Finite Volume vs Finite Element: A CFD User’s Guide

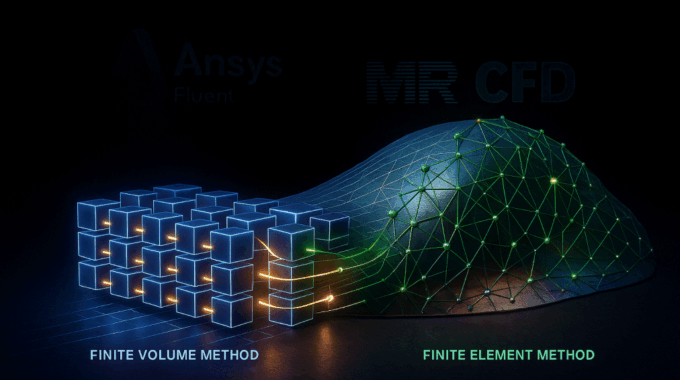

As an engineer diving into the world of simulation, you’ll quickly encounter two titans of numerical methods: the Finite Volume Method (FVM) and the Finite Element Method (FEM). The debate over finite volume vs finite element isn’t just an academic exercise reserved for textbooks; it’s a fundamental choice that has profound, practical consequences on your simulation’s accuracy, speed, and ultimate success. Choosing the right method for your specific problem is one of the most critical decisions you’ll make, especially within the integrated ANSYS ecosystem. This guide is designed to cut through the dense theory and give you the practical, experience-based knowledge you need to choose wisely and simulate with confidence.

Why Should Engineers Care About This Difference?

Let’s be direct: you should care because your choice directly impacts your project’s bottom line. In my 10+ years of teaching and consulting, I’ve seen brilliant engineers waste weeks of computational time—and thousands of dollars in HPC for ANSYS Resource—simply because the wrong numerical method was applied. It’s a common pitfall that can lead to disastrous outcomes:

- Inaccurate Results: Using a non-conservative method for a fluid dynamics problem can lead to results that look plausible but are physically wrong, violating fundamental conservation laws.

- Convergence Failure: A solver might struggle or fail to converge entirely if the chosen method is ill-suited for the problem’s physics, leading to endless troubleshooting.

- Wasted Resources: An inefficient method can require a much finer mesh or significantly more computational time to achieve the same level of accuracy, tying up valuable software licenses and processing power.

Making the correct choice between FVM and FEM is the first step in ensuring your simulation is not only successful but also efficient and reliable. This decision is foundational to producing validation against experimental data and delivering trustworthy results.

What Is the Finite Volume Method (FVM) at Its Core?

Imagine you’re trying to balance a budget for a building with many interconnected rooms. You don’t necessarily care about the exact amount of money at every single point within a room; you care about the total amount of money in that room and the flow of money (the flux) through the doors connecting it to other rooms. This is the essence of the Finite Volume Method.

FVM discretizes your simulation domain into a finite number of small control volumes (the “rooms”). It then solves the integral form of the governing equations (like the Navier-Stokes equations) for each control volume, ensuring that the fluxes of mass, momentum, and energy across the cell faces are perfectly balanced. What flows into a control volume must, after accounting for any sources or sinks, flow out.

How does FVM guarantee the conservation of physical quantities?

This “flux balancing” act is FVM’s superpower. Because the calculation for each cell is based directly on the fluxes from its neighbors, the conservation of physical quantities is inherently guaranteed, both at the level of a single cell and across the entire domain. If you sum up the change in all the control volumes, the internal fluxes cancel out perfectly, and you are left only with the fluxes at the domain boundaries. This property is absolutely critical for fluid dynamics, where even tiny numerical errors in conservation can accumulate and corrupt the entire solution. 💡

Where is FVM most commonly used in engineering simulations?

Given its strength in conservation, FVM is the undisputed industry standard for computational fluid dynamics (CFD). Its robustness and efficiency make it the engine behind the world’s leading CFD solvers.

🎯 Key applications include:

- Aerodynamics: Simulating airflow over aircraft wings, vehicles, and buildings.

- Turbomachinery: Analyzing flow through turbines, compressors, and pumps.

- Heat Transfer: Modeling convection in heat exchangers and electronics cooling systems.

- Multiphase Flows: Simulating interactions between liquids and gases, like in pipelines or reactors.

This is why a powerhouse solver like ANSYS Fluent is built upon the finite volume method. It’s engineered from the ground up to provide the robust, conservative solutions required for the vast majority of fluid flow problems.

How Does the Finite Element Method (FEM) Work Differently?

Now, let’s switch analogies. Imagine you’re trying to create a complex, curved sculpture using only simple, straight-edged building blocks, like LEGOs or triangles. You can approximate the sculpture’s surface by connecting these blocks at their corners (nodes). The Finite Element Method works similarly.

FEM breaks down a complex domain into a collection of simpler, smaller shapes called “elements.” It then approximates the solution within each element using a simpler function (a basis function), ensuring that the solution is continuous and well-behaved where the elements connect at the nodes. Instead of balancing fluxes across faces, FEM seeks to minimize the error of this piecewise approximation across the entire domain, a process often based on a weighted residual method.

Why is FEM so dominant in structural and thermal analysis?

FEM’s mathematical foundation is exceptionally well-suited for problems governed by elliptic partial differential equations, which describe phenomena that reach a state of equilibrium, like stress distribution in a solid part or steady-state heat conduction. It excels at calculating gradients (like stress and strain) with high accuracy. This is why Ansys Mechanical and other leading structural analysis tools are built on FEM. It is the gold standard for predicting stress, deformation, and vibration in solid components.

Can FEM be effectively used for fluid simulations?

This is a common point of confusion. The answer is yes, but with important caveats. FEM can be used for fluids, and some solvers, like Ansys CFX, use a specialized, coupled FEM-based formulation. However, to make it work effectively for the convection-dominated equations of fluid dynamics, special numerical treatments are required to enforce stability and conservation, which FVM provides naturally. For the majority of CFD applications, FVM remains the more direct, robust, and computationally efficient choice.

How Do FVM and FEM Compare on Meshing and Geometry?

The theoretical differences between the methods have very practical consequences when it comes to the first and often most time-consuming step of any analysis: meshing. Your approach to CFD meshing techniques will differ depending on your solver choice.

Does FVM’s cell-centered approach offer advantages for complex meshes?

Absolutely. FVM solvers like Ansys Fluent store solution variables at the center of the control volumes. This cell-centered approach makes them incredibly flexible and forgiving with mesh topology. This is a huge advantage for engineers dealing with real-world, complex, or “dirty” CAD geometry.

✅ FVM Meshing Strengths:

- Element Flexibility: Easily handles a mix of element types, including tetrahedrons, hexahedrons, prisms, and pyramids.

- Polyhedral Meshes: Excels with modern polyhedral meshes, which can reduce cell count while improving accuracy for complex geometries.

- Non-Conformal Interfaces: Robustly handles meshes that don’t perfectly align at interfaces, simplifying the meshing of large assemblies.

Here at MR CFD, we often leverage this flexibility in our CFD consulting projects to rapidly mesh intricate industrial components that would be a nightmare to handle otherwise.

What makes FEM’s node-based approach so flexible for element shapes?

FEM solvers store solution variables at the element nodes. This approach is naturally suited for using higher-order elements (e.g., quadratic tetrahedrons with midside nodes). These elements can capture geometric curvature with far fewer elements than their linear counterparts, which is a significant advantage. This is particularly useful for structural problems where accurately capturing stress concentrations around features like holes and fillets is critical for predicting failure.

What Are the Practical Differences in Solver Performance and Accuracy?

Beyond meshing, the choice between FVM and FEM impacts what you experience every day: how long your simulation takes to run and how much you can trust the results. This is where numerical accuracy and stability become paramount.

Why is FVM considered inherently conservative and robust for fluids?

As we’ve discussed, FVM’s flux-balancing approach is its defining feature. This isn’t just an elegant mathematical property; it means your simulation will not artificially create or destroy mass, momentum, or energy. For a CFD engineer, this is the bedrock of trust. It ensures that even on coarse meshes, the overall physical behavior is captured correctly, making FVM exceptionally robust for a wide range of fluid dynamics problems, from slow laminar flows to highly turbulent, compressible flows.

When might FEM offer higher solution accuracy for the same mesh density?

For problems where FEM is in its element—like structural mechanics—its ability to use higher-order basis functions can provide a more accurate solution per degree of freedom. This means you can sometimes achieve the required accuracy for stress or deformation with a coarser mesh than you would need with a lower-order method, saving computational resources. This is a clear trade-off: FVM prioritizes conservation and robustness, while FEM can prioritize solution accuracy for specific types of equations.

Which method is typically faster for large-scale CFD problems?

Based on extensive benchmark results and industry experience, for the vast majority of large, single-physics fluid flow simulations, FVM-based solvers are computationally faster and more memory-efficient. The matrices generated by FVM are typically more sparse and better structured for rapid iterative solving, which is crucial when dealing with millions or even billions of cells. This efficiency is a key driver behind FVM’s dominance in the CFD field. 🚀

Which Method Should You Choose for Specific Physics?

This is the ultimate question. The answer lies not in crowning one method superior, but in applying the right tool for the job. This is one of the core principles we teach in our MR CFD Ansys fluent courses.

Why is FVM the industry standard for most fluid dynamics problems?

For any problem where fluid flow is the primary concern, FVM is your go-to method.

- Strong Conservation: Essential for accurate prediction of pressures, forces, and heat transfer.

- Solver Robustness: Handles a massive range of flow regimes, from incompressible to supersonic.

- Efficiency: Faster and more memory-efficient for convection-dominated problems.

Whether you’re simulating aerodynamics, heat transfer, or multiphase flow, FVM (and therefore Ansys Fluent) is the tool designed for the task.

When is FEM the undeniable choice for structural and thermal analysis?

For problems dominated by solid mechanics or heat conduction within solids, FEM is the clear winner.

- High Accuracy for Stresses: Superior for predicting stress, strain, and deformation.

- Vibrational Analysis: The natural choice for modal and harmonic analysis.

- Geometric Precision: Better suited for problems where precise capture of geometric detail dictates the physical response.

For any task involving structural integrity, Ansys Mechanical is the purpose-built, FEM-powered tool you need.

How should you approach complex Fluid-Structure Interaction (FSI) problems?

What about problems that involve both? This is where modern multiphysics platforms shine. For a Fluid-Structure Interaction (FSI) analysis, you don’t choose one method over the other; you use both! The Ansys Workbench workflow is engineered precisely for this. You use:

- ⚙️ Ansys Fluent (FVM) to accurately solve the fluid dynamics and calculate the pressure and thermal loads on the structure.

- ⚙️ Ansys Mechanical (FEM) to accurately solve the structural response (deformation, stress) resulting from those fluid loads.

Workbench seamlessly couples the two solvers, transferring data between the fluid (FVM) and solid (FEM) domains to provide a high-fidelity, two-way coupled solution. This is the epitome of industry best practices for complex multiphysics problems.

What Is the Final Verdict for the Practicing Engineer?

The debate of finite volume vs finite element is resolved by understanding your physics. It’s not a competition; it’s a toolbox. Your job as an engineer is to know which tool to pull out for which task.

- For Fluid Dynamics (CFD) → Choose the Finite Volume Method.

- For Structural Mechanics (FEA) → Choose the Finite Element Method.

- For Multiphysics (FSI) → Choose a Coupled Approach.

By understanding the fundamental strengths of each method, you can leverage the power of integrated platforms like Ansys Workbench to simulate with greater accuracy, efficiency, and confidence.

Ready to move beyond the fundamentals and master these powerful tools? Subscribe to the MR CFD newsletter for more expert guides, practical tutorials, and insights delivered straight to your inbox.

Frequently Asked Questions

Is CFD always solved with the Finite Volume Method?

No, but it is the most common and often most suitable method. While FVM (used in Ansys Fluent) dominates the industry due to its excellent conservation properties and robustness, other methods exist. For example, some solvers (like Ansys CFX) use a highly effective FEM-based approach, and specialized fields might use Finite Difference (FDM) or other niche methods.

Can you use the Finite Element Method for high-speed, compressible flows?

Yes, it is possible, but it requires special numerical formulations (e.g., stabilization techniques like SUPG) to handle the shockwaves and strong convective effects present in high-speed flows. FVM is generally more naturally suited and robust for these types of problems “out of the box.”

What is the Finite Difference Method (FDM) and how does it compare?

FDM is another method that approximates the governing differential equations using Taylor series expansions on a structured, rectilinear grid. It is conceptually simpler than FVM or FEM but is very limited by its requirement for structured meshes, making it impractical for the complex geometries found in most industrial engineering problems.

Does Ansys Fluent only use FVM, or can it use other methods?

Ansys Fluent is primarily a cell-centered, finite-volume-based solver. However, it incorporates elements of other methods for certain functionalities. For example, it can use an FEM-based approach for some specific models like shell conduction for modeling thin solid regions.

How does mesh quality (e.g., skewness, aspect ratio) affect FVM and FEM results differently?

Both methods are sensitive to poor mesh quality, but in slightly different ways. In FVM, high skewness can directly impact the accuracy of the flux calculations between cells, potentially leading to slower convergence or less accurate results. In FEM, highly distorted elements (poor aspect ratio) can lead to an ill-conditioned stiffness matrix, causing significant numerical errors in the solution. Both require adherence to mesh quality industry best practices.

For conjugate heat transfer (CHT) problems, which method is used for the fluid and solid zones?

In a solver like Ansys Fluent, the Finite Volume Method is used for both the fluid and solid zones. The solver applies the FVM to the energy equation across the entire domain. The key difference is that in the fluid zone, both convection and conduction are solved, while in the solid zone, only the conduction term of the equation is active.

Why do some solvers like Ansys CFX use an FEM-based approach for fluids?

Ansys CFX uses a unique, coupled solver that is element-based and vertex-centered, which shares heritage with FEM. It solves the equations for pressure and momentum simultaneously, which can offer exceptional robustness and a high convergence rate, particularly for challenging turbomachinery applications. It’s a prime example of how FEM principles can be successfully adapted for high-performance CFD.

Comments (0)