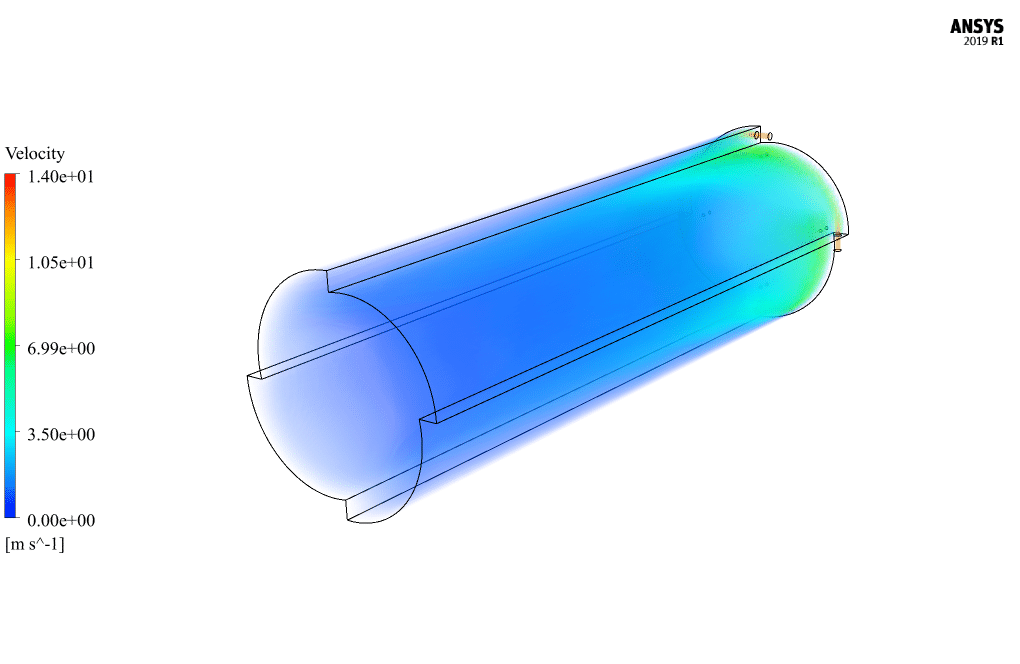

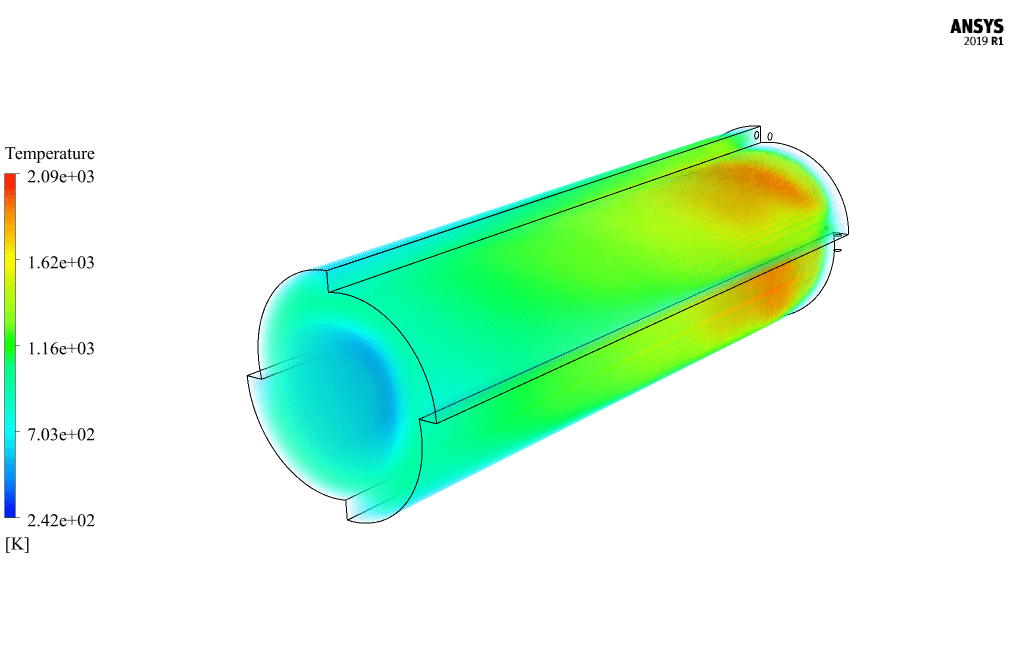

At the end of the solution process, two-dimensional and three-dimensional contours related to pressure, temperature, velocity, and mass fraction O2, CH4, H2O, CO2, and N2 are obtained.

The contours show that when the combustion reaction occurs between the fuel and the air, the temperature increases near the inlet sections of the chamber.

Also, due to the chemical reaction of combustion, the volume fraction of methane fuel is reduced, and the volume fraction of reaction products such as CO2 and H2O is increased.

Gabe Flatley –

The simulation details of the combustion process are very thorough, and I appreciate the clarity on species and temperature distribution. Were any specific boundary layer treatments used to capture the near-wall effects due to high temperature and combusting flows?

MR CFD Support –

In the simulation of combustion processes like this, boundary layer treatments are critical to accurately resolving the gradients near the walls, especially considering the high temperatures and combustion effects. In Fluent, special wall functions such as enhanced wall treatment or non-equilibrium wall functions can be employed to give better predictions of velocity and thermal boundary layers. This would ensure the turbulence modeling near the wall and the heat transfer are handled accurately, although this detail isn’t provided in your description.

Reid Gleichner –

This training has enhanced my CFD knowledge significantly! The setup clearly demonstrates the intricacies involved in simulating a vortex flame combustion chamber. The distinction between the directional inlets for fuel and air have been highlighted well, ensuring a comprehensive understanding of the combustion dynamics. A structured approach made complex concepts approachable.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that the training enhanced your understanding of CFD and the complexities of combustion simulations. If you need further information or assistance with similar projects, feel free to reach out. Your success is what drives us to create these in-depth simulations.

Daryl Bahringer –

I enjoyed how the simulation captures the complex interplay between fuel and airflow in the vortex flame combustion chamber. The detailed analysis and clear visualizations of temperature and species mass fractions provided valuable insights into the combustion process.

MR CFD Support –

Thank you for your feedback! We’re thrilled that our simulation met your expectations and provided you with a deeper understanding of the combustion process. It’s great to hear that you appreciated the complexity and detail of the analysis. If there’s anything more you wish to explore or discuss, please don’t hesitate to reach out.

Gunnar Hand –

I am very impressed by how the chemical reaction and temperature distributions were simulated within the vortex flame combustion chamber. The details provided on airflow direction, fuel inlets, and the structured mesh approach add a considerable depth to understanding the functionality of the chamber. Can’t wait to see what other insights the CFD simulation will reveal upon further analysis!

MR CFD Support –

Thank you for your positive feedback! We’re delighted that you found the simulation details of the vortex flame combustion chamber informative and thorough. Our team works hard to ensure comprehensive CFD analyses that offer deep insight into complex systems. Your enthusiasm for further analysis is much appreciated, and we look forward to bringing you more high-quality simulations.

Flo Gislason –

The training was thorough and comprehensive. The way the species transport model was incorporated to simulate the chemical reactions was particularly impressive, and observing the effect of the combustion reaction on the temperature and mass fraction distributions was enlightening.

MR CFD Support –

Thank you for your positive review! We’re thrilled to hear that you found the training on the vortex flame combustion chamber CFD simulation enlightening and impressive.

Ulises Kris MD –

I appreciate the intricate nature of simulating the vortex flame in a combustion chamber. The detailed description of the methodology and the results gives great insight into the behavioral patterns of the temperature and reactants during combustion. Great job on utilizing the RNG k-epsilon model for turbulent flow and the species transport model for the chemical reaction calculations. This kind of simulation is crucial for optimizing combustion processes in industrial applications.

MR CFD Support –

We’re absolutely thrilled to hear you found the vortex flame combustion simulation invaluable. It’s indeed vital for us to provide high-fidelity simulations that offer profound insights and real-world applicability. Thank you for acknowledging the proficiency of the RNG k-epsilon model and the species transport model in predicting combustor performance. Your understanding of its importance for industrial optimization is greatly appreciated. Reach out anytime if you need further information or assistance!

Nicholaus McKenzie Jr. –

The tutorial for the combustion simulation is comprehensive, but I’m wondering can this be set up for different fuels like Hydrogen or Propane instead of Methane?

MR CFD Support –

Absolutely, the simulation setup can be modified to handle different fuels like Hydrogen or Propane. You would just need to adjust the species transport model to include the appropriate chemical reactions for the new fuel, along with their respective properties. This should be done carefully as changing the fuel will affect the combustion dynamics and outcome results.

Irving Adams –

I found the explanation of the temperature increase and chemical reactions in the combustion chamber particularly enlightening. It indeed shows the power and preciseness of simulation in understanding complex processes.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our simulation for the vortex flame combustion chamber met your expectations and provided you with a clear insight into the combustion process. We appreciate your feedback!

Dr. Nona Kreiger –

I found the 4-inlet design of the combustion chamber extremely efficient for creating a homogenous mixture and observed stable combustion in the simulation results. Great application of theory to practice!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the simulation matched the theoretical expectations and provided insight into the stable combustion processes inside the vortex flame combustion chamber. Your recognition of the design efficiency truly means a lot to us!

Dr. Oma Bartell –

I found the whole CFD process and the methodology intuitive. Kudos on clear explanations on species transport model application and turbulence modeling with RNG k-epsilon. Thanks for demonstrating how the inlet angles and positioning affect the vortex formation.

MR CFD Support –

Thank you for your feedback! We appreciate your recognition of the methods and detailed explanations provided in our training material. Ensuring that complex concepts like species transport and turbulence modeling are clearly understood is vital to us. We’re glad to hear you found the content insightful for learning about vortex dynamics in a combustion chamber.

Jerry Stroman –

Great detail in explaining the vortex flame process! Just one question: how is the performance of the combustion chamber affected by varying the inlet airflow velocity?

MR CFD Support –

Thank you for your kind words! The performance of the combustion chamber can be significantly affected by varying the inlet airflow velocity. Higher airflow velocity can promote faster combustion and improved flame stability, but it can also induce turbulence and cooling effects that may alter the combustion process. Lower airflow velocities might lead to incomplete combustion and higher emissions. It’s essential to find an optimal balance for the velocity to achieve efficient combustion.

Dixie Ruecker –

The project facilitates a complete understanding of the Vortex Flame Combustion Chamber’s functionality. Great use of structured mesh for clarity in results. The outcome details are impressive, especially the particulate plotting of species involved in combustion. Well executed!

MR CFD Support –

Thank you so much for your kind words. We’re really glad to hear that the project met your expectations and provided clear insights into the combustion process with detailed outcomes. It’s great to know that the structured mesh and the plotting of various species streamlined your understanding. Your feedback is invaluable to us!

Mara Fadel –

The detailed explanation of methane and air inlets suggests a thorough setup, but could you clarify whether the fuel and air inlets have different diameters or same dimensions for virtual simulation purposes?

MR CFD Support –

In the provided simulation setup for the vortex flame combustion chamber, the dimensions of the air and fuel inlets are not explicitly stated. It is common in such simulations to have different inlet dimensions to adjust for flow rates, fuel-air ratios and achieve detailed combustion kinetics. However, specific inlet dimensions can be designed based on the engineering requirements and goals of the simulation.

Candice Schumm –

I am very pleased with how the Vortex Flame Combustion Chamber simulation training aided in my understanding of combustion processes. The clear visual representations of temperature changes and species concentrations during combustion were particularly illuminating

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear the simulation training was helpful to you and that the visual representations enhanced your understanding of combustion processes. If there’s anything more we can do to assist you in your learning journey, please let us know!

Mr. Trevion Little –

I am extremely impressed by how detailed the flame combustion simulation in a vortex chamber is, especially how the air and fuel inlets are designed to create ideal combustion conditions. Great job!

MR CFD Support –

Thank you for your positive review and acknowledgment of the combustion simulation’s intricacy. We pride ourselves on providing comprehensive and realistic CFD simulations. Your feedback is greatly appreciated!

Otto Tromp –

I’m impressed with the comprehensiveness of this CFD simulation on a vortex flame combustion chamber. The detailed analysis of reactants and combustion products provided insights that seem invaluable for optimizing combustion chamber designs. Great work!

MR CFD Support –

Thank you for your positive feedback! We are always glad to hear that our clients are satisfied with the insights provided by our CFD simulations. Our goal is to help you optimize your designs for better performance and efficiency. If you require any more detailed analysis or have a new project in mind, please don’t hesitate to contact us for further assistance.

Prof. Elisha Blanda –

The tutorial seems extensive, but I’m curious about the reaction mechanism for the combustion. Does the training include the detailed reaction pathways or only surface reactions?

MR CFD Support –

In this simulation, the species transport model is employed which generally considers surface reactions and provides mass fraction data for various species involved. The simulation output includes detailed data on the main reactants and products, such as CH4, O2, CO2, and H2O, indicating the holding of the chemical combustion reaction.

Mrs. Mariane Cormier PhD –

I truly appreciate the detail presented in the Vortex Flame Combustion Chamber simulation project. It seems like both the species transport model and the RNG k-epsilon model have been crucial for capturing the complex physics of combustion. The temperature and species distribution results must provide deep insights into the efficiency and design optimization of the chamber.

MR CFD Support –

Thank you for your kind words and for noticing the details in our simulation project. We’re delighted that the incorporation of sophisticated models like the species transport and RNG k-epsilon was able to convey the complex interplay of factors involved in the combustion process. Your recognition of the depth and usefulness of the data produced for chamber optimization is very much appreciated. If you need further information about the product or have additional questions, feel free to reach out!

Eric Braun –

I’m truly amazed by the detailed analysis of the vortex flame combustion chamber. The project seems very thorough with its approach to simulating the combustion process. Great work using structured mesh and species transport models for accuracy!

MR CFD Support –

Thank you for appreciating our efforts in conducting a thorough CFD analysis of the vortex flame combustion chamber. We’re glad you found the simulation details and methodology impressive. If you have any further inquiries or need assistance, feel free to reach out!

Prof. Shannon Boyer IV –

I am impressed with the detailed simulation of vortex flame combustion in a chamber with four inlets using ANSYS Fluent. The various aspects such as species transport model, RNG k-epsilon model, and the specific boundary condition setup for airflow and fuel have been meticulously presented. The training appears to cover all the necessary CFD analyses to understand the complex interactions during combustion.

MR CFD Support –

Thank you for your positive review! We are thrilled to hear that you are impressed with the level of detail and comprehensive nature of our vortex flame combustion simulation training. It is our goal to provide intricate and accurate simulations to aid understanding of complex physical phenomena such as the combustion process. Your feedback is greatly appreciated!

Robyn Turcotte –

I’m so impressed with the detail level of the methane and air flow rates and temperatures. It sounds like this project provides excellent insights into the combustion process in a vortex flame combustion chamber.

MR CFD Support –

Thank you for your compliment! We are really glad that you found the information detailed and insightful. It’s our goal to ensure that our training provides a comprehensive understanding of the CFD analysis process and the intricate phenomena involved in combustion processes. If you have any further questions or need more information, feel free to reach out to us.

Kristin Stiedemann –

What a detailed and informative description! The methodology of simulating the vortex flame combustion chamber with four inlets in ANSYS Fluent looks thoroughly crafted.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that you found the description informative and useful for understanding the simulation methodology. If you have any further questions or need assistance, feel free to reach out to us. We’re here to help!

Nettie Stracke II –

Everything was nicely laid out in this learning product about vortex flame combustion chambers. Thank you for such an informative session!

MR CFD Support –

We are thrilled to hear that you found the session on vortex flame combustion chambers informative. Thank you for choosing our learning product! If you have any more questions or need further assistance, feel free to reach out. We’re always here to help!

Xander Hilpert –

The detailed combustor simulation sounds fascinating. Could someone explain if the temperature distribution inside the chamber results in any significant loss of combustion efficiency?

MR CFD Support –

The temperature distribution in the combustion chamber is crucial for the efficiency of the combustion process. Areas of higher temperature generally relate to better combustion regions, whereas cooler regions may indicate incomplete combustion. The project results should display whether the temperature distribution is uniform or if there are areas that could lead to inefficiencies, such as cold spots. However, without having direct access to the actual results data, one would need to see the temperature contour plots to determine if there are any regions indicating significant loss in combustion efficiency.

Paige Fisher –

I am very impressed with how comprehensive the simulation seems to be. Can you tell me if the simulation takes into account the heat losses to the environment through the combustion chamber walls?

MR CFD Support –

Yes, the simulation takes into account heat losses. It is assumed that the outer wall of the combustion chamber has a convection heat transfer with the free stream of its surroundings with an ambient temperature of 300 K and a heat transfer coefficient of 25 W/m2K to account for heat dissipation to the environment.

Prof. Lon Bauch DDS –

I’ve noticed high-temperature gradients near the inlets—are these due to the geometry of the combustion chamber or the characteristics of the methane and air inlets?

MR CFD Support –

The high-temperature gradients near the inlets observed in the results are due to the convergence of methane and air that initiates the combustion reaction at those points, generating a localized increase in temperature. This effect is also influenced by the specific structure and the aerodynamics within the cylindrical combustion chamber designed to favor a vortex flow pattern.

Malcolm Pouros –

Absolutely impressed with the CFD simulation of the vortex flame combustion chamber! The level of detail explained in the airflow and fuel mixture entering the chamber paints a good picture of the combustion process dynamics. The results concerning temperature distribution and species concentration changes offer great insights for optimizing combustion efficiency. The incorporation of the structured mesh for accuracy is commendable too.

MR CFD Support –

Thank you for the positive feedback on our CFD simulation of the vortex flame combustion chamber. We’re glad to hear that the detailed process description and the results provided you with valuable insights into combustion efficiency. Your acknowledgment of our meshing approach is also much appreciated. Should you have further questions or need more information about this or any of our other simulations, please feel free to reach out to us.

Waino Rowe –

I’m utterly thrilled with the detailed analysis of vortex flame combustion in cylindrical chambers. The separation of inlet flows provided an intricate understanding of combustion dynamics, which greatly augments my thermodynamics knowledge.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation training has enriched your thermodynamics knowledge and provided insightful details on combustion dynamics. It’s our pleasure to deliver quality education that allows you to deepen your understanding. If you have further inquiries or need assistance, don’t hesitate to reach out!

Dante Bins –

I was impressed by the details in the combustion chamber simulation project. The multi-species chemical reactions are intricately handled. It’s fascinating to see how methane reacts with oxygen to produce these results in CFD.

MR CFD Support –

Thank you for your kind words! We’re thrilled that you’re impressed with the level of detail and the accurate handling of the chemical reactions in the simulation. If you’re curious about any specific aspects of the project or if you want to further your knowledge in combustion simulations, remember that our team is always here to support you with more training materials and guidance!

Enola Mohr –

This training helped clarify the behavior of combustion dynamics for me. The detailed explanation on how the vortex flame develops in the chamber with multiple inlets and how the temperature changes were really informative. I also appreciate the breakdown of the species involved in the reactions and how their presence is visualized in the results.

MR CFD Support –

Thank you for taking the time to provide your positive feedback on our ‘Vortex Flame Combustion Chamber with Four Inlets’ CFD Simulation Training. We are delighted to hear that the project contributed to your understanding of combustion dynamics. Your appreciation motivates us to continue creating high-quality learning resources for our users.

Martin Marquardt –

I am impressed with the level of detail in the modeling of the combustion process within the chamber. Could you clarify if the tutorial includes a step-by-step guide on defining the species transport model and setting up the chemical reactions in ANSYS Fluent?

MR CFD Support –

Thank you for your positive feedback. Yes, the tutorial provides a comprehensive step-by-step guide on how to set up and define the species transport model for the chemical reactions, including defining the necessary species and their respective flow rates, as well as configuring the reaction mechanisms in ANSYS Fluent.

Isaias Gerlach –

I’m genuinely intrigued by how the flame stabilizes within the vortex combustion chamber through ANSYS Fluent simulation. The separation of reactants entrances and control over mixing appear to really demonstrate the robust insights offered by computational simulations in understanding complex fluid dynamics and reactions.

MR CFD Support –

Thank you for your interest in our project on vortex flame combustion chambers and for recognizing the value of CFD simulations. It’s delightful to hear that our work has offered insights into flame stabilization and the detailed analysis of fluid and chemical dynamics. Your complement encourages us to continue providing in-depth educational materials. If you have any further questions about our simulations or projects, feel free to ask, and we would be more than happy to share additional knowledge on the topic.

Javier Pfeffer –

This simulation seems fascinating! Could you elaborate more on how the different inlets’ effects are modeled to create the vortex inside the combustion chamber?

MR CFD Support –

In the simulation, the inlet sections are designed such that the directional and tangential velocities at which air and fuel enter the chamber are calculated to induce swirling motion. The geometry and boundary conditions work together to create a complex flow pattern that sustains a stable vortex flame within the combustion chamber. Specific turbulence models and species transport definitions within ANSYS Fluent track these effects to accurately represent the flame characteristics and flow dynamics.

Dr. Joannie Ernser DDS –

This CFD training product is superb! It demonstrates comprehensive -flow and combustion dynamics in great detail. Really appreciated the visual representation through both 2D and 3D temperature, pressure and mass fraction contours. It dissected the complex process simply.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the training materials were helpful and provided a detailed understanding of the vortex flame dynamics in the combustion chamber. Your satisfaction is our top priority. We look forward to bringing you more quality learning products.

Tiffany Considine –

I appreciate the details provided on the simulation of the vortex flame combustion chamber. The breakdown of the species included in the chemical reaction was particularly helpful. The complexity of the simulation with multiple inlets for fuel and air and the consideration of various species provides confidence that the analysis must have resulted in comprehensive insights into the combustion process within the chamber. Great work incorporating the RNG k-epsilon model and energy equation — meaningful for those interested in the nuances of turbulent flow and temperature distribution. Looking forward to seeing more projects like this illustrated with granular details.

MR CFD Support –

Thank you for your kind words and your appreciation of the intricacies of the simulation. We are delighted to hear that you found the details on the species in the chemical reaction useful. We strive to provide comprehensive information on our projects to ensure our clients have a full understanding of the processes involved. Your feedback is truly valued, and we are excited to continue providing quality simulations and training that meet your expectations. Stay tuned for more informative projects!

Keyon Feeney Jr. –

I was very impressed by the detailed representation of the combustion process in the CFD simulation. Could you explain how the air and fuel inlets contribute to the stability of the flame within the chamber?

MR CFD Support –

Thank you for your positive feedback on our detailed CFD simulation. The air and fuel inlets are designed to facilitate efficient mixing of methane and air, thus contributing to a stable combustion process. The radial positioning of the air inlets helps to create a swirling effect, enhancing turbulence and mixing which is critical for flame stabilization. Methane, introduced from the top, mixes with the swirling air, providing a consistent fuel-air mixture that supports continuous combustion. The chamber’s geometry and inlet configuration are meticulously crafted to maintain a vortex that ensures the flame’s sustainability.

Mohammed Olson –

This is one of the most comprehensive trainings on combustion simulations I’ve had the pleasure to complete. The methods applied here are clearly explained, and the results are consistent with theoretical expectations, particularly the temperature changes near the inlet sections. What impressed me most was the detailed explanation of the species transport model and the successful simulation of the complex vortex dynamics within the chamber.

MR CFD Support –

We’re thrilled to hear that our vortex flame combustion chamber training exceeded your expectations! Seeing the successful application of complex models like the species transport to effectively simulate combustion dynamics truly showcases the power of CFD analysis. We appreciate your positive feedback and are glad that we could contribute to your knowledge and understanding of combustion simulations. Thank you for your kind words.

Gabriella Bashirian –

This course sounds very comprehensive! The details on the combustion process and species transport model are especially interesting.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you found the training on the vortex flame combustion chamber simulation enlightening, particularly the segments on the combustion process and the species transport model. Should you have any further queries or need additional information, feel free to reach out to us. We appreciate you choosing MR CFD for your learning journey!

Prof. Armani Kreiger –

Could you please provide some detailed visuals that illustrate the temperature and species concentration distributions within the combustion chamber?

MR CFD Support –

Thank you for your interest in the Vortex Flame Combustion Chamber CFD simulation. While we can’t provide visuals directly through this medium, within the simulation report there are certainly detailed two- and three-dimensional temperature and species concentration contours that have been generated. These visuals help in understanding how the combustion process affects temperature distribution and how the reactants are consumed while the products are formed inside the chamber.

Mrs. Connie Schoen –

I just completed the Vortex Flame Combustion Chamber CFD Simulation course and was amazed by the level of detail it provided. The step by step procedure of setting up the combustion model using the species transport model was particularly insightful. The results section was comprehensive, explaining how the combustion impacts the temperature and the species distribution within the chamber. Certainly, a highly recommended course!

MR CFD Support –

We’re delighted to hear that you found the Vortex Flame Combustion Chamber CFD Simulation course to be informative and detailed. It’s always encouraging to learn that our courses are well-received and helpful to our users. We strive to provide thorough and comprehensive training, and your feedback motivates us to continue delivering quality education. Thank you for the high recommendation and for taking the time to share your positive experience!

Mrs. Ines Sanford –

Absolutely phenomenal training for understanding combustion chamber simulations in ANSYS Fluent! It provided deep insights into the vortex flame behavior. The visual representations with volume fractions for species transport were another highlight which made the complex phenomena far more accessible.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training has been so helpful in deepening your understanding of combustion chamber simulations and vortex flames. We always strive to present complex information in a clear and visual manner. Your satisfaction is our greatest motivation!

Ida Anderson –

Fantastic resource for understanding complex combustion dynamics within a chamber! The detailed explanation of the interaction between the fuel and the airflow creating that critical vortex flame is highly instructive. As a visual person, the pressure, temperature, and velocity contours are superb for grasping the concepts at play. Thank you, MR CFD, for creating this simulation; it’s neatly meshed and clearly outlined every crucial aspect necessary for academic and professional development in the field of CFD.

MR CFD Support –

We’re thrilled to hear that our ‘Vortex Flame Combustion Chamber with Four Inlets’ CFD Simulation training exceeded your expectations! Thank you for acknowledging the detail we put into illustrating complex combustion processes. Our goal is to provide an intuitive learning experience through our simulations, and it’s rewarding to know you found the contours valuable. Your feedback is much appreciated, and if you ever need further guidance or have questions, our team is always ready to assist.

Prof. Elwyn Stehr –

This training seems thorough. The combustion simulation of a 4-inlet vortex chamber is complex but looks like it’s very well explained in your training.

MR CFD Support –

Thank you for the compliment on our Vortex Flame Combustion Chamber CFD simulation training. We strive to deliver detailed and comprehensive training materials. We are glad you find the content thorough and well explained.

Prof. Marta Reilly Sr. –

Is the RNG k-epsilon model the most suitable for this type of combustion simulation?

MR CFD Support –

In this simulation, the RNG k-epsilon model is chosen because it offers improved accuracy for rapidly strained flows and is more reliable for complex combustion chamber flow patterns. It incorporates additional terms to account for the effects of swirls and vortices, which are present in the vortex flame combustion chamber setup.

Yesenia Spencer –

I’ve learned so much from the Delta Wing External Aerodynamics CFD simulation training! The clarity of the instructions was outstanding and the thoroughness of the post-processing analysis gave me real insights into aerodynamic behaviors. Absolutely top-notch material for anyone serious about CFD in aerospace applications.

MR CFD Support –

Thank you for your wonderful feedback! We are delighted to hear that our Delta Wing External Aerodynamics CFD simulation training was both informative and clear. It’s great to know the course helped deepen your understanding of aerospace aerodynamics. We appreciate your kind words and hope you’ll find our other courses equally beneficial.

Abbey Spinka –

Which turbulence model was chosen for this CFD simulation and why?

MR CFD Support –

The RNG k-epsilon model was chosen for this CFD simulation to solve turbulent fluid equations. It was likely selected due to its ability to capture the effects of swirl and recirculation in the combustion chamber accurately.

Dr. Jerel Blick Sr. –

The description captures the complexity and attention to detail put into the simulation. Well done!

MR CFD Support –

Thank you for your kind words! We are pleased to know that the effort and detail put into our CFD simulation of the vortex flame combustion chamber have been recognized.

Rosario West –

The simulation concept is fascinating! How does the species transport model accurately represent the actual chemical reactions between the methane and air?

MR CFD Support –

The species transport model in ANSYS Fluent includes various sub-models and mechanisms to realistically simulate chemical reactions. The model tracks the individual species throughout the combustion chamber, allowing for the prediction of species concentration, temperature, and mass fractions. The inclusion of reactions within the model is done through pre-defined reaction rates and stoichiometry, ensuring that the combustion process between methane and air accurately reflects the production of H2O, CO2, and other resulting combustion products.